Bosch [Robert Bosch GmbH] Business Report FY ended Dec. 2015

Financial Overview |

(in million EUR) |

| FY ended Dec. 31, 2015 | FY ended Dec. 31, 2014 | Rate of Change (%) | Factors | |

| Overall | ||||

| Sales | 70,607 | 48,951 | 44.2 | 1) |

| EBIT | 4,587 | 3,030 | 51.4 | 2) |

| Mobility Solutions | ||||

| Sales | 41,657 | 33,318 | 25.0 | 3) |

| EBIT | 3,216 | 2,402 | 33.9 | - |

Factors

1) Net Sales

-In the fiscal year ended December 31, 2015, the Company’s net sales were EUR 70,607 million, an increase of 44.2%. Positive currency exchange effects accounted for approximately EUR 4 billion in increased sales, primarily due to the euro’s weakness against the U.S. dollar, yuan, pound, and franc. The full consolidation of former joint ventures BSH Hausgerate and Automotive Steering accounted for a gain of EUR 16.5 billion in 2015. Excluding currency effects and acquisitions, the Company’s sales increased by 3.8% in 2015.

2) EBIT

-The Company’s EBIT in the fiscal year ended December 31, 2015 grew by 51.4% to EUR 4,587 million. The gain in EBIT from operations is equivalent to the gain in overall EBIT, as the gains from positive extraordinary effects cancelled out losses from negative extraordinary effects. Positive extraordinary effects primarily include the consolidation of Automotive Steering and BSH Hausgerate while negative effects include goodwill impairments in the Industrial Technology sector and losses from the sale of the Company’s large-gears business.

3) Mobility Solutions Sales

-The Company’s Mobility Solutions business sector had sales of EUR 41,657 million in the fiscal year ended December 31, 2015, an increase of 25.0% over the previous year. Contribution to the business sector’s gains came from increased demand for efficient powertrain systems, driver assistance systems, and modern display and infotainment systems. Other systems that had success during the fiscal year included brushless motor platforms, electric steering systems, sensors, exhaust gas treatment systems, and fuel-injection systems.

Acquisitions

-The Company completed its acquisition of ZF Friedrichshafen AG's 50% share in the joint venture ZF Lenksysteme GmbH. This means that the Company now owns all shares in the formerly 50:50 joint venture. It will be incorporated into the Company as a new division with the name Robert Bosch Automotive Steering GmbH. (From a press release on January 30, 2015)

-The Company announced that it has acquired Seeo Inc., a U.S. company that develops next-generation lithium-ion batteries. The acquisition boosts the Company’s own development in battery technology with crucial know-how in solid-state cells for lithium batteries as well as exclusive patents. By using solid-state technology, the Company can manufacture the anode out of pure lithium, which increases storage capacity. The Company is debuting a new battery technology for electric cars that could be production-ready in as little as five years. With the new solid-state cells, the Company sees the potential to more than double energy density at lower cost by 2020. (From a press release on September 15, 2015)

Joint Venture

-The Company announced a joint venture with the wiper manufacturer Kyung Chang Wiper Corp. (KCW) of South Korea. In the next few weeks, the joint venture will start operations under the name KB Wiper Systems (KBWS). Approximately 700 associates are expected to work there. The Company plans to contribute its wiper business in South Korea to the new company, whose headquarters will be in Daegu. In the past five years, the Company has invested more than EUR 200 million in the expansion of its manufacturing and engineering locations in Korea. (From a press release on July 6, 2015)

Restructuring

-The Company announced that its Starter Motors and Generators division will be made a legally independent entity by the end of 2015. In addition, the quest for suitable partners and potential buyers will continue. (From a press release on July 2, 2015)

Business Partnership

-Kunming Yunnei Power Co., Ltd. announced that it signed a basic agreement with the Company’s subsidiary, Bosch Automotive Diesel Systems Co., Ltd. that sets the framework to form a long-term strategic partnership agreement. Areas of collaboration will include the joint development, technical cooperation, and marketing of environmentally friendly electronically controlled high-pressure common-rail diesel engines in China, and the introduction of clean diesel vehicles. (From an announcement on November 19, 2015)

-The Company and Tencent announced that they will collaborate in the area of vehicle telematics systems. Tencent will integrate all its driving-related applications and services into a single app, while the Company will introduce the app in vehicles via its mySPIN smartphone integration solution. mySPIN has cooperated with more than 20 of the most popular apps including Tencent Automotive app, Sogou Navigator, AutoNavi, and Baidu Navi, with their scope of service ranging from navigation, music, news to voice interaction and maintenance services. (From news releases issued by multiple sources on September 21, 2015)

-ULVAC, Inc., headquartered in Kanagawa Prefecture, Japan, announced that it has signed a basic agreement with the Company to jointly develop new piezoelectric devices for micro-electromechanical systems (MEMS). Under this agreement, the Company will utilize ULVAC's SME-200 sputtering system to develop advanced MEMS devices. (From an article in the Nikkan Jidosha Shimbun on April 11, 2015)

Contracts

-The Company announced that its multimedia unit is in several Suzuki models worldwide. The 7-inch color touchscreen displays a host of practical and convenient connectivity options in a single device, including smartphone integration via Mirror Link and Apple CarPlay, advanced map navigation and voice control, a hands-free Bluetooth system, and exceptional music via audio-streaming or the radio. The SD map navigation in the new Suzuki system gives precise driving directions to guide drivers to their destination. (From a press release on November 5, 2015)

-The Company delivers its clean diesel technology to the 2015 Ram 1500, which includes a 3.0-liter EcoDiesel V6 equipped with a Company common-rail diesel fuel-injection system. In addition, the Company provides the system's high-pressure pump, sensors, engine control unit and the vehicle's emission control system. The 3.0-liter EcoDiesel V6 was chosen for Ward's 10 Best Engines for the second time earlier this year. (From a press release on May 19, 2015)

-The Company announced that its drive systems are installed on three plug-in hybrid models from Porsche. The Company supplies the power electronics, battery pack, and IMG-300 electric motors for the Cayenne S E-Hybrid and Panamera S E-Hybrid and the SMG 180/120 electric motor installed on the front axle of the 918 Spyder. (From a press release on May 12, 2015)

-The Land Rover Discovery Sport utilizes the Company’s new stereo video camera and emergency braking system as standard features. Other driver assistance functions which use the stereo video camera include road-sign recognition and lane-departure warning. (From a press release on May 4, 2015)

-The Company announced that its Jet Wiper will now be standard equipment in the new Volvo XC90. The Jet Wiper, featuring a wiper drive and Aerotwin wiper blades, is far superior to conventional windshield wipers due its smart control and spray nozzles integrated in the wiper arm. These nozzles distribute the washer fluid evenly, thus ensuring that the windshield is cleaned over the entire length of the wiper blade. Benefits of the system are that the drivers' vision is not impaired by spray mist, and consumption of washer fluid is reduced by as much as 50%. (From a press release on March 16, 2015)

Recent Developments

-The Company supplied the common-rail injection system and the supply and dosing module for exhaust-gas treatment for Volkswagen models listed in the reports about the automaker's diesel test manipulations in the U.S. As is standard, these components were supplied to the automaker's specifications. How the components were calibrated and integrated into complete vehicle systems is the responsibility of each automaker. (From a press release on September 24, 2015)

-Bosch Corporation, the Company’s Japanese subsidiary, held its annual press conference in Tokyo. The company announced that it ended 2014 with JPY 275 billion (EUR 2 billion) in consolidated sales to third parties in Japan, thus registering a growth of 9% compared to the previous year. Strong sales of components for two-wheelers and four-wheelers including anti-lock braking systems, electronic stability control systems and continuously variable transmission belts contributed to the positive turnover. Udo Wolz, president and representative director of Bosch Corporation, said that the company expects a further increase in sales in 2015, though the growth rate will be smaller than that in 2014. (From an article in the Nikkan Jidosha Shimbun on June 23, 2015)

Outlook for FY ending Dec. 31, 2016

-The Company expects its sales to increase between 3% and 5% in the fiscal year ending December 31, 2016. The Mobility Solutions business sector is expected to achieve a higher growth rate than the Company overall.

Corporate Strategy

Regional planning

-In the Asia Pacific region, the Company invested EUR 1.1 billion in the fiscal year ended December 31, 2015, compared to EUR 620 million in the previous year. Most of the investment was directly specifically towards diesel and gasoline direct-injection systems, particularly in China. In addition, the Company began construction of a new engineering center in Vietnam, and expanded manufacturing facilities and engineering centers in India. The Company’s capital expenditure in the Asia Pacific region amounted to 26.8% of the Company’s total capital expenditure.

-In the fiscal year ended December 31, 2015, the Company invested EUR 460 million in capital expenditures in North and South America, compared to EUR 220 million in the previous year. Investments included the expansion of the engineering location in Plymouth, MI, U.S., the manufacturing facility in Charleston, SC, U.S., and manufacturing facilities in Toluca, Juarez, Mexico, and Aguascalientes, Mexico. Investment in North and South America totaled 11.2% of the Company’s total capital expenditure.

Avenues of development in the automotive market

-The Company’s goal for its Mobility Solutions business sector is to hold leading positions in the areas of connected, automated, and electrified driving.

-The Company invests approximately EUR 400 million in the electromobility field alone each year.

-As the Company decides to focus on the fields of electrification, automation, and connectivity in vehicles, it made the decision to spin off the Starter Motors and Generators division and look for a partner or buyer for the division.

-In the field of electrification, the Company’s acquisition of the U.S.-based startup Seeo Inc., in 2015 strengthens its position in electric vehicles. Specifically, Seeo’s expertise in solid-state cells for lithium-ion batteries provides an opportunity for the Company to develop batteries that can surpass the industry’s targets of doubling battery energy density and halving costs by the end of the decade.

-The Company is also exploring electrification and connectivity as possible supplements to reduce emission and fuel consumption of internal combustion engines. In fall 2015, the Company introduced the second generation of its 48V hybrid system. The hybrid system provides fuel savings, generates an additional 150 N-m of torque, and can enable the vehicle to drive in a full electric mode over short distances. The development of a connected powertrain provides another opportunity for fuel savings, by timing the regeneration of a particulate filter based on information from the navigation system. This allows the battery in hybrid vehicles to be charged proactively.

-Based on the motivation of improving road safety, the market for advanced driver assistance systems has been quickly growing in recent years. This is evidenced in the Company’s sales in the field, which have been growing by one-third annually. The Company has 2,500 employees dedicated towards the development of driver assistance systems.

-One key task that the Company accomplished is the integration of the Automotive Steering division, formerly the joint venture ZF Lenksysteme GmbH. Electric power steering is an essential part of numerous safety-relevant assistance systems, as well as future automated driving systems. While electric power steering is primarily seen on passenger cars and light trucks, the division has recently introduced the Servotwin electrohydraulic steering system for heavy trucks, driver assistance functionality can be extended to those vehicles as well.

-As sensors play a key role in automated driving, the Company has looked to improve upon its position in the field of radar sensors by introducing its MRR mid-range radar sensor, expanding its customer base. The MRR sensor can be used as the basis for several driver assistance functions such as adaptive distance and speed control, and lane-keeping systems.

-One of the approaches that the Company uses to connect a car to the internet is utilizing a driver’s smartphone. The Company currently uses mySPIN to link the driver’s smartphone to the vehicle’s infotainment system. Currently, the Company offers approximately 50 compatible apps for the mySPIN system. The Company also organizes hackathons where programmers, software developers, designers, and project managers gather and collaboratively work to develop new apps.

-In regards to connectivity, the Company has also focused on growing service businesses associated with the technology. The Company offers a Drivelog mobility portal for drivers to locate vacant charge spots for electric vehicles, or to receive information in regards to regular vehicle maintenance appointments. The Company is also working to develop connectivity between different modes of travel. For example, the Company developed a single chip card for the Stuttgart Services project which can be used for car-sharing, bike-sharing, train, and bus travel, as well as for admission to various amenities.

R&D Expenditure |

(in million EUR) |

| FY ended Dec. 31, 2015 | FY ended Dec. 31, 2014 | FY ended Dec. 31, 2013 | |

| Overall | 6,378 | 4,959 | 4,543 |

| -Mobility Solutions | 4,784 | 4,066 | ~3,600 |

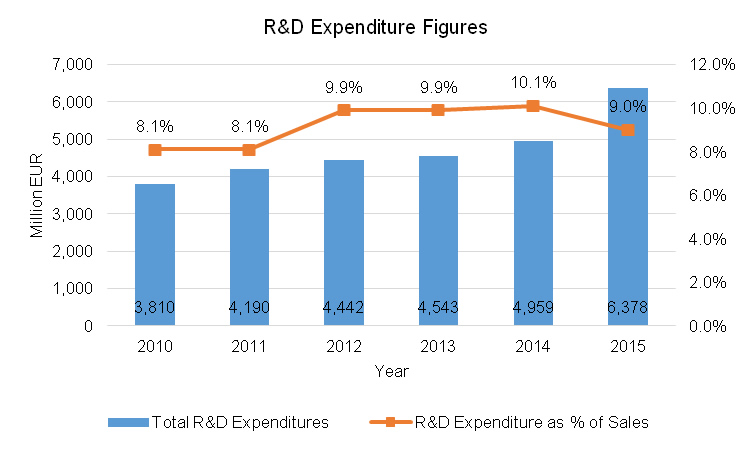

-One part of the Company's mission statement focuses on the Company playing an active role in influencing changes occurring in both technology and various markets. These changes represent opportunities for the Company to take advantage of. In order to seize these opportunities, the Company has continued to invest an increasing amount in research and development. This holds true especially in the Mobility Solutions business sector, where vehicle technologies are trending towards electrification, connectivity, and autonomous driving.

-One part of the Company's mission statement focuses on the Company playing an active role in influencing changes occurring in both technology and various markets. These changes represent opportunities for the Company to take advantage of. In order to seize these opportunities, the Company has continued to invest an increasing amount in research and development. This holds true especially in the Mobility Solutions business sector, where vehicle technologies are trending towards electrification, connectivity, and autonomous driving.

-While the Company's research and development expenditures in the fiscal year ended December 31, 2015 grew 28.6% to EUR 6,378 million, the ratio of R&D expenditure to total sales fell from 10.1% to 9.0%. This was due to the first time consolidation of the Automotive Steering business sector and BSH Hausgerate. If the two entities were included in consolidation in the 2014 fiscal year, the R&D expenditure ratio would have been approximately 9%.

R&D Structure

-As of December 31, 2015, the Company has approximately 55,800 employees working in research and development.

R&D Facilities

-The Company announced it will open a 51,667-square-foot technology center in Pittsburgh, Pennsylvania, U.S. in July 2016, nearly doubling its footprint in the region. The development of this center was driven by the need to accommodate growth of the Company’s business units, including its subsidiary Akustica, a manufacturer of micro-electromechanical system (MEMS) microphone products, and its Research and Technology Center in Pittsburgh. The new building will initially house approximately 140 associates. (From a press release on December 21, 2015)

-The Company announced that Bosch (Donghai) Automotive Test & Technology Center Co., Ltd. in Lianyungang has opened new test courses and facilities that were developed in the second phase of its construction project. The test center covers a land area of approximately 1,396,000 square meters and is expected to involve a total investment of CNY 591 million. The center opened in June 2013 once the first phase of construction was completed. The second phase includes a brake test area, a slope for testing traction control systems, test circuits, and maneuverability testing tracks. These new courses will allow on-road testing of safety technologies, including anti-lock brake systems, electronic stability programs, and driver assistance technologies. This test center is open to external users, offering them test rides according to their needs. (From news releases issued by multiple sources on November 16, 2015)

-The Company announced that it has opened its new research campus in Renningen, Germany. The Company has invested approximately EUR 310 million in the new location. Currently, the campus has a total of 1,200 associates in corporate research and advance engineering, plus 500 PhD students and interns. Their work will focus on areas such as software engineering, sensor technology, automation, driver assistance systems, battery technology, and improved automotive powertrain systems. The campus includes a main building, eleven laboratory and workshop buildings, two site maintenance buildings, and a modern proving ground for testing driver assistance systems. (From a press release on October 14, 2015)

-The Company announced that it has opened its new Mobility Solutions development center in Budapest, Hungary. The site boasts nearly 1,300 engineers – twice as many as four years ago – who develop electronics and components for driver assistance and engine control systems. Since 2011, approximately EUR 100 million was invested in expanding the 50,000-square-meter Budapest site. (From a press release on August 7, 2015)

-The Company is planning to expand its development center in Abstatt, Germany, and expects to invest EUR 70 million in the project. The location is home to the Company's Chassis Systems Control division and the wholly owned subsidiary Bosch Engineering GmbH. The Company is planning to construct two new buildings and 1,300 additional parking spaces. Approximately 30,000 square meters of space will be added. Construction of the new buildings is scheduled to be completed in mid-2018. (From a press release on August 3, 2015)

R&D Activities

-The Company’s subsidiary, Bosch India, further enhanced its partnership with the Indian Institute of Science (IISc) by signing a memorandum of understanding (MoU). Through this MoU, the Company and IISc will collaborate to address India-centric requirements. They expect to see positive results as they collaborate in research in areas such as mobility, healthcare, energy and water. (From a press release on November 4, 2015)

-The Company started testing an autonomous vehicle on public highways in Tochigi Prefecture, Japan. While the Company has conducted such tests in Germany and the U.S., this is its first autonomous driving test in Japan. In the future, the test will be conducted in Kanagawa and Hokkaido. The Company has mounted its cameras, radars and sensors on a Japanese automaker's vehicle and has developed and installed a software package that incorporates an autonomous driving algorithm in the control unit. (From an article in the Nikkan Jidosha Shimbun on October 29, 2015)

-The Company announced that it has joined forces with a number of other suppliers, automakers, and public sector partners to launch the "cooperative highly automated driving" (Ko-HAF) research initiative, which aims to advance development of automated driving. The project will tackle the challenges of highly automated driving. Within the Ko-HAF project, the Company has assumed primary responsibility for developing a backend solution to collect and provide information about a vehicle's current surroundings, such as traffic infrastructure. In addition to the backend solution, the Ko-HAF project is also working on precise self-localization for highly automated vehicles. With total funding of EUR 36.3 million, The Ko-HAF project is scheduled to run until November 2018. The German Federal Ministry for Economic Affairs and Energy (BMWi) is supporting the project with EUR 16.9 million in funding as part of its "new vehicle and systems technology" program. (From a press release on August 25, 2015)

-The Company announced that it is participating in the AMALTHEA4public project to develop embedded systems with central processing units that work in parallel. The project involves 21 partners from Germany, Spain, Sweden, and Turkey, with the German project partners focusing primarily on automotive industry requirements. AMALTHEA4public will run through August 2017. The trend towards automated driving leads to individual computers running more software, and more complex systems. Thus, embedded systems will need more computing power in the future. (From a press release on July 7, 2015)

-The Company, Daimler AG, and car2go, a subsidiary of Daimler providing car-sharing services, have launched a joint pilot project for automated parking in a car park. The automated parking system utilizes the car park’s intelligent infrastructure, the Company’s vehicle control unit in conjunction with the newest generation of Mercedes-Benz on-board sensors, and car2go’s car-sharing expertise. A smartphone is used to book a vehicle via car2go. As soon as the user is ready in the pick-up-zone of the car park, the car drives up independently and the ride can begin. Once the trip is completed, the customer parks the car in the drop-zone of the car park and uses a smartphone to return the car. The intelligent system of the car park registers the vehicle, starts it, and directs it to an assigned parking space. (From a press release on June 9, 2015)

-The Company announced that two new Tesla Model S test vehicles have joined its fleet. The test vehicles were retrofitted to prepare for automated driving. Fifty new Company components were installed in each car. Components included a stereo video camera (SVC), which the car uses to recognize lanes, traffic signs, and clear spaces. In addition, 1,300 meters of cable were laid in each car and fixed in place with 400 cable ties. Thanks to the retrofits, the two Teslas can now autonomously drive from on-ramp to off-ramp without constant monitoring. The Company started testing automated driving on public roads at the beginning of 2013. It has been using test vehicles based on the BMW 325d Touring. (From a press release on May 19, 2015)

-The Company, BMW Group, and Vattenfall AB have launched the Second Life Batteries project. The project will drive progress on electromobility and power storage technologies by interconnecting used batteries from electric vehicles to form a large-scale energy storage system in Hamburg. (From a press release on January 21, 2015)

Technological Alliance

-The Company and Dutch map and traffic provider TomTom have agreed to collaborate on map usage for highly automated driving. Under the agreement, TomTom is designing the necessary maps, while the Company is defining the specifications these maps have to meet. Even now, the maps are already being used in the automated vehicles the Company is testing on certain public roads in Germany and in the U.S. By the end of 2015, the companies want to have high precision maps for automated driving for all freeways in Germany. Road coverage will subsequently be extended to the rest of Europe and North America. (From a press release on July 21, 2015)

Product Development

High-pressure diesel common rail system

-The Company developed a high-pressure diesel common rail system capable of pressures up to 2,700 bar. The pressure level is 200 bar higher than the Company’s current system. The higher injection pressure causes the fuel to be better atomized and mixed with the air in the cylinder. This makes the combustion process cleaner and reduces particulate matter and NOx emissions. The Company's NOx aftertreatment technology and the high-pressure diesel common rail system are expected to help automakers achieve future emission targets. (From an article in the Nikkan Jidosha Shimbun on December 1, 2015)

48V hybrid system

-The Company announced that it will start production of its 48V hybrid system by 2017. The entry-level system improves vehicle's fuel consumption by 15% in both controlled tests and everyday driving situations. Also, the system’s electronic boost feature provides engines with more dynamic acceleration. The electrical powertrain provides the combustion engine with an additional 150 Nm of torque during acceleration. As the system is based on a lower voltage versus standard 400-volt hybrids, it can function with less expensive components. Instead of a large electric motor, the generator has been enhanced to output four times as much power. The motor generator uses a belt to support the combustion engine with up to 10 kW. A DC/DC converter supplies power to the car's 12-volt on-board network from the system’s vehicle electrical system. The newly developed lithium-ion battery is also significantly smaller. At the IAA 2015, the Company will also present a new second generation of the entry-level hybrid that is currently in development. (From a press release on September 4, 2015)

Stereo video camera

-The Company has developed a stereo video camera which can be used as the sole information source for an emergency braking system. Normally, the system would require a radar sensor or a combination of radar and video sensors. Land Rover offers the stereo video camera together with the Company’s emergency braking system as standard in its new Discovery Sport. When the camera recognizes another vehicle ahead in the lane as an obstruction, the emergency braking system prepares for action. If the driver does not react, then the system initiates maximum braking. Besides the emergency braking system, the new Land Rover Discovery Sport offers other driver assistance functions, some of which are also based on the Company’s stereo video camera. These functions include road-sign recognition and lane-departure warning. (From a press release on May 4, 2015)

Real-time maps of available parking

-The Company has developed solutions to create real-time maps of available parking spaces with the help of wireless sensors installed on the pavement. These sensors recognize whether a parking space is occupied or not, and share this information via the internet. In the future, cars passing by available parking spaces will be capable of reporting them. The ultrasonic sensors installed in many modern cars to support their parking assistance functions identify gaps along the side of the road. Since many vehicles are connected online, this information can also be transmitted over the internet and displayed on a real-time map. Transmitting this real-time information to users’ smartphones or directly to their cars' navigation devices can help shorten the time used to find a parking space. (From a press release on February 13, 2015)

Patents

-In 2015, the Company filed approximately 5,400 patent applications.

Capital Expenditure |

(in million EUR) |

| FY ended Dec. 31, 2015 | FY ended Dec. 31, 2014 | FY ended Dec. 31, 2013 | |

| Overall | 4,058 | 2,585 | 2,539 |

| -Mobility Solutions | 3,100 | 2,200 | 2,200 |

Investments outside Germany

-The Company’s continuous investments in Hungary have created a total of 130 new jobs through three supported development projects for its Hungarian subsidiary Robert Bosch Automotive Steering Kft. The projects have a total value of HUF 36 billion (approximately USD 125 million) and includes a HUF 2 billion grant by the European Union and a HUF 700 million grant by the Hungarian government. While two projects were completed earlier this year, the final project with a value of HUF 7.2 billion, including HUF 1 billion support of the European Union, was recently completed at Maklar. The project has retained jobs, upgraded manufacturing technology, and increased production capacity of steering components. Other developments at Robert Bosch Automotive Steering Kft. Include a project which was awarded a HUF 1 billion grant from the European Union, which enabled the Company to start up a project for assembling electrical steering gear for cars in 2014. Another project involved expanding the plant and increasing capacity with the adoption of new technologies. Serial production of steering components started up at the Maklar site in May 2015. (From a press release on December 7, 2015)

-The Company’s subsidiary, Bosch Limited in India, has inaugurated its 14th manufacturing facility in the country. The new plant is located at Bidadi, Bengaluru in the state of Karnataka and will manufacture products for the Diesel Systems division. Since the ground breaking in September 2013, approximately INR 3,400 million (EUR 45 million) has been invested in the new plant at Bidadi, which spans 38,000 square meters. The construction of the Bidadi plant is split into two phases, with the second phase scheduled to be completed by 2018. The manufacturing facility will produce diesel products that were previously manufactured at the Adugodi plant, and will have over 2,600 associates. Like the previous location, the new Bidadi plant will continue to be the lead plant for the production of single cylinder common rail pumps along with conventional fuel injection pumps. The Bidadi plant will start the production of the common-rail fuel injection system pump. By 2017, production of the newer version of common rail fuel injection pump is expected. (From a press release on August 27, 2015)

-The Company’s subsidiary, Bosch Limited in India, announced that it has inaugurated its sixth manufacturing unit in India at State Industries Promotion Corporation of Tamil Nadu (SIPCOT). Built with an investment of around INR 500 million (EUR 6.2 million) and spread across 6,500 square meters, this new facility will facilitate the company's Gasoline Systems business. The facility will produce powertrain sensors, fuel delivery modules and air management components for automotive and two-wheeler systems. (From a press release on January 22, 2015)

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India