Röchling SE & Co. KG.

Company Profile

Business Overview

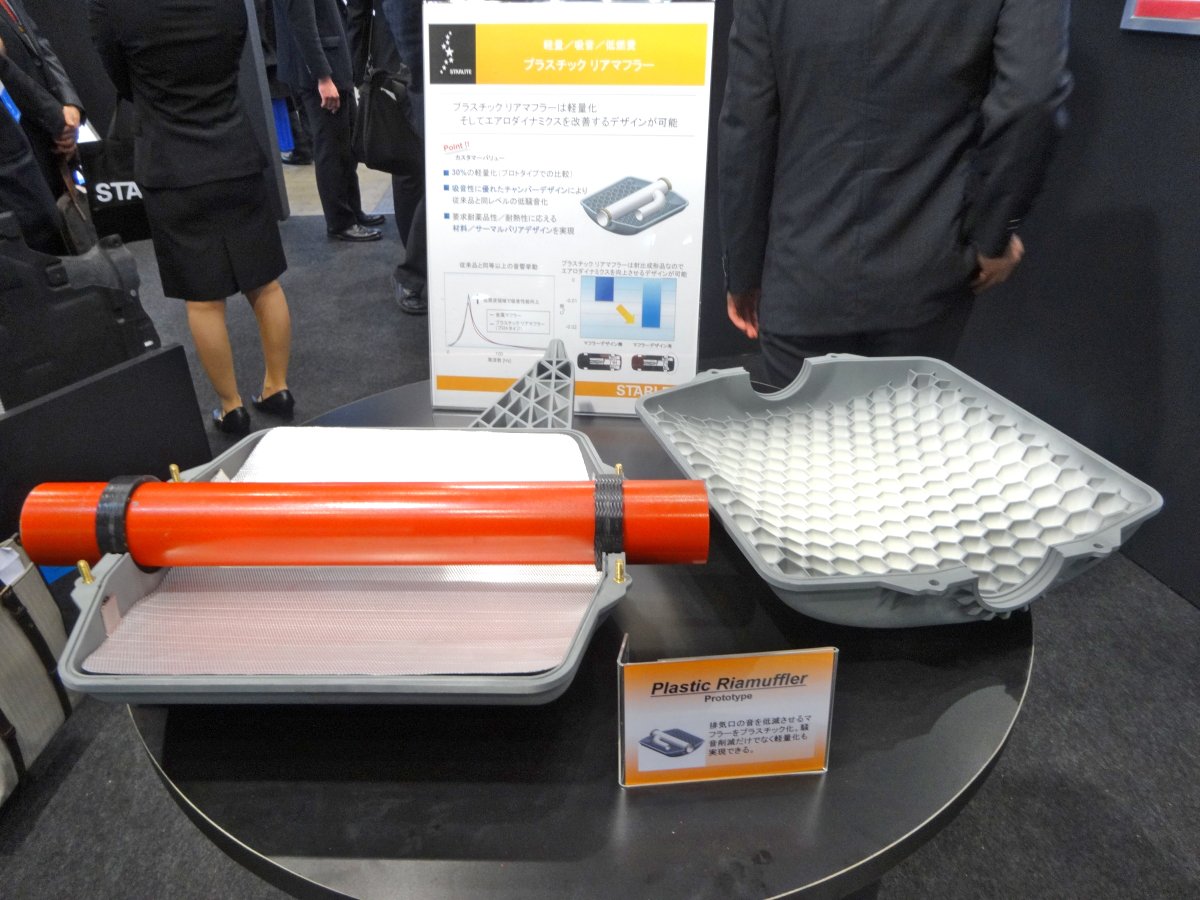

--The Company is a family-owned entity specializing in the development and manufacturing of engineered plastic systems and components for multiple industrial sectors, including the automotive industry.

-The Company is organized into three divisions:

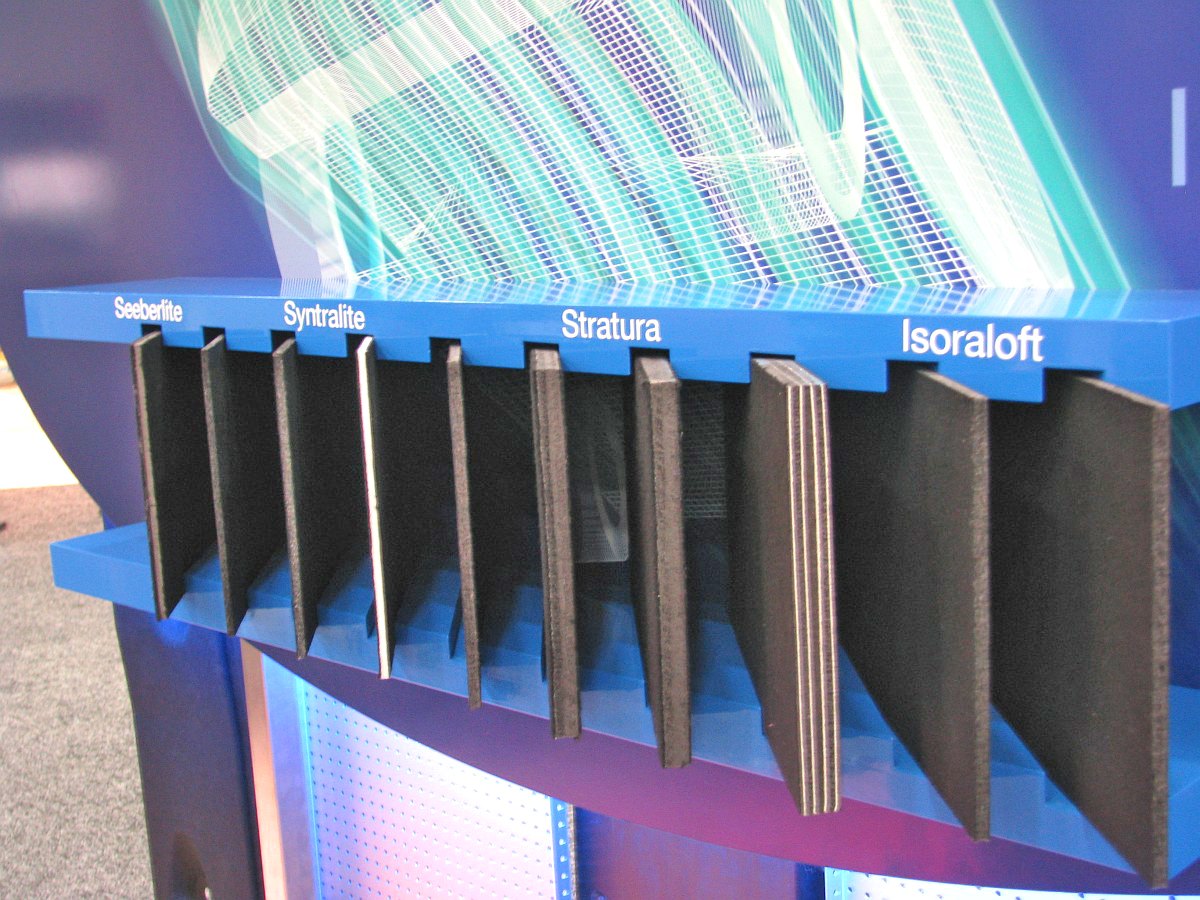

- Industry Division: Develops and supplies thermoplastics and composite materials in the form of semi-finished products or machined parts for a wide range of markets

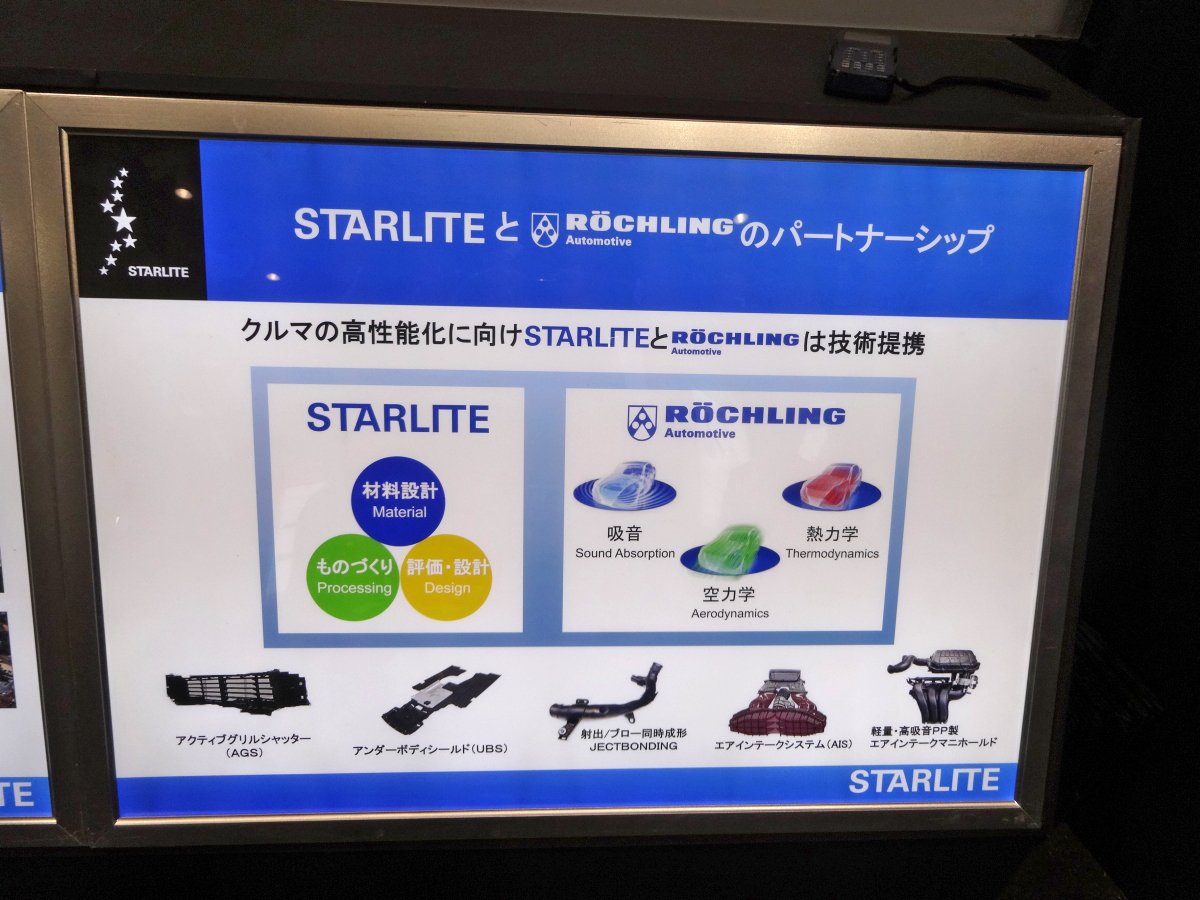

- Automotive Division: Develops and manufactures plastic solutions for the automotive industry across four product areas: battery applications, aerodynamics, propulsion, and lightweight structures

- Medical Division: Develops products, services, and platform solutions for the healthcare industry including pharmaceutical packaging, drug delivery systems, consumables, and other components

-In the fiscal year ended December 31, 2024, sales in the Company’s Automotive division were EUR 1,241 million, a decrease of 1.6% from the previous year’s EUR 1,261 million. The division had 5,733 employees at the end of 2024 and capital expenditures of approximately EUR 34 million during the fiscal year. The decrease in the Automotive division’s capital expenditure was due to the Company’s strategic focus on cautious cash management.

-In 2024, the Company’s Automotive division announced that it would consolidate its production sites in Germany, closing its plant in Wackersdorf as well as the Röchling Precision Components subsidiary in Mainburg. In addition, in April 2025, the Automotive division announced that it would close its production facility in Chengdu, China by the end of 2025, shifting its production to other locations in the country.

Shareholders

-The Company is privately owned by members of the Roechling family.

Products

Aerodynamics

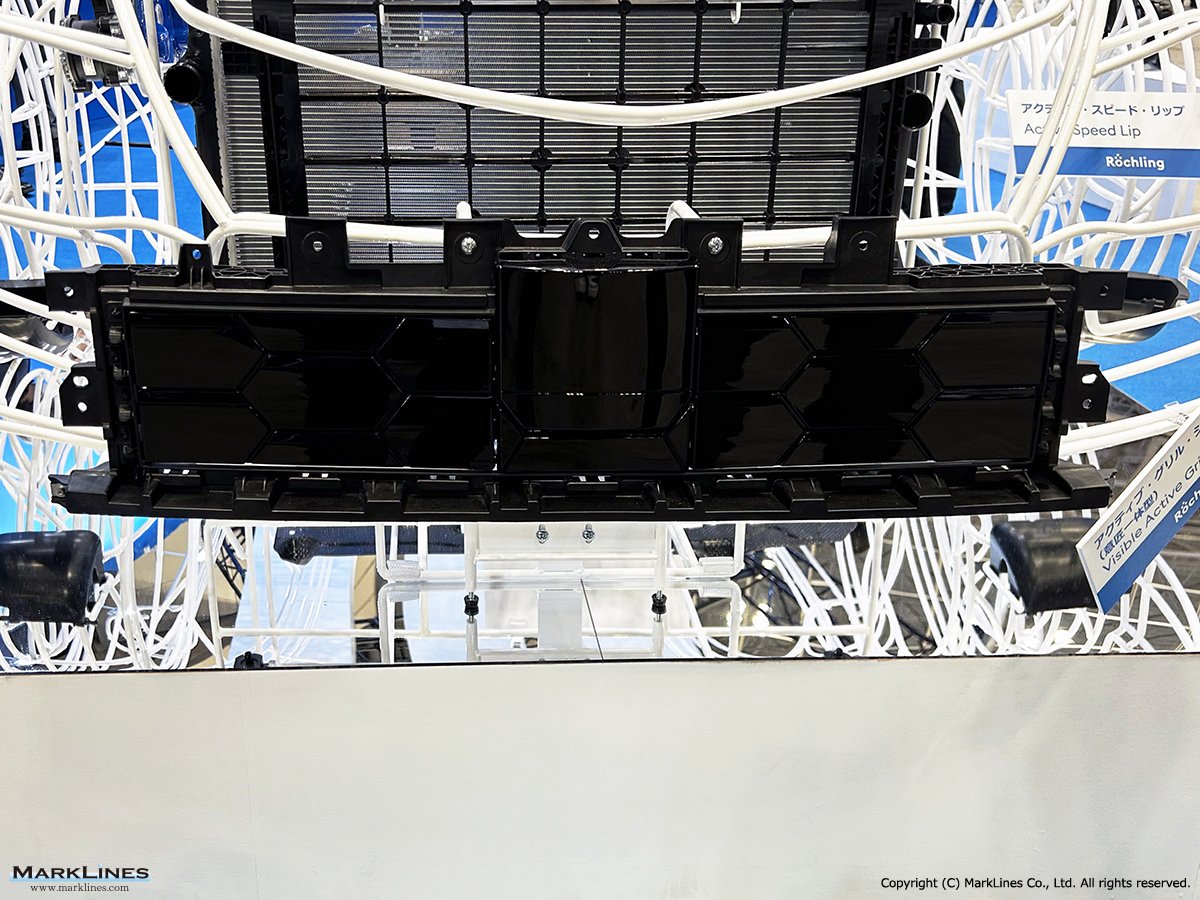

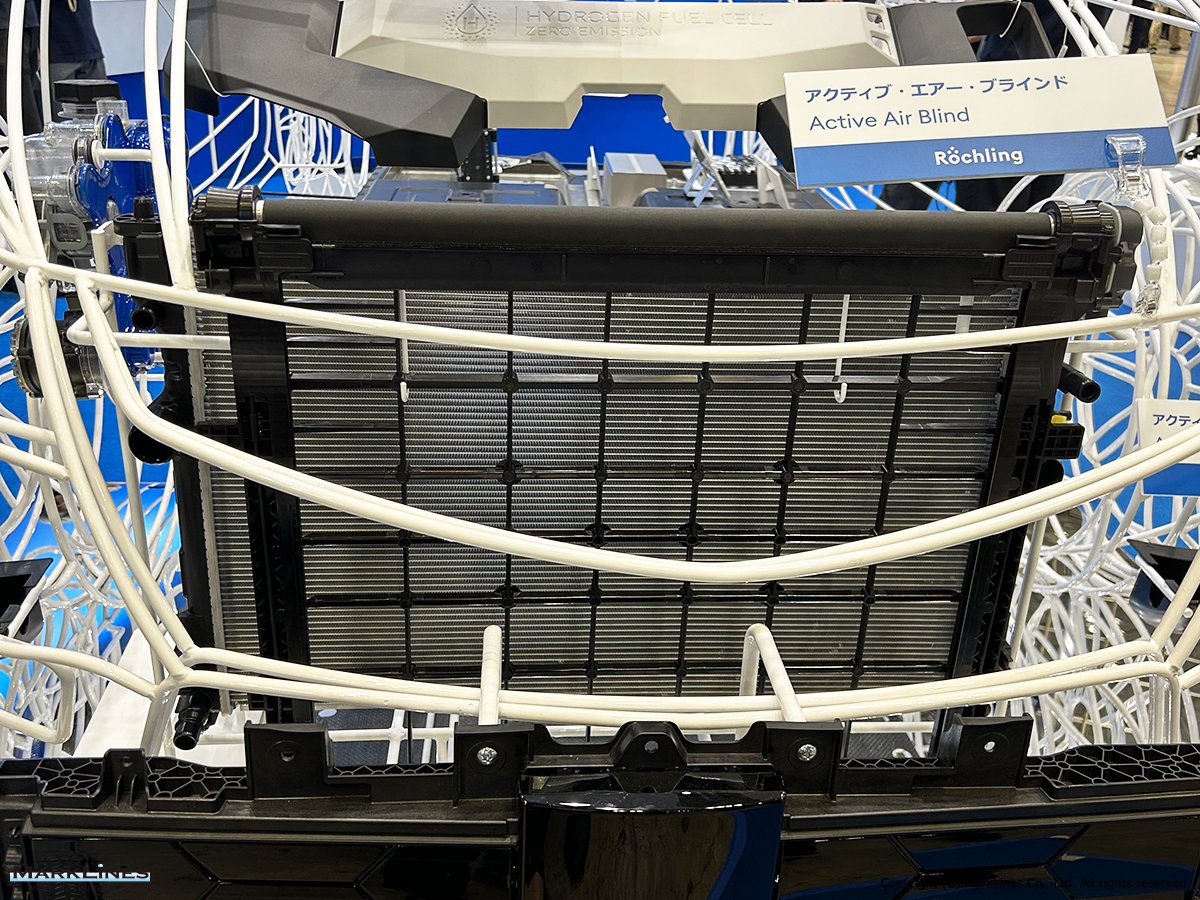

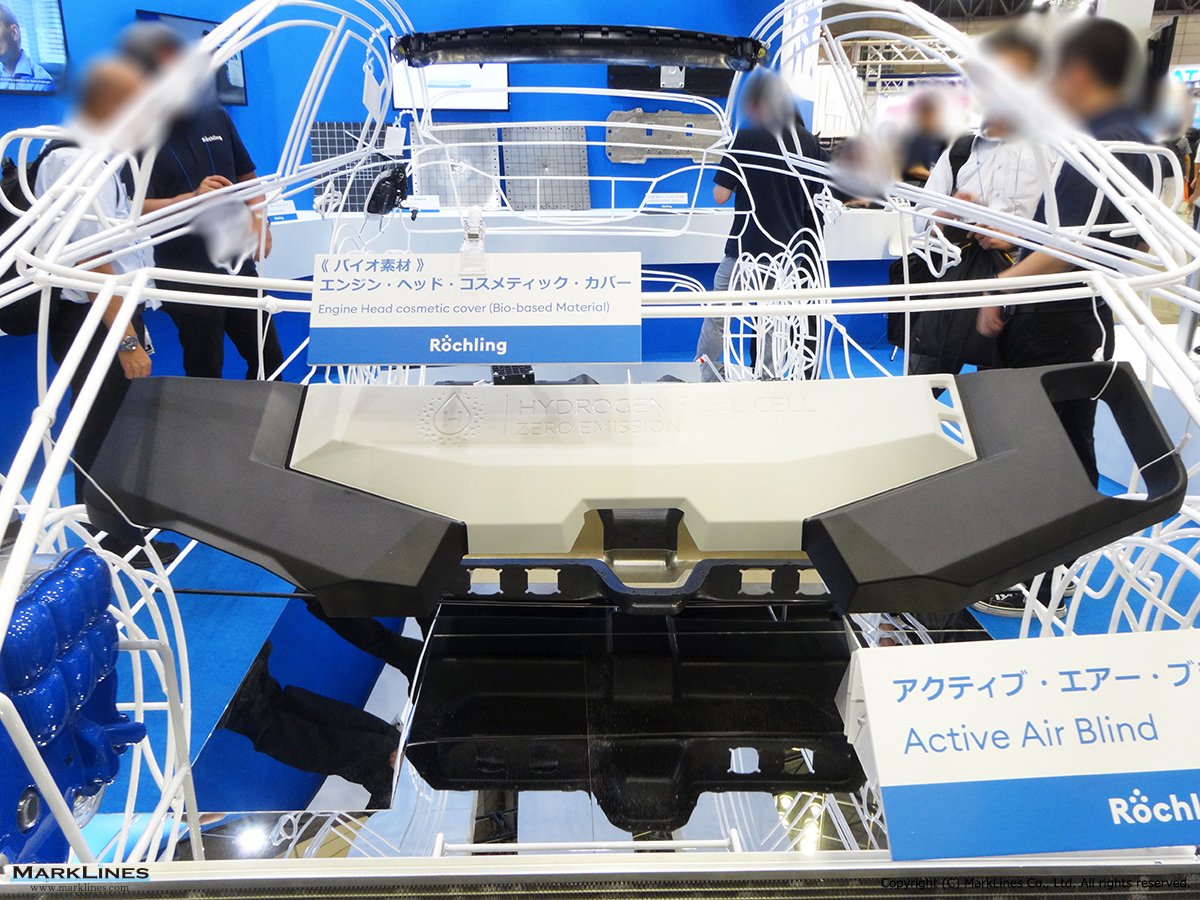

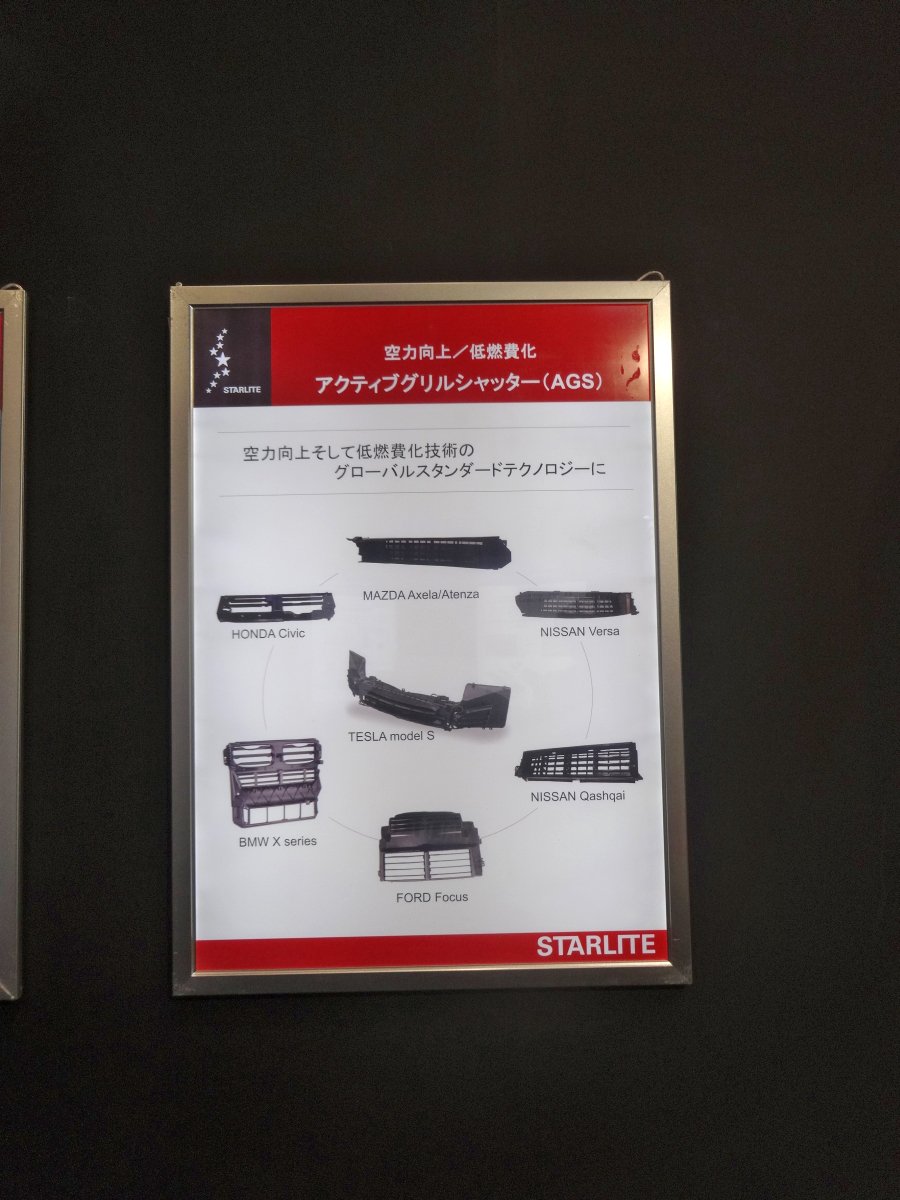

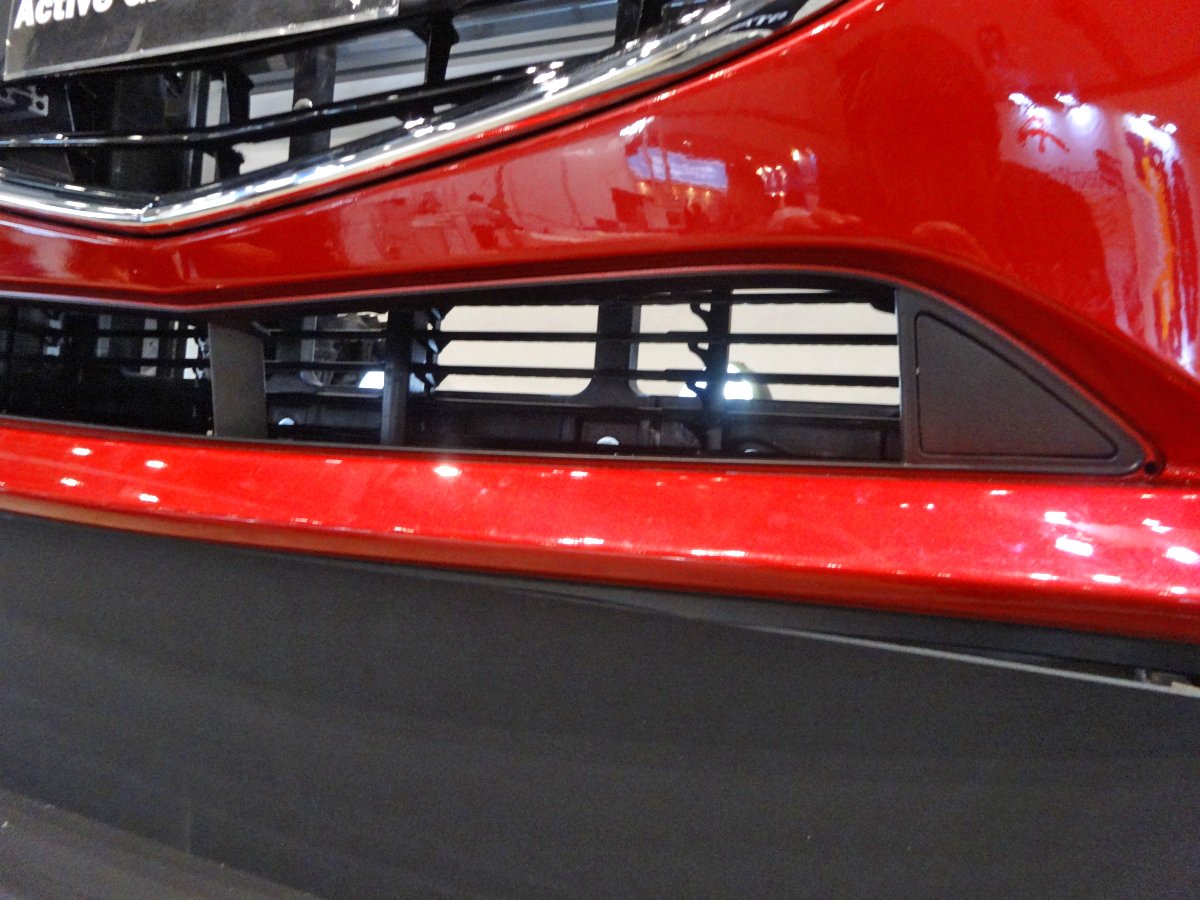

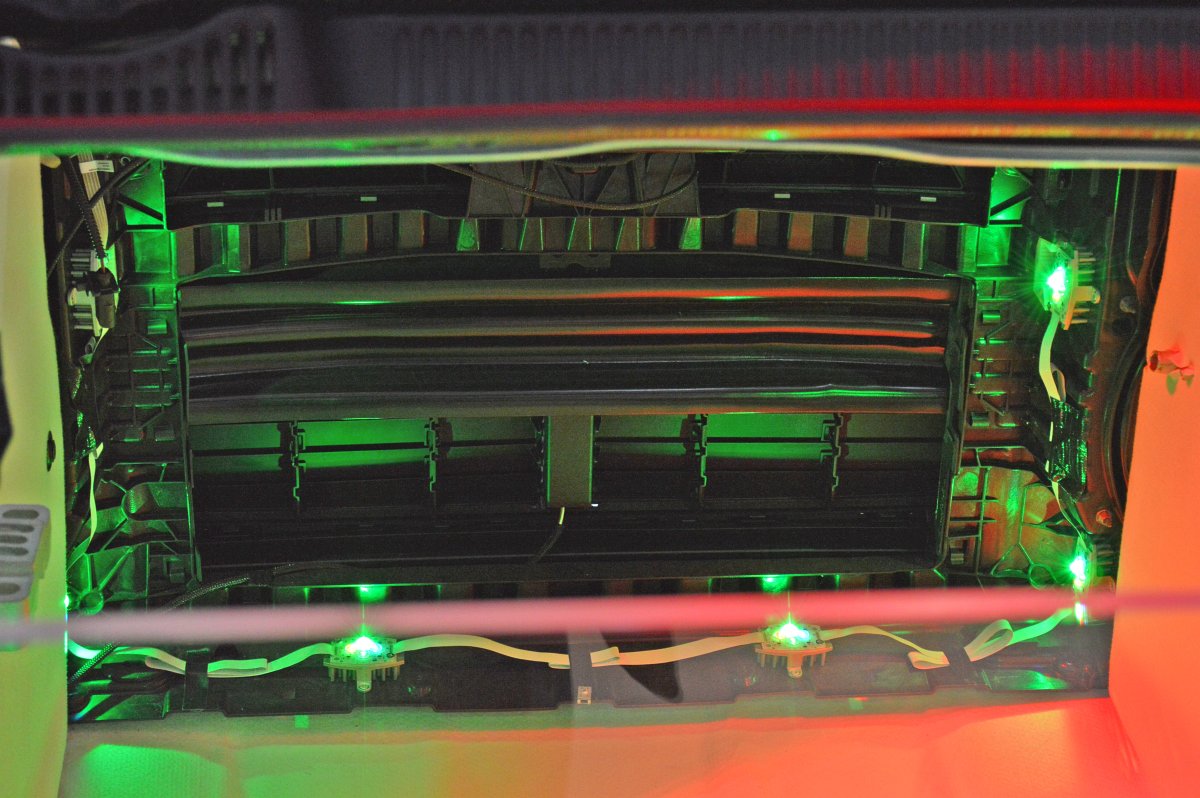

-Active Air Blinds (AAB)

-Active Air Dams

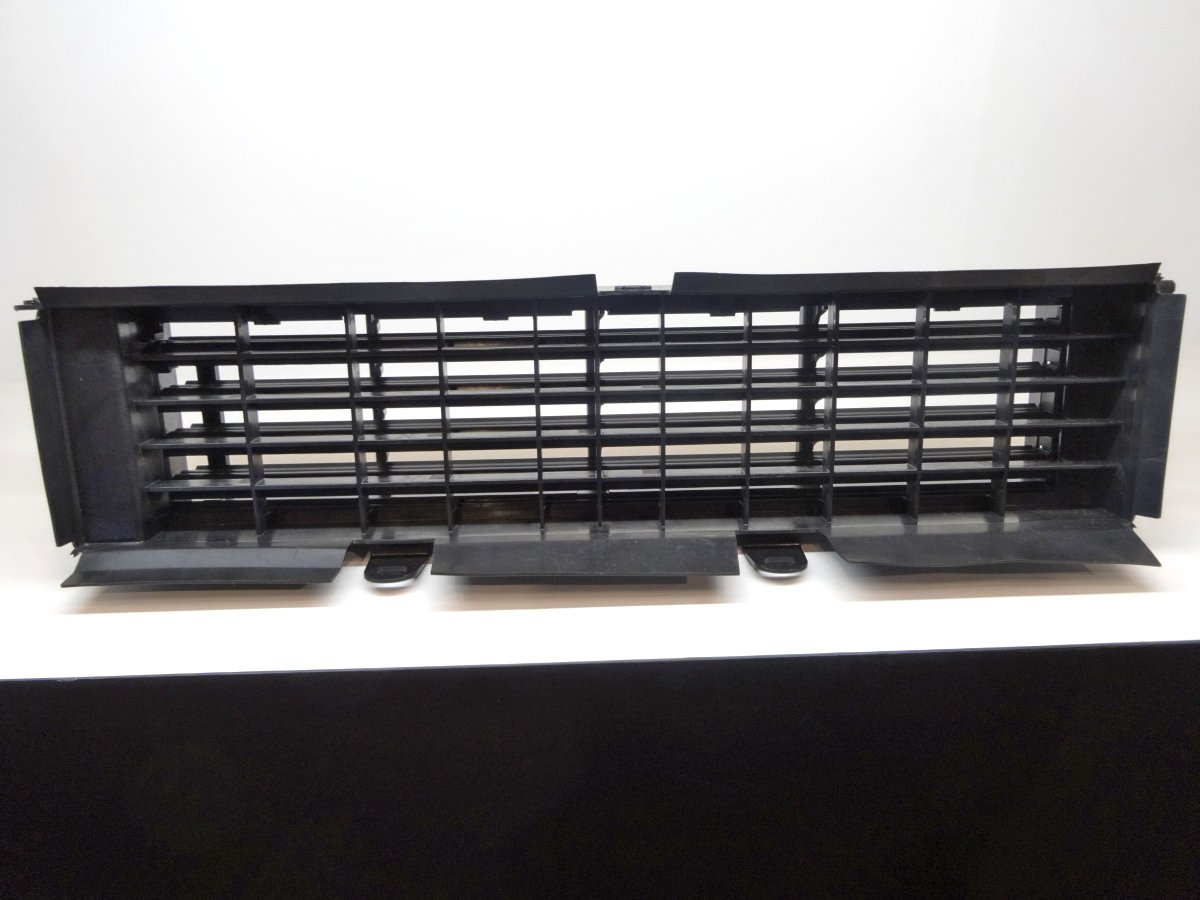

-Active and passive grille shutter modules

-Active Speed Lips

-Underbody panels

-Acoustic covers with foam absorber

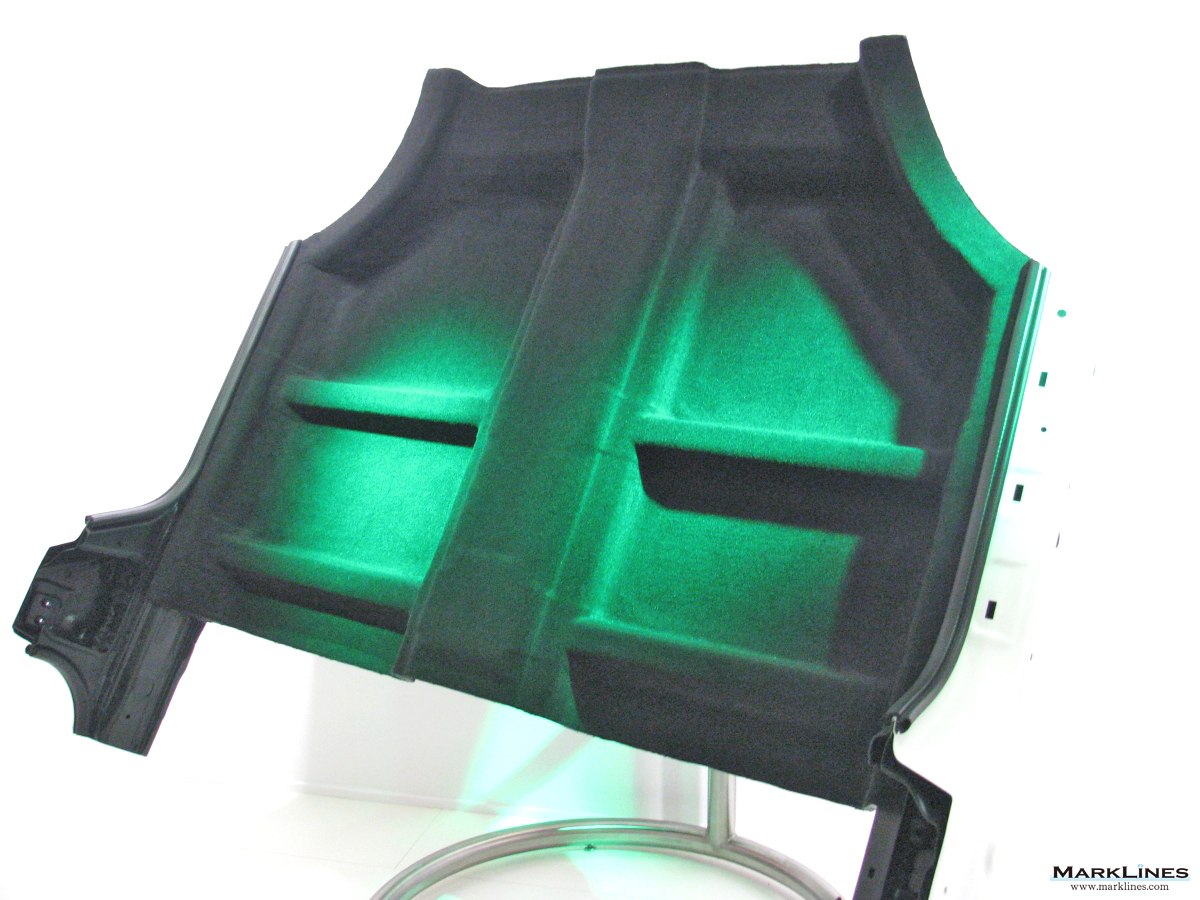

Partition walls

-Partition walls with noise dampening characteristics

-Extension dash panels with noise dampening characteristics

Wheel arch liners

-Wheel arch liners with aerodynamic speed lips

-Wheel arch liners made from different textile materials

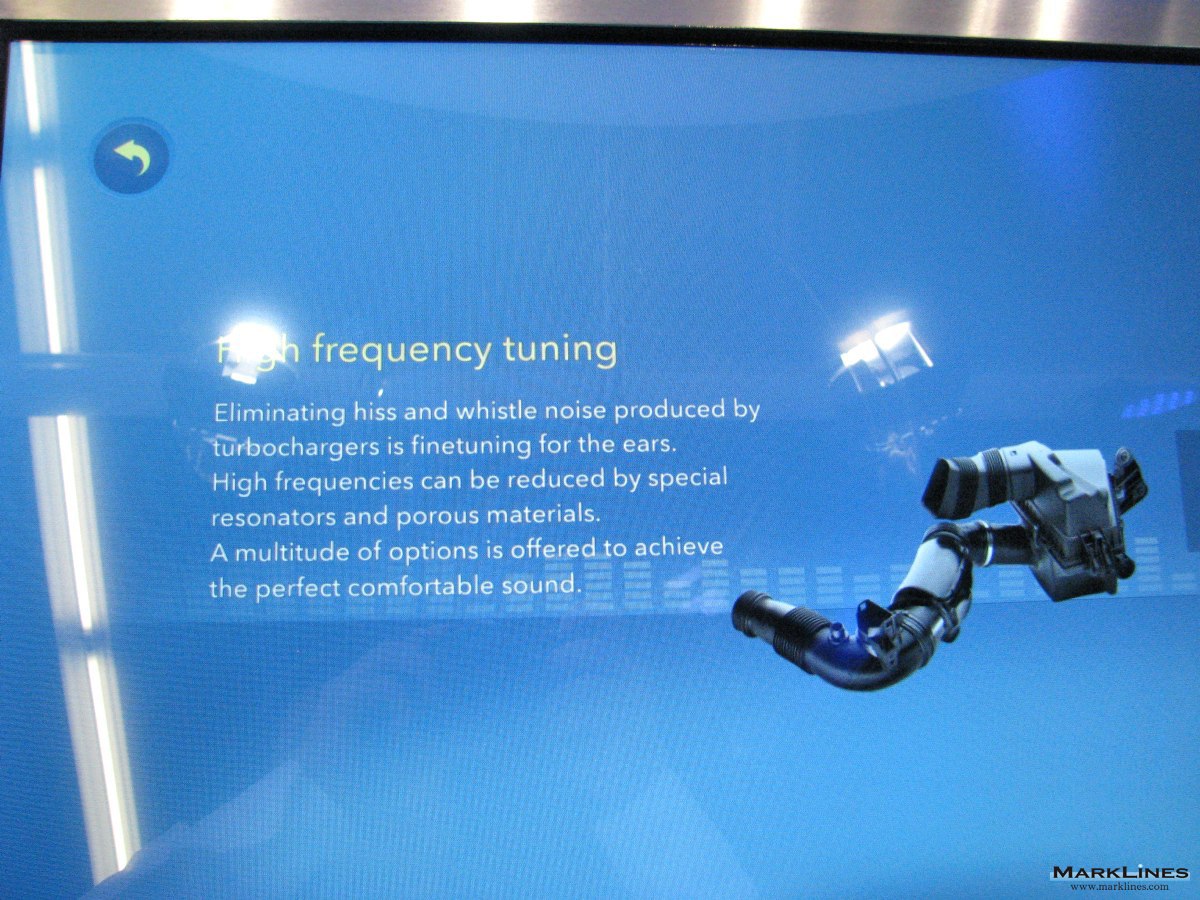

Air ducts

-Blow molded air ducts

-Air distribution systems

-Noise absorbing air ducts

-Air duct seals

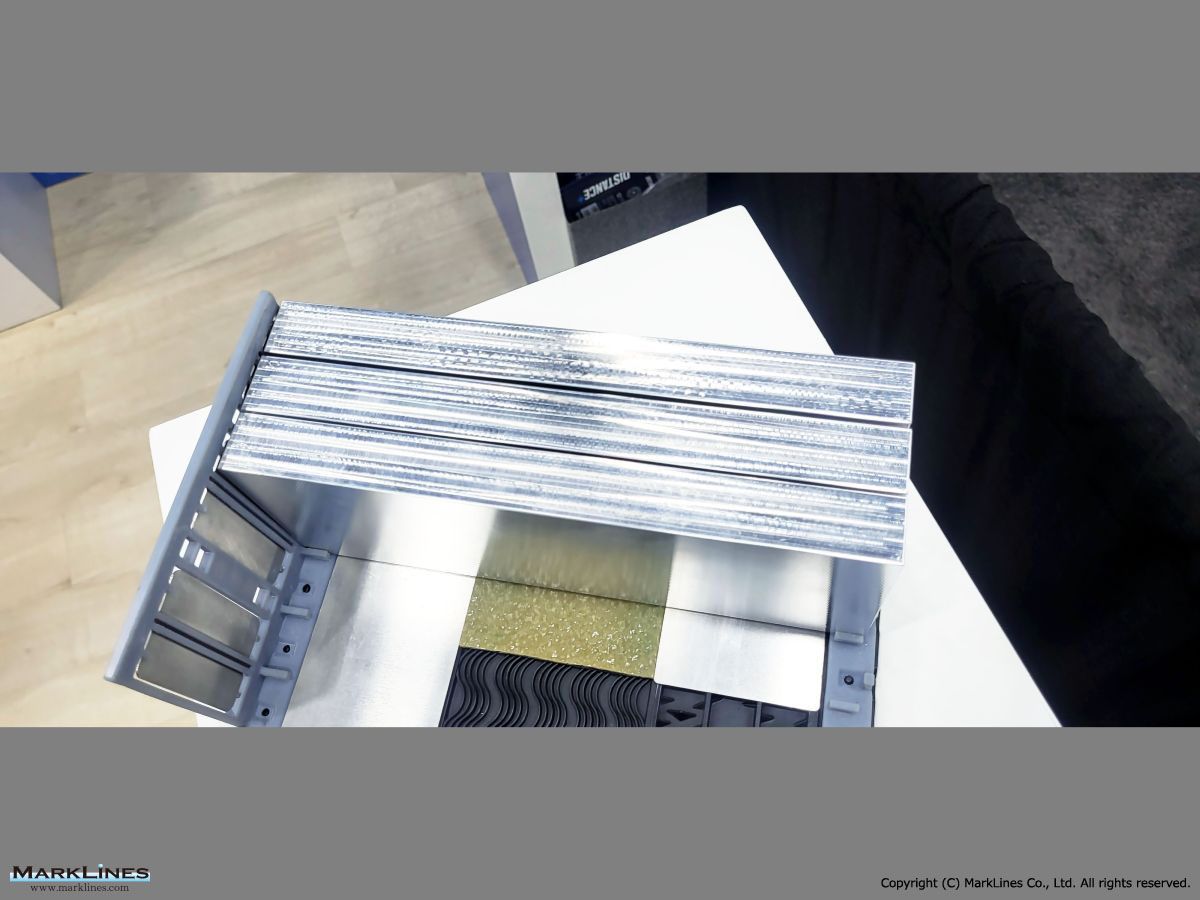

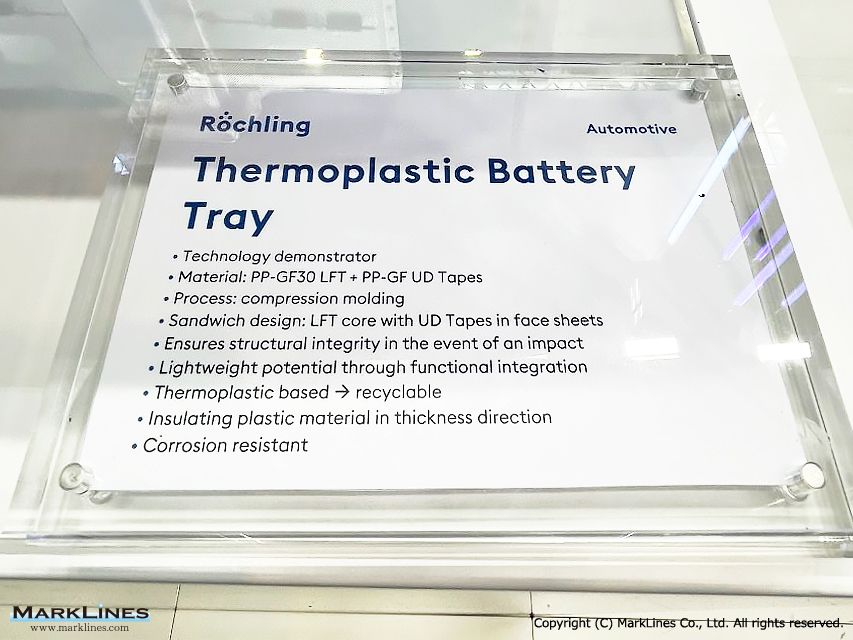

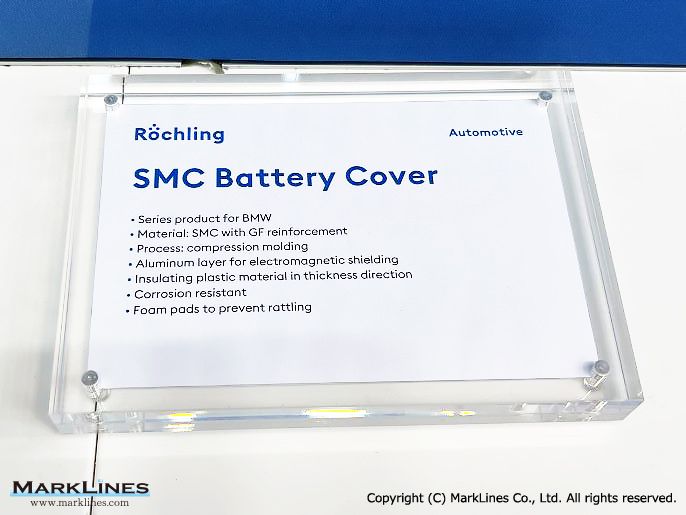

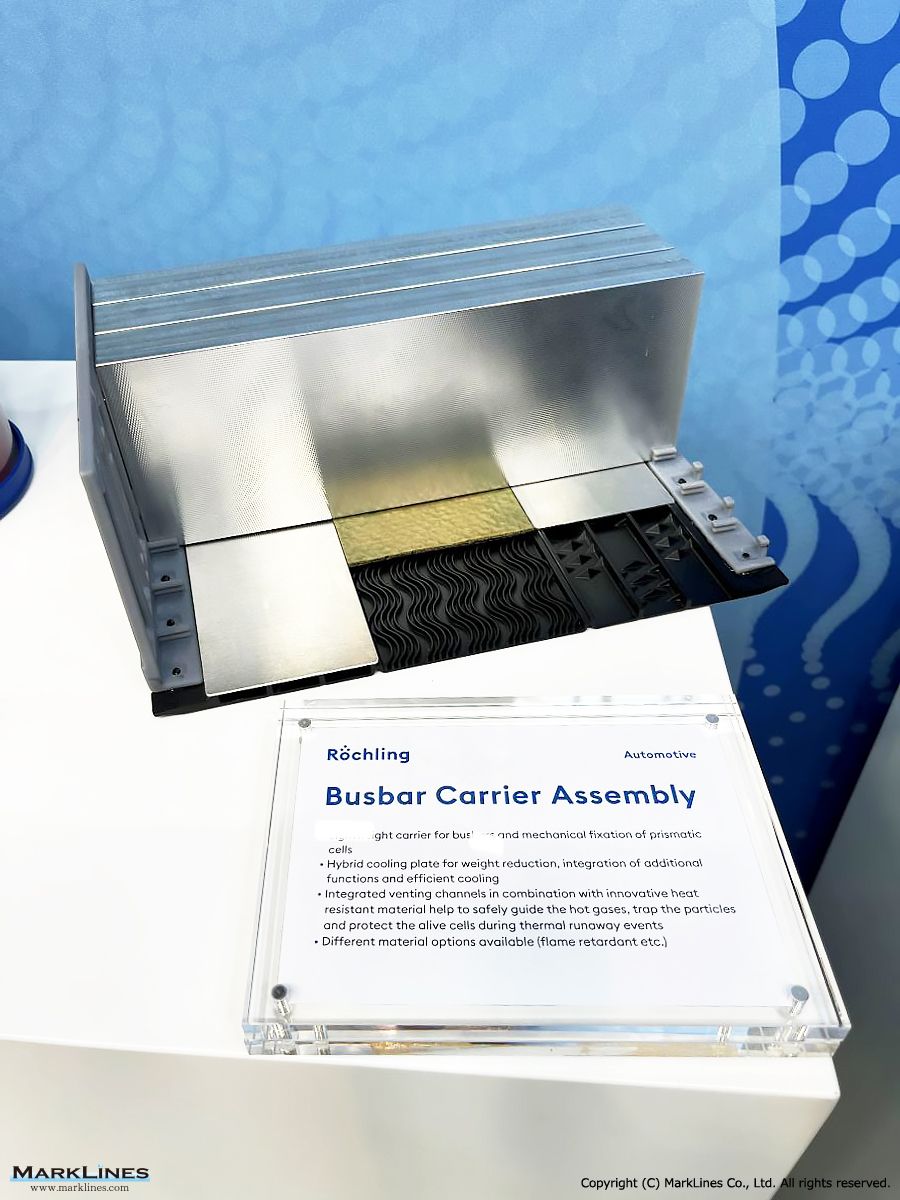

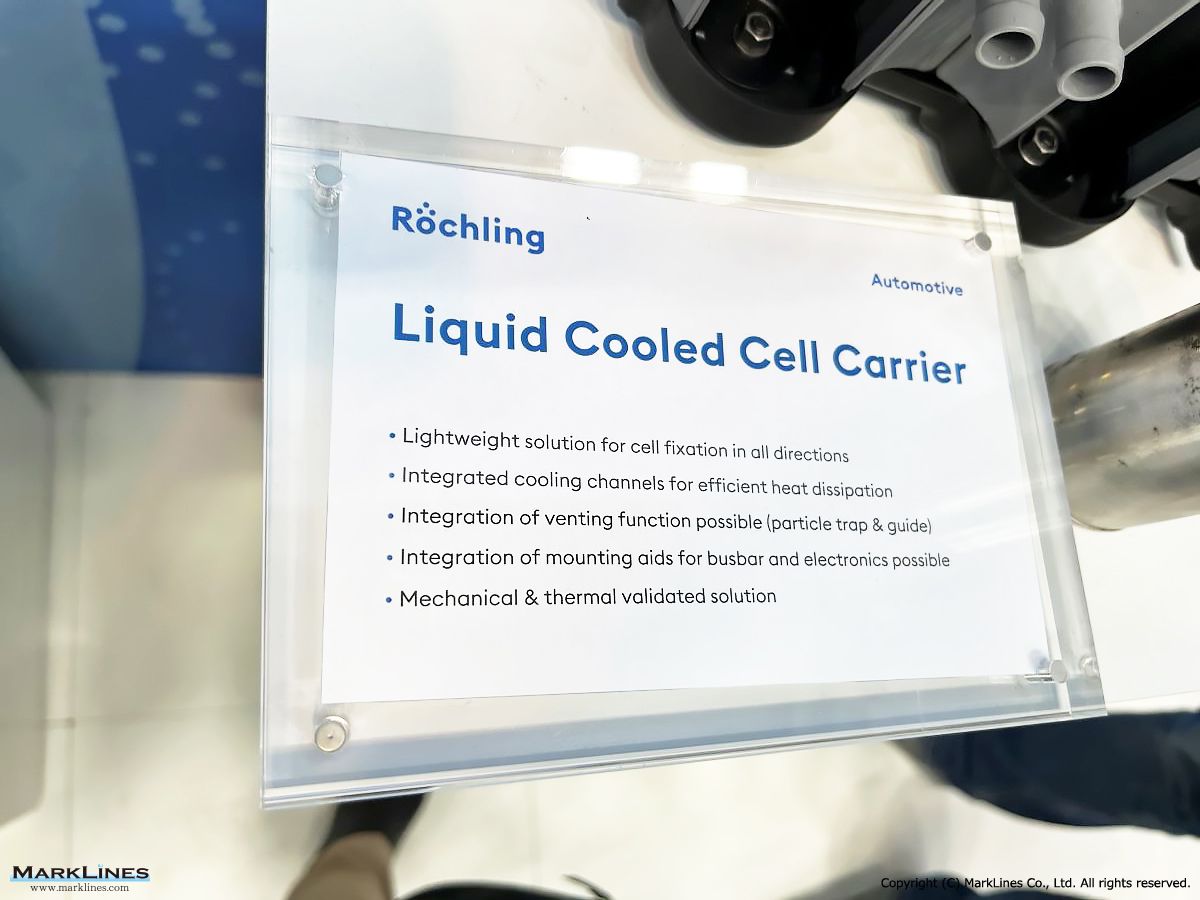

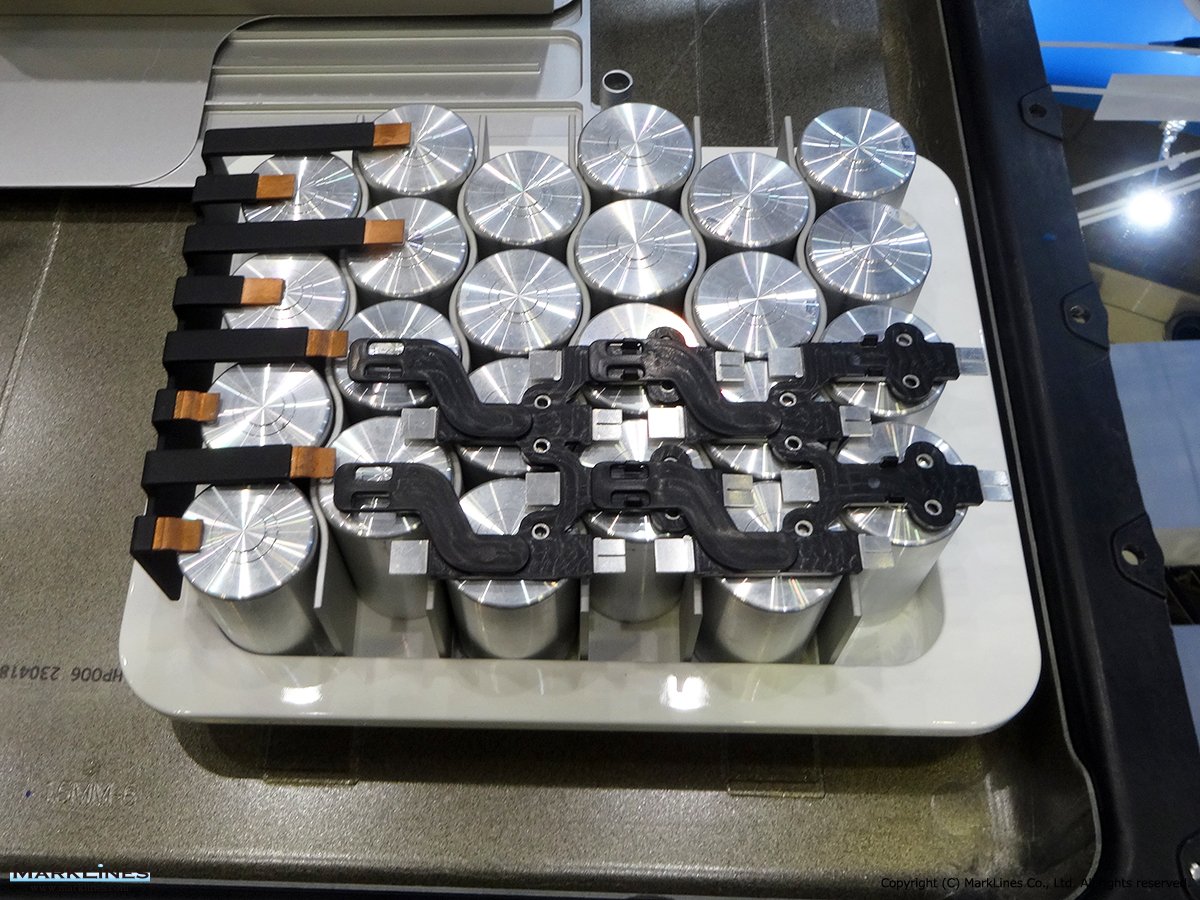

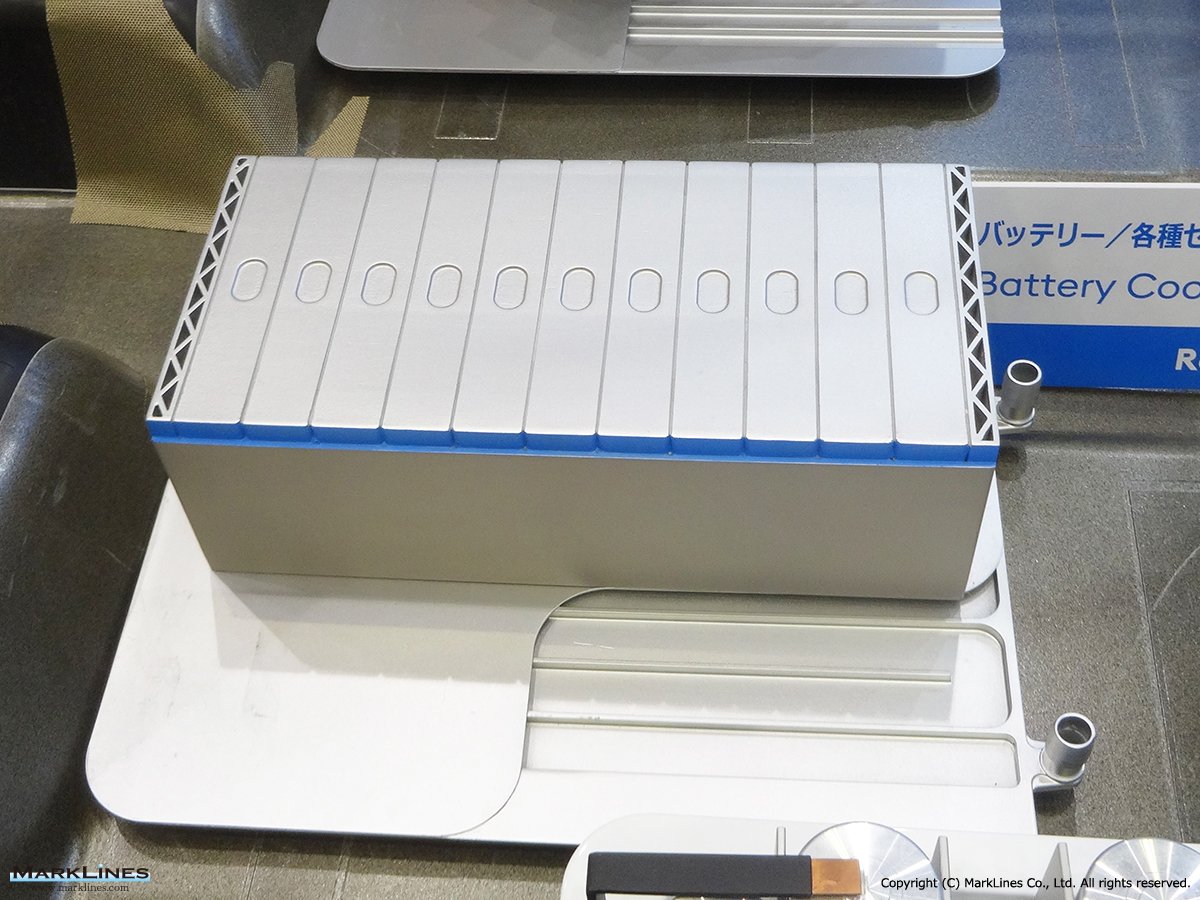

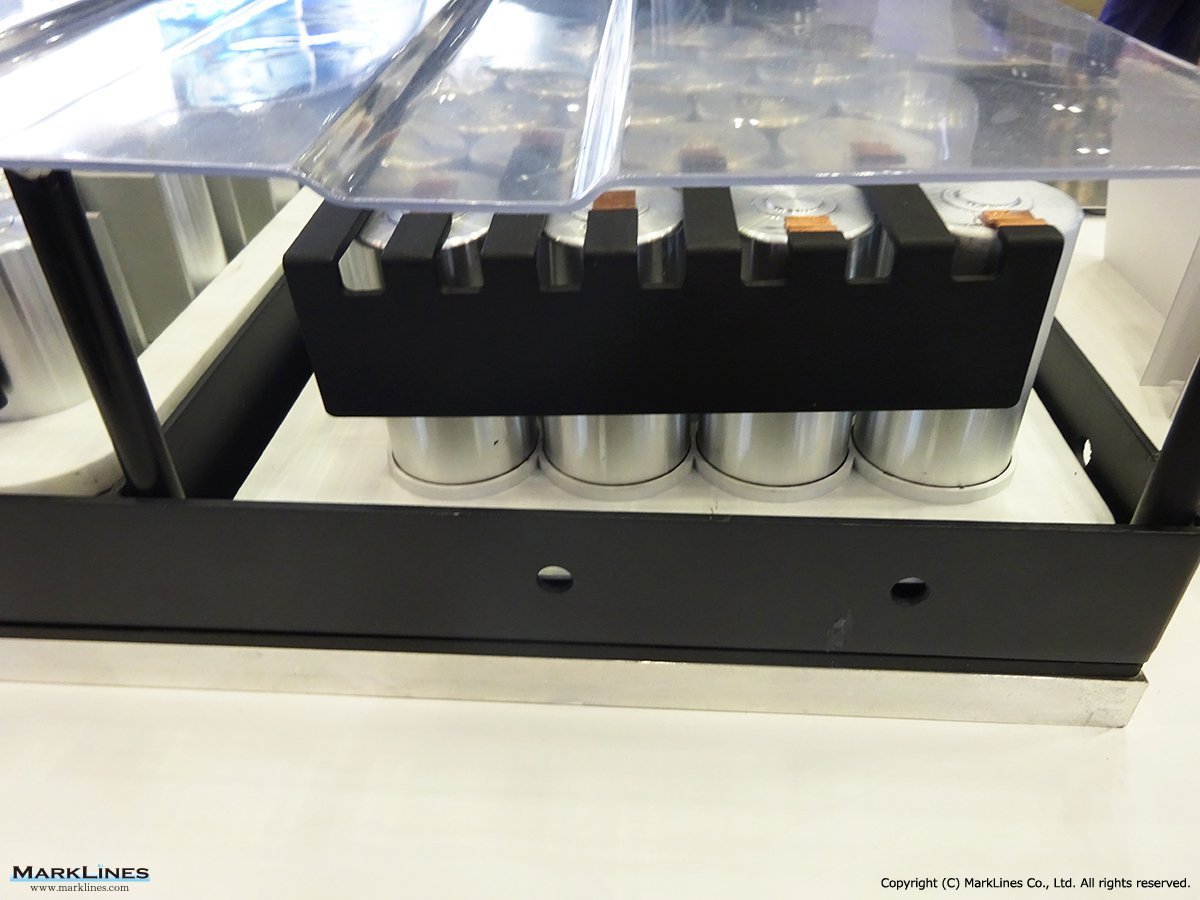

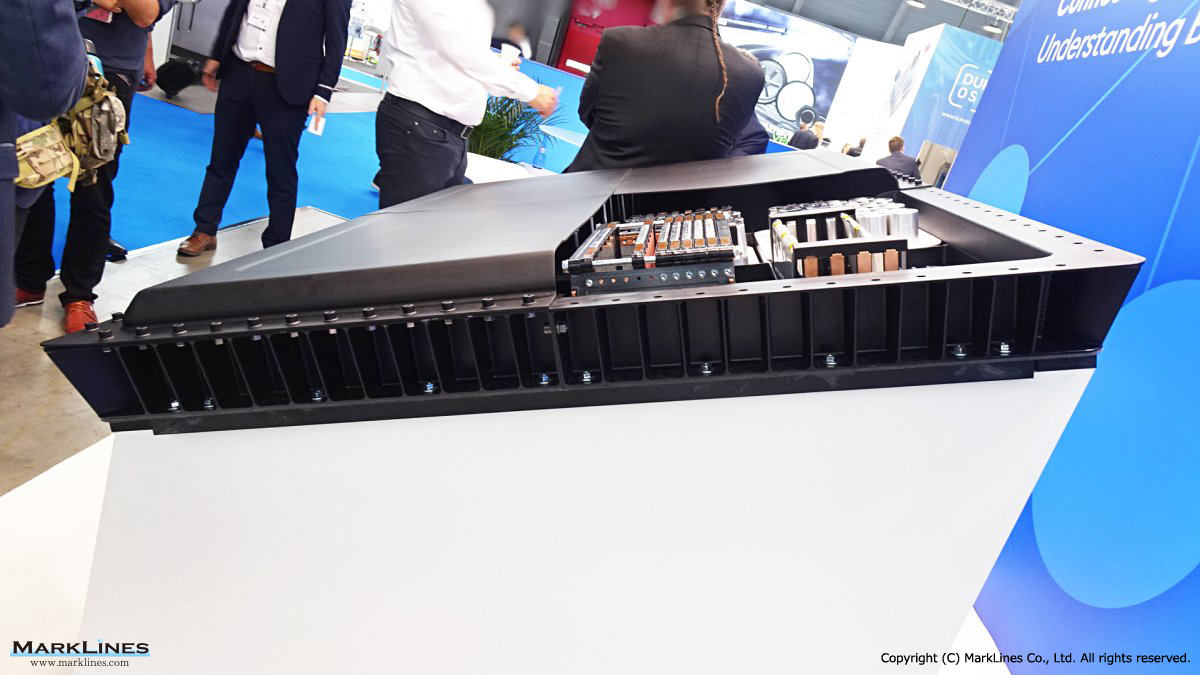

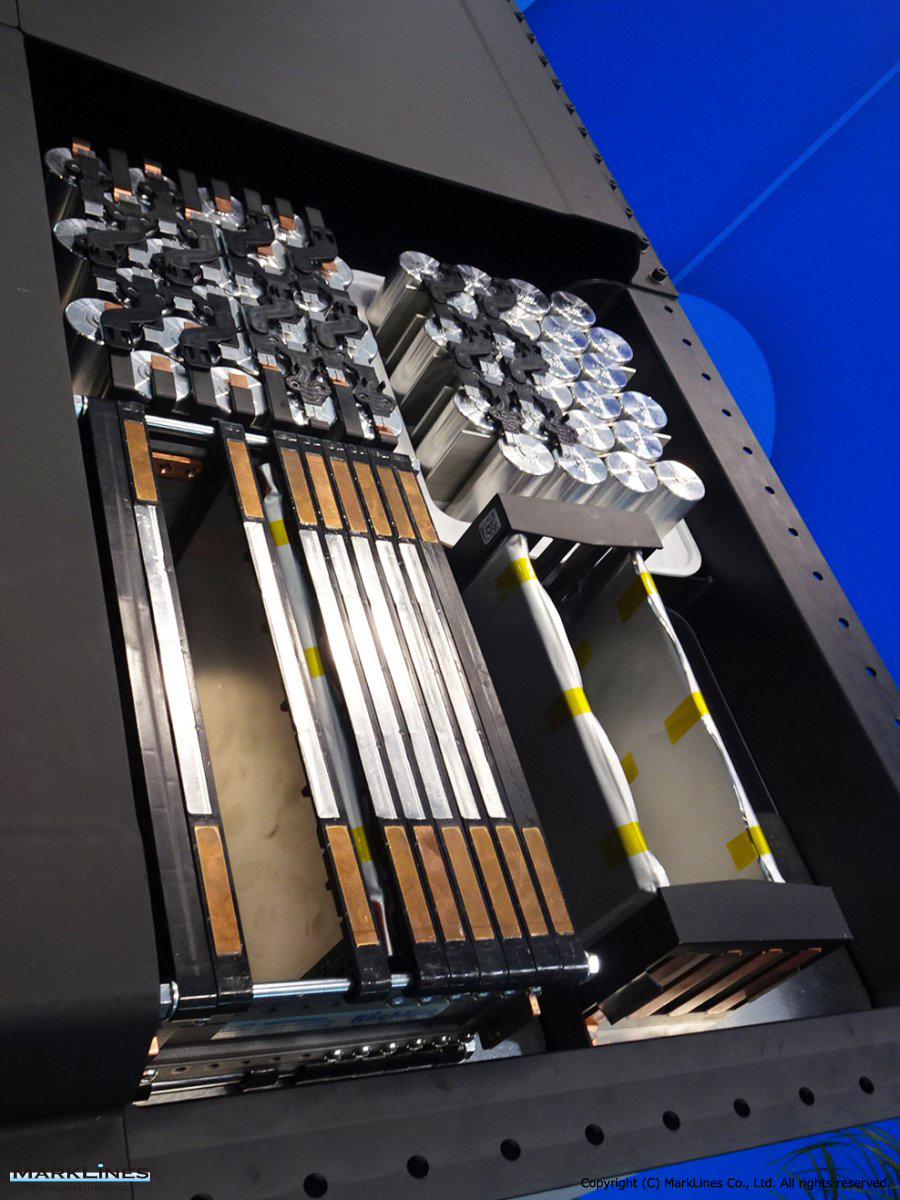

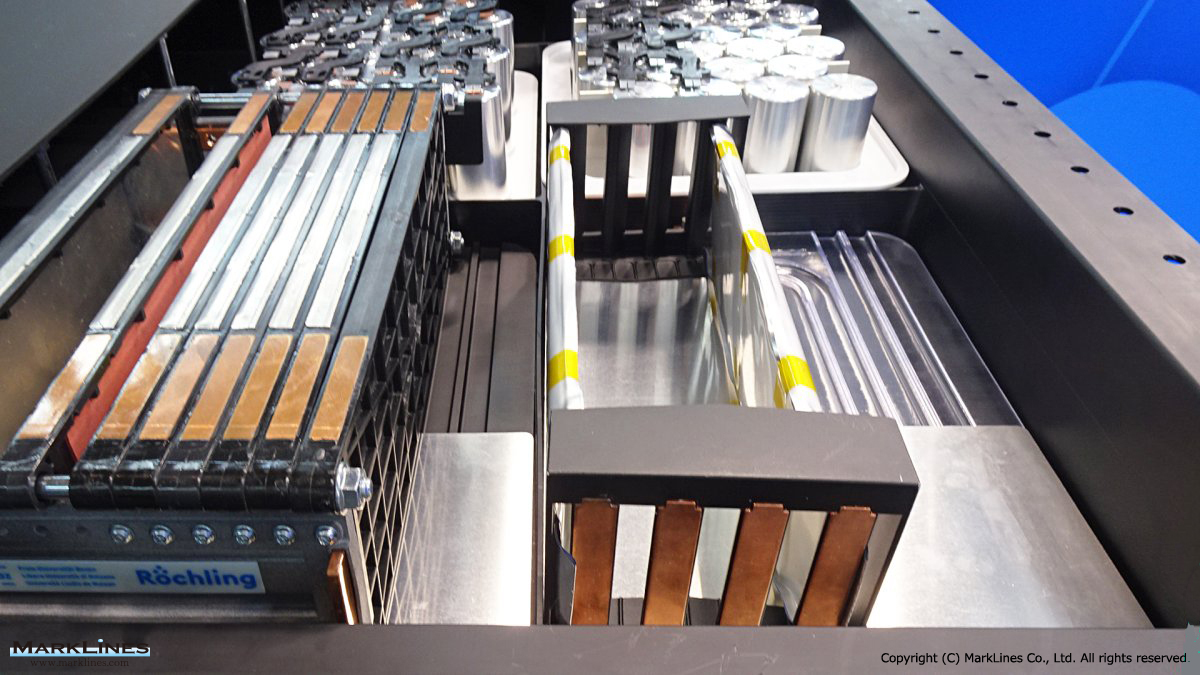

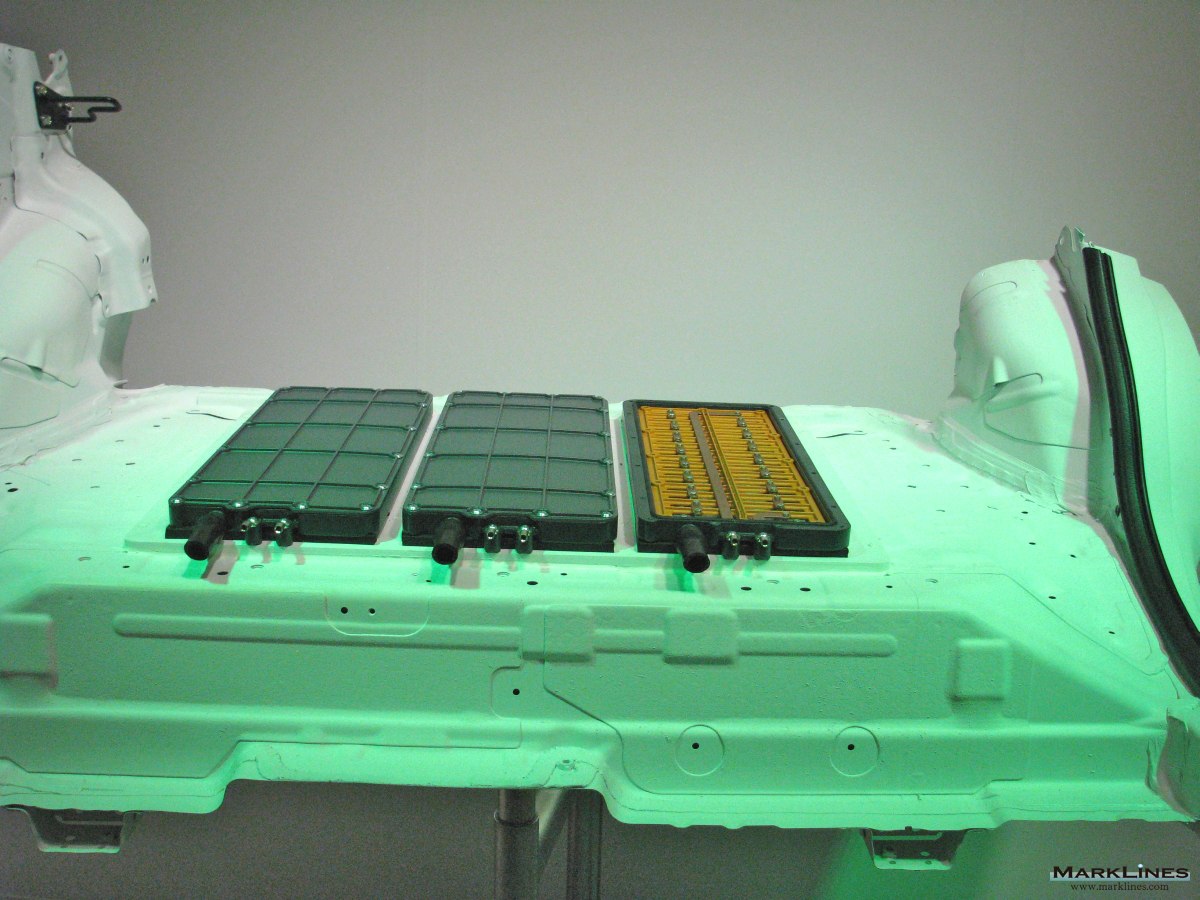

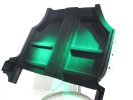

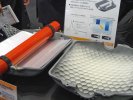

Battery solutions

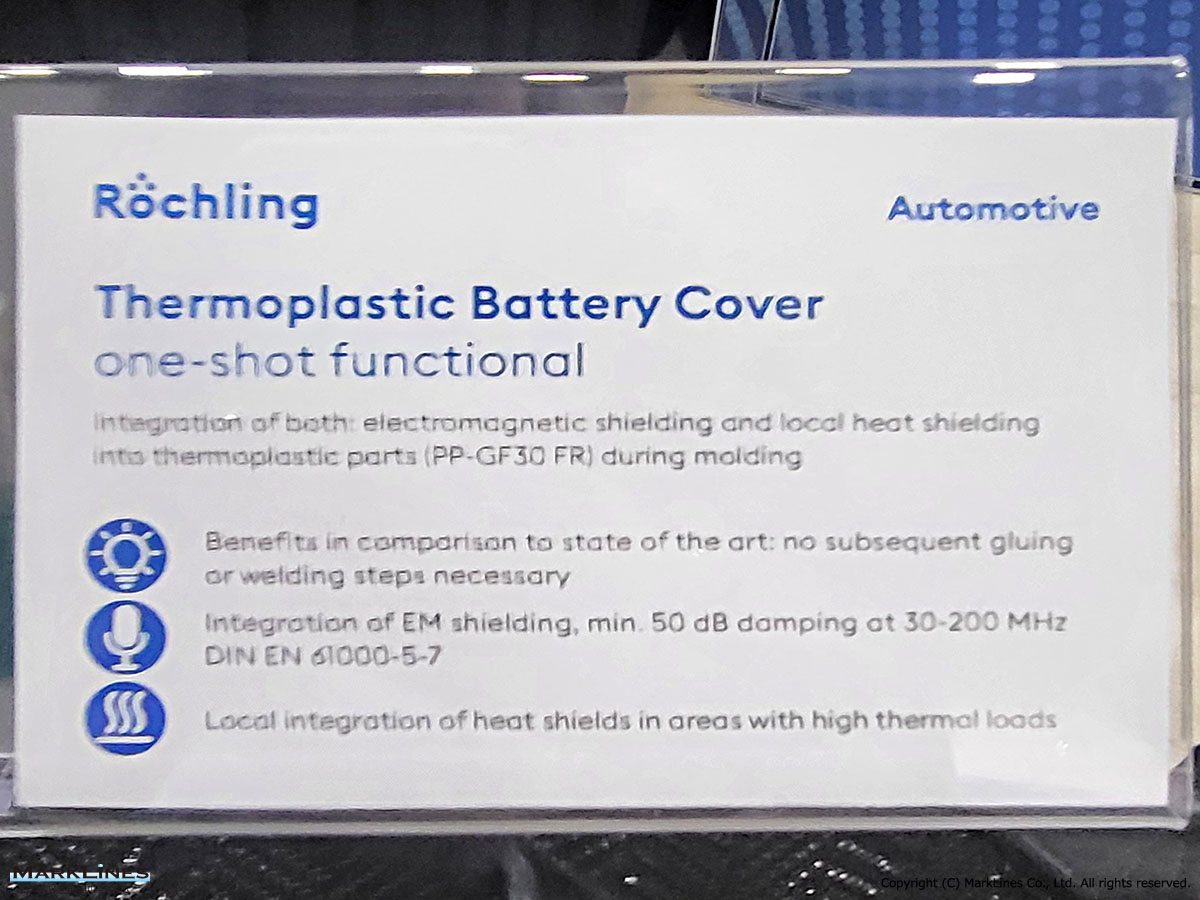

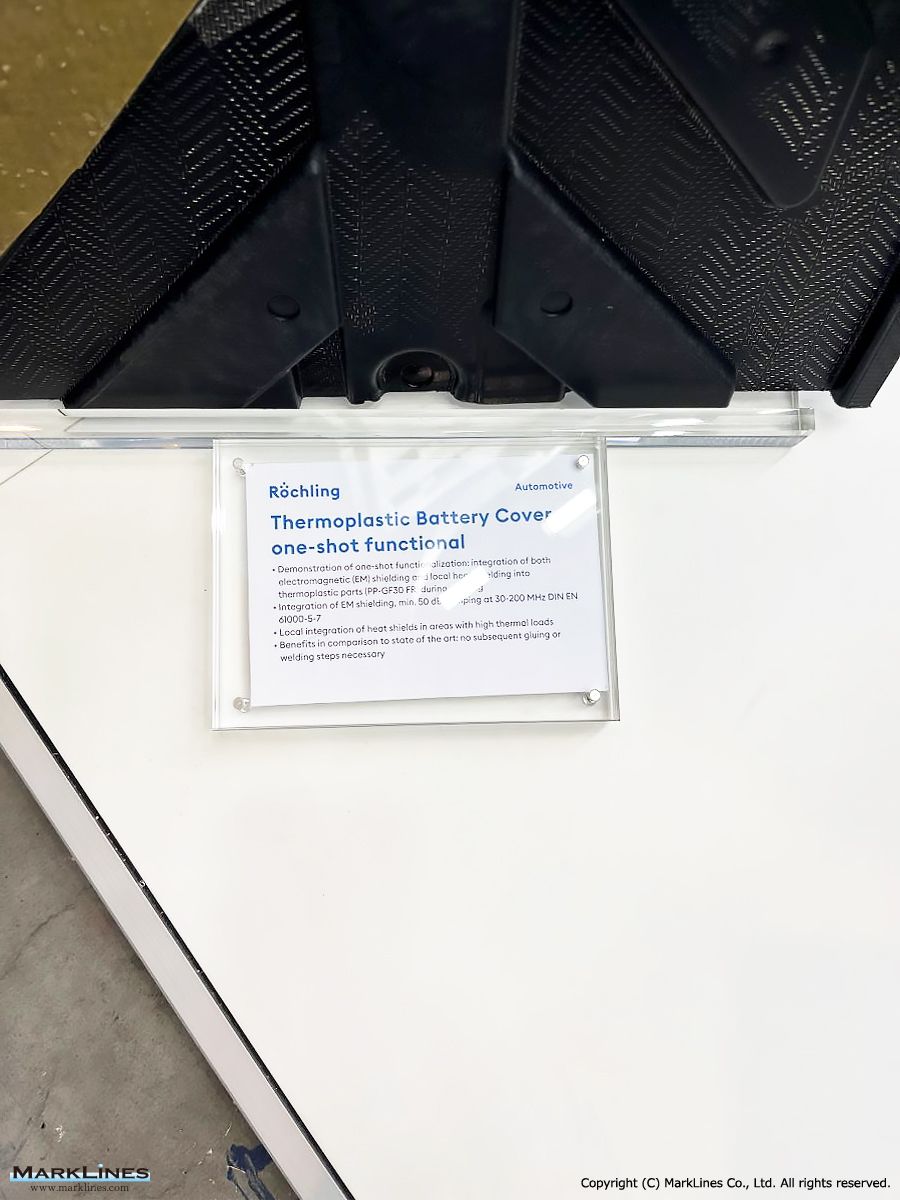

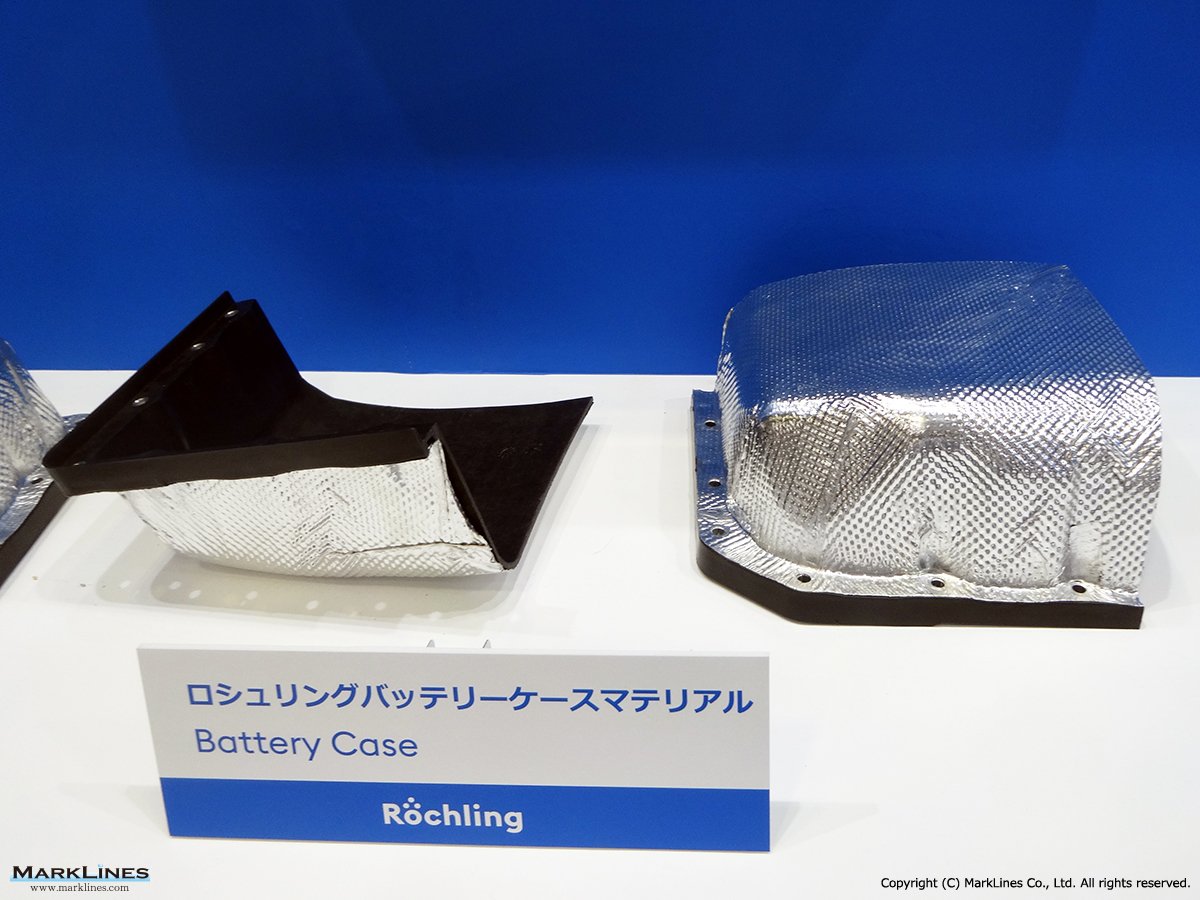

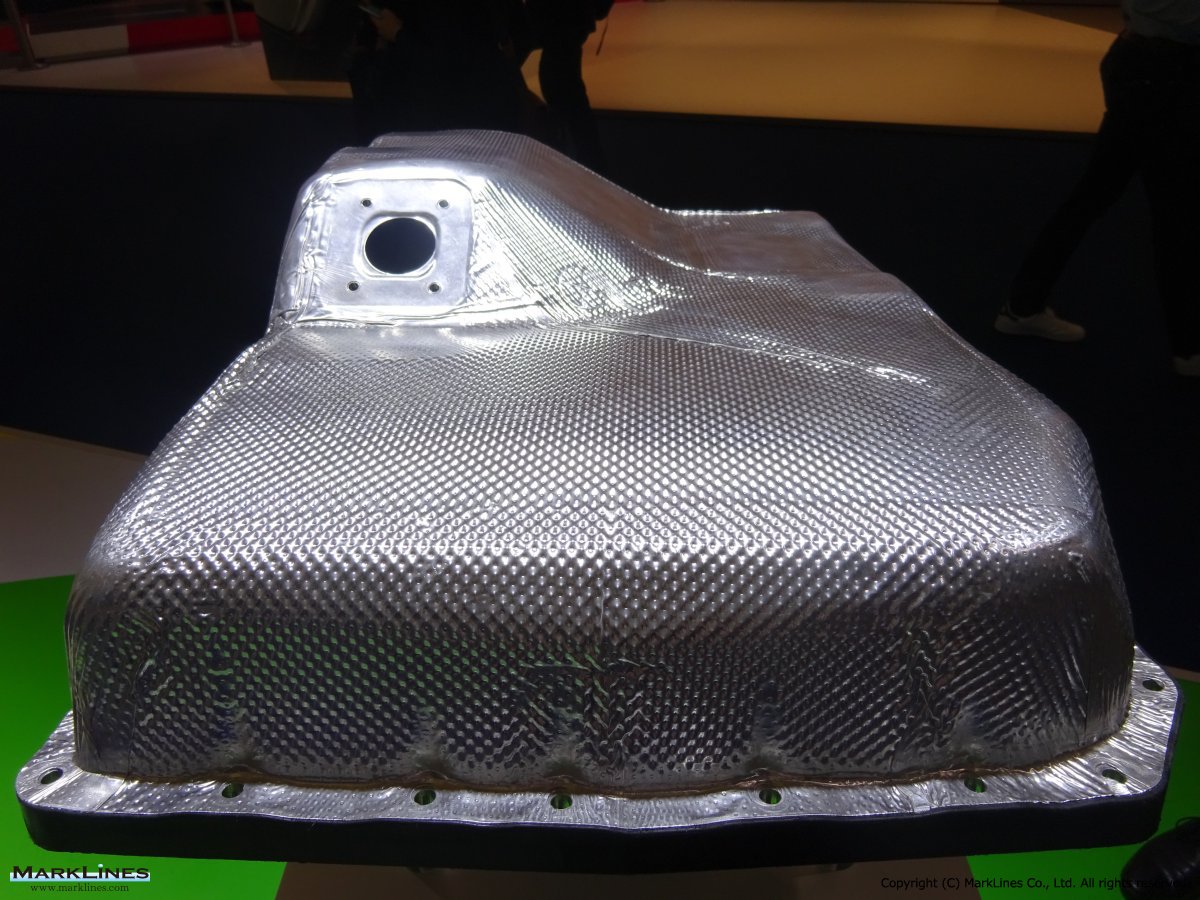

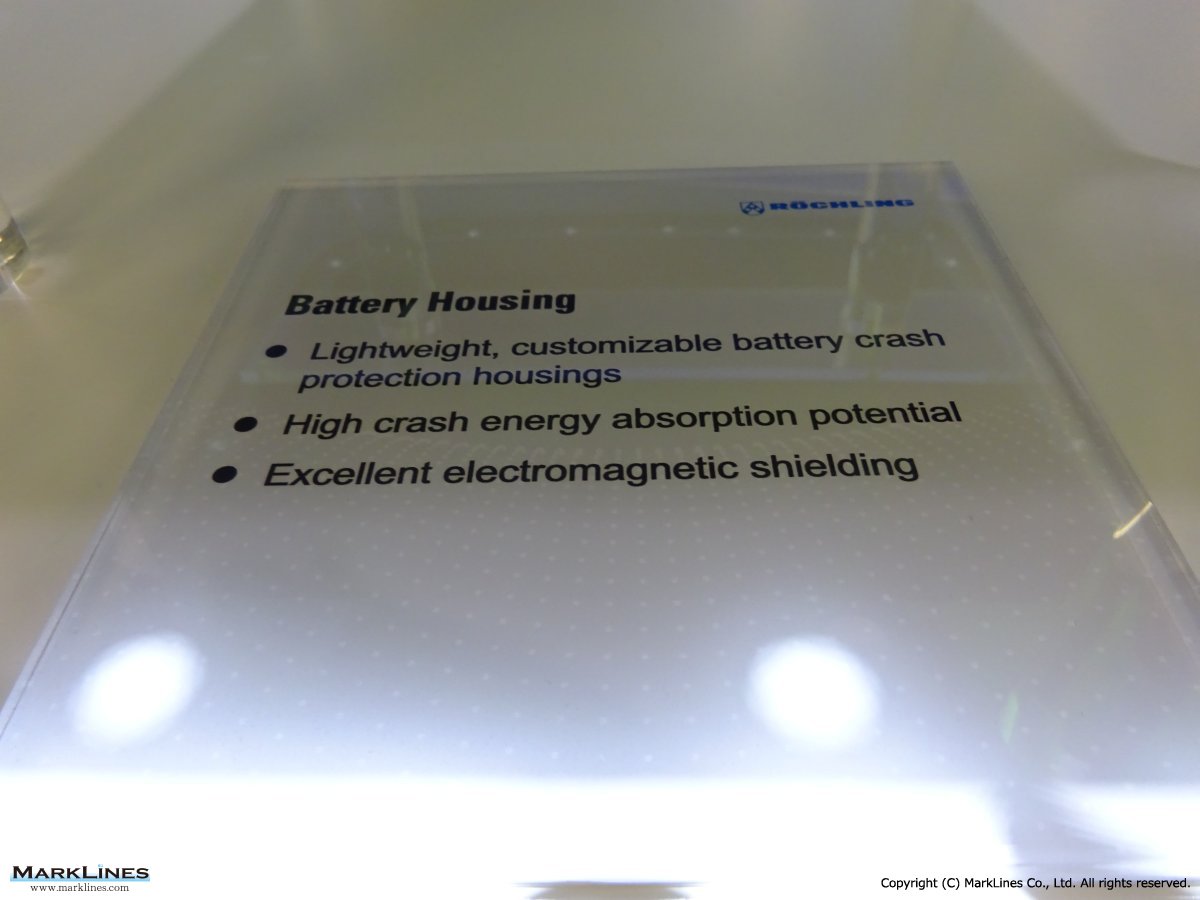

-Battery housings and covers

-Cell frames

-Insulating sheets

-Cell contact systems

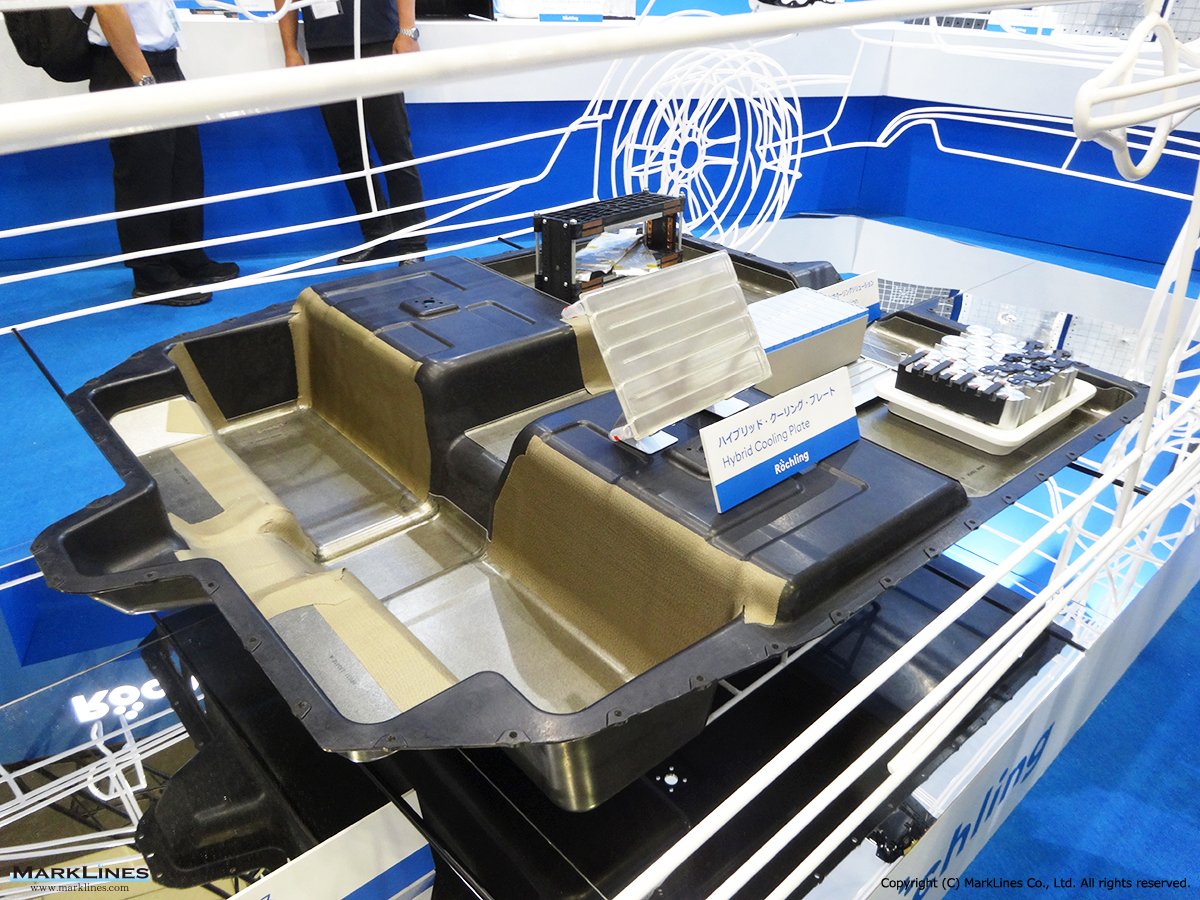

-Battery pack thermal management

-Battery cross members

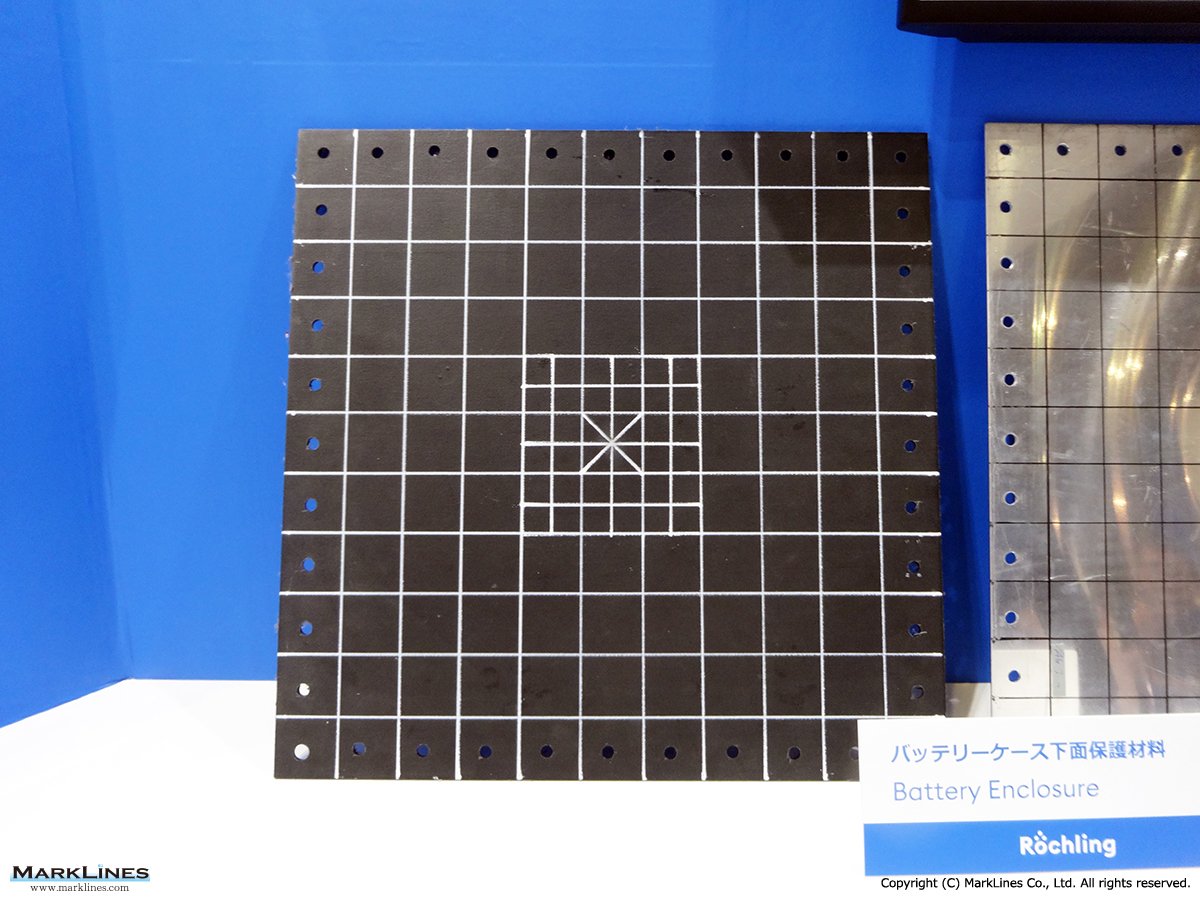

-Battery protection

-Battery enclosures

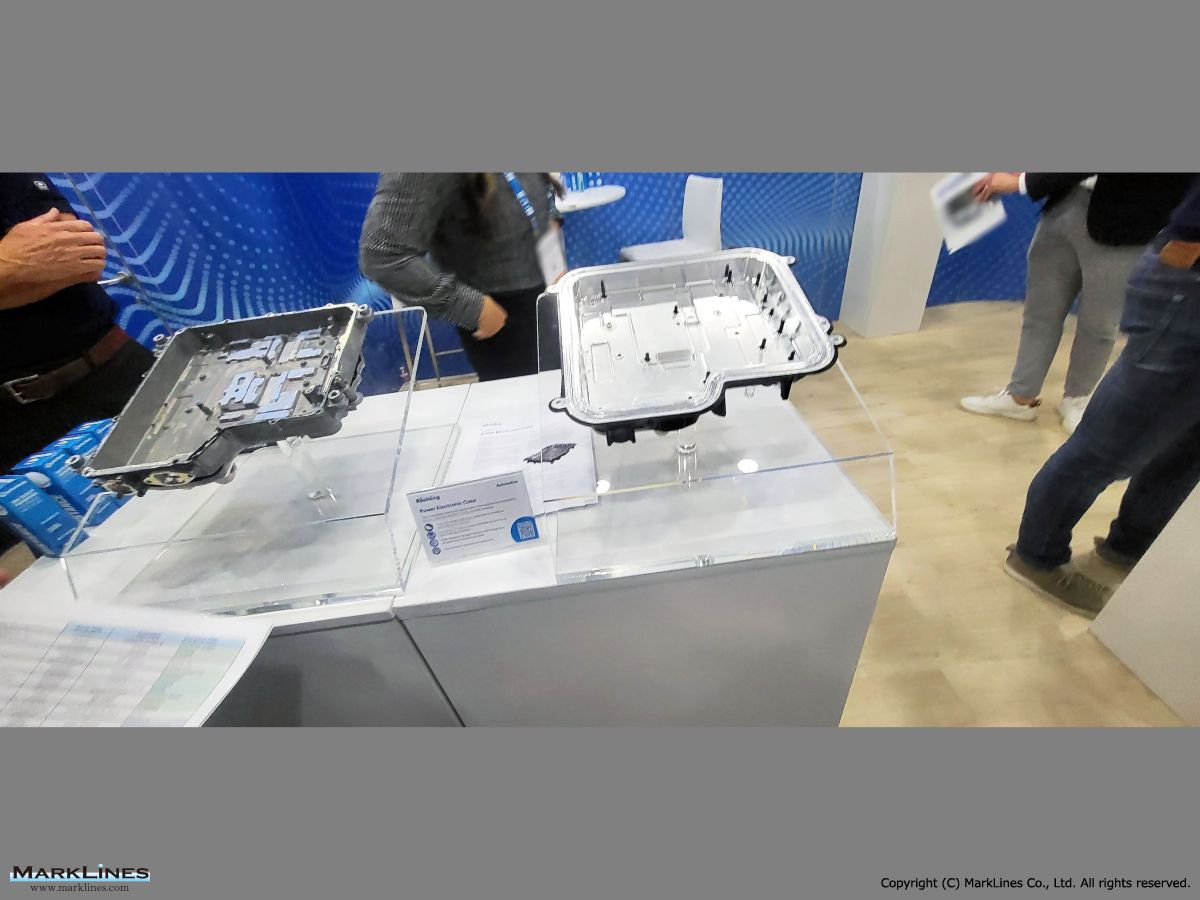

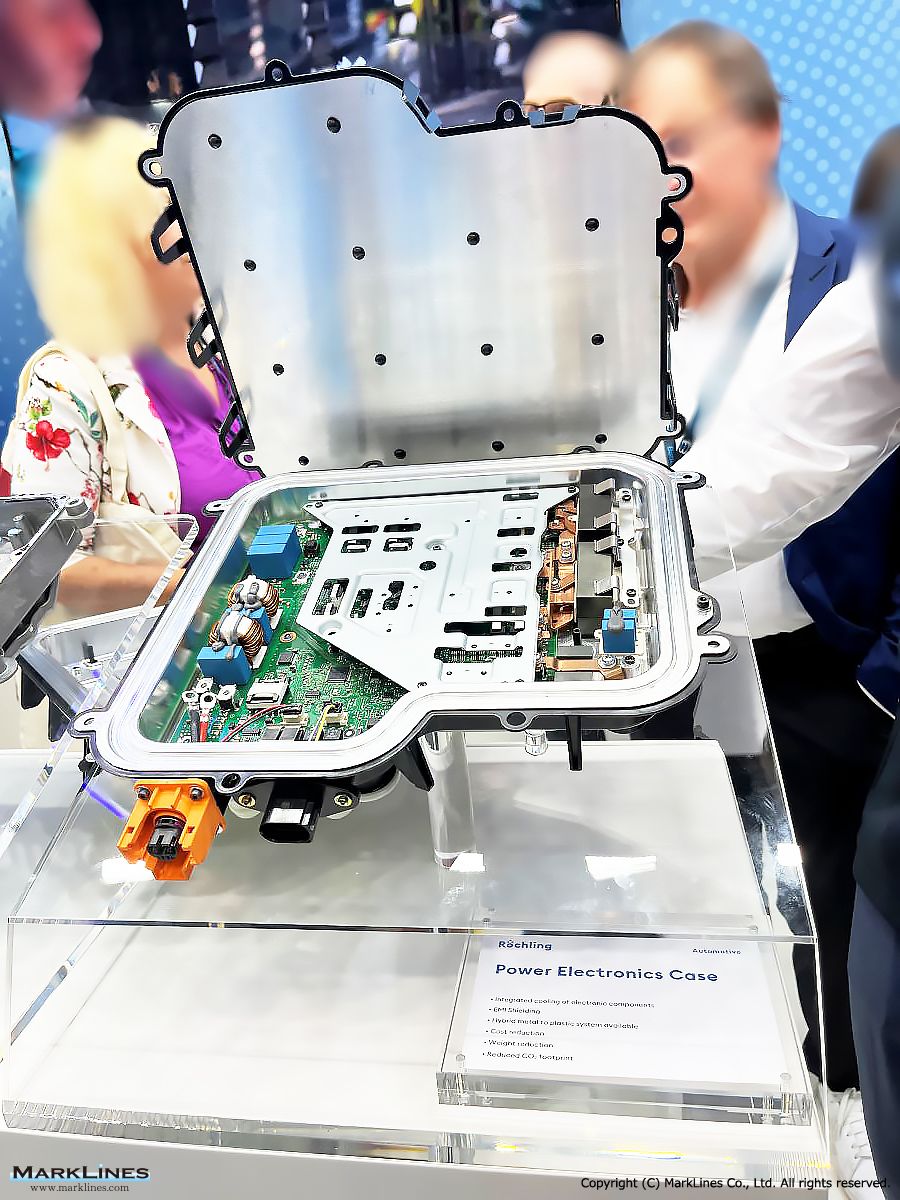

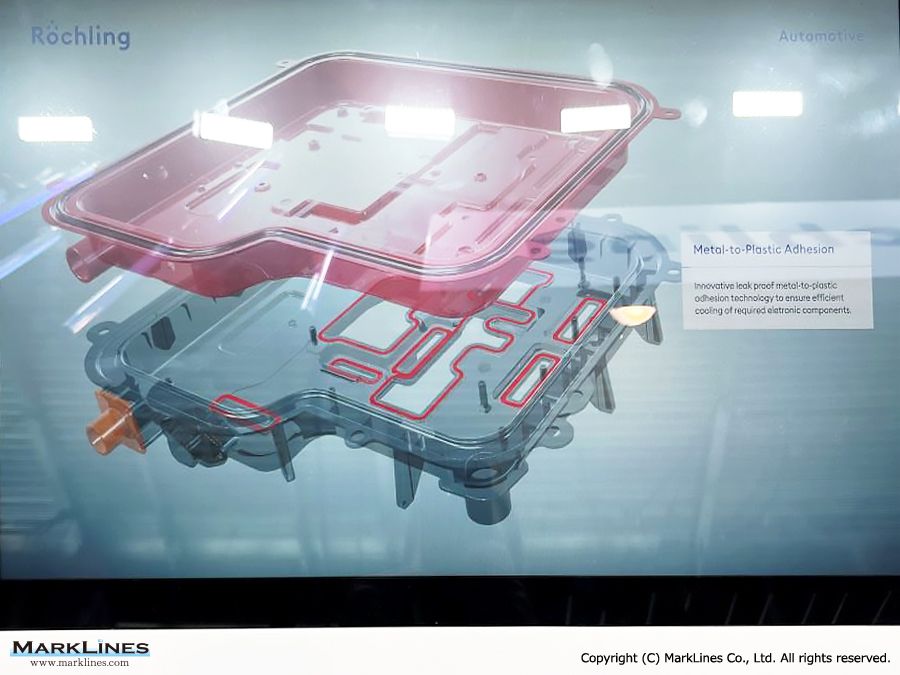

-Aluminum power electronics cases

-Structural assembly components for batteries

-Charge ports

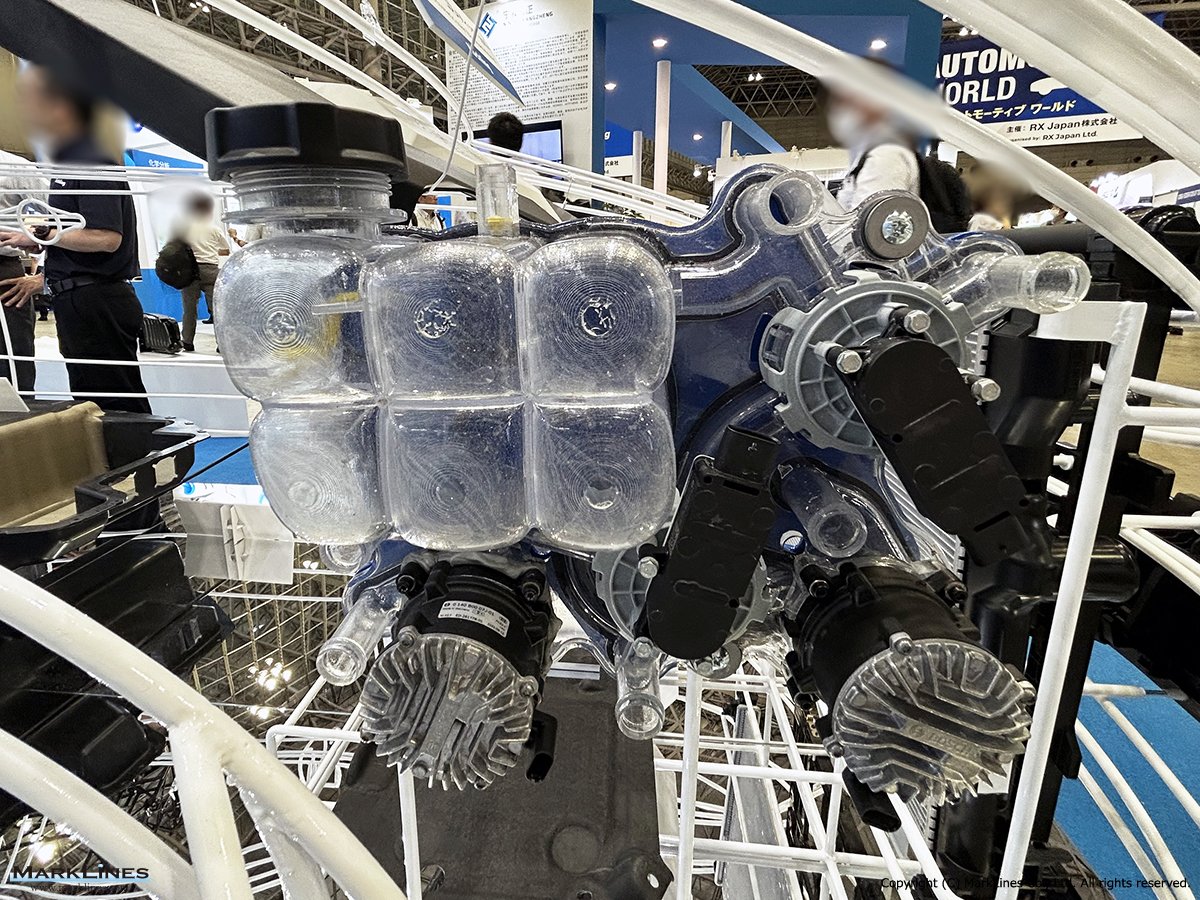

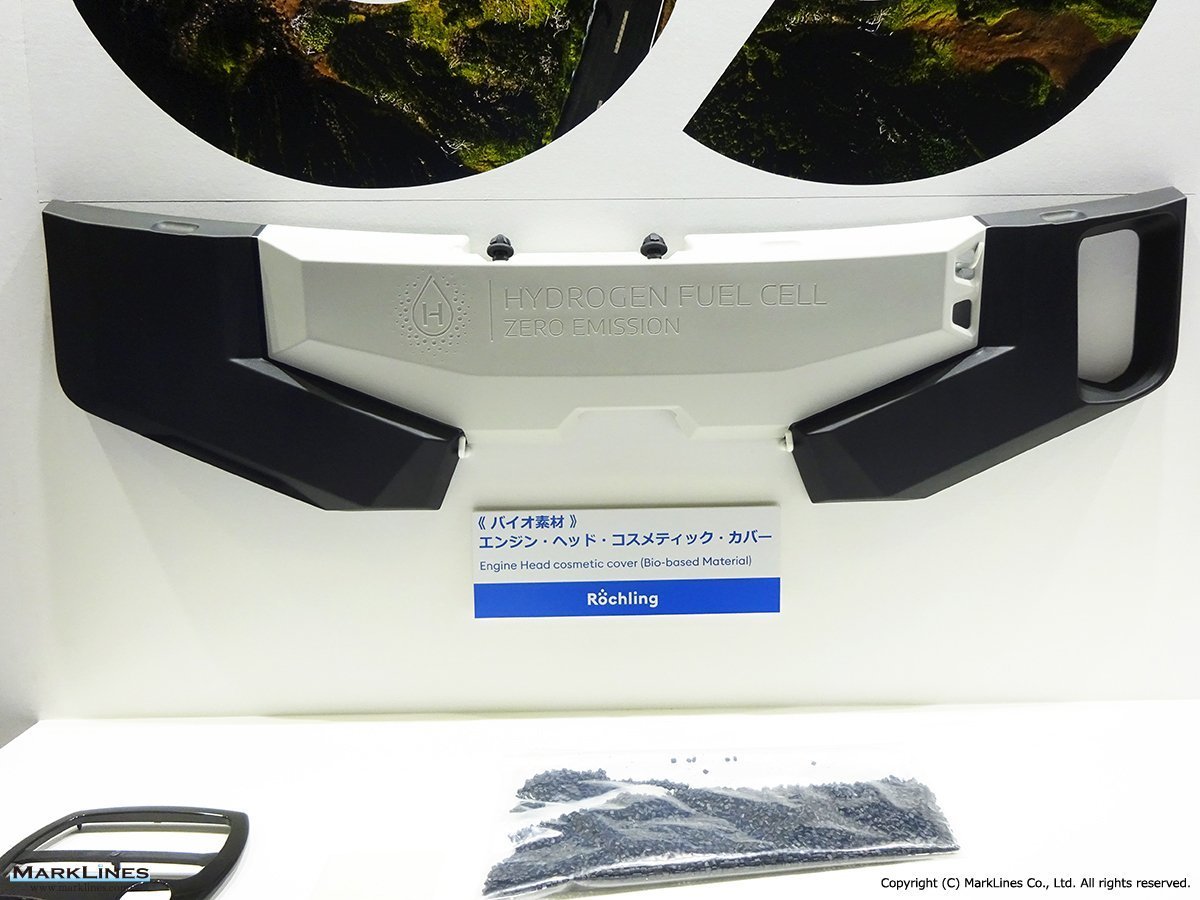

Fuel cell components

-Bipolar plastic sheets

-Ion-exchange cartridges

-Filter elements

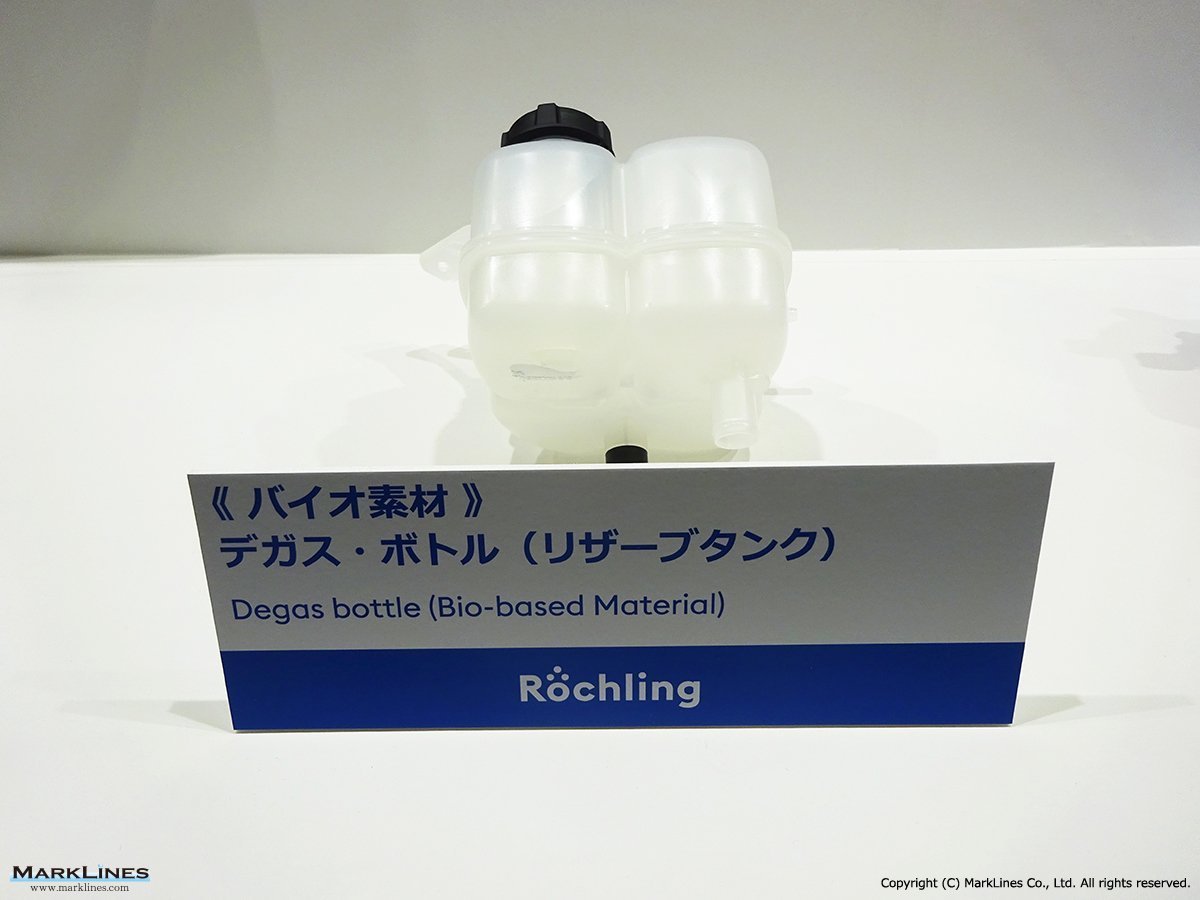

-Degas bottles

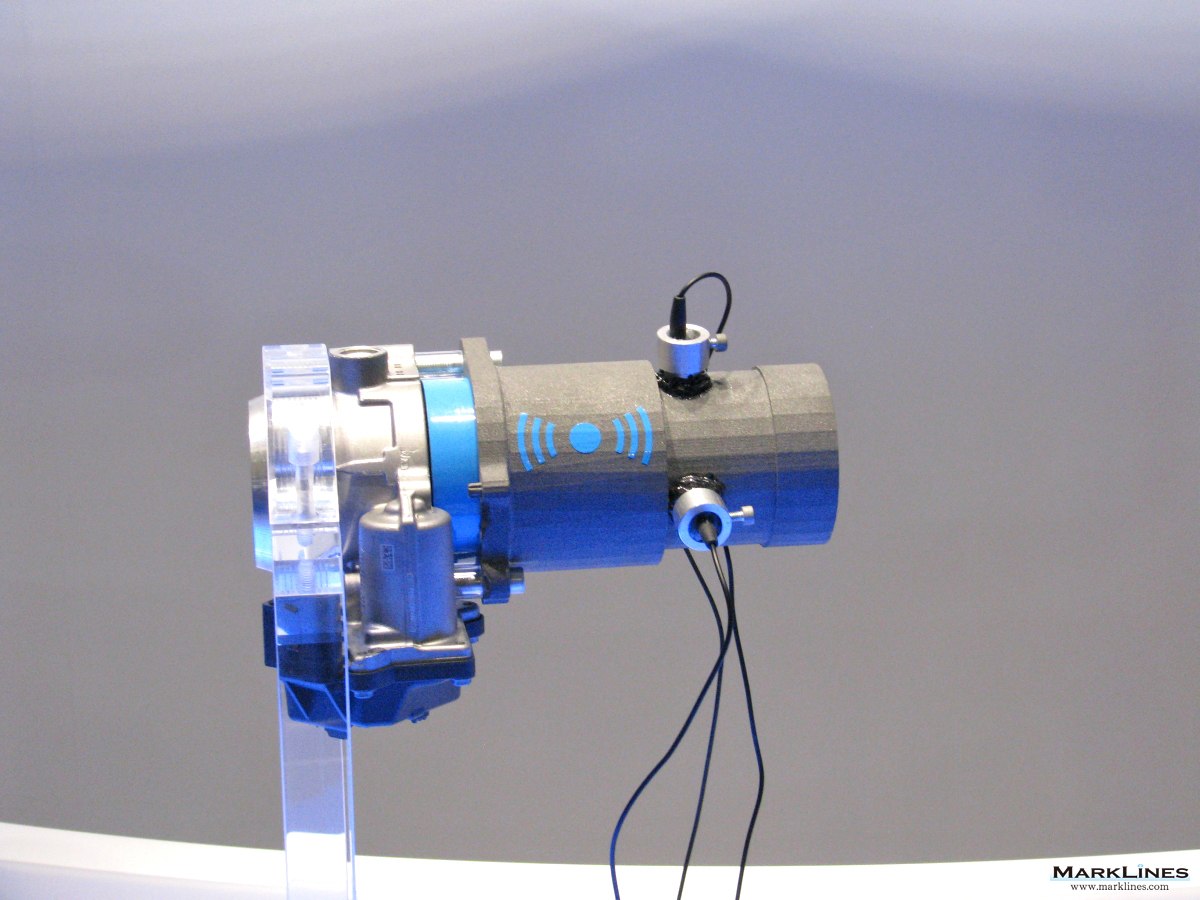

Propulsion

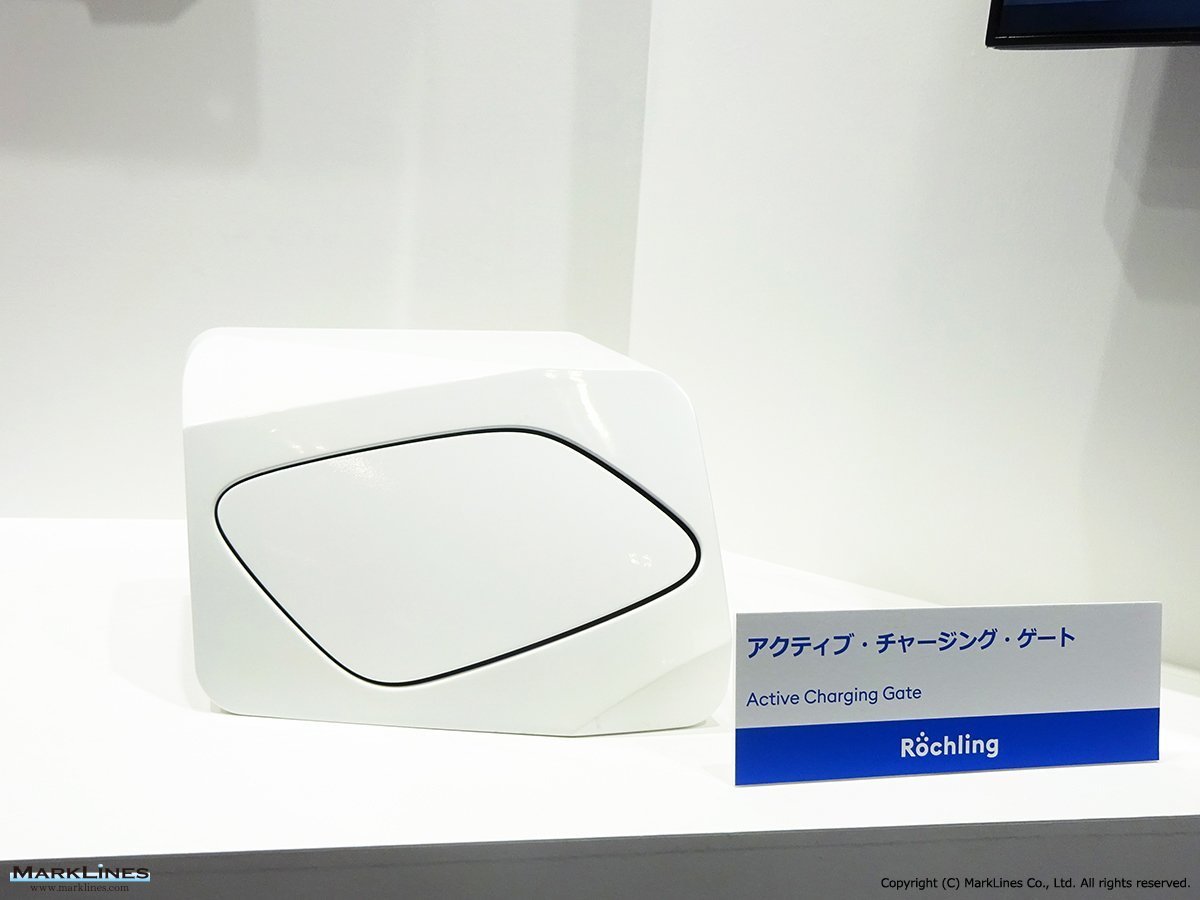

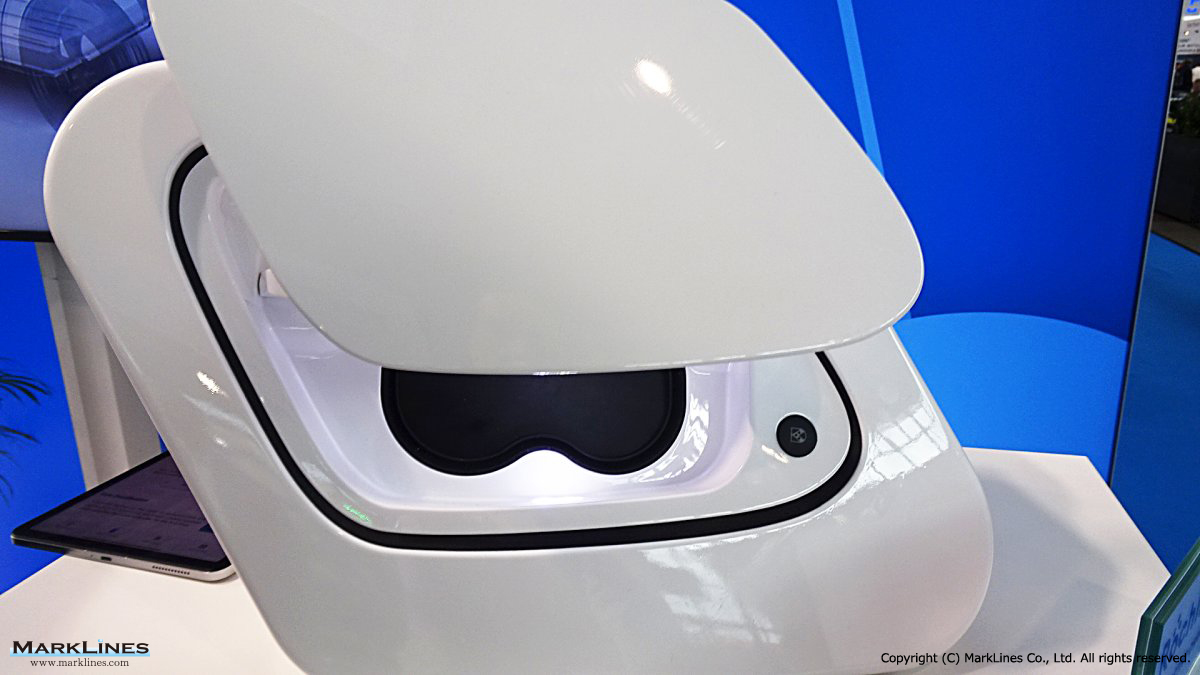

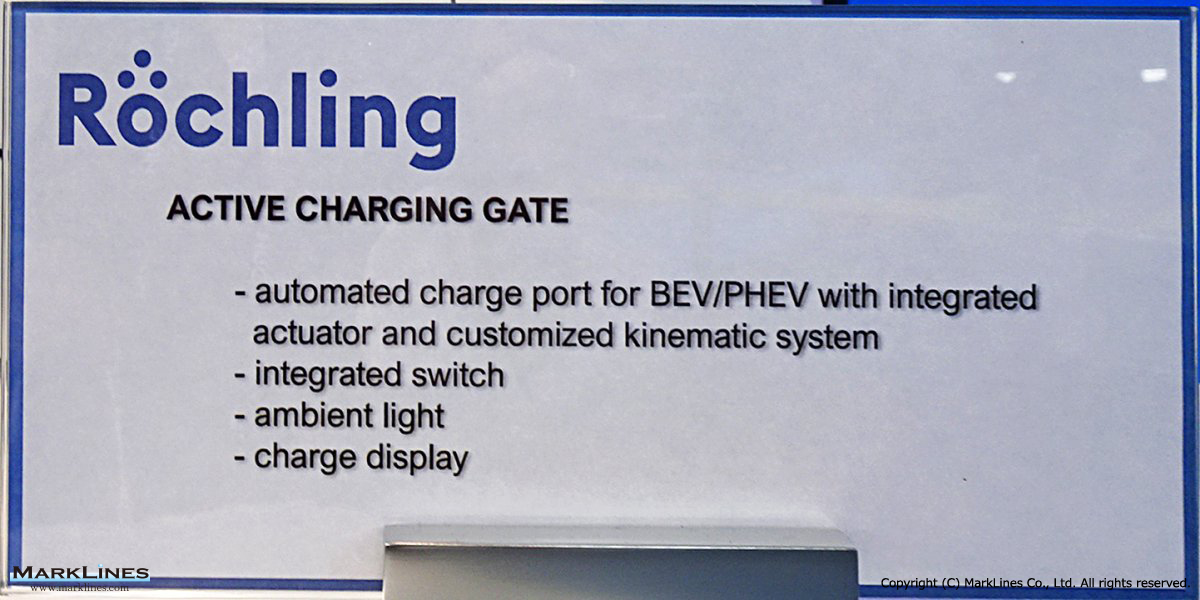

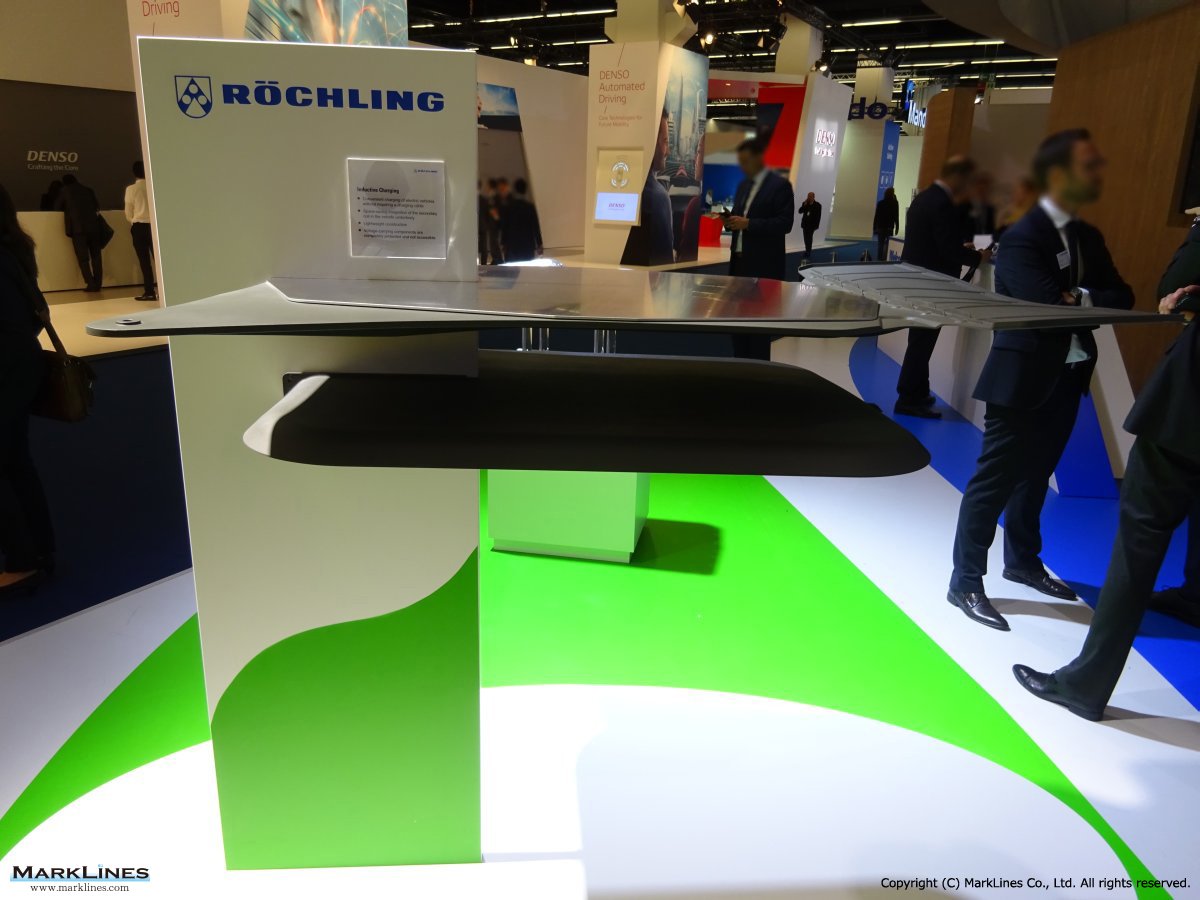

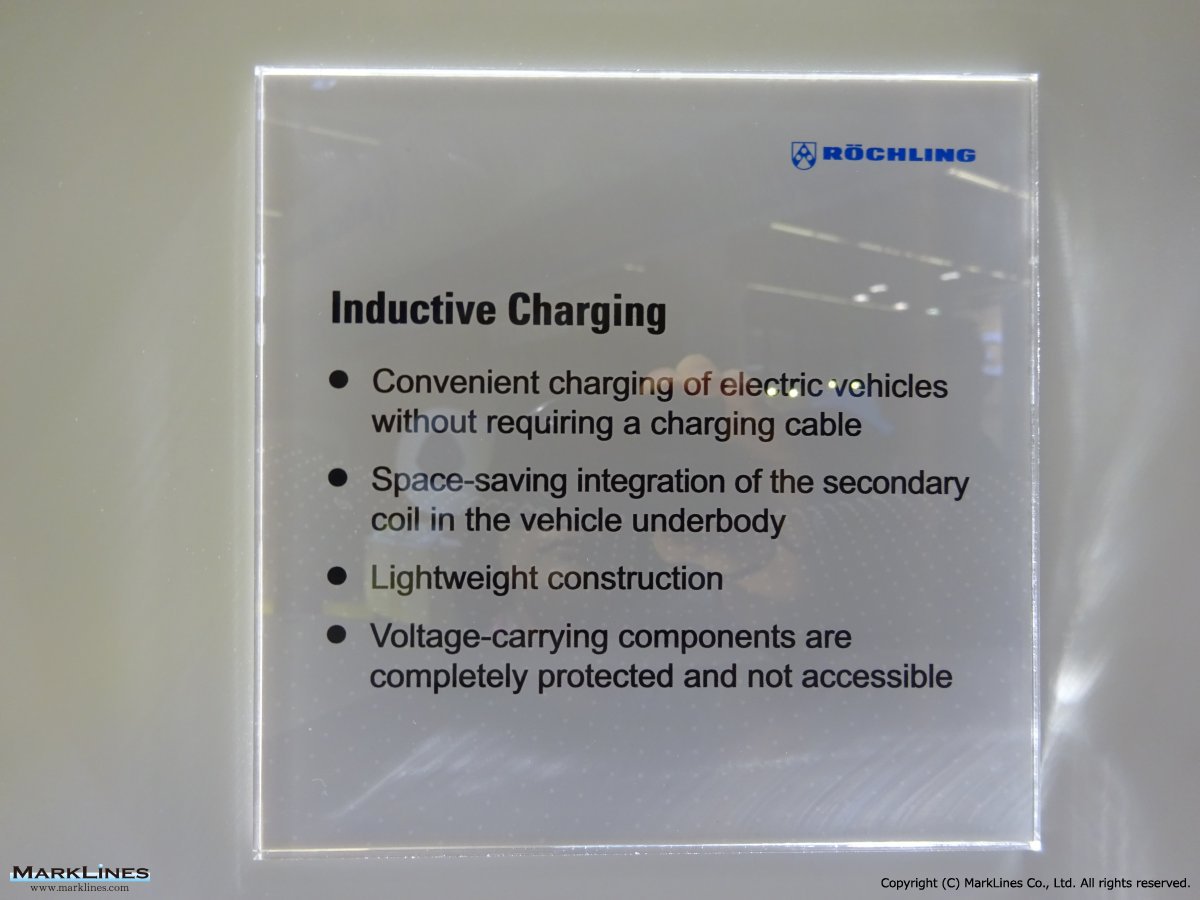

-Active charging gates

-Air-water management solutions

-Motorcycle fuel tanks

-Water injection systems

Advanced Active Cleaning Systems

-Liquid cleaning fluid container

-Cleaning fluid distribution system

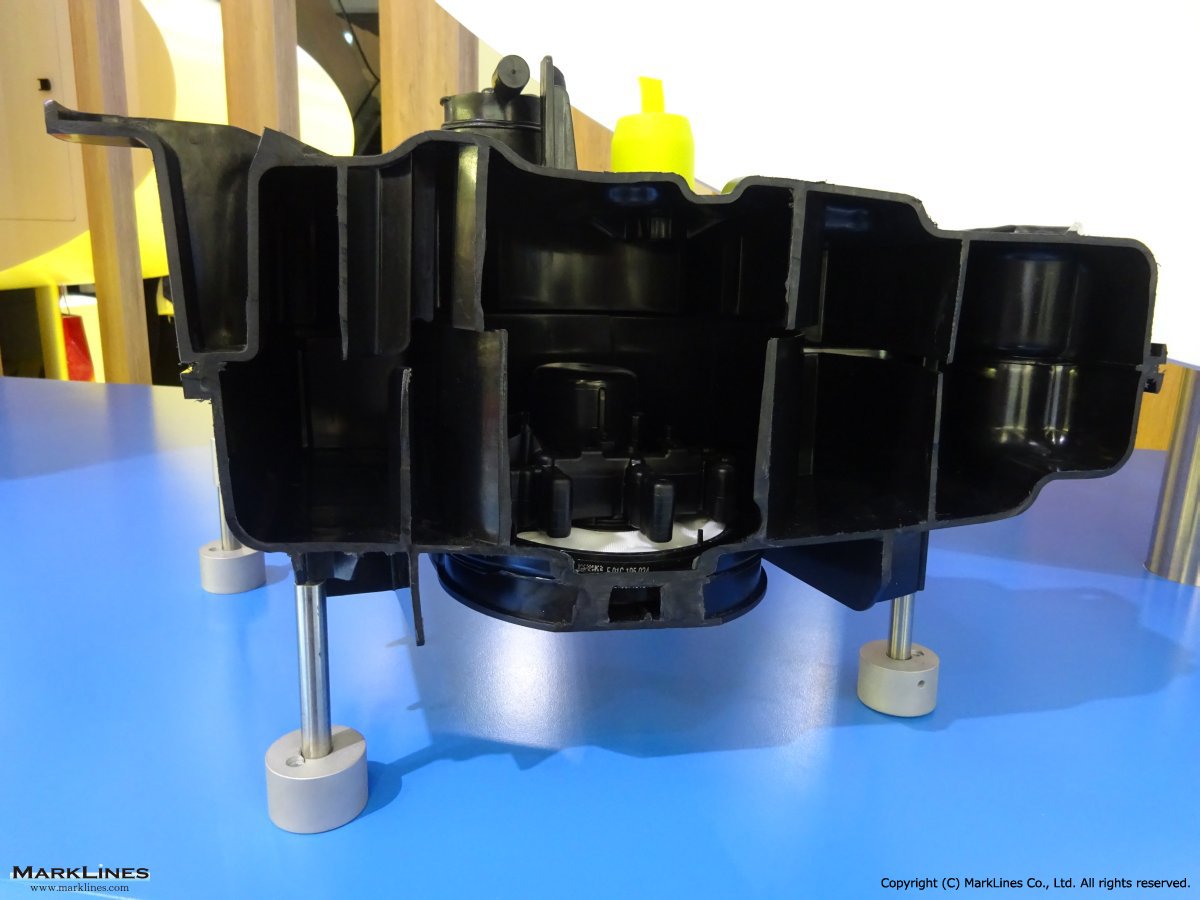

Air intake systems

-Air intake systems with nonwoven filters

-Paper filters

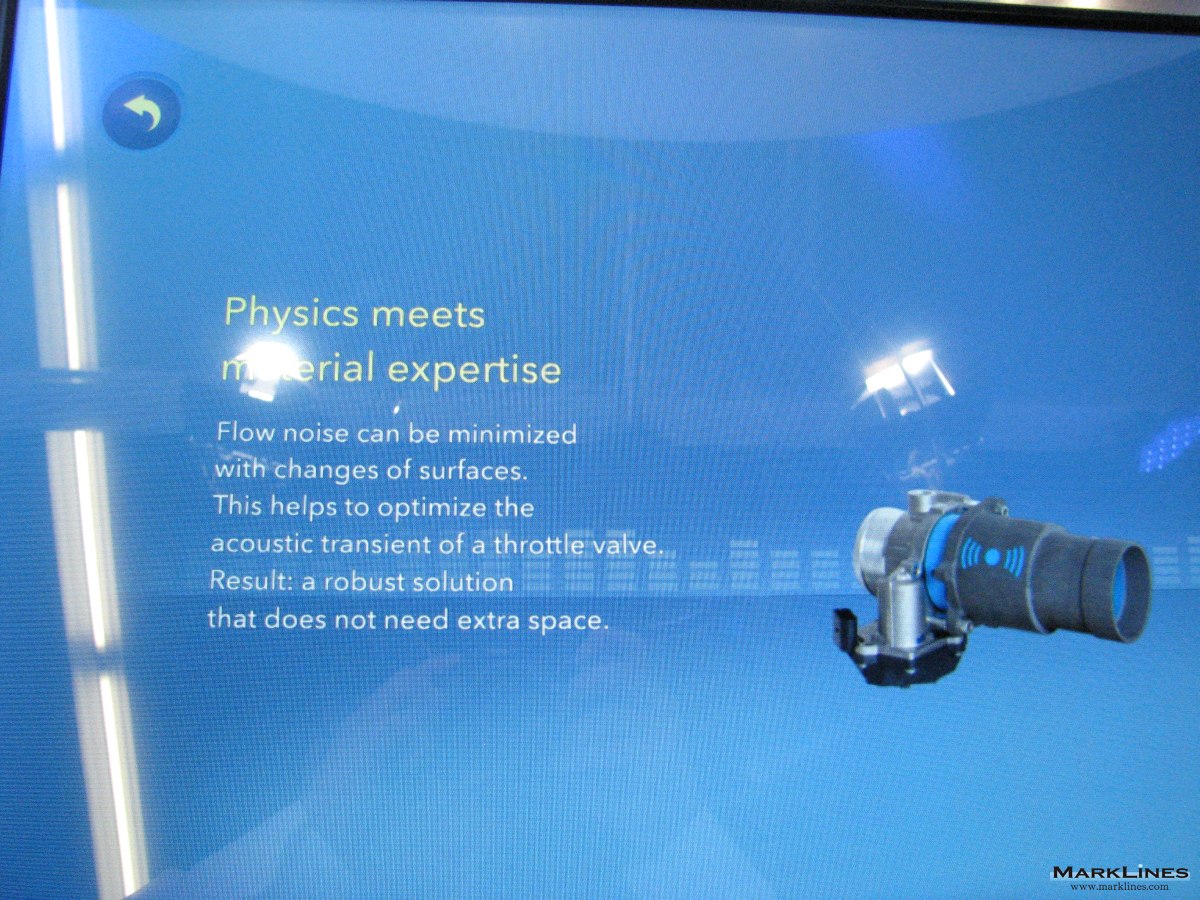

-Air intake modules with optimized air flow

-Air intake modules with sharp cut raw air stroke for higher performance

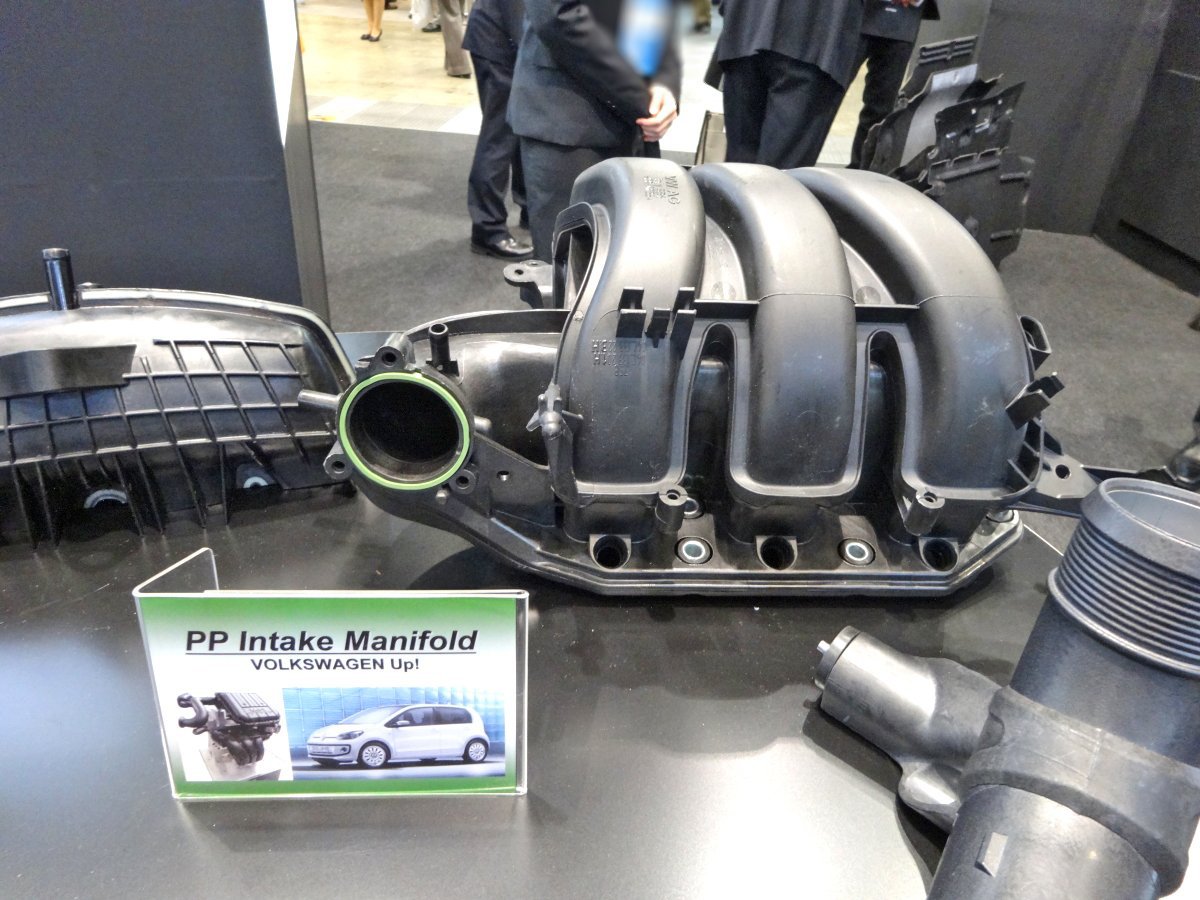

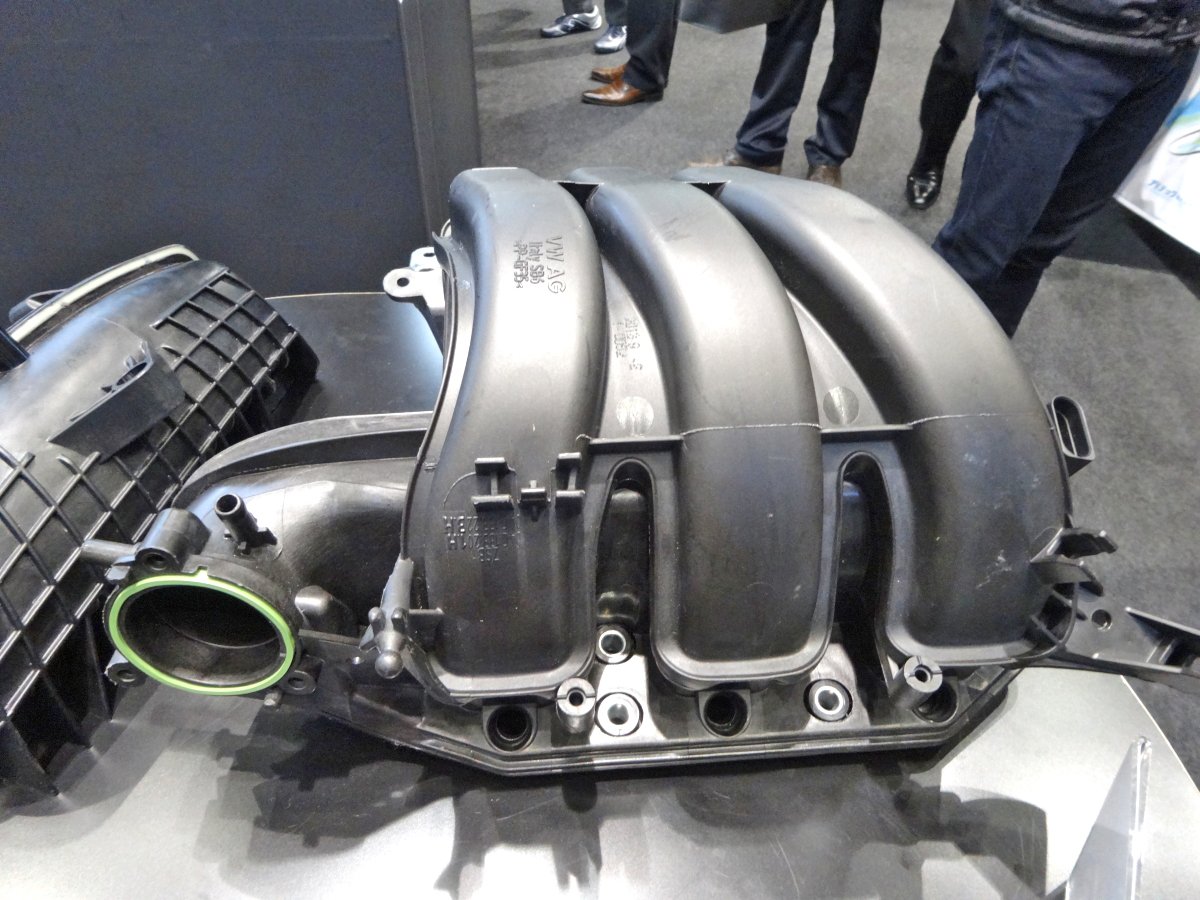

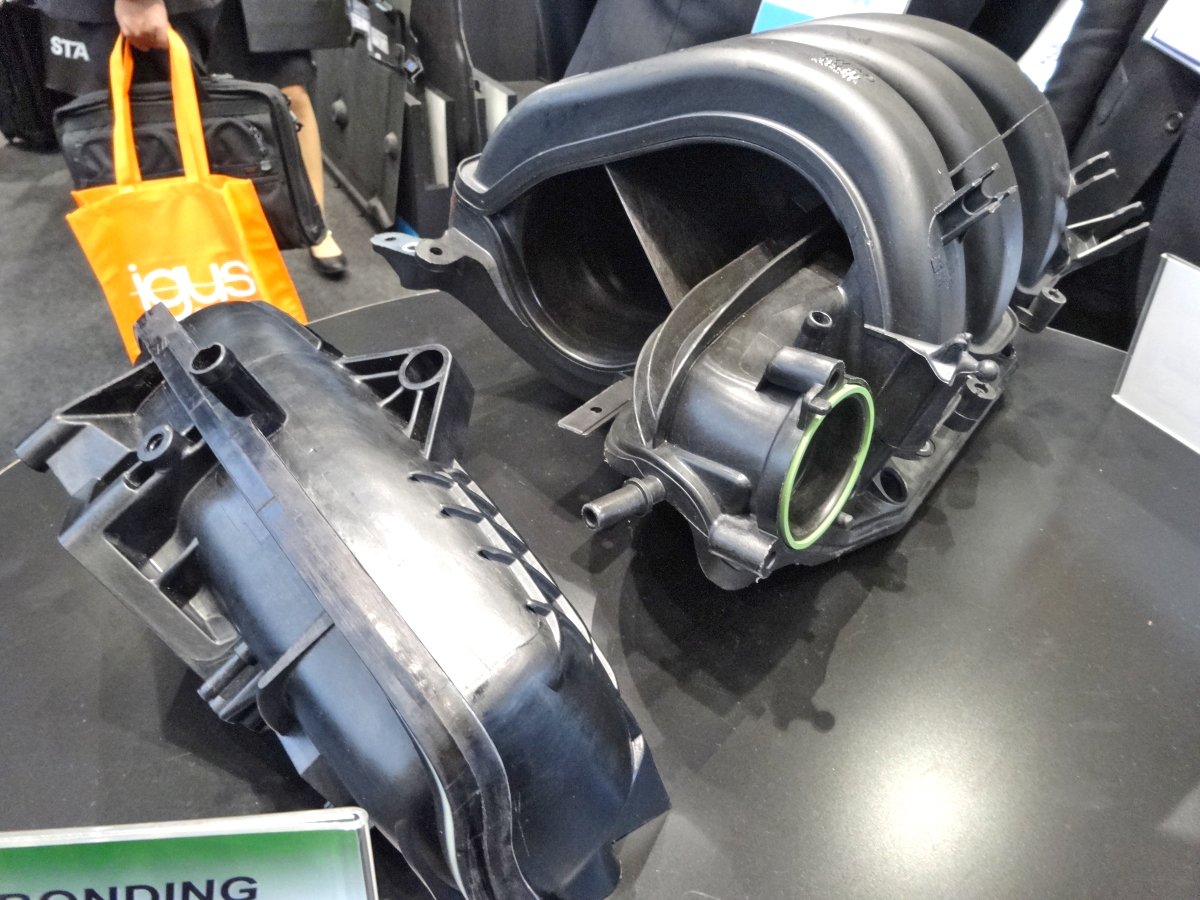

Intake manifolds

-Intake manifolds with integrated water to air intercooler

-Intake manifolds with variable length adjustment

-Intake manifolds for high performance V10 engine

-Intake manifolds for twin charged gasoline engine

Climate cabin air solutions

-Acoustic pads

-Acoustic climate air ducts

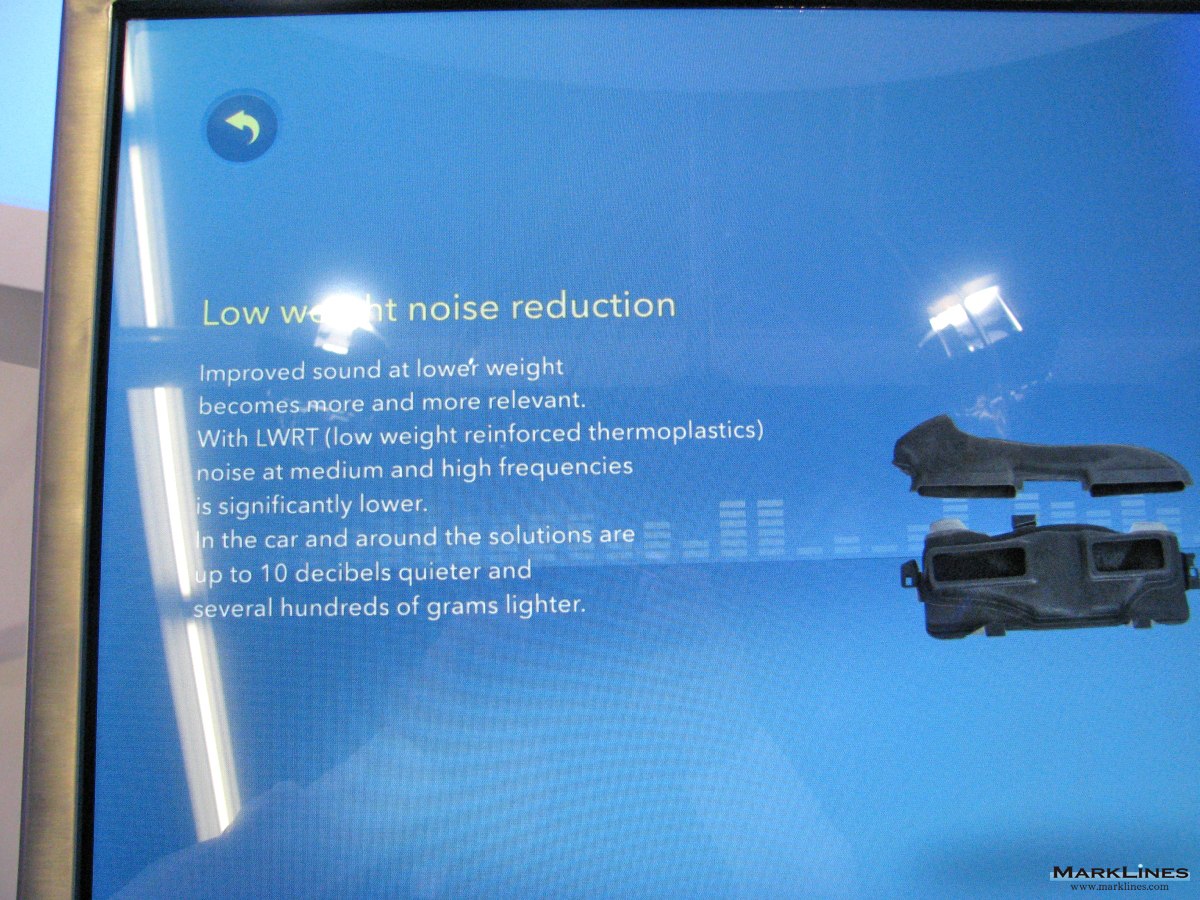

-Climate channels made from LWRT

Air tubes

-Temperature resistant charge-air tubes

-Flexible charge-air tubes

-Clean air tubes with resonators

-Pre-intercooler ducts

-Post-intercooler flexible ducts

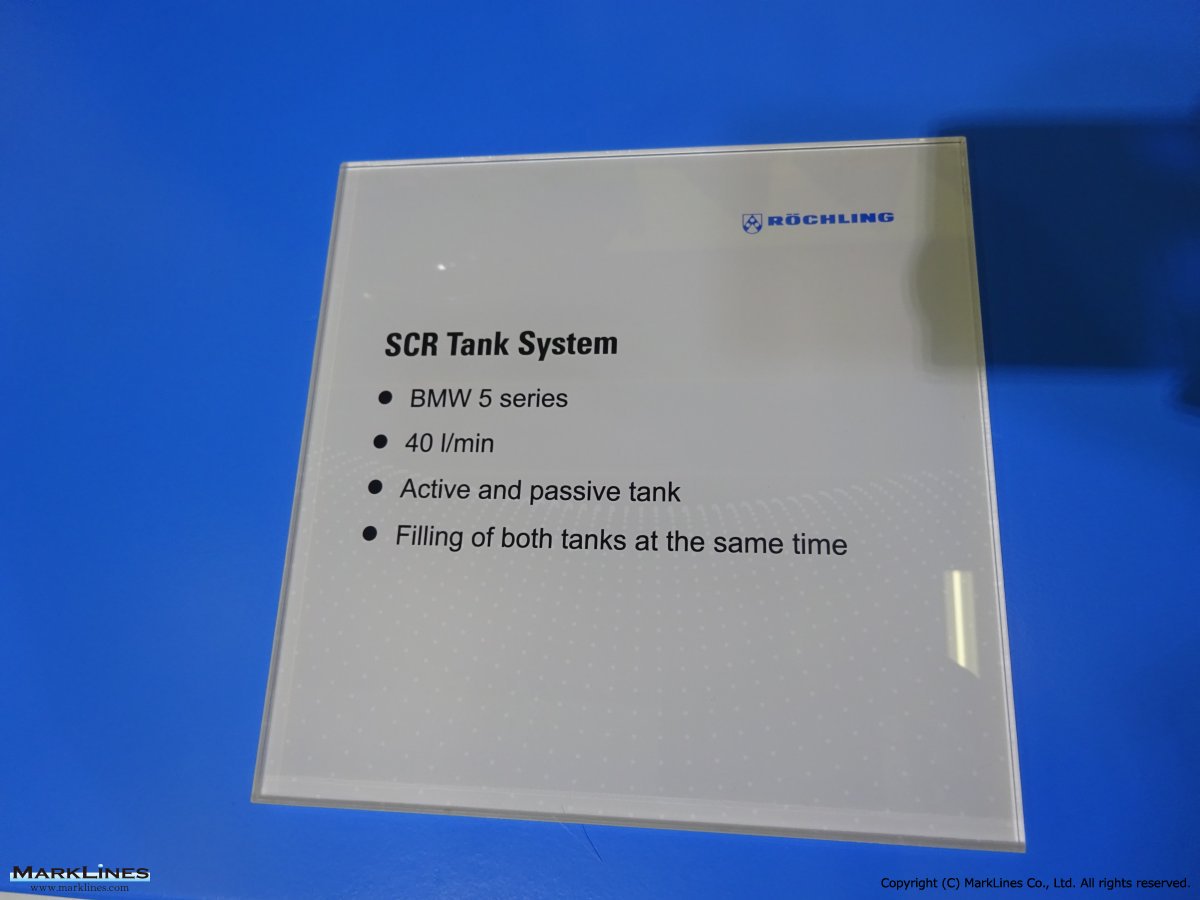

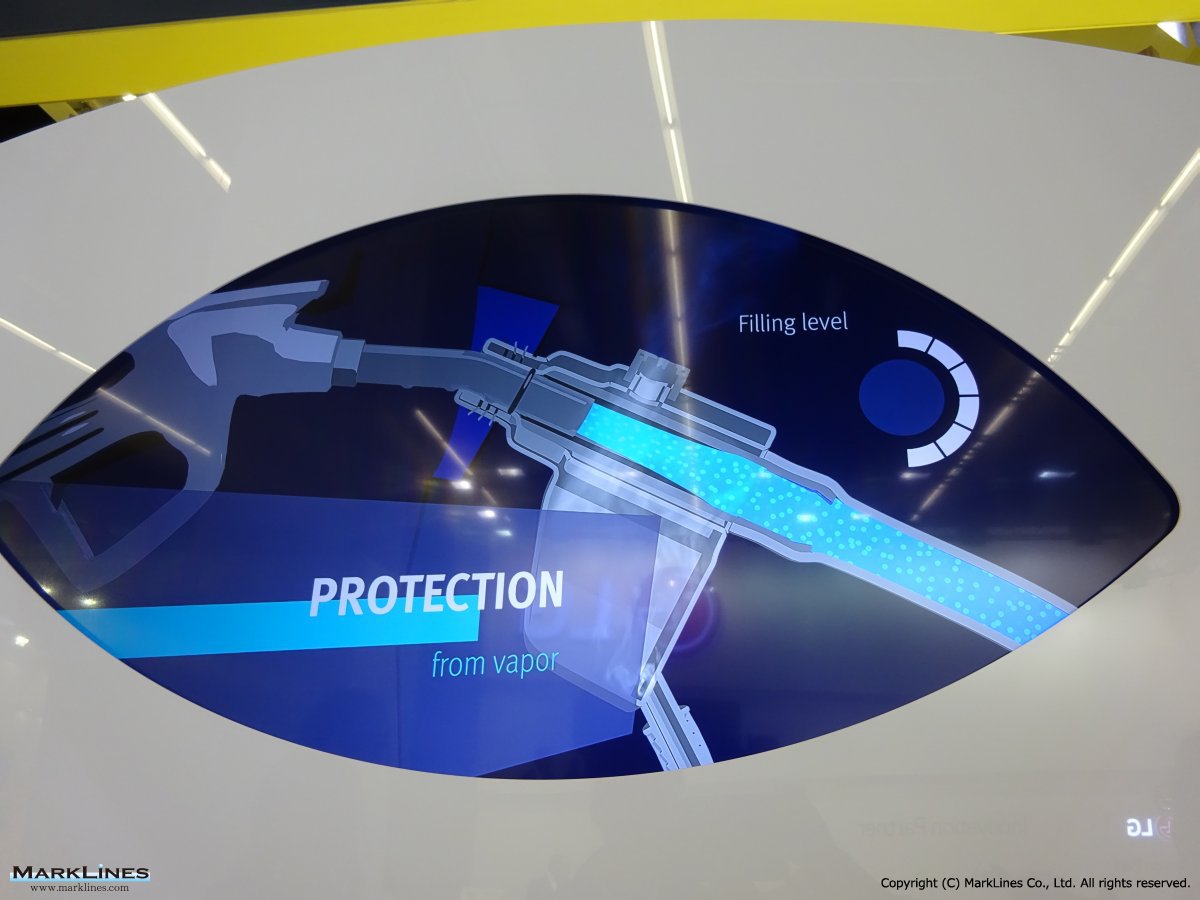

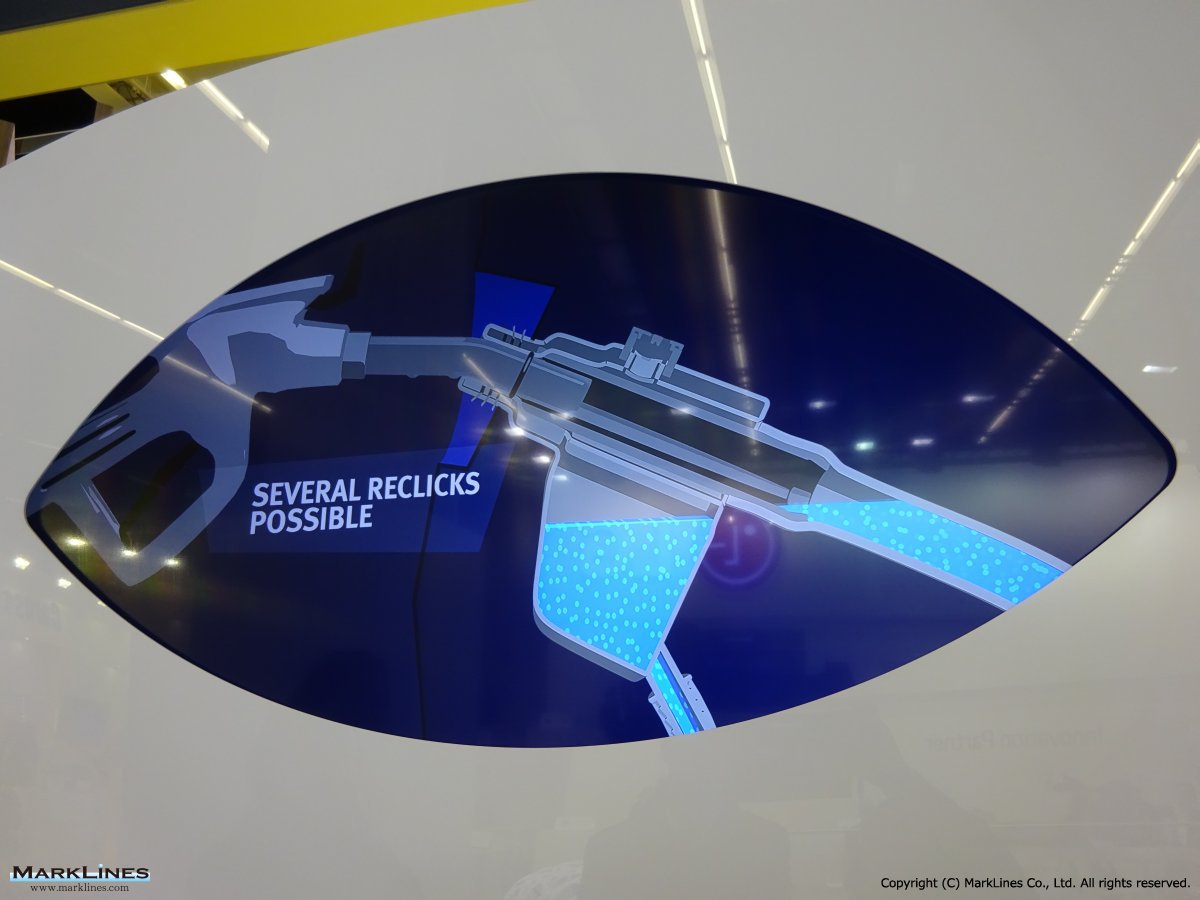

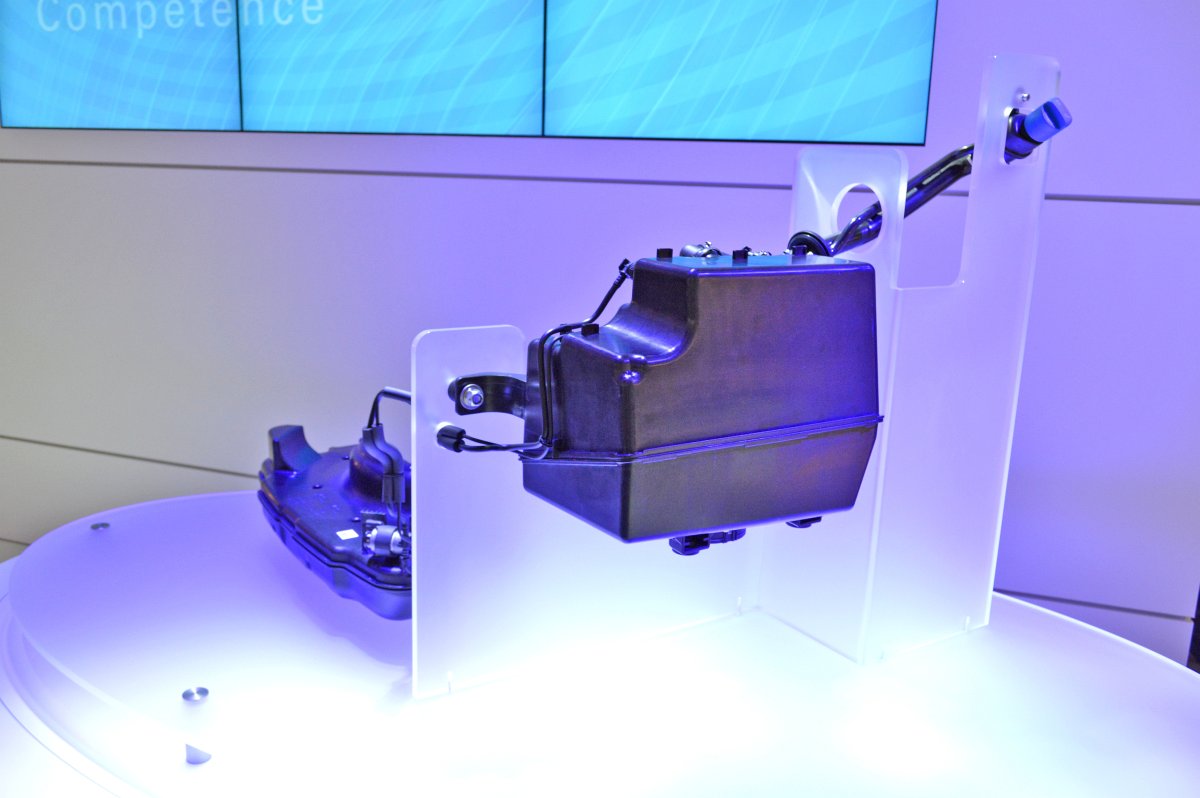

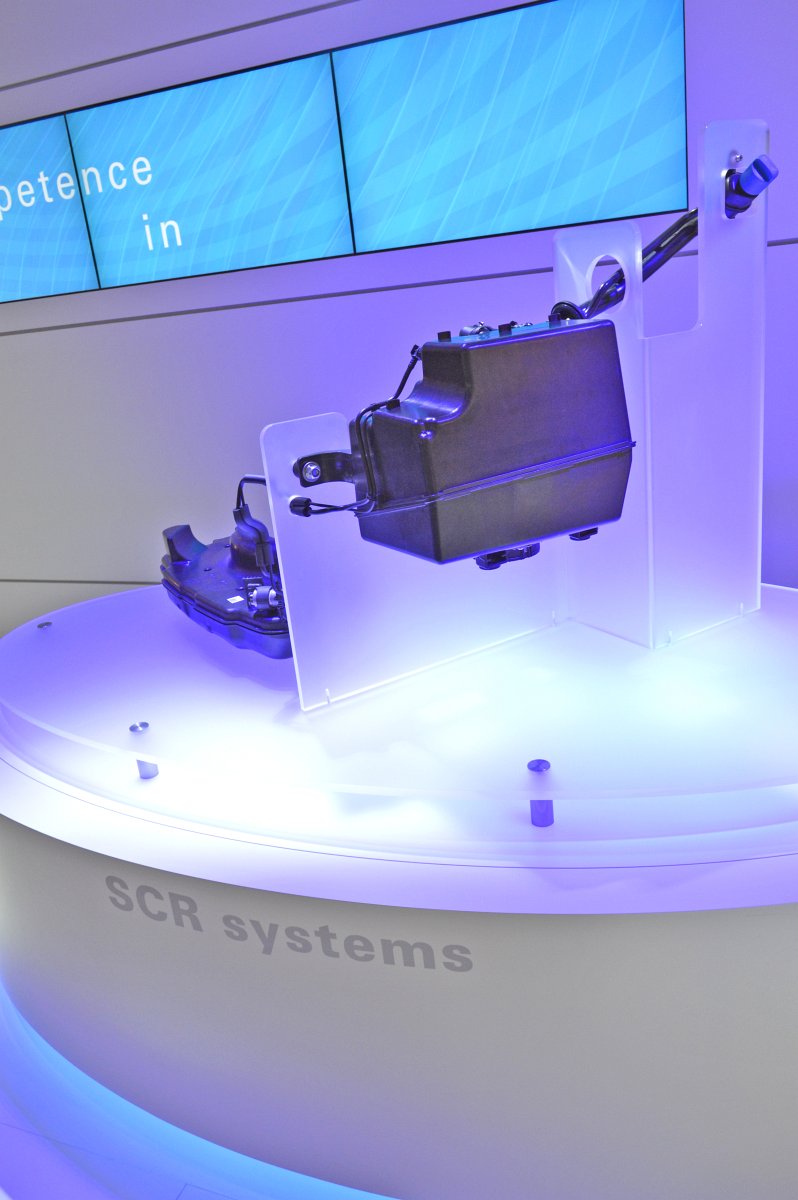

SCR systems

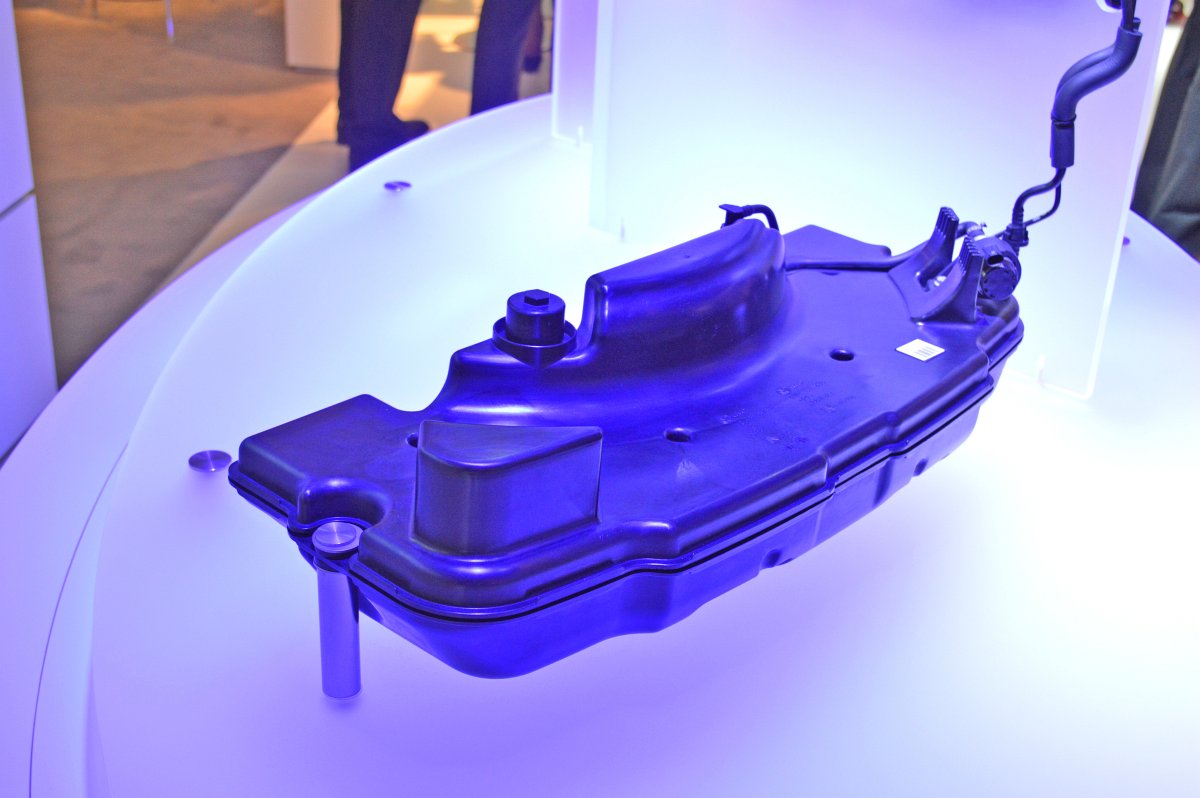

-SCR tanks with filling and degas pipe

-Secondary tanks for SCR fluid

-Complete SCR tank systems

-SCR filling heads

-SCR filling systems

Oil systems

-Oil pipes

-Hydraulic oil bottles

-Oil distribution systems

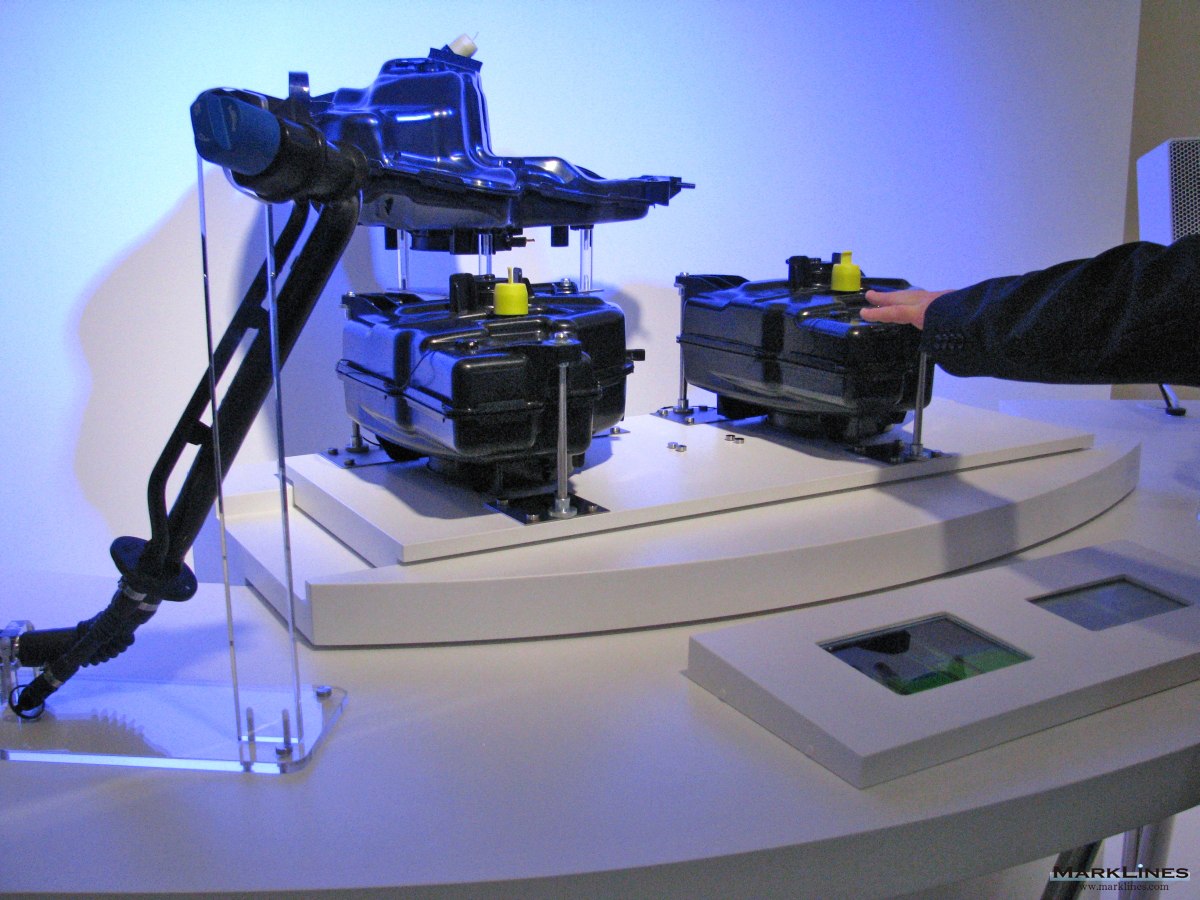

Degas bottles

-Degas bottles with level sensors

-Multi-chamber bottles for anti-corrosion

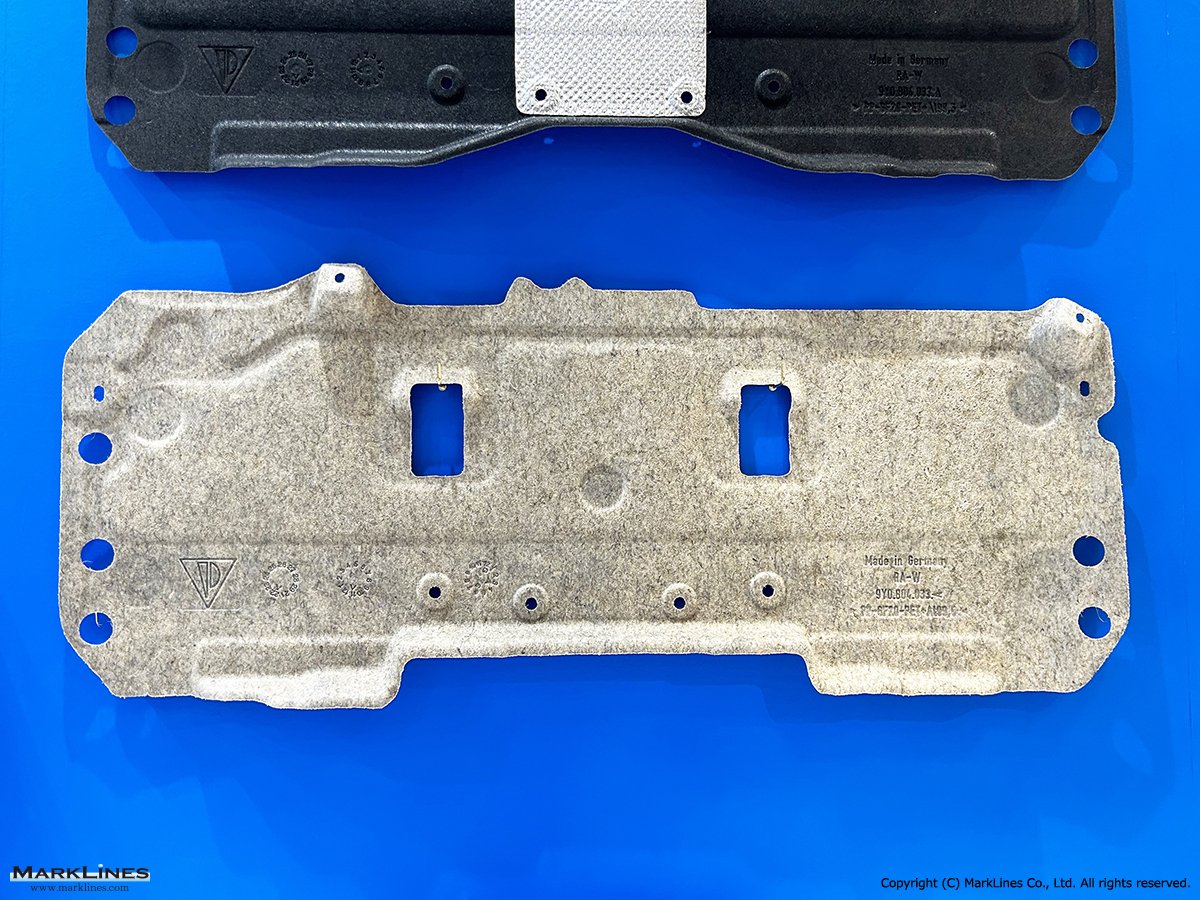

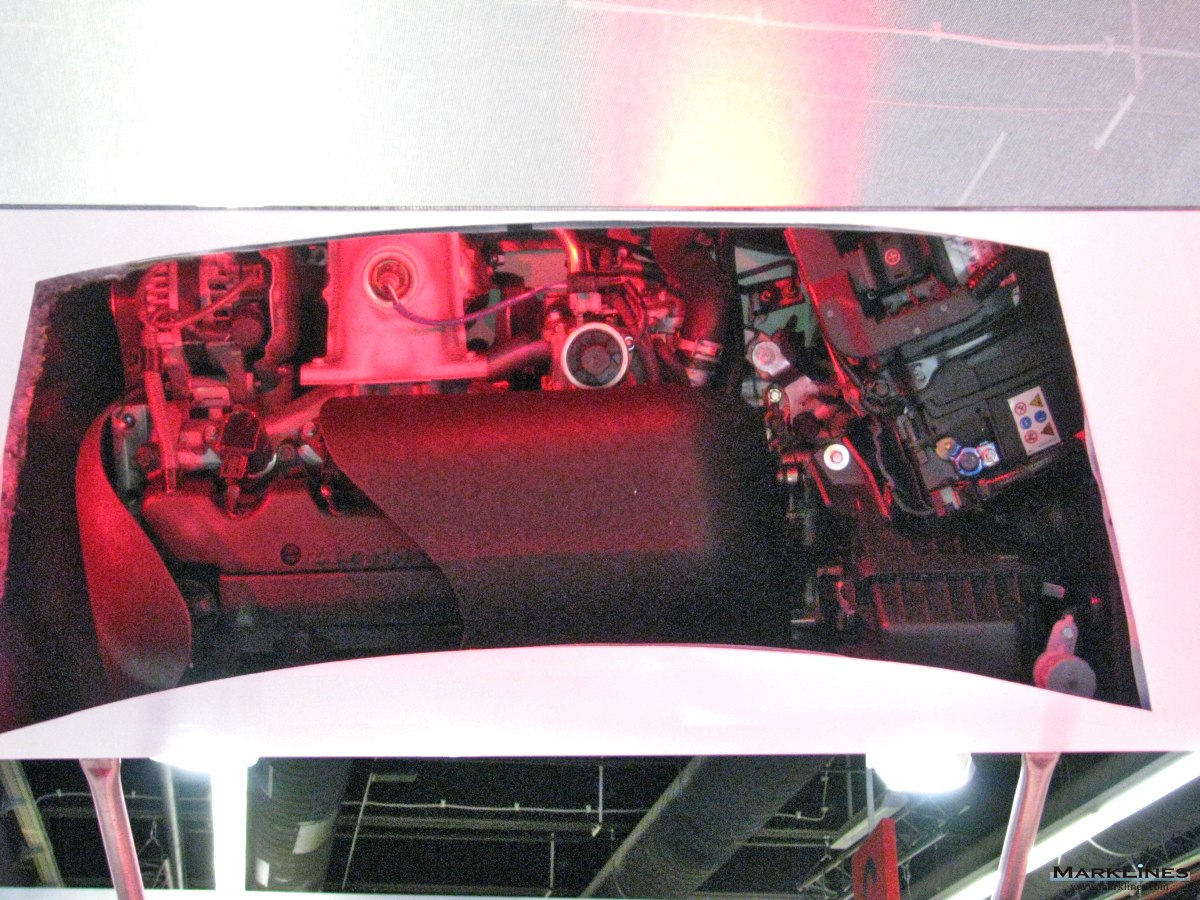

Thermal engine encapsulation

-Engine sideshields and undershields

-Engine encapsulation made from low-weight reinforced thermoplastic insulation materials

Windshield cowl covers and water drains

-Windshield cowls with soft seals

-Windshield cowls with molded grills

-Windshield cowls with metal grids

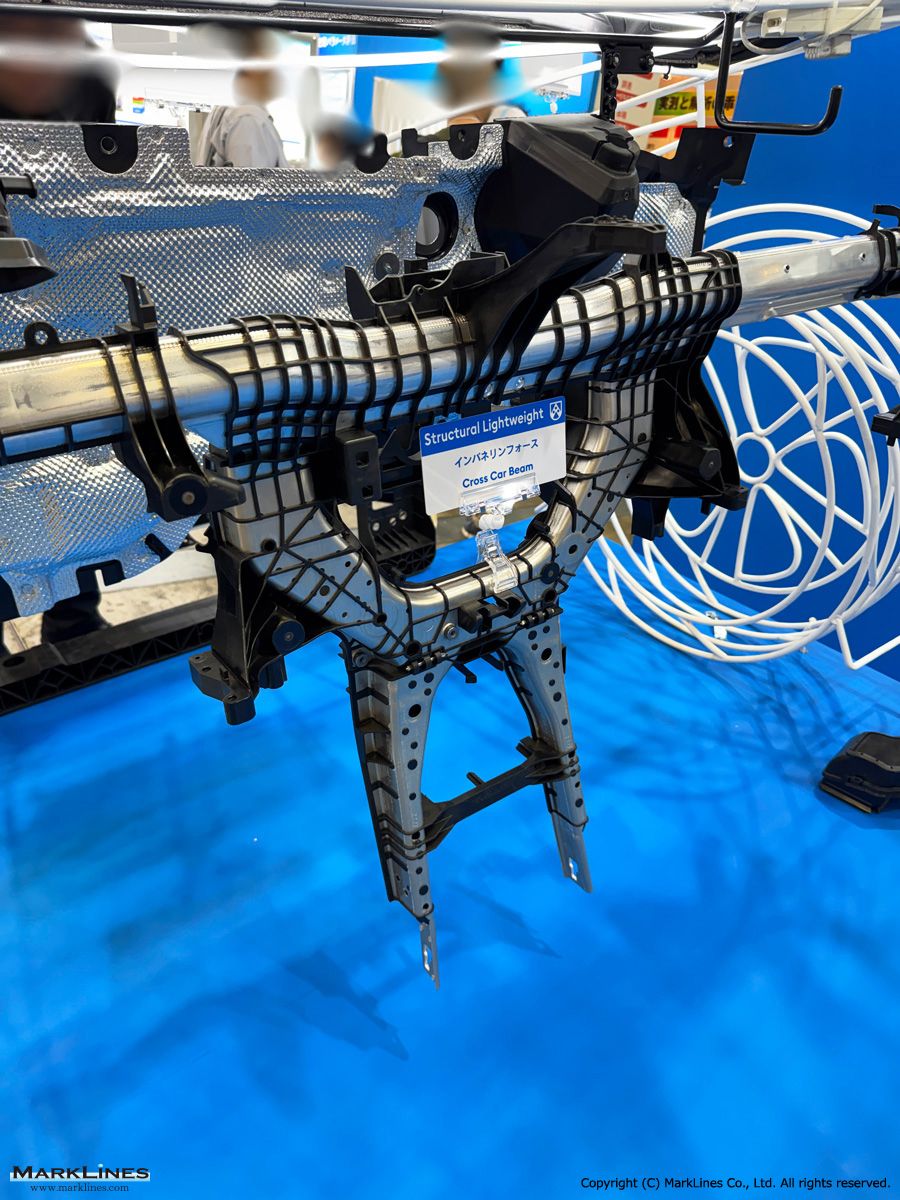

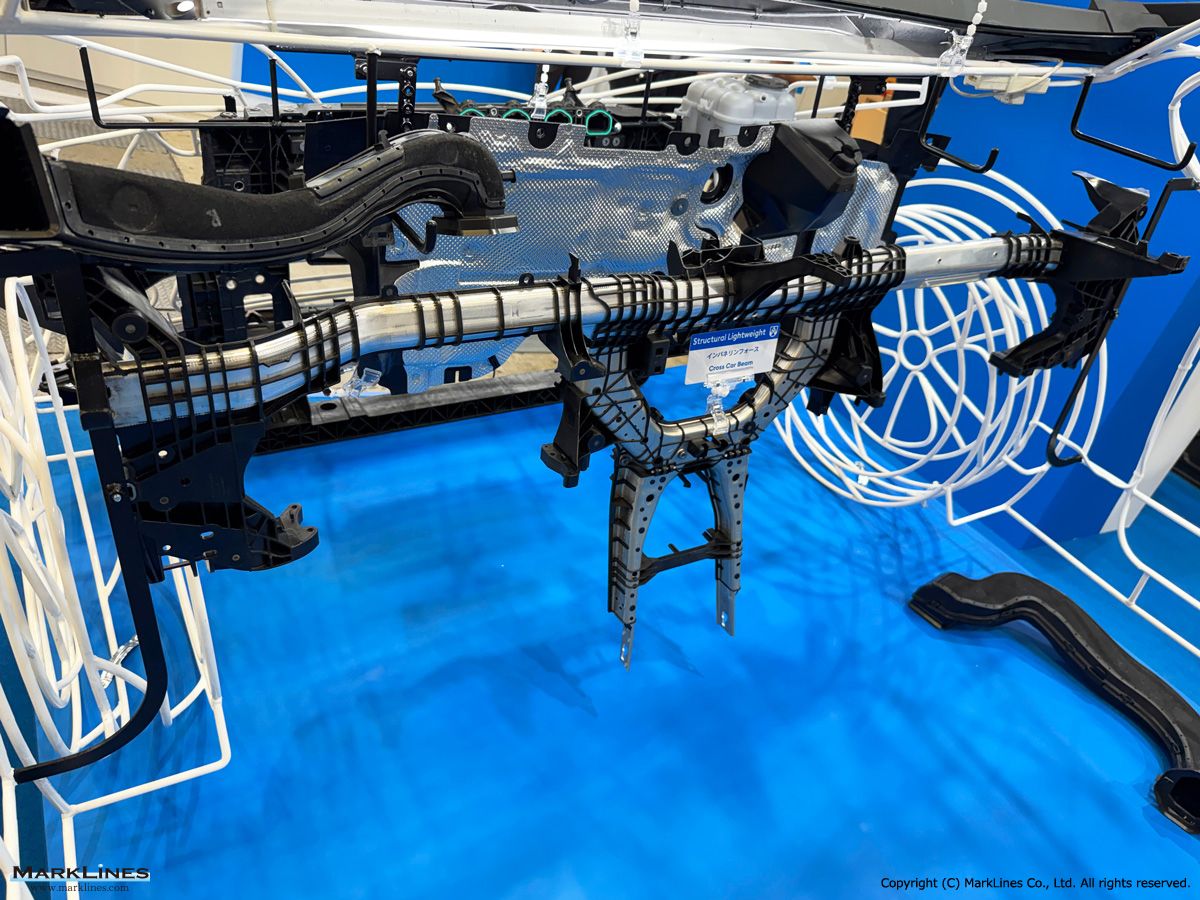

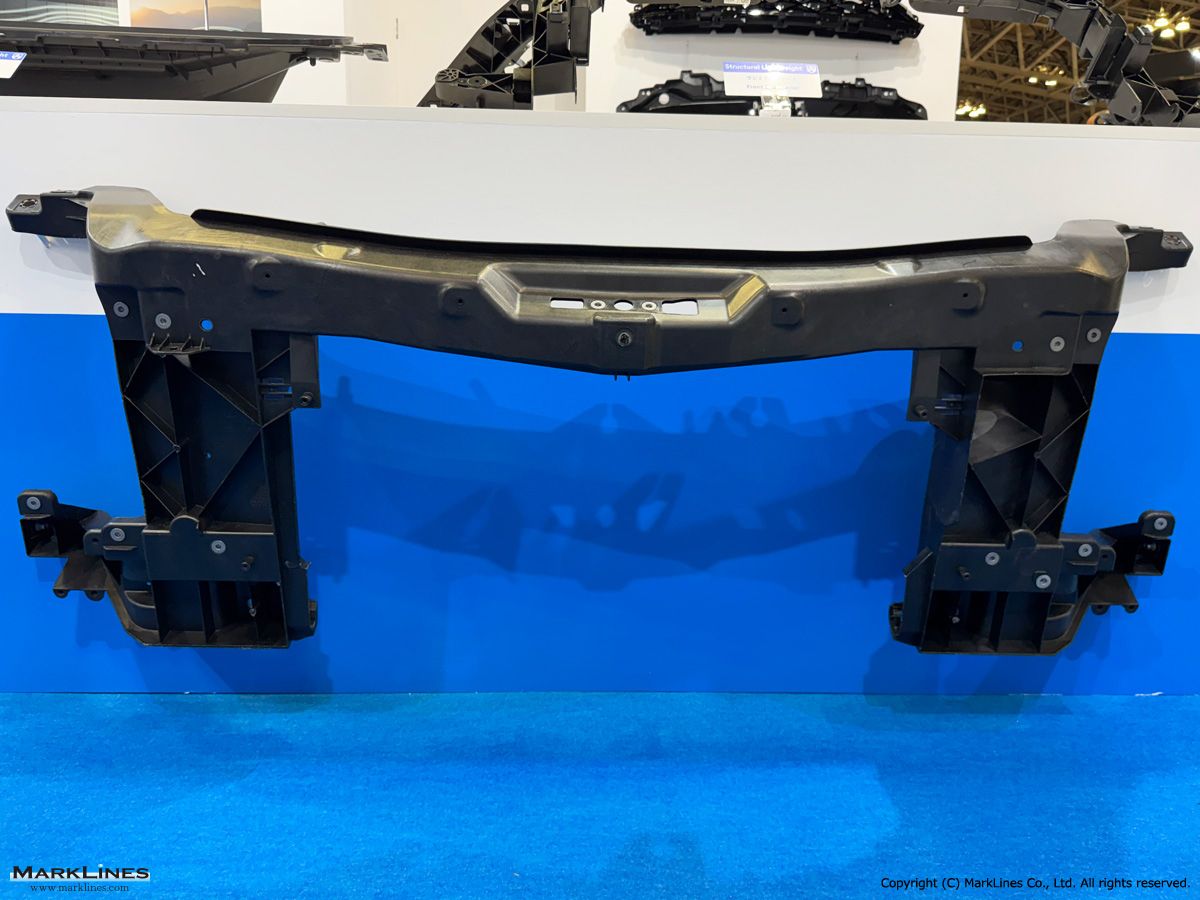

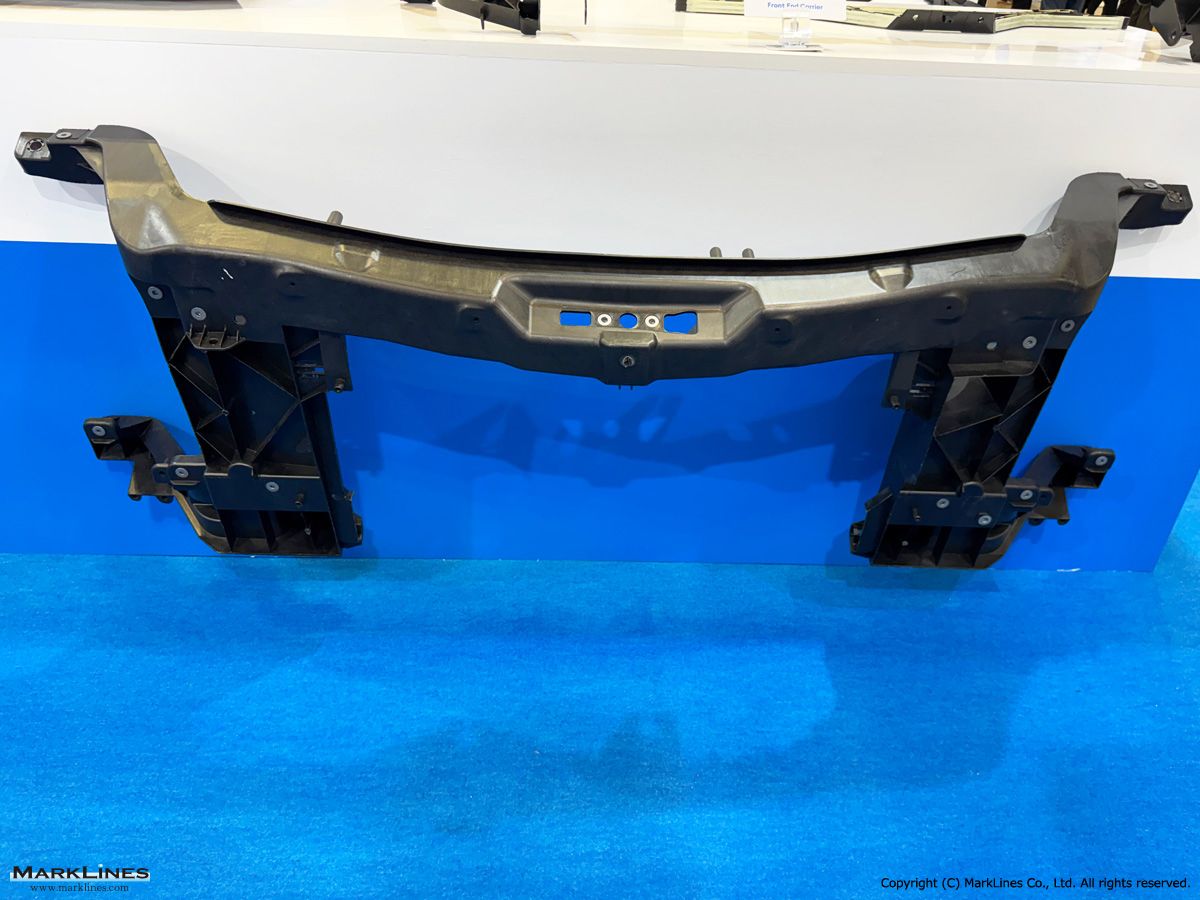

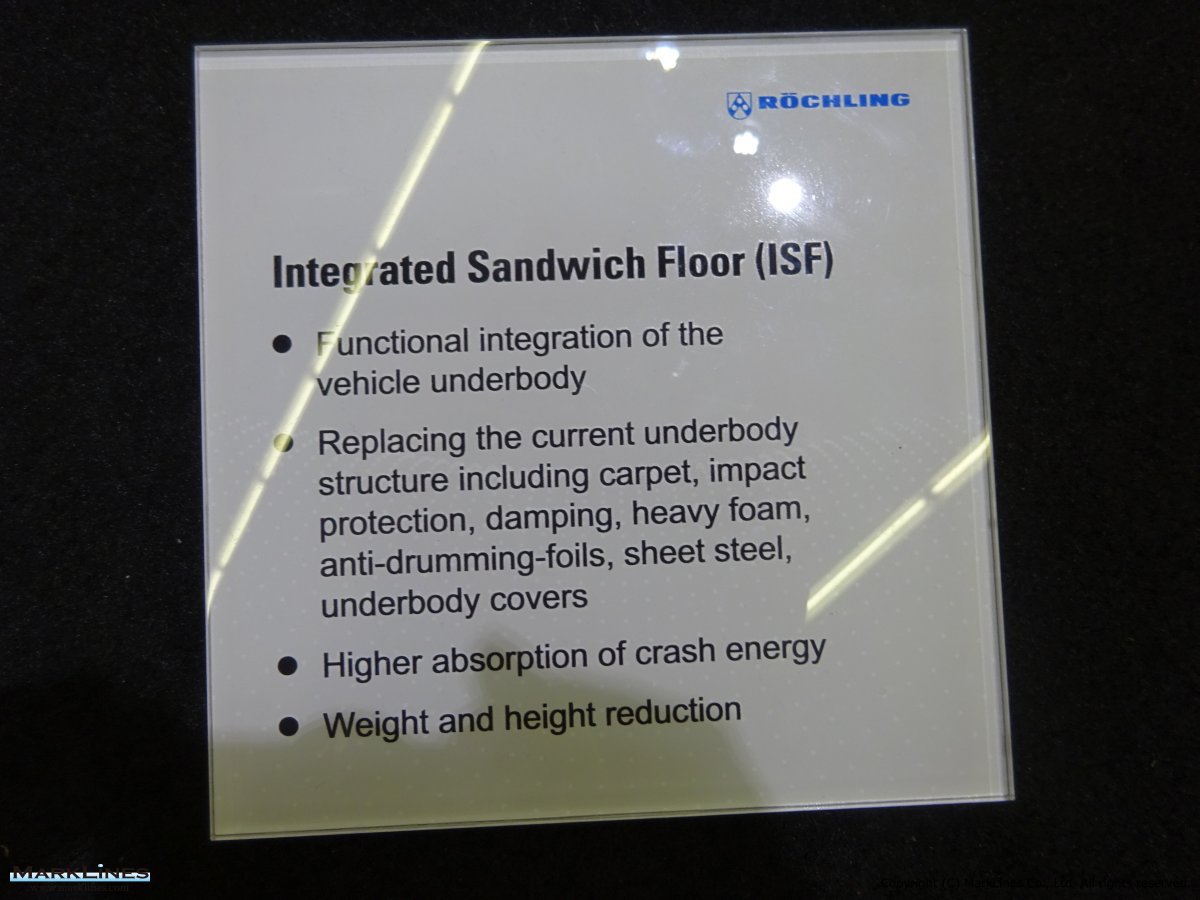

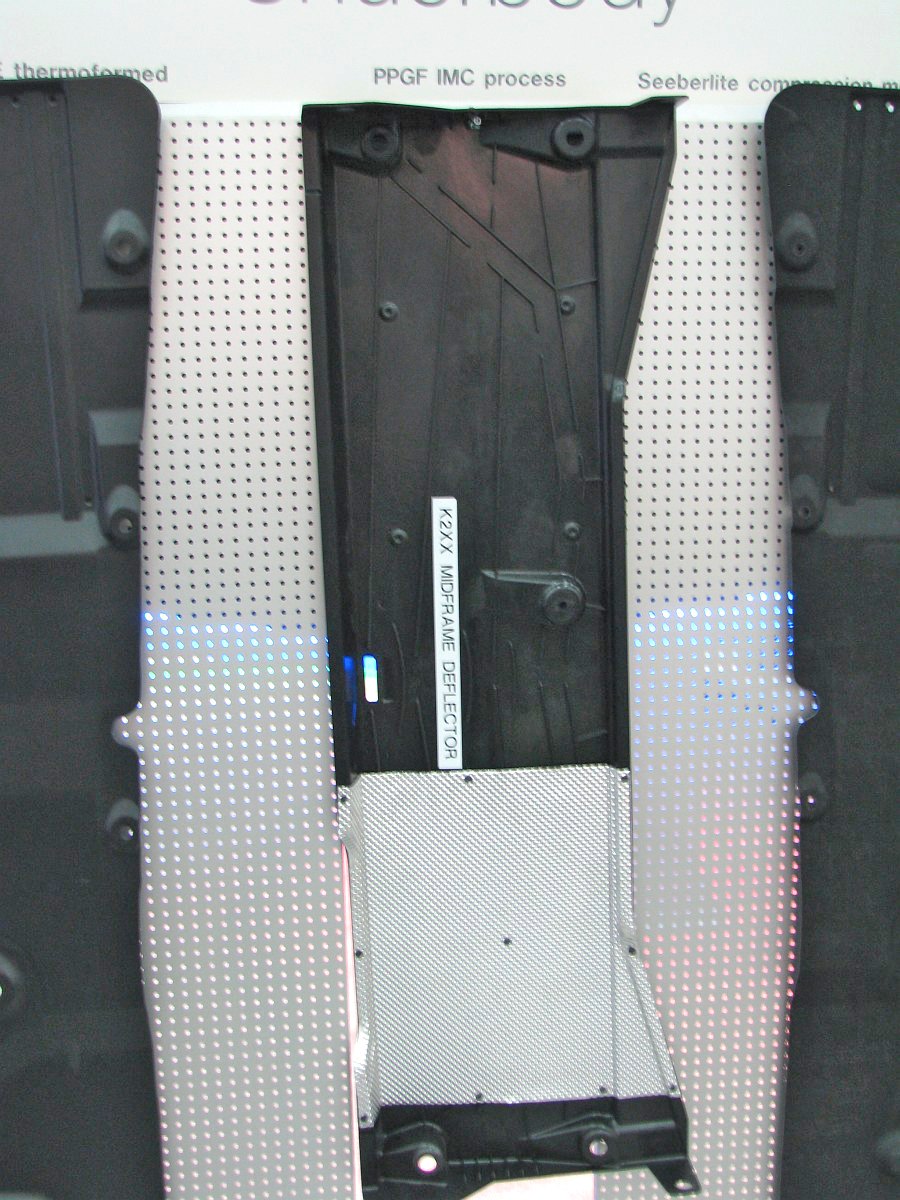

Structural lightweight systems

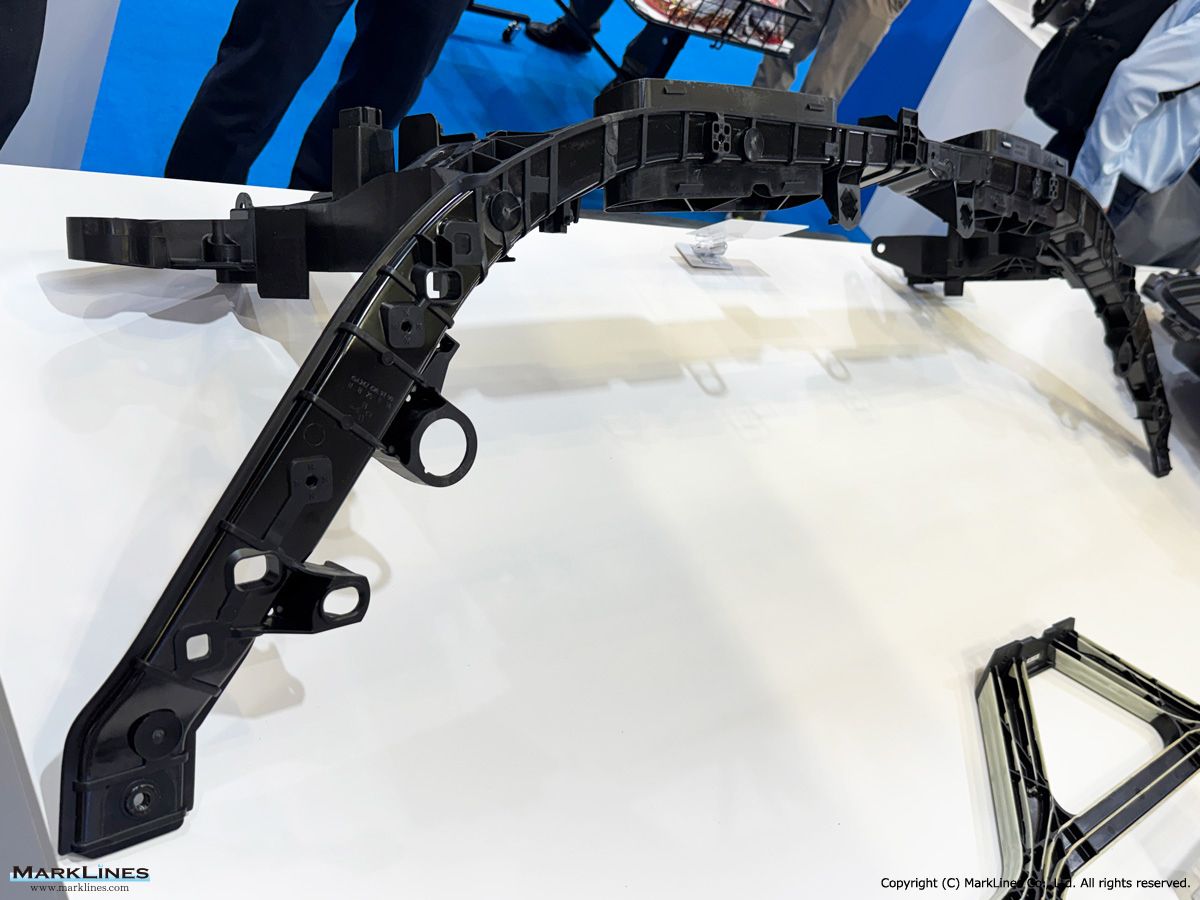

-Cross car beams

-Battery covers

-Battery enclosures

-Tubs, trunks and frunks

-Front end carriers

-Intrusion protection plates

-Door and side panels

-Suspension braces

-Spare wheel trays

-Multifunctional trays

-Battery trays

-Emergency wheel wells

-Complete body undershielding

-Rear axle covers

-Integrated underbody using lightweight, high-strength, Stratura material

History

| 1956 | Foundation of Seeber S.r.l. by Willi Seeber in Rentsch, in the Bozen area. |

| 1986 | Takeover of Seeber S.r.l. by Roechling. |

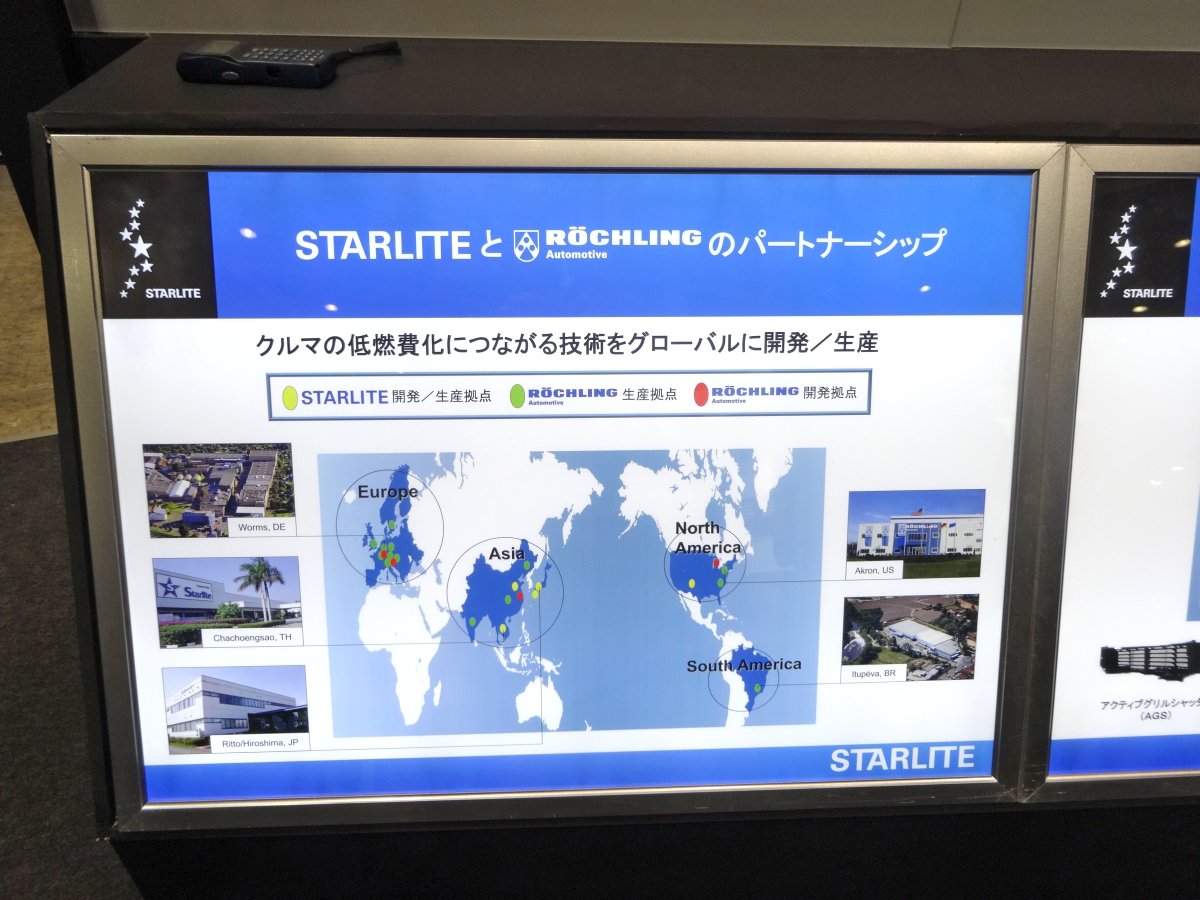

| 1992/93 | Acquisition of BASF/Elastogran Kunststofftechnik plant in Worms and Kast group by Roechling. |

| 1997/98 | Foundation of Seeber AG & Co. KG, Mannheim. |

| 2000 | Joint Venture Seeber Fastplas in Diadema (SP), Brazil. New production plant in Trento, Italy. New engineering office and production facility in Turin, Italy. |

| 2001 | Formation of 3 competence centers for the engine compartment, underbody and interior. Joint Venture in Changchun, China. Joint Venture in Araia, Spain. |

| 2003 | New production plant in Worms, Germany. New production plant in Hattorf, Germany. |

| 2004 | New production plant in Changchun, China. |

| 2005 | Added the new production plant in Changchun, China. Seeber Belgium N.V. become 100% subsidiary. |

| 2014 | New production plant in Wackersdorf. |

| 2014 | New factory in Kunshan, China put into operation. |

| 2016 | Laid the foundation stone for the new technical center in Worms, Germany. |

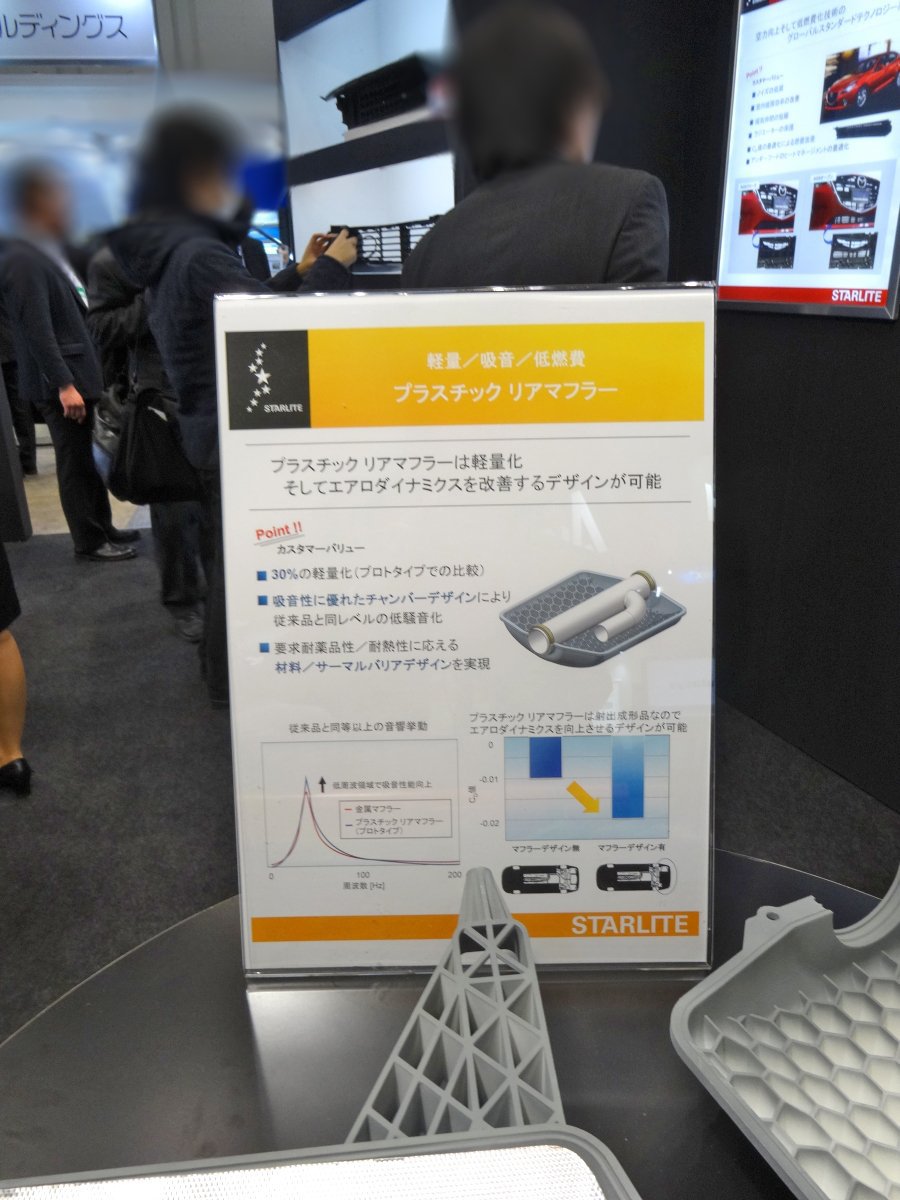

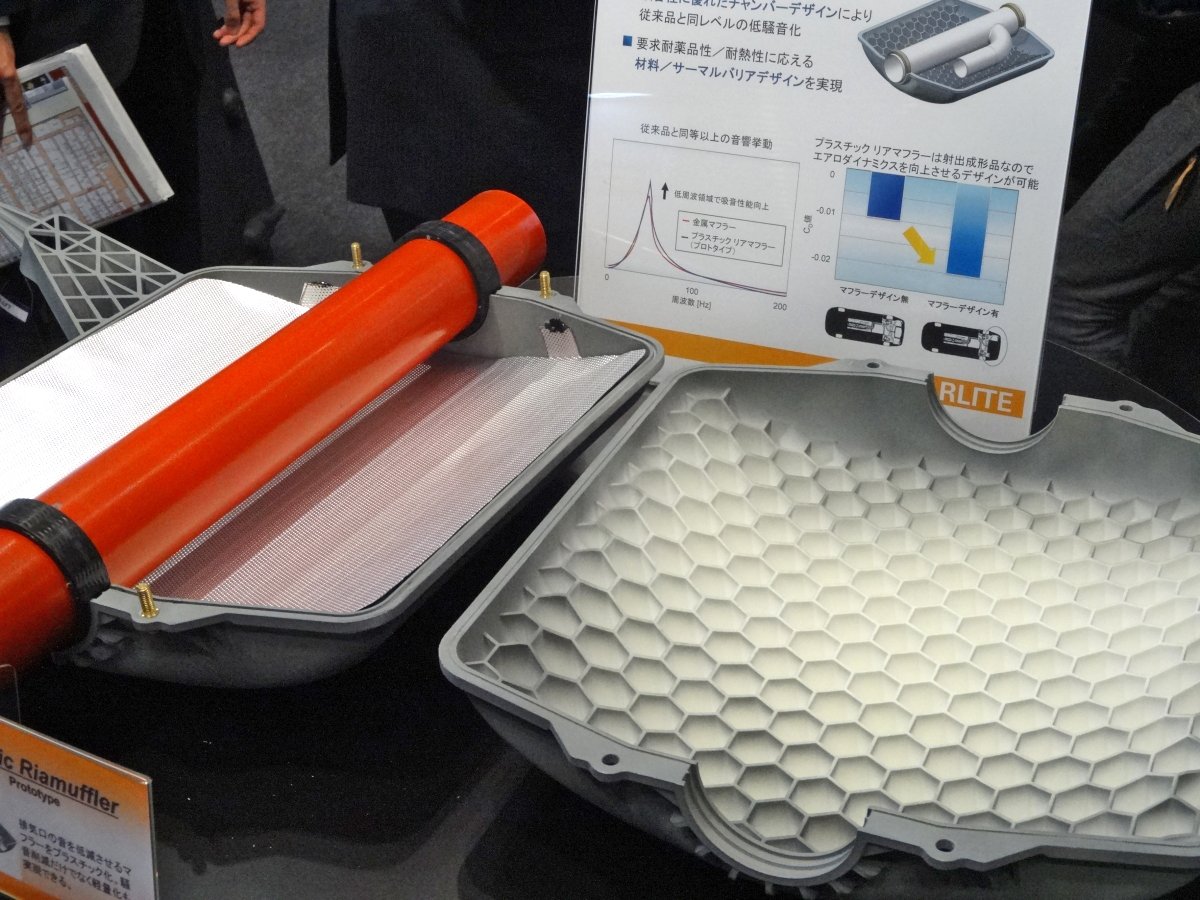

| 2016 | Establishes a joint venture in Japan. |

| Sep. 2017 | Opened its second factory in Spain. Opened a new plant in Shenyang, China with an investment of EUR 3 million. |

| May 2019 | Entered into an agreement with Kasai Kogyo Co., Ltd to sell its plant in Wolfsburg-Hattorf. |

| Jul. 2019 | Opened its new production plant in Kocovce in Slovakia. |

| May 2020 | Opened the Roechling Direct Manufacturing Center (RDMC) in Waldachtal |

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India