Bosch [Robert Bosch GmbH] Business Report FY ended Dec. 2017

Financial Overview |

(in million EUR) |

| FY ended Dec. 31, 2017 | FY ended Dec. 31, 2016 | Rate of Change (%) | Factors | |

| Overall | ||||

| Net Sales | 78,066 | 73,129 | 6.8 | 1) |

| EBIT | 4,916 | 3,594 | 36.8 | 2) |

| Mobility Solutions | ||||

| Sales | 47,384 | 43,936 | 7.8 | 3) |

| EBIT | 3,322 | 2,210 | 50.3 | 4) |

Factors

1) Net Sales

-In the fiscal year ended December 31, 2017, the Company’s net sales were EUR 78,066 million, an increase of 6.8% over the previous year. Excluding negative currency effects during the year, the Company’s sales increased by 8.4% for the year, as negative currency effects accounted for a loss of EUR 1.2 billion. Sales increased in the Asia Pacific region and Europe by 13.5% and 5.6%, respectively. Sales in North America decreased by 2.0%, while sales in South America increased by 16.4%.

2) EBIT

-The Company’s EBIT in the fiscal year ended December 31, 2017 was EUR 4,916 million, an increase of 36.8% from the previous year. The primary reason behind the increase in earnings was improved results from the Company’s Mobility Solutions business sector.

3) Mobility Solutions Sales

-The Company’s Mobility Solutions business sector’s sales increased by 7.8% in the fiscal year ended December 31, 2017 to EUR 47,384 million. The inclusion of ITK Engineering added approximately EUR 85 million, while the divestiture of the Starter Motors and Generators division had no impact on the figures for the 2017 fiscal year. In Powertrain Solutions, increased demand for gasoline direct injection systems, power electronics, transmission technologies and continuously variable automatic gearboxes all increased sales. Sales of diesel systems also increased due to growth in China. Sales in the Chassis Systems Control division grew due to higher demand for modern driver assistance systems, specifically with safety systems, displays and infotainment systems. Control units and sensors drove increased sales in the Automotive Electronics division, while electric steering systems were the primary source of increased sales for the Automotive Steering division.

4) Mobility Solutions EBIT

-The Mobility Solutions business sector had EBIT of EUR 3,322 million in the fiscal year ended December 31, 2017, an increase of 50.3%. Significant adjustment charges and investments, especially in the Automotive Steering and Car Multimedia divisions, were offset by increases in earnings across the business sector’s other divisions.

Acquisitions

-The Company announced that it intends to acquire all shares in the Italian company Albertini Cesare S.p.A. Albertini is a manufacturer of die-cast aluminum and produces cast housings primarily for the automotive industry, including for electric steering systems. The company is headquartered in Villasanta, near Milan, and currently employs more than 400 people at two locations in northern Italy. The Company plans to integrate Albertini into its Automotive Steering division. (From a press release on June 1, 2017)

Restructuring

-The Company announced that it has sold its entire stake in Akebono Brake Industry Co., Ltd. through a group company. The Company was a major shareholder of Akebono Brake with a 12.13% stake. The Company said that operations will not be affected by the transaction, though the companies will continue to supply each other. The Company signed a technical assistance agreement with Akebono Brake in 1987 and later acquired its shares. (From an article in the Nikkan Jidosha Shimbun on December 21, 2017)

-On September 23, 2017, Zhengzhou Coal Mining Machinery Group Co., Ltd. said that it would acquire 100% of Robert Bosch Starter Motors Generators Holding GmbH (SG Holding) from Robert Bosch Investment Nederland B.V. jointly with Chizhou Zhongan Zhaoshang Equity Investment Llp and China Renaissance Capital Investment Inc. The transfer price was estimated at EUR 545 million. SG Holding is a managing company of the Company’s starter and alternator business subsidiary. After the share purchase transactions, Zhengzhou Coal Mining Machinery will acquire the research and development platforms, production networks and sales networks of SG Holding. (From a corporate announcement on September 23, 2017)

-Mahle Group informed that the Company and Mahle are planning to sell their joint venture Bosch Mahle Turbo Systems (BMTS), to FountainVest Partners, a private equity investor backed by global institutional investors. A contract for the sale was signed on September 6th by the parties involved. The buyer intends to take over the entire business, including its 1,300 employees. The two companies revealed their plans for the sale at the beginning of 2017. The new owner will open up important prospects and growth opportunities for BMTS in markets such as China and North America. (From a press release on September 7, 2017)

-Knorr Bremse completed the acquisition of the Company’s Bosch Transmission Systems division in Japan on March 31, 2017, which included 113 employees. The acquisition of the business will improve Knorr Bremse’s expertise regarding electromotive and hydraulic transmission management systems for medium and light commercial vehicles. (From a press release on August 21, 2017)

-The Company announced plans to sell Robert Bosch Starter Motors Generators Holding GmbH, including all subsidiaries, to the purchaser consortium ZMJ (Zhengzhou Coal Mining Machinery Group Co., Ltd.), Zhengzhou, China, and CRCI (China Renaissance Capital Investment), Hong Kong, China. ZMJ is an automotive supplier of starters, generators, and other engine components for commercial vehicles and passenger cars. The financial investor CRCI will support ZMJ in this acquisition as its long-standing business partner. (From a press release on May 2, 2017)

-The Company announced that it is establishing an operating unit specifically for electromobility that, combined with the current Gasoline Systems and Diesel Systems divisions, will become the new Powertrain Solutions division. Starting at the beginning of 2018, the new Powertrain Solutions division will supply existing and new customers with all powertrain technologies from a single source. The Powertrain Solutions division, with 88,000 associates at more than 60 locations, will focus on three core segments: passenger cars and trucks with combustion engines, hybrid powertrains, and electric vehicles. The Company annually spends several billion euros on improving powertrain solutions, including a EUR 400 million investment in electromobility, primarily focusing on battery research and development. The Company has received more than 30 electromobility-related orders from international OEMs to date. (From a press release on February 7, 2017)

Joint Ventures

-The Company, Mitsubishi Electric, Geo++ and u-blox announced the creation of Sapcorda Services GmbH, a joint venture that will bring high precision GNSS positioning services to mass market applications. The four parties recognized that current solutions for GNSS positioning services do not meet the needs of emerging high precision GNSS mass markets. As a result, they formed the joint venture to facilitate the establishment of a globally available and affordable solution for system integrators, OEMs and receiver manufacturers. Sapcorda Services will offer globally available GNSS positioning services via internet and satellite transmission and enable centimeter-accurate precision. The services are designed to serve high-volume automotive, industrial and consumer markets. The real-time correction data service is provided in an open format, publicly accessible, and not tied to receiver hardware or systems. (From a press release on August 8, 2017)

Business Partnership

-The Company announced a development partnership with Nikola Motor Company to market fuel cell and commercial vehicle eAxles for Nikola class 8 hydrogen-electric trucks. By 2021, Nikola Motor Company will bring the Nikola One and Two to market. Nikola and the Company will use their expertise to commercialize the world’s first true dual-motor commercial-vehicle eAxle for a long-haul truck. The eAxles will be paired with a custom-designed fuel cell system jointly developed between the two companies. The overall vehicle controls will be jointly developed based upon the Company’s vehicle control software and hardware. The two companies will also jointly develop the overall powertrain system for the Nikola lineup, which will include the safety concept and vehicle electrical architecture. (From a press release on September 19, 2017)

Recent Developments

-The Company’s new 48-volt battery for hybrids is in demand by automakers across the globe. The system is standardized for easy integration into new vehicle models. Production of the battery is scheduled to start in late 2018. The 48-volt battery is in high demand, particularly among Chinese manufacturers. The Company estimates that some 15 million 48-volt hybrid vehicles will be on the road by 2025. (From a press release on October 10, 2017)

-The Company announced that Bosch India will offer local customers the complete value chain of offerings with respect to electromobility. Currently, Bosch India is the advanced stage of development and will move into series production after 2018. The Company has developed an integrated electrification system including motor, control unit, battery, charger, display, and an app that can power light two-, three- and four-wheel electric vehicles. In a pilot project, the powertrain system was integrated to define the adaptations required to create a powertrain platform specifically tailored to the India market. (From a press release on September 1, 2017)

-The Company's Thai operations is optimistic about its 2017 sales outlook, which is driven by the Thai government’s big-ticket infrastructure development projects that are expected to help boost economy and industrial growth. Projects are expected to start positively affecting the economy from the second half of 2017. The automotive industry is also showing signs of recovery from domestic sales despite murky prospect for exports. The Company has a long-term strategy to integrate Industry 4.0 aligned with the government’s policy, which is expected to support a smooth transition of the Company from being a global supplier of products and services to a leading provider of connectivity solutions in the Internet of Things. (From an article of Bangkok Post on July 6, 2017)

-The Company’s subsidiary, Bosch India, announced that it will invest INR 9 billion for the financial year 2017-18. 15% of Bosch India’s yearly investment goes towards research and development. India accounts for 30% of the Company’s engineer pool, making it the largest center outside Germany with 18,500 engineers. (From a press release on June 14, 2017)

-On May 18, the Company announced that it has obtained the final approval for a settlement agreement between itself and civil claimants in the U.S. related to Volkswagen, Audi and Porsche diesel vehicles. Judge Charles R. Breyer of the United States District Court of the Northern District of California formally approved the settlement concluded with the Plaintiffs’ Steering Committee on behalf of current and former owners, lessees, and reseller dealers of the affected vehicles. The Company agreed to pay a total of USD 327.5 million for 2009-2015 model year VW and Audi vehicles with 2.0-liter diesel engines and 2009-2016 model year VW, Audi, and Porsche vehicles with 3.0-liter engines. The agreement finally settles the claims of consumers and dealers of used vehicles against the Company, its affiliates, employees, and directors. As the settlement agreement concerns only civil law claims, the Company will continue to defend its interests in all other civil and criminal law proceedings and cooperate with the investigating authorities in Germany and other countries. (From a press release on May 18, 2017)

-The Company’s Bosch India subsidiary announced that it temporarily ceased operations at its Adugodi plant after receiving a notice from the Karnataka State Pollution Control Board (KSPCB). The KSPCB directed closure of all industrial units within the catchment area of Bellandur Lake in Bengaluru. The approximate loss of turnover is INR 39.3 million per day. On May 8, Bosch India announced the resumption of operations after it made representation to the KSPCB. (From Bosch India Stock exchange filing)

-Robert Bosch Venture Capital (RBVC), the Company’s corporate venture capital company, announced that it has completed an investment in TetraVue. RBVC currently co-leads a USD 10 million Series A funding round for TetraVue. TetraVue is a leader in advanced 3D lidar technology used to enhance the capabilities of automated vehicles. This latest investment adds to the RBVC portfolio of companies in the field of sensors and software for driverless vehicles. TetraVue’s core technology differentiation is its patented “light slicer” technology, which uses time and distance measurements to find optical intensities using standard CMOS sensors. The company’s approach allows it to produce ultra-high resolution images for a wider range of distances at a lower cost with greater reliability. TetraVue’s technology results in 2 million or more simultaneous distance measurements at ranges of up to 200 meters in all weather conditions and utilizes less power than competitors. (From a press release on February 16, 2017)

-The Company announced that it has entered into a settlement agreement with civil claimants in the U.S. to settle the largest part of the civil law proceedings in connection with Volkswagen Group diesel vehicles sold in the U.S. The agreement would settle the claims of consumers and dealers of used vehicles against the Company, its affiliates, employees, and directors concerning 2009-2015 model year Volkswagen and Audi diesel vehicles with 2.0-L engines and 2009-2016 model year Volkswagen, Audi, and Porsche diesel vehicles with 3.0-L engines. According to the settlement, the Company will pay a total of USD 327.5 million. The settlement agreement concerns only civil law claims. (From a press release on February 1, 2017)

Contracts

-On June 8, the Bosch Corporation, a Japanese subsidiary of the Company, held an annual press conference at its headquarters in Shibuya-ku, Tokyo. Udo Wolz, president and representative director of the Bosch Corporation, revealed that it has received orders for its 48-V mild hybrid systems and units compatible with firmware updates over the air from Japanese OEMs. The company will start supplying both products in 2019. (From an article in the Nikkan Jidosha Shimbun on June 9, 2017)

Outlook for FY ending Dec. 31, 2018

-Ignoring currency effects, the Company expects to have sales growth between 0% and 2% in the fiscal year ending December 31, 2018, with the Company’s Consumer Goods and Energy and Building Technology business sectors exhibiting higher than average growth.

-In the long term, the Company expects to achieve an average annual sales growth of 8%, with up to 3% stemming from acquisitions. The Company also aims to achieve an EBIT margin from operations of approximately 7%.

Corporate Strategy

Regional planning

-The Company’s capital expenditure for the fiscal year ended December 31, 2017 was distributed across its regions of operations as follows:

- Europe: EUR 2.7 billion

- Asia Pacific: EUR 1.2 billion

- North and South America: EUR 470 million

-The Company’s capital expenditure in Germany was primarily focused on increasing production capacity for semiconductors and sensors, investing in new buildings at Reutlingen as well as investing in gasoline direct injection and exhaust sensors. The Company is also expanding development activities in Abstatt to focus on automated and connected technologies.

-Outside of Germany, the Company invested in an expansion of a site in Hatvan, Hungary which manufactures power electronics. The Company also expanded capacity for exhaust treatment systems in Ceske Budejovice, Czech Republic and electronic systems in Cluj, Romania. Other investments went into a site in Braga, Portugal, which manufactures head units and automotive displays, and a site in Bursa, Turkey which focuses on diesel powertrain systems.

-The Company’s capital expenditure in the Asia Pacific region again focused primarily on China, specifically on expanding capacity for the Mobility Solutions business sector. The Company is also in the process on constructing a new engineering center in Suzhou. Other expansions in the Asia Pacific region include facilities at Bidadi and Naganathapura, India; Hemaraj, Thailand; Long Thanh, Vientam; and Penang, Malaysia.

-The Company’s capital expenditure in North and South Americas also focused primarily on the Mobility Solutions business sector. Expenditures were invested at the Company’s plants in Charleston, Anderson and Florence in South Carolina, U.S. as well as various locations in Mexico. In South America, the Company’s capital expenditure was primarily directed to its location in Campinas, Brazil.

Avenues of development in the automotive market

-In its Mobility Solutions business sector, the Company’s goal is to become one of the world’s leading suppliers in electrified, automated, and connected driving. The Company is also aiming to become one of the world’s leading companies in the Internet of Things.

-The Company announced that it would invest EUR 300 million into expanding the locations of the Bosch Center for Artificial Intelligence over the next five years, highlighting the potential of AI in various applications, including autonomous driving.

-The Company is currently in the process of building a new wafer fabrication facility in Dresden, Germany in response to growing demand from IoT and mobility applications. The Company will invest a total of EUR 1 billion on the facility, making it the single largest investment in the Company’s history.

-In 2017, the Company executed the divestitures of the following:

- Starter Motors and Generators division

- In conjunction with the Mahle Group, the Bosch Mahle Turbo Systems joint venture

- Bosch Transmission Systems division in Japan

The Company also discontinued operations of a Emission Systems plant in Neunkirchen, Germany.

-The Company, in order to focus its operations on electrified, autonomous and connected technologies, announced transactions in its Mobility Solutions business sector:

- The Company intends to divest its Rund um das Rad wheel business in the Automotive Aftermarket division.

- The Company is currently studying various restructuring options for its steering columns unit.

R&D Expenditure |

(in million EUR) |

| FY ended Dec. 31, 2017 | FY ended Dec. 31, 2016 | FY ended Dec. 31, 2015 | |

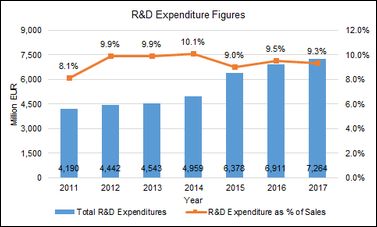

| Overall | 7,264 | 6,911 | 6,378 |

| -Mobility Solutions | 5,739 | 5,285 | 4,784 |

-The Company’s investment in research and development during the fiscal year ended December 31, 2017 was focused on automated driving technology, display and infotainment systems, and sensors. The Company also increased investment into electric steering.

-The Company’s investment in research and development during the fiscal year ended December 31, 2017 was focused on automated driving technology, display and infotainment systems, and sensors. The Company also increased investment into electric steering.

-One part of the Company's mission statement focuses on the Company playing an active role in influencing changes occurring in both technology and various markets. These changes represent opportunities for the Company to take advantage of. In order to take advantage of these opportunities, the Company has continued to invest an increasing amount in research and development. This holds true especially in the Mobility Solutions business sector, where vehicle technologies are trending towards electrification, connectivity, and autonomous driving.

-The Company's research and development expenditures in the fiscal year ended December 31, 2017 grew 5.1% to EUR 7,264 million, while the ratio of R&D expenditure to total sales decreased from 9.5% to 9.3%. The Mobility Solutions business sector continues to be the primary driver of the Company's research and development costs. Specifically, the Company made investments in automated driving, displays, infotainment systems, and sensors. In the fiscal year ended December 31, 2017, the Mobility Solutions business sector accounted for 79% of the Company's total R&D expenditure, an increase over the previous year's figure of 76%.

R&D Structure

-As of December 31, 2017, the Company has approximately 64,400 employees working in research and development, an increase of approximately 5,700 employees over the previous year. More than half of the employees working in research and development are located outside Germany.

-In 2017, the Company is planning to recruit approximately 20,000 specialists and executives in the technical and commercial fields. Nearly half of all jobs currently advertised are related to software. The Company is combining its expertise in hardware and software to develop IoT solutions such as connected production lines or agriculture. The Company’s staffing needs are greatest in Germany (3,400 jobs), India (3,100 jobs), and China (2,500 jobs). In addition to the 20,000 specialists and executives, the Company is also planning to hire workers in manufacturing. (From a press release on March 30, 2017)

R&D Facilities

-The Company announced that it will invest EUR 300 million in the Bosch Center for Artificial Intelligence over the next five years to extend its expertise in artificial intelligence. The Bosch Center for Artificial Intelligence will employ approximately 100 experts at locations in India, the U.S., and Germany. A self-driving car will generate as much as one gigabyte of data a second. The large amount of data will require artificial intelligence over classic control units. The Company’s AI onboard computer is expected to go into production by the beginning of the next decade at the latest. (From a press release on July 4, 2017)

-The Company announced that it has reopened its French headquarters as an innovation campus at the existing location in Saint-Ouen. The Company has invested a total of EUR 19 million in the new main building. The building’s 5,000 square meters of floor space accommodate up to 300 of the location’s 1,300 employees. The 1,300 employees include administrative associates and developers from the Bosch Engineering subsidiary, and will be joined in the future by sales teams from BSH Hausgerate GmbH. Following the opening of the new building, additional parts of the current complex in Saint Ouen are slated for remodeling by 2020 at the latest. (From a press release on March 28, 2017)

R&D Activities

-At the start of 2018, the Company decided to discontinue research into current and future battery cell technologies. As such, the Company will dissolve the Lithium Energy and Power GmbH & Co. KG joint venture held with GS Yuasa and Mitsubishi Corporation, which focuses on the development of next-generation lithium-ion battery technology. The Company will also sell Seeo, Inc., which focuses on the research of solid-state battery technology.

-The Company is working on various improvements to internal-combustion engines, including the combination of gasoline inlet manifolds and gasoline direct injection. The Company is also developing needle closing control systems, enabling the injection period in diesel engines to be more precisely controlled, and a vehicle control unit, which consolidates control units in a vehicle to a smaller number.

-The Company announced that its connected and automated parking solutions for urban mobility will reduce pollution and save fuel and time. Using ultrasonic sensors from their parking assist system, cars can identify and measure the gaps between parked cars as they drive past. The Company is testing this service in cities across Europe. Connected functions will save almost 400,000 metric tons of CO2. Strategies such as community-based parking and active parking-space management can reduce the distance driven in search of parking spaces by 480 million kilometers, while highly automated driving can save fuel. (From a press release on November 21, 2017)

-The Company demonstrated driverless parking in the parking garage of the Mercedes-Benz Museum. The automated, smartphone-based parking service launched as a pilot project. Driverless parking was made possible through intelligent parking garage infrastructure supplied by the Company and Mercedes-Benz. The sensors installed in the parking garage monitor the driving corridor and its surroundings while guiding the vehicle. The presented pilot solution is the world’s first-ever infrastructure-based solution for a fully automated valet parking service in real conditions. The project was overseen by local agencies including the Stuttgart regional administrative authority, the state of Baden-Württemberg’s transportation ministry and experts from TUV Rheinland. The regulatory authorities must issue their final approval before driverless parking can be offered to customers. (From a press release on July 24, 2017)

-Klaus Meder, who became the new President of Bosch Corporation, a subsidiary of the Company, on July 1, told the Nikkan Jidosha Shimbun that it will increase the number of its engineers to enhance its development capability for autonomous driving and automotive electrification technologies. It will recruit engineers, growing its engineering workforce between 4% to 5% annually while focusing on automotive software. The Bosch Corporation will also focus on developing technologies for fuel cell vehicles and robotics. (From an article in the Nikkan Jidosha Shimbun on July 19, 2017)

-The Company will be part of one of China’s pioneering smart-city projects. The Company signed a strategic cooperation framework agreement with the city of Tianjin to explore possibilities for putting the “Smart Tianjin” initiative into practice. The Company will contribute the expertise gained from other smart-city projects, including Singapore, San Francisco, Stuttgart, Berlin, and the Hamburg docks. The Company offers solutions for smart cities in the areas of mobility, energy, buildings, security, and e-governance. (From a press release on June 20, 2017)

-The Company announced that it will ramp up its AI research in the foreseeable future. The Company has launched a new research center to consolidate AI-related expertise. The Company will also invest EUR 300 million by 2021 and apply AI technology to systems and products developed by all of its departments. The Company anticipates that products featuring AI will account for 10% of its sales within five years. The new research center's branches have been established at centers in Germany, India, and the U.S. The new center will initially employ approximately 100 experts and is scheduled to increase its workforce several times by 2021. The new center will pursue research on AI and utilize developed AI technology across the entire Company. (From an article in the Nikkan Jidosha Shimbun on January 31, 2017)

Technological Alliance

-The Company has multiple collaborations in relation to possible electrification of commercial vehicles. The Company is collaborating with Weichai to develop fuel-cell powertrains for commercial vehicles. The Company is also working with the Nikola Corporation to develop an efficient electrical powertrain with a fuel cell acting as both a power generator and storage medium

-On November 30, Shanghai AIWAYS Technology Co., Ltd., an automotive technology company that has invested CNY 13.3 billion in a new energy project in Shangrao, Jiangxi, signed a strategic cooperation agreement with Bosch (China) Investment Ltd. The companies will team up to work on technologies including electric vehicle systems, autopilot, weight reduction, and car connectivity. (From an AIWAYS Technology press release on December 1, 2017)

-The Company announced that it has jointly developed the "radar road signature" system with TomTom International BV. Radar road signature enables autonomous vehicles to determine their location with an error margin of a few centimeters by checking obstacle data collected by radar technology against high-resolution map data, regardless of conditions. The first vehicles are expected to provide data for the radar road signature in Europe and the U.S. by 2020. High-resolution maps are made up of a number of overlapping layers. The Company’s newly developed localization layer is the first to use radar and cameras as sensors. Communication boxes such as the Company’s Connectivity Control Unit transmits collected data to the manufacturers' cloud and then on to the Bosch IoT Cloud. The radar road signature only transmits five kilobytes of data to a cloud per kilometer, half as much compared to a map relying exclusively on camera video data. (From an article in the Nikkan Jidosha Shimbun on July 3, 2017)

-The Company and Baidu, the largest search engine firm in China, signed a strategic partnership framework agreement in the field of smart mobility in China. The Company plans to take part in Baidu’s Apollo project as a partner to provide sensors, related hardware, and the “Bosch Road Signature” localization service. Also, the two companies intend to form a technical alliance to support the development of regulations and standards for autonomous driving cars in China. (From a press release on June 1, 2017)

-The Company announced that it reached an agreement with Sony Semiconductor Solutions Corporation on a technical tie-up for autonomous vehicle cameras. The two companies will jointly develop camera technologies for reliable surround view systems even in low-light conditions. They will develop cameras for advanced driver assistance systems and autonomous vehicles by utilizing the Company’s monocular camera and stereo camera technologies, as well as Sony Semiconductor Solutions' image sensing technology. (From an article in the Nikkan Jidosha Shimbun on May 31, 2017)

-The Company announced that it has signed a collaboration agreement with the Chinese internet group Baidu and the map providers AutoNavi and NavInfo. The four partners are working on a solution that will let them use information collected by the Company’s radar and video sensors in vehicles to generate and update maps. Automated vehicles will use the collected data to determine their location. This data will be compatible with the three partners’ map data. The collaborating parties want to present their solution before the end of 2017. (From a press release on April 19, 2017)

-The Company’s Bosch Corporation subsidiary and the University of Amsterdam will cooperate closely in the field of artificial intelligence. The two partners have announced a research alliance in Amsterdam. Known as Delta Lab, the alliance aims to promote regular professional exchange and knowledge transfer. Over the next four years, the Bosch Corporation will make EUR 3 million available to support the research of ten PhD students and postdoctoral fellows at the University of Amsterdam. (From a press release on April 6, 2017)

-On April 4, Daimler and the Company announced that they have entered into a development agreement to bring fully automated (SAE Level 4) and driverless (SAE Level 5) driving to urban roads by the beginning of the next decade. The primary objective is the development of a driving system which will allow fully autonomous cars to drive in the city to improve taxi services and increase the attraction of car sharing. The project is based on the idea that the vehicle should come to the driver. Customers will be able to request an automated shared vehicle through their smartphone within a specified city area. The vehicle will then autonomously drive to the user and transport them to their destination. (Daimler press release on April 4, 2017)

-Nvidia announced that it will develop a new AI platform for self-driving cars in collaboration with the Company. The collaboration represents the first announced Drive PX platform incorporating Nvidia’s forthcoming Xavier technology. Nvidia will deliver technology enabling Level 3 autonomous capabilities by the end of this year, and Level 4 capabilities by the end of 2018. (From a press release on March 16, 2017)

-The Company’s Bosch Corporation subsidiary and NTT Data Enterprise Application Services Co., Ltd. announced that they have signed an agreement to jointly propose IoT solutions. The Company will offer manufacturing solutions that were developed at its own production sites by utilizing NTT Data Enterprise Application Services' expertise and a sales network cultivated through its enterprise resource planning system business. (From an article in the Nikkan Jidosha Shimbun on February 22, 2017)

-The Company and IBM announced a new collaboration whereas Bosch IoT Suite services will be launched on open standards-based IBM Bluemix and Watson IoT Platform for clients to update their IoT devices. Clients of both companies will be able to access “Bosch IoT Rollouts” via the IBM Cloud. By 2020, 20.8 billion connected devices are projected to be in use. Automotive manufacturers will be able to schedule and organize software updates to millions of vehicles in an organized fashion securely and efficiently, without requiring the vehicles to go to a workshop. (From a press release on February 16, 2017)

Product Development

Products displayed at CES 2018

-The Company will exhibit solutions for connected cities at CES 2018 in Las Vegas, U.S. The Company will present a next-generation cockpit, which will uses a cockpit camera and voice-recognition software to recognize drivers and help them operate an infotainment system through voice control or a touchscreen with haptic feedback. The Company will also exhibit connected vehicle mobility services that help drivers easily find a charging spot or parking space, as well as other solutions such as a MEMS sensor that consumes ten times less energy than existing products while delivering the same performance. (From an article in the Nikkan Jidosha Shimbun on December 26, 2017)

iDisc disc brake

-The Company’s new iDisc brake disc from its Buderus Guss subsidiary generates up to 90% less brake dust. As 32% of the particle emissions in road traffic comes from brakes and tires, the iDisc can provide significant environmental improvements. The iDisc features a carbide coating made of tungsten carbide, which is exclusive to Buderus Guss. The carbide coating both reduces brake dust and ensures greater operational safety, providing braking power similar to a ceramic brake. iDisc goes into production in November 2017. (From a press release on November 22, 2017)

smartInfotainment Series entertainment system for buses and coaches

-The Company has developed the new Coach smartInfotainment Series and is presenting it for the first time at Busworld Kortrijk 2017, the leading international trade show for buses and coaches in Belgium. The core components of the new entertainment system are the Coach smartRadio and Coach smartPanel. The Coach smartRadio can receive DAB+ radio stations and stream music from a smartphone via Bluetooth; it also enables the driver to make phone calls without becoming distracted and while keeping both hands on the steering wheel. The Coach smartPanel expands the range of functions, bringing more entertainment to the passenger cabin and driver’s cockpit. (From a press release on October 19, 2017)

Servotwin steering system

-The Company is taking its comprehensive expertise in steering systems for cars and transferring it to commercial vehicles and buses to create new technological solutions. The Servotwin steering system is the world’s first integrated electro-hydraulic steering system for production commercial vehicles, specifically, heavy trucks and buses. The Company has redesigned electro-hydraulic rear-axle steering to improve the maneuverability of heavy commercial vehicles. Buses with large wheelbases gain significant benefits, as the redesigned system reduces turning radius. (From a press release on October 19, 2017)

Over-the-air software update systems

-The Company announced that its over-the-air software updates will soon be a standard feature in cars. The Company has developed all the features required for wireless updates in-house, including the control units, in-car communication infrastructure, modern encryption technologies and the Bosch IoT cloud. Over-the-air software updates enable vehicle software to be up to date without having to visit the repair shop. OTA updates also help OEMs prevent vehicle recalls due to software issues. Online security updates are started and any new functions that need to be downloaded can be selected on a smartphone or the vehicle’s infotainment system. Data security is ensured by the latest encryption technologies developed at the Company’s Escrypt subsidiary. (From a press release on September 6, 2017)

eAxle electric axle

-The Company’s electric axle drive combines three powertrain components into one unit. The motor, power electronics, and transmission form one compact unit that directly drives the car’s axle, making it more efficient and affordable. The components are flexible, which means the e-axle can be installed in hybrids and electric cars, compact cars, SUVs, and light trucks. The start of mass production is planned for 2019. (From a press release on August 31, 2017)

Perfectly Keyless digital vehicle access system

-The Company announced that it has developed Perfectly Keyless, a digital vehicle access system by which one can use a smartphone to unlock the car, ignite the engine, and lock the car again. To use it, drivers download an app onto their smartphones, and connect their cars to the app. Once they have done this, the smartphone generates a one-off security key that fits their respective vehicle’s digital lock. Perfectly Keyless uses a wireless connection to the on-board sensors. Once the distance between driver and the vehicle is less than two meters, the car door is unlocked. As soon as the vehicle has been unlocked, any predetermined individual settings are activated. (From a press release on August 24, 2017)

European Secure Truck Parking platform

-The Company announced that its European booking platform, Bosch Secure Truck Parking, helps in finding a suitable parking space. This allows better planning of travel and rest times. The platform is now online after successful testing at the Company’s site in Karlsruhe. The system records the occupancy of truck parking spaces in real-time. Forwarders and truck drivers can reserve parking spaces along their route in advance or during the trip via a free online portal or through an app. Bosch Secure Truck Parking indicates the available parking spaces and provides valuable information about their safety equipment. The portal also provides automatic and cashless billing. (From a press release on August 3, 2017)

Communication technologies integrated into parking solutions

-The Company will introduce parking solutions utilizing communication technologies in Japan. Active Parking Lot Management will be introduced to the Japanese market by the end of 2017. Sensors installed in a parking lot detect the current occupancy status and report it to the driver via the Internet. Automated Valet Parking, enabling the parking of unmanned vehicles by communicating with parking lot infrastructure will be introduced to Japan in 2019. In-vehicle sensors, communication functions, and the equipment necessary for the infrastructure will be developed by the Company. The systems will be put into commercial application at shopping centers, hospitals and hotels in Germany in 2018. (From an article in the Nikkan Jidosha Shimbun on August 1, 2017)

Prototypes of small electric vehicles

-The Company displayed two prototypes of the e.GO small four-seater and the electric version of the Schwalbe-Rollers scooter at the Bosch Mobility Experience. Both vehicles feature an integrated system that includes a 48-volt motor, control unit, lithium-ion battery, charger, display and Bluetooth-compatible application. Since the system consists of developed automotive components, OEMs benefit from standard products and low development costs. This gives established OEMs and new market players on the chance to rapidly bring a vehicle onto the market. According to the Company’s estimates, around 100 million light electric vehicles will be produced worldwide by 2020. (From a press release on July 4, 2017)

Augmented Reality applications

-The Company has announced its future oriented solutions for servicing and repairs by Augmented Reality (AR) applications. AR applications connect both real and virtual worlds by displaying useful and time-saving complementary information. The Company supports everyday mechatronics work through Augmented Reality solutions, for instance, by simplifying complicated repair cases. By pointing the device camera onto the vehicle, additional information can be integrated into the real image using a tablet or smart glasses. In order to integrate the diversity of versions and products in modern automotive technology into AR applications at low costs, the Company developed the Common Augmented Reality Platform. It accesses the existing database and collects matching data for the intended Augmented Reality application. (From a press release on June 27, 2017)

Onboard device development platform shown at Automotive Engineering Exposition 2017 in Yokohama

-For the first time in Japan, the Company exhibited an onboard device development platform and feature store at Automotive Engineering Exposition 2017 Yokohama. The platform is an open ecosystem which enables onboard software to be updated after production via firmware updates over the air and software updates over the air. The platform covers global management of software applications, license permissions and its delivery. The Company also developed the cloud platform needed for the software update. (From a press release on May 18, 2017)

Precision vehicle location system

-The Company will develop a technology to accurately pinpoint vehicle location within several centimeters. Data is collected by in-vehicle camera sensors, gathered in the cloud, are then compared with high precision 3D maps to precisely identify the vehicle location. The Company will put this technology into practical application in cooperation with automakers and map companies developing high precision 3D digital maps. (From an article in the Nikkan Jidosha Shimbun on April 20, 2017)

Automotive Cloud Suite platform for mobility services

-The Company announced the launch of the Bosch Automotive Cloud Suite, a new platform for mobility services. The Automotive Cloud Suite offers OEMs and mobility service providers a software platform plus a comprehensive toolkit for developing all kinds of services for drivers and for quickly bringing them to a wide market. In its Automotive Cloud Suite, the Company provides individual software modules, such as a digital logbook or solutions for implementing software updates. Providers of mobility services can use them to develop a broad range of connected car services for drivers. The Company is demonstrating a range of new services on a Jaguar F-Pace-based show car at Bosch ConnectedWorld 2017. Five services that are due to become standard in every vehicle are wrong-way alert, predictive diagnostics, community-based parking, personal assistant, and software updates over the air. (From a press release on March 15, 2017)

AI-compatible on-board computer

-The Company presented an onboard computer for automated vehicles at Bosch ConnectedWorld 2017. The AI onboard computer is expected to guide self-driving cars through complex or new traffic situations. Using artificial intelligence, it will also be able to interpret readings to make predictions about the behavior of other road users. The Company plans to collaborate with Nvidia to building the onboard computer. Nvidia will supply the Company with a chip that stores algorithms, generated with machine learning methods. The AI onboard computer is expected to go into production by the beginning of the next decade at the latest. (From a press release on March 15, 2017)

Connected Gateway

-The Company will put its Connected Gateway, which enables over the air updates of in-vehicle software, into practical use in late 2017 or 2018. The Bosch Central Gateway, a communication hub between ECUs, will be adapted for wireless communication. By modifying programs, vehicle faults are repaired remotely and new functions including advanced driver assistance systems can be added. The Company is also planning to commercialize its Vehicle Computer in 2018, which features more processing capability than that of the Central Gateway and a more simplified structure. (From an article in the Nikkan Jidosha Shimbun on January 23, 2017)

eAxle electric axle drive system shown at NAIAS 2017

-At NAIAS 2017, the Company presented its eAxle electric axle drive system. The eAxle makes electrification accessible for automakers through a scalable, modular platform that can provide cost efficiencies between 5-10% compared to stand-alone components. The flexible eAxle can be installed on multiple platforms and brings together top-of-the-line Company powertrain components into one system. (From a press release on January 10, 2017)

Connected concept car shown at CES 2017

-At CES 2017, the Company is presenting a new concept car that shows how different spheres of life will be seamlessly interconnected in the future. "Personalization is a growing trend in the realm of connectivity, and we are driving this trend forward," said Dr. Werner Struth, member of the the Company’s board of management. By 2022, the global market for connected mobility is set to grow by almost 25% per year. In just a few years, cars will become an active part of the IoT and will be able to communicate with other modes of transportation and the smart home. The moment the driver sits down in the concept, facial recognition technology sets the steering wheel, mirrors, interior temperature, and radio station according to the driver's individual preferences. The system is controlled via a haptic touch display and an innovative gesture control system, both of which give tangible feedback when they are used. High-performance algorithms assess the plausibility of the data and make forecasts on the parking spot situation. Pilot projects in the U.S. are planned for 2017. In cooperation with Mercedes-Benz, the Company is currently testing the community-based parking concept in metropolitan Stuttgart. (From a press release on January 4, 2017)

Second-generation iBooster electromechanical brake booster

-The Company is developing a next-generation iBooster electromechanical brake booster. The second-generation iBooster is significantly lighter than its predecessor and also enables faster brake-pressure build up. In addition, the iBooster in combination with ESP provides barking system redundancy needed for autonomous vehicles.

Anti-glare instrument cluster

-The Company has developed an anti-glare instrument cluster which can be more easily read from any angle and lighting condition. The cluster is manufactured through a new process which uses a thin layer of fluid to bond the screen with the glass.

Capital Expenditure |

(in million EUR) |

| FY ended Dec. 31, 2017 | FY ended Dec. 31, 2016 | FY ended Dec. 31, 2015 | |

| Overall | 4,345 | 4,252 | 4,058 |

| -Mobility Solutions | 3,300 | 3,300 | 3,100 |

-In the fiscal year ended December 31, 2017, the Company’s Mobility Solutions business sector capital expenditure totaled EUR 3.3 billion, remaining level compared to the previous fiscal year. The Company’s capital expenditure in the Mobility Solutions focused on gasoline direct injection systems, driver assistance systems, infotainment systems and displays. The Company also invested on increasing manufacturing capacity for semiconductors, sensors and control units.

Investments in Germany

-The Company will build a wafer fabrication facility in Dresden. The new plant will manufacture chips on 12-inch wafers to satisfy demand from the growing number of IoT and mobility applications. Construction of the high-tech plant will be completed by the end of 2019. Following a rollout phase, manufacturing operations will likely start at the end of 2021. Total investment in the location will total roughly EUR 1 billion. The new plant will create up to 700 new jobs. (From a press release on June 19, 2017)

Investments outside Germany

-The Company announced that it inaugurated its first production plant for automotive steering components in Mexico. The 15,000-square-meter facility in Colon, Queretaro was established with an USD 80 million investment. The facility will initially assemble manual-adjust steering columns, along with Servolectric column type and Servolectric dual-pinion electric power steering units. This will be the first time that Servolectric power steering units, which enable driver assistance functions, will be produced in Mexico. (From a Mexico-Now article on December 5, 2017)

-The Company will start operations at a new USD 80 million production site in Queretaro, Mexico, by the end of 2017. Production at the new facility will focus on steering systems, although future upgrades will be directed towards braking and other automotive systems. According to Gonzalo Simental, Vice President for Finance at Bosch Mexico, the Company views the Queretaro location “as a center of gravity” in close proximity to assembly plants from General Motors, Mazda, Honda, Toyota and BMW, as well as having extended connections to Volkswagen and Audi plants in Puebla. (From a Mexico-Now article on July 11, 2017)

-By 2020, the Company will invest USD 13 million to triple its workforce at its Guadalajara facilities. During a recent interview, Vice President of Finances at Bosch Mexico, Gonzalo Simental, said that USD 11 million is budgeted for equipment in the operation center currently under construction while USD 2 million was invested for the recently inaugurated innovation center in Guadalajara, which begins operations on August 14. The innovation center will provide space for collaboration and technological entrepreneurship projects, as well as training rooms. The Company will maintain offices at the Digital Creative City located in downtown Guadalajara while they search for a new building in the area. (From a Mexico-Now article on July 10, 2017)

-The Company is opening a new plant for injection technology in Hemaraj, 130 kilometers east of Thailand’s capital Bangkok. The plant is the first smart factory and the Company’s second Mobility Solutions plant in Thailand. The Company has invested EUR 80 million in the plant through the end of 2017. The 10,000-square-meter plant will manufacture injection valves, connection technology, knock sensors, and other components. In 2018, the Company plans to expand its manufacturing activities in Vietnam. (From a press release on December 4, 2017)

-The Company is further extending its manufacturing capacity in China. The Company is investing nearly EUR 100 million in a new plant in the southeastern Chinese city of Nanjing. Starting in 2019, the 20,000-square-meter plant will manufacture iBoosters for customers in the Asia-Pacific region. This vacuum-independent electromechanical brake booster is a key component for electromobility and driver assistance systems. The new plant will also be equipped with Industry 4.0 solutions. Currently, 14 Company plants in China feature connected technologies. The Company is partnering with the Chinese State Council’s Development Research Center to drive forward connected manufacturing across China. (From a press release on August 1, 2017)

-On February 22, the Changchun Branch of Robert Bosch Motor (China) Co., Ltd. signed an agreement with the Changchun High Tech Industrial Development Zone to establish a starter motor plant in the area with an annual capacity of 3 million sets. A total of CNY 200 million is expected to be invested in this project. The plant will have an area of 45,000 square meters, and a building area of 31,500 square meters. Its annual output is expected to reach CNY 700 million in 2017 and CNY 1 billion after 2020, when full-scale production is scheduled to begin. (From news releases issued by multiple sources on February 27, 2017)

-The Company’s Bosch Corporation subsidiary will fully implement IoT technology at its plants in Japan. The Company has set up 26 IoT projects in the country that include managing manufacturing lead times by attaching ID tags to materials and parts. The Company has already started implementing these projects on an experimental basis at several of its plants. In addition to adopting IoT technology for its plants and equipment, the Company intends to cooperate with automakers and suppliers in networking production sites at an early stage. By doing so, the Company will accelerate its efforts to improve productivity in the entire value chain. (From an article in the Nikkan Jidosha Shimbun on February 28, 2017)

-The Company’s Bosch India subsidiary announced that it has been building capacity at its Pune plant to meet future demands for ABS and ESP systems in India due to legislation mandates and improved customer awareness. Bosch India has invested over INR 4 billion to develop and manufacture ABS, ESP and hydraulic actuation products. It employs 1,000 associates at two plants and one research and development center on a seven hectares’ campus in Pune. The Company’s Chakan plant is also a member of the International Production Network (IPN) for ABS and ESP systems. Each single machine for the ABS line is connected in the IPN and managed by a Manufacturing Execution System that helps reduce deviation in the manufacturing process. (From a press release on January 23, 2017)

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India