Archives of Past Exhibits:NGK Spark Plug

Tokyo Motor Show 2015

Ceatec Japan 2015

Emissions meter

-Under development -Mass production scheduled to begin in 2016 -Enables real-time measurement of PM/PN and NOx from moving vehicles’exhaust gas

-Under development -Mass production scheduled to begin in 2016 -Enables real-time measurement of PM/PN and NOx from moving vehicles’exhaust gas

2015 JSAE Automotive Engineering Exposition

Shanghai International Automobile Industry Exhibition 2015

2014 JSAE Automotive Engineering Exposition in NAGOYA

2014 JSAE Automotive Engineering Exposition

High-Ignitability Spark Plug for High Boosted Engines

-First exhibit -Spark consumption reduced by 60%.

-First exhibit -Spark consumption reduced by 60%.

High-Ignitability NI Type Spark Plug

-For 2 wheelers -High cost performance using NI -Under production

-For 2 wheelers -High cost performance using NI -Under production

Ceramic GIPS (Glow function integrated Pressure Sensor)

-Target regulation: Euro6c/7、ULEV125/70-Under development Competition: Beru

-Target regulation: Euro6c/7、ULEV125/70-Under development Competition: Beru

Zirconia Exhaust Gas Oxygen Sensor

-Number 1 global market share, about 30%, in Oxygen sensor. Competition: Denso, Bosch

-Number 1 global market share, about 30%, in Oxygen sensor. Competition: Denso, Bosch

Compact Zirconia Exhaust Gas Oxygen Sensor for 2 wheelers / Stacked Film type Oxygen Sensor for 2 wheelers

2014 Auto China - Beijing International Automotive Exhibition

Delhi Auto Expo 2014

Tokyo Motor Show 2013

2013 IAA Frankfurt Motor Show

2013 JSAE Automotive Engineering Exposition

Shanghai International Automobile Industry Exhibition 2013

2012 JSAE Automotive Engineering Exposition

TOKYO motor show 2011

| Air quality sensor - for air duct installation (two elements) /for front grille installation (three elements) | Air quality sensor - MEMS element | ||

|

|

||

| image |  |

|

|

| Non-resonant type knock sensor | Wide range exhaust gas temperature sensor/EGR temperature sensor | ||

|

|

||

|

image |  |

|

| Wide range oxygen sensor | Zirconia oxygen sensor-Standard type/Small non-heated type/Small heated type | ||

|

|

||

| image |  |

|

|

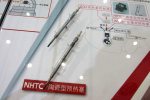

| NOx sensor | NHTC(New High Temperature Ceramic)Glow plug/Metal glow plug | ||

|

|

||

|

|

||

| Glow control unit | Intake air heater | ||

|

|

||

|

image |  |

|

| Micro tubular solid oxide fuel cells | Hydrogen leak detection sensor | ||

|

|

||

| image image |

|

image |  |

| MEMS element for hydrogen leak detection sensor | Hydrogen production module | ||

|

|

||

|

|||

| Ceramic bearing ball | Ceramic package/Organic package | ||

|

|

||

| image |  |

|

|

| Plasma jet plug | Spark plug with extra long reach | ||

|

|

Installed vehicles: Daihatsu "Tanto Exe", Subaru "Lucra", smart "fortwo cabrio" |

|

|

image |  |

|

| Iridium plug with extra long reach (SPE) | Iridium plug with extra long reach (PSPE) | ||

|

Installed vehicles: Subaru "Impreza" |

|

Installed vehicles: Subaru "Legacy" |

| Metal fitting protrusion-type iridium plug | Single iridium plug with extra long reach |

||

|

Installed vehicles: Honda"Step WGN" |

|

Installed vehicles: Suzuki "WagonR" |

| DFE type plug with extra long reach | DFE type plug | ||

|

Installed vehicles: Nissan "GT-R", "Serena", Matsuda "Demio", Honda "Insight", "Fit", Mitsubishi "RVR" |

|

Installed vehicles: Mitsubishi "Delica D:5" |

| Green plug | Protrusion-type green plug | ||

|

Installed vehicles: Renault "Megane", Citroen "C2" |

|

Installed vehicles: Mitsubishi "eK Wagon" |

| Platinum plug | Platinum plug (SPE) |

||

|

Installed vehicles: Lotus "Elise", Audi "A4", Porsche "Cayenne" |

|

Installed vehicles: Ferrari "California" |

| Single platinum plug | Protrusion-type single platinum plug with extra long reach | ||

|

Installed vehicles: Alfa Romeo "159" |

|

Installed vehicles: Nissan "Note" |

| Two-polar single platinum plug with extra long reach | Metal fitting protrusion-type general plug | ||

|

Installed vehicles: Lamborghini "Aventador LP700-4" |

|

Installed vehicles: VW "Polo", Fiat "500" |

| Ceramic type glow plug | Metal type glow plug | ||

|

Installed vehicles: Mercedes-Benz "E320 CDI Avantgarde" |

|

Installed vehicles: UD Truck "Condor", Isuzu "Forward" |

JSAE 2011

| <Plugs> |

|||

|---|---|---|---|

| AQGS(R) [Advanced Quick Glow System] |

NHTC glow plug |

||

|

|

|

|

| Image | Image | ||

| M10 Spark plug with extra long reach |

|||

|

|

||

| Image | |||

| Plasma jet plug (Under development) |

High-ignitability spark plug with thinner Ni (Under development) |

||

|

|

|

|

| Image | Image | ||

| <Sensor> |

|||

|---|---|---|---|

| EGAS(R)-A (Air quality sensor) |

CTAS(R)-T (Wide range exhaust gas temperature sensor) |

||

|

|

|

|

| Image | Image | ||

| ERAS(R)-KN (Non-resonant knock sensor) |

ERAS(R)-KR (Resonant knock sensor) |

||

|

|

|

|

| Image | Image | ||

| OZAS(R)-S2 (Zirconia exhaust gas oxygen sensor) |

ZFAS(R)-N2 (NOx sensor) |

||

|

|

|

|

| Image | Image | ||

| ZFAS-U2 (Zirconia exhaust gas oxygen sensor) (Under development) |

ZFAS-U2-SM (Universal A/F heated exhaust gas oxigen sensor) (Under development) |

||

|

|

|

|

| Image | Image | ||

| Hydrogen leak detection sensor (Under development) |

|||

|

|

||

| Image | |||

| Micro tubular solid oxide fuel cells (Under development) |

|||

|

|

||

| Image | |||

JSAE 2010

| M10 spark plugs with extra long reach | PSPE spark plug | ||

|---|---|---|---|

|

|

||

| Image Image Image Image(M10 BI-HEX12 spark plug with extra long reach) Image(M12, HEX14 spark plug with extra long reach) Image(M14, HEX16 spark plug with normal reach) |

Image Image(PSPE spark plug) Image(Conventional type) Image(Conventional type) |

||

| NHTC glow plug | |||

|---|---|---|---|

|

|||

| Image Image Image |

|||

| AQGS(R) | EGAS(R)-A (Air quality sensor) | ||

|---|---|---|---|

|

|

||

| Image Image Image Image Image |

Image Image Image |

||

| ERAS(R)-KN (Non-resonant knock sensor) ERAS(R)-KR (Resonant knock sensor) |

|||

|---|---|---|---|

| ERAS(R)-KR | ERAS(R)-KN | ||

|

|

||

| Image Image Image |

Image | ||

| OZAS(R)-S2 (New type zirconia exhaust gas oxygen sensor) | |

|---|---|

|

|

| Image | |

| ZFAS(R)-U2 (New type universal A/F heated exhaust gas oxygen sensor) XCU(R)-UA3 (ASIC) |

CTAS(R)-T (Wide range exhaust gas temperature sensor) |

||

|---|---|---|---|

|

|

||

| Image | Image | ||

| Hydrogen separation module with structured catalyst for use in membrane reformer (Under development) |

Plasma jet plug (Under development) |

||

|---|---|---|---|

|

|

||

| Image | Image Image |

||

| Micro tubular solid oxide fuel cell (Under development) |

ZFAS(R)-N2 (NOx sensor) (Under development) |

||

|---|---|---|---|

|

|

||

| Image Image |

Image Image Image Image Image |

Image | |

TMS 2009

| PSPE spark plug | |||

|---|---|---|---|

|

Image 1 Image 2 (Standard Iridium spark plug) |

Image 3 (PSPE spark plug <Iridium type>) Image 4 (PSPE spark plug <Iridium type>) |

|

| M10 BI-HEX12 spark plug with extra long reach | |||

|---|---|---|---|

|

Image 1 Image 2 (M10 BI-HEX12 spark plug with extra long reach) |

Image 3 (M12, HEX14 spark plug with extra long reach) Image 4 (M14, HEX16 spark plug with normal reach) |

|

| NHTC glow plug | Metal glow plug for AQGS(R) | ||

|---|---|---|---|

|

Image |  |

Image |

| Glow control unit | Intake air heater | ||

|---|---|---|---|

|

Image |  |

Image |

| New type Zirconia exhaust gas Oxygen sensor | |||

|---|---|---|---|

|

Image | ||

| Quick start type universal A/F heated exhaust gas Oxygen sensor | Application specific IC (ASIC) for ZFAS(R)-U sensor |

||

|---|---|---|---|

|

Image |  |

Image |

| Knock sensor | |||

|---|---|---|---|

|

Image 1 Image 2(Non-resonant knock sensor) Image 3(Resonant knock sensor) |

||

| Air quality sensor | Wide range exhaust gas temperature sensor | ||

|---|---|---|---|

|

Image 1 Image 2 Image 3 Image 4 |

|

Image |

| Hydrogen separation module with structured catalyst |

|||

|---|---|---|---|

|

Image | ||

| Eco-friendly plugs | |||

|---|---|---|---|

|

Image 1 Image 2 |

Image 3 Image 4 |

|

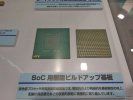

| Multi-layered substrate for RF module | Ceramic PKG for LED | ||

|---|---|---|---|

|

Image |  |

Image |

| Ceramic PKG for Quarts Crystal unit & SAW filter | Ceramic PKG for G-sensor | ||

|---|---|---|---|

|

Image |  |

Image |

| Ceramic PKG for yaw rate sensor | |||

|---|---|---|---|

|

Image | ||

| ICTM-HSK tooling system | Ceramic bearing ball | ||

|---|---|---|---|

|

Image 1 Image 2 |

|

Image 1 Image 2 Image 3 |

| Glow plugs | |||

|---|---|---|---|

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Citroen C5 (2004-) | Installed in the Peugeot 308 (2004-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the VW Golf (2008-) | Installed in the Forward (2004-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Mitsubishi Fuso Canter (2009-) |

Installed in the Nissan Diesel Condor (2009-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Peugeot 207 (2007-) | Installed in the Renault Twingo (2008-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the VW Passat V6 4motion (2008-) |

Installed in the Hyundai Sonata (2005-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Jaguar XFR (2009-) | Installed in the Jaguar XKR (2009-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Maserati Gran Turismo S (2008-) |

Installed in the Ferrari 599 (2006-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Fiat 500 (2008-) | Installed in the Fiat Panda (2007-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the BMW X5 (2008-) | Installed in the Chrysler Aspen Limited (2007-) |

||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Chrysler Jeep Grand Cherokee (2008-) |

Installed in the Citroen C4 (2007-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Alfa Romeo MiTo (2009-) | Installed in the Audi A6 (2007-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Audi R8 (2007-) | Installed in the BMW 320i Coupe (2007-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Suzuki Splash (2008-) | Installed in the Suzuki Wagon R (2008-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Toyota Estima HB (2006-) | Installed in the Toyota Passo Sette (2008-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Nissan Note (2008-) | Installed in the Nissan GTR (2007-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Subaru Forester (2007-) | Installed in the Subaru Legacy (2009-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Mazda Biante (2009-) | Installed in the Mazda RX-8 (2003-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Mitsubishi Delica D:5 (2007-) | Installed in the Mitsubishi i (2006-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Honda Accord (2008-) | Installed in the Isuzu Forward (2002-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Lexus HS250h (2009-) | Installed in the Lexus SC (2005-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Daihatsu Tanto (2007-) | Installed in the Daihatsu Move (2006-) | ||

|

Image 1 Image 2 |

|

Image 1 Image 2 |

| Installed in the Honda Insight (2009-) | Installed in the Hyundai i30 (2008-) | ||

JSAE 2006

-The Company exhibited various technology applications to reduce exhaust emissions and fuel consumption of gasoline and diesel engines.

For Gasoline

Long Reach M10 Spark Plug <Under development>

<Under development>

<Features>

While keeping almost the same level of performance as the current spark plug (M14), this plug has a smaller bore. Its features:

-Narrower plug hole caliber and valve holding angle

-Expanded valve caliber and water jacket

For Diesel

ERAS-UM Integrated Urea Sensor <Under development>

<Under development>

-This integrated urea sensor to detect urea thickness, water level and temperature contributes to reducing NOx from diesel engines. It is a sensor to manage the urea tank for urea selective catalyst reduction, responding to regulations following the new long-term exhaust emission regulations and Euro 4.

<Features>

-Since this sensor is able to detect water level based on electrical capacitance, moving parts have been eliminated, creating greater reliability

-Linear detection is possible.

-The sensor detects density by heat conduction, and determines air, diesel oil and irregular density.

-Temperature is detected by heater resistance. Linear detection is possible in all temperature ranges.

For Fuel Cell

Hydrogen Sensors for Fuel Cell Applications <In R&D stage>

<In R&D stage>

EGAS-HL (Hydrogen Leak Detection Sensor for Fuel Cell Applications)

-This sensor is capable of detecting hydrogen leakage in the air by use of a contact combustion system.

-Lower consumption of electricity and quicker responses are possible with the addition of a micro-heater.

-This device is designed to function under the normal driving conditions.

EGAS-H (Hydrogen concentration Sensor for Fuel Cell Applications)

-Limiting current system using polymer proton conductivity as electrolyte can produce output compatible with hydrogen of high density.

-It can function in the low temperature range from ordinary temperature to 100 degrees.

-Detection is possible even in the atmosphere of high humidity.

For Gasoline/Diesel

New Type Universal A/F Heated Exhaust Gas Oxygen Sensor

-This sensor contributes to reducing hazardous exhaust emissions.

<Features>

-Precision lambda control in the catalyst upstream (High level of precision and responsiveness)

-Output in proportion to oxygen density (A/F=10 to atmosphere)

-The integrated element and heater structure reduces time required for activation from 12 seconds to 5 seconds. (8 seconds guaranteed)

-Long-term assurance (Protection from poisoning)

For Gasoline

Long Reach M10 Spark Plug

<Features>

While keeping almost the same level of performance as the current spark plug (M14), this plug has a smaller bore. Its features:

-Narrower plug hole caliber and valve holding angle

-Expanded valve caliber and water jacket

For Diesel

ERAS-UM Integrated Urea Sensor

-This integrated urea sensor to detect urea thickness, water level and temperature contributes to reducing NOx from diesel engines. It is a sensor to manage the urea tank for urea selective catalyst reduction, responding to regulations following the new long-term exhaust emission regulations and Euro 4.

<Features>

-Since this sensor is able to detect water level based on electrical capacitance, moving parts have been eliminated, creating greater reliability

-Linear detection is possible.

-The sensor detects density by heat conduction, and determines air, diesel oil and irregular density.

-Temperature is detected by heater resistance. Linear detection is possible in all temperature ranges.

For Fuel Cell

Hydrogen Sensors for Fuel Cell Applications

EGAS-HL (Hydrogen Leak Detection Sensor for Fuel Cell Applications)

-This sensor is capable of detecting hydrogen leakage in the air by use of a contact combustion system.

-Lower consumption of electricity and quicker responses are possible with the addition of a micro-heater.

-This device is designed to function under the normal driving conditions.

EGAS-H (Hydrogen concentration Sensor for Fuel Cell Applications)

-Limiting current system using polymer proton conductivity as electrolyte can produce output compatible with hydrogen of high density.

-It can function in the low temperature range from ordinary temperature to 100 degrees.

-Detection is possible even in the atmosphere of high humidity.

For Gasoline/Diesel

New Type Universal A/F Heated Exhaust Gas Oxygen Sensor

-This sensor contributes to reducing hazardous exhaust emissions.

<Features>

-Precision lambda control in the catalyst upstream (High level of precision and responsiveness)

-Output in proportion to oxygen density (A/F=10 to atmosphere)

-The integrated element and heater structure reduces time required for activation from 12 seconds to 5 seconds. (8 seconds guaranteed)

-Long-term assurance (Protection from poisoning)

Tokyo Motor Show 2005

The Company presented a variety of spark plugs (mainly iridium spark plugs) and sensors for automotive uses which take into consideration environmental issues.

-Plugs for gasoline engines (Factory installed)

High Ignition Iridium Spark Plug

Upgraded version of the current iridium plug with greater ignition capability. Two types were presented, namely the projected angle type and the DFE (double fine electrode) type, and their application depends on the intended use. These plugs are for gasoline engines.

Iridium Long Reach M10 Spark Plug

Almost the same level of performance as the current M14, but in a smaller package. These are for use in gasoline engines. Their advantages include:

-Plug hole caliber was able to be made more narrow.

-Valve holding angle was able to be made more narrow.

-Valve caliber was able to be enlarged.

-Water-jacket was able to be expanded.

Iridium Hybrid Spark Plug

Under normal conditions sparks are generated between main electrodes, but when they smolder, sparks occur between side electrodes and burn off all carbon, so they are highly effective against pollution (as their insulation properties don't dissipate quickly). These are being used in direct-injection diesel engines as well as in high output engines.

<>>>Technical Information>

-Plugs for diesel engines (factory installed)

NHTC (New High Temperature Ceramic ) Glow Plug

These plugs improve diesel engine starts and contribute to lowering exhaust emissions (HC and white smoke) based on their quick temperature speeds, greater heat resistance, and longer product lives. In addition, they can be used in DPF regeneration.

-Heat resistance:1,350 degrees C.

-Quick temperature speed :2 seconds to reach 1,000 degrees C. at 11V

-Able to be used in small and middle size diesel engines

<>>>Technical Information>

AQGS (Advanced Quick Glow System)

-High performance plugs take 2 seconds to reach 1,000 degrees C. (Previous plugs took 4.5 seconds to reach 800 degrees C.)

-Following a rapid rise to high temperature, the plugs are able to maintain the high temperature as a result of PWM control, and thus are capable of responding to long after-glows.

-Precise control of the glow plug temperature is possible by controlling effective-voltage by means of fast-speed switching of FET.

-Systematic diagnosis is possible for breaks, cuts, shorts, and other failures in the plugs.

-These are used in small and mid-size diesel engines

<>>>Technical Information>

-Sensors for diesel engines (factory installed)

Universal A/F Heated Exhaust Gas Oxygen Sensor (ASIC)

-High level of both precision and response

-Output in proportion to density of O窶啣

-Long-term assurance

-ASIC can be mounted on ECU, reducing both costs and space.

-Used to control diesel combustion and detect the timing for rich spike endings.

<>>>Technical Information>

NOx Sensor

-Output in proportion to density of NOx (e.g.0-500ppm)

-Simultaneously capable of measuring oxygen density. (air/fuel ratio: 10 to atmosphere)

-Interfering gas. Able to respond to NH3 in almost the same level as it does to NOx.

-Takes about 5 minutes to warm up.

-Is dependent upon pressure, temperature and O2 density.

-Is used to control NOx absorption and SCR catalyzation in diesel engines.

<>>>Technical Information>

Wide Range Exhaust Temperature Sensor

-C-type sensors can measure a wide range of exhaust gas temperatures, from 100 to 900 degrees. E-type sensors, which the Company is still developing, will measure an ever greater range, from minus 40 to 900 degrees.

-High degree of responsiveness (6 seconds) made possible with only a small element and a narrow heat-sensing design.

-Made lighter in weight (18 g) by reducing component sizes.

-Longer term reliability through the use of single-unit stamped metallic tubes.

-Capable of controlling DPF/NOx-CAT and SCR and protecting turbochargers.

<>>>Technical Information>

Urea Level Sensor

-Since this sensor is able to detect water level based on electrical capacitance, moving parts were eliminated, creating greater reliability.

-Linear detection is possible.

-Capable of detecting water levels in urea tanks used in Urea SCR systems that are compliant with the new long-term emission regulations and post EURO 4 regulations.

<>>>Technical Information>

Oil Level Sensor (still in R&D stage)

-Water level is detected through electrical capacitance, thus eliminating moving parts and heightening reliability.

-Oil level and temperature are measured linearly.

-Quick startups possible.

-It is possible to monitor electrical capacitance changes caused by deteriorating oil.

-These sensors monitor when oil changes are needed and when oil needs to be added.

<>>>Technical Information>

-Sensors for fuel cells

Sensors to Detect Hydrogen Leaks in Fuel Cells (still in R&D stage)

-Lower consumption of electricity and quicker responses are possible with the addition of a micro-heater

-Sensors can detect even low levels of gas through the use of a contact combustion system.

-Able to respond to onboard vehicle environment.

<>>>Technical Information>

Sensor to Detect Level of Hydrogen in Fuel Cells (still in R&D stage)

-Output is in proportion to level of hydrogen density

-Activation at low temperatures, from ambient to 100 degrees C.

-Capable of measuring even during high-humidity conditions.

-Not susceptible to interfering gas such as CO contained in reformulated fuel.

<>>>Technical Information>

-Sensors for gasoline engines (factory installed; four-wheeled vehicles),

Universal A/F Heated Exhaust Gas Oxygen Sensor / ASIC

-Precise intake control due to catalyzer installed upstream (high precision, high response)

-Output in proportion to O2 density of (A/F=10-atmosphere)

-Complete water-proof structure requiring no basic atmosphere.

-Long-term assurance (anti poisoning properties)

-ASIC that can be mounted on ECU, reducing both costs and space.

<>>>Technical Information>

New Universal A/F Heated Exhaust Gas Oxygen Sensor / ASIC

-Highly heat resistant; offers greater ease in installation.

-Can be actuated within 5 seconds of the engine being ignited, as the element and heater mechanisms are integrated.

<>>>Technical Information>

Zirconia Exhaust Gas Oxygen Sensor

-Highly resistant to forming deposits, also has even longer product life.

-After the engine is ignited, FLO starts to activate within 15 seconds, while FLO (U) starts within 10 seconds. (Standard type takes 40 seconds)

-Sub-feedback system for use by downstream catalyzer in response to OBD decision.

-High level of reliability based on specifications that meet OBD.

-Extremely tight seals, eliminating all gasoline and water leaks.

-Reduces emissions by taking advantage of quick activation made possible through installing a catalyzer upstream; or sub-controlling OBD intake through a catalyzer installed down stream.

<>>>Technical Information>

New Zirconia Oxygen Sensor

-Highly heat resistant. Offers greater flexibility in installation under high temperature environments such as rear end exhaust gases.

-Dramaically improves resistance to deposit formation, and thus achieves longer life.

-Starts to activate within 8 seconds of the engine being ignited, further improving on conventional FLO (U) types.

-Sub-feedback system for use by downstream catalyzer in response to OBD determination.

-Highly water-proof in responding to installation of catalyzers downstream.

<>>>Technical Information>

Non-Resonant Knock Sensor

-High revolution control is possible due to excellent response performance.

-The same component is compatible with a variety of engines by merely changing only the band bass filter because of its flat frequency properties.

-Long term warranty

<>>>Technical Information>

Air Quality Sensor

-Equipped with two types of sensor elements, one for gasoline engines and the other for diesel engines, the sensor has a high degree of detection capability.

-Various auxiliary functions such as one that reduces the frequency of errors in detecting noise, other than gas.

-Automatic ventilation control systems for car air-conditioners.

<>>>Technical Information>

Oil Level Sensor (still in R&D stage)

-Detects water level by electrical capacitance, and thus eliminates moving parts while heightening reliability.

-Linear detection of oil level and temperature is possible.

-Quick to start up (about one second)

-It is possible to monitor electrical capacitance changes caused by deteriorating oil.

-These sensors monitor when oil changes are need and when oil needs to be added.

<>>>Technical Information>

-Plugs for gasoline engines (Factory installed)

High Ignition Iridium Spark Plug

Upgraded version of the current iridium plug with greater ignition capability. Two types were presented, namely the projected angle type and the DFE (double fine electrode) type, and their application depends on the intended use. These plugs are for gasoline engines.

Iridium Long Reach M10 Spark Plug

Almost the same level of performance as the current M14, but in a smaller package. These are for use in gasoline engines. Their advantages include:

-Plug hole caliber was able to be made more narrow.

-Valve holding angle was able to be made more narrow.

-Valve caliber was able to be enlarged.

-Water-jacket was able to be expanded.

Iridium Hybrid Spark Plug

Under normal conditions sparks are generated between main electrodes, but when they smolder, sparks occur between side electrodes and burn off all carbon, so they are highly effective against pollution (as their insulation properties don't dissipate quickly). These are being used in direct-injection diesel engines as well as in high output engines.

<>>>Technical Information>

-Plugs for diesel engines (factory installed)

NHTC (New High Temperature Ceramic ) Glow Plug

These plugs improve diesel engine starts and contribute to lowering exhaust emissions (HC and white smoke) based on their quick temperature speeds, greater heat resistance, and longer product lives. In addition, they can be used in DPF regeneration.

-Heat resistance:1,350 degrees C.

-Quick temperature speed :2 seconds to reach 1,000 degrees C. at 11V

-Able to be used in small and middle size diesel engines

<>>>Technical Information>

AQGS (Advanced Quick Glow System)

-High performance plugs take 2 seconds to reach 1,000 degrees C. (Previous plugs took 4.5 seconds to reach 800 degrees C.)

-Following a rapid rise to high temperature, the plugs are able to maintain the high temperature as a result of PWM control, and thus are capable of responding to long after-glows.

-Precise control of the glow plug temperature is possible by controlling effective-voltage by means of fast-speed switching of FET.

-Systematic diagnosis is possible for breaks, cuts, shorts, and other failures in the plugs.

-These are used in small and mid-size diesel engines

<>>>Technical Information>

-Sensors for diesel engines (factory installed)

Universal A/F Heated Exhaust Gas Oxygen Sensor (ASIC)

-High level of both precision and response

-Output in proportion to density of O窶啣

-Long-term assurance

-ASIC can be mounted on ECU, reducing both costs and space.

-Used to control diesel combustion and detect the timing for rich spike endings.

<>>>Technical Information>

NOx Sensor

-Output in proportion to density of NOx (e.g.0-500ppm)

-Simultaneously capable of measuring oxygen density. (air/fuel ratio: 10 to atmosphere)

-Interfering gas. Able to respond to NH3 in almost the same level as it does to NOx.

-Takes about 5 minutes to warm up.

-Is dependent upon pressure, temperature and O2 density.

-Is used to control NOx absorption and SCR catalyzation in diesel engines.

<>>>Technical Information>

Wide Range Exhaust Temperature Sensor

-C-type sensors can measure a wide range of exhaust gas temperatures, from 100 to 900 degrees. E-type sensors, which the Company is still developing, will measure an ever greater range, from minus 40 to 900 degrees.

-High degree of responsiveness (6 seconds) made possible with only a small element and a narrow heat-sensing design.

-Made lighter in weight (18 g) by reducing component sizes.

-Longer term reliability through the use of single-unit stamped metallic tubes.

-Capable of controlling DPF/NOx-CAT and SCR and protecting turbochargers.

<>>>Technical Information>

Urea Level Sensor

-Since this sensor is able to detect water level based on electrical capacitance, moving parts were eliminated, creating greater reliability.

-Linear detection is possible.

-Capable of detecting water levels in urea tanks used in Urea SCR systems that are compliant with the new long-term emission regulations and post EURO 4 regulations.

<>>>Technical Information>

Oil Level Sensor (still in R&D stage)

-Water level is detected through electrical capacitance, thus eliminating moving parts and heightening reliability.

-Oil level and temperature are measured linearly.

-Quick startups possible.

-It is possible to monitor electrical capacitance changes caused by deteriorating oil.

-These sensors monitor when oil changes are needed and when oil needs to be added.

<>>>Technical Information>

-Sensors for fuel cells

Sensors to Detect Hydrogen Leaks in Fuel Cells (still in R&D stage)

-Lower consumption of electricity and quicker responses are possible with the addition of a micro-heater

-Sensors can detect even low levels of gas through the use of a contact combustion system.

-Able to respond to onboard vehicle environment.

<>>>Technical Information>

Sensor to Detect Level of Hydrogen in Fuel Cells (still in R&D stage)

-Output is in proportion to level of hydrogen density

-Activation at low temperatures, from ambient to 100 degrees C.

-Capable of measuring even during high-humidity conditions.

-Not susceptible to interfering gas such as CO contained in reformulated fuel.

<>>>Technical Information>

-Sensors for gasoline engines (factory installed; four-wheeled vehicles),

Universal A/F Heated Exhaust Gas Oxygen Sensor / ASIC

-Precise intake control due to catalyzer installed upstream (high precision, high response)

-Output in proportion to O2 density of (A/F=10-atmosphere)

-Complete water-proof structure requiring no basic atmosphere.

-Long-term assurance (anti poisoning properties)

-ASIC that can be mounted on ECU, reducing both costs and space.

<>>>Technical Information>

New Universal A/F Heated Exhaust Gas Oxygen Sensor / ASIC

-Highly heat resistant; offers greater ease in installation.

-Can be actuated within 5 seconds of the engine being ignited, as the element and heater mechanisms are integrated.

<>>>Technical Information>

Zirconia Exhaust Gas Oxygen Sensor

-Highly resistant to forming deposits, also has even longer product life.

-After the engine is ignited, FLO starts to activate within 15 seconds, while FLO (U) starts within 10 seconds. (Standard type takes 40 seconds)

-Sub-feedback system for use by downstream catalyzer in response to OBD decision.

-High level of reliability based on specifications that meet OBD.

-Extremely tight seals, eliminating all gasoline and water leaks.

-Reduces emissions by taking advantage of quick activation made possible through installing a catalyzer upstream; or sub-controlling OBD intake through a catalyzer installed down stream.

<>>>Technical Information>

New Zirconia Oxygen Sensor

-Highly heat resistant. Offers greater flexibility in installation under high temperature environments such as rear end exhaust gases.

-Dramaically improves resistance to deposit formation, and thus achieves longer life.

-Starts to activate within 8 seconds of the engine being ignited, further improving on conventional FLO (U) types.

-Sub-feedback system for use by downstream catalyzer in response to OBD determination.

-Highly water-proof in responding to installation of catalyzers downstream.

<>>>Technical Information>

Non-Resonant Knock Sensor

-High revolution control is possible due to excellent response performance.

-The same component is compatible with a variety of engines by merely changing only the band bass filter because of its flat frequency properties.

-Long term warranty

<>>>Technical Information>

Air Quality Sensor

-Equipped with two types of sensor elements, one for gasoline engines and the other for diesel engines, the sensor has a high degree of detection capability.

-Various auxiliary functions such as one that reduces the frequency of errors in detecting noise, other than gas.

-Automatic ventilation control systems for car air-conditioners.

<>>>Technical Information>

Oil Level Sensor (still in R&D stage)

-Detects water level by electrical capacitance, and thus eliminates moving parts while heightening reliability.

-Linear detection of oil level and temperature is possible.

-Quick to start up (about one second)

-It is possible to monitor electrical capacitance changes caused by deteriorating oil.

-These sensors monitor when oil changes are need and when oil needs to be added.

<>>>Technical Information>

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India