Continental AG Business Report FY ended Dec. 2018

Financial Overview |

(in million EUR) |

| FY ended Dec. 31, 2018 | FY ended Dec. 31, 2017 | Rate of change (%) |

Factors | |

| Overall | ||||

| Sales | 44,404.4 | 44,009.5 | 0.9 | 1) |

| EBITDA | 6,235.7 | 6,678.9 | (6.6) | - |

| Chassis & Safety | ||||

| Sales | 9,588.0 | 9,767.8 | (1.8) | 2) |

| EBITDA | 1,213.3 | 1,301.6 | (6.8) | - |

| Powertrain | ||||

| Sales | 7,741.0 | 7,660.9 | 1.0 | 3) |

| EBITDA | 574.6 | 854.8 | (32.8) | - |

| Interior | ||||

| Sales | 9,707.2 | 9,305.2 | 4.3 | 4) |

| EBITDA | 1,389.2 | 1,140.0 | 21.9 | - |

| Tires | ||||

| Sales | 11,352.2 | 11,325.8 | 0.2 | 5) |

| EBITDA | 2,495.2 | 2,748.7 | (9.2) | - |

| ContiTech | ||||

| Sales | 6,344.7 | 6,246.4 | 1.6 | 6) |

| EBITDA | 701.4 | 750.9 | (6.6) | - |

Factors

1) Net Sales

-The Company’s net sales for the fiscal year ended December 31, 2018 increased by 0.9% over the previous year to EUR 44,404.4 million. Excluding changes in the Company’s scope of consolidation or currency exchange effects, sales increased by 3.1% over the previous year. The increase in sales was caused by improved performance in both the Automotive Group and Rubber Group. Of the Company’s operating regions, its sales increased the most in Asia, specifically Japan. Changes in the Company’s scope of consolidation also contributed to the increased in sales. However, this increase was more than offset by negative currency translation effects.

2) Chassis & Safety sales

-The Chassis & Safety division had sales of EUR 9,588.0 million in the fiscal year ended December 31, 2018, a decrease of 1.8% from the previous year. Sales volumes of electronic brake systems in the Vehicle Dynamics business unit decreased by 1.8% from the previous year. Brake booster sales volumes decreased by 2.2% from the previous year. While sales volumes of conventional brake calipers decreased by 13%, volumes of brake calipers with integrated electric parking brakes increased by 17%, offset that decrease. Air-bag control unit sales decreased by 4% while sales of advanced driver assistance systems increased by 31%. Organic sales in the Chassis & Safety division increased by 0.5% prior to changes in consolidation scope and currency translation effects.

3) Powertrain sales

-Sales for the Company’s Powertrain division increased by 1.0% to EUR 7,741.0 million during the fiscal year ended December 31, 2018. Sales volumes of engine control units, injectors, pumps and turbochargers increased over the previous year. The division’s Hybrid Electric Vehicles business unit began deliveries of 48 volt drive systems during the fiscal year. Sales of power electronics increased over the previous year, while sales of battery systems and on-board power supply systems decreased. For the Fuel & Exhaust Management business unit, sales of ECUs for fuel delivery modules, catalytic converters and SCR systems increased over the previous year, while sales of fuel delivery modules decreased. Excluding the changes in consolidation scope and currency translation effects, sales increased by 2.9% over the previous year.

4) Interior sales

-In the fiscal year ended December 31, 2018, the Interior division had sales of EUR 9,707.2 million, an increase of 4.3% over the previous year. Sales volumes of multimedia and connectivity products increased significantly compared to the previous year while sales of audio products decreased. Growing demand in replacement parts contributed to growth in the Commercial Vehicles & Aftermarket business unit. In the Instrumentation & Driver HMI business unit, sales volumes increased due to increased sales from European and Chinese automakers for instrument clusters and display systems. Sales in the division increased by 6.3% excluding the effects of changes in consolidation scope and currency translation.

5) Tires sales

-The Company’s Tire division’s sales in the fiscal year ended December 31, 2018 were EUR 11,352.2 million, an increase of 0.2% from the previous year. Sales of original equipment tires for passenger vehicles and light trucks decreased slightly compared to the previous year, but increased by approximately 1% in the replacement tire business. Sales of commercial vehicle tires increased by 5% over the previous year. Excluding changes in the division’s scope of consolidation and currency translation effects, sales in the Tire division increased by 3.1%.

6) ContiTech sales

-Sales for the ContiTech division increased by 1.6% over the previous year to total EUR 6,344.7 million in the fiscal year ended December 31, 2018. The division’s strength was driven by increased sales in the industrial segment, particularly in the Conveyor Belt Group and Industrial Fluid Solutions business units. Sales for automotive replacement parts also increased, while sales for automotive original equipment remained level. The division’s sales, excluding changes in scope and currency translation effects increased by 3.2%.

Acquisitions

-The Company reached an agreement with Cooper Standard, on the purchase of its anti-vibration systems business. With the acquisition, the Company is expanding its global presence for anti-vibration and noise reduction technology, particularly in North America, where Cooper Standard has extensive anti-vibration systems expertise. The agreement includes a binding offer from the Company to purchase substantially all of Cooper Standard’s anti-vibration business in France and its respective interest in a joint venture in India. The anti-vibration systems business of Cooper Standard includes five manufacturing facilities, and R&D capabilities in Canada, France, India and the U.S. (From a press release on November 2, 2018)

-The Company announced that it is acquiring Kathrein Automotive, a leading specialist and manufacturer of vehicle antennas. Following antitrust approval, Kathrein Automotive and its entire workforce are expected to become part of the Company in the first quarter of 2019. Kathrein Automotive has over 1,000 employees across eight locations in Brazil, China, Germany, Mexico, Portugal, and the U.S. The two parties have agreed not to disclose the purchase price. The acquisition follows a successful and long-standing relationship between Kathrein Automotive and the Company. (From a press release on October 29, 2018)

-The Company has acquired the Czech machine tool manufacturer VUK. The acquisition of VUK strengthens the Company’s presence in the city of Otrokovice, Czech Republic, which is also the home to its largest tire plant worldwide. Together with the new unit, the Company will be driving forward the development and production of tire assembly machines on the newest technological standards. The Company acquired 100% of the shares in VUK, an essential supplier of components for tire assembly machines. (From a press release on July 9, 2018)

-HERE Technologies announced that Bosch and the Company have signed a definitive agreement to acquire an indirect ownership stake in HERE Technologies from its indirect shareholders Audi AG, BMW Group, and Daimler. Both Bosch and the Company are acquiring a 5% indirect ownership stake in HERE Technologies. The acquisition gives a boost to Bosch's services business. It also helps HERE advance its goal of becoming a global provider of data-based real-time location services to customers. In addition, the Company will sign a collaboration agreement with HERE. This new collaboration will leverage the both companies’ complementary technologies, including the Company’s experience from its Intelligent Transportation Systems business unit in mobility services, cyber security and embedded systems capabilities and HERE's expertise in high-resolution digital mapping, software and cloud services. (From a press release on January 4, 2018)

Restructuring

-The Company’s subsidiary, Continental Automotive Japan K.K., announced that it will split its powertrain business on January 1, 2019. The powertrain business will be transferred to a newly established company, CPT Japan. This transfer is tied to the Company’s plan to separate its powertrain division announced in July. CPT Japan will research, develop, and produce hybrid systems, electrical drive systems, batteries, and engine parts. (From an article in the Nikkan Jidosha Shimbun on December 20, 2018)

-The Company’s Executive Board decided to undertake one of the largest organizational realignments in its history. The decision involves the creation of a holding structure of the Company under the new Continental Group umbrella brand. This holding structure will be supported by three strong business sectors: Continental Rubber, Continental Automotive and Powertrain. The reporting structure and the new names will be used starting in 2020. The current Chassis & Safety and Interior divisions will be reorganized by the beginning of 2020. They will become two business areas named Autonomous Driving Technologies and Vehicle Networking Technologies, with their business results being reported in the new Continental Automotive group sector. The Tires division, which will be renamed Tire Technologies, and ContiTech will retain their independent organizational structure. Their business results will be reported in the future Continental Rubber group sector. The Powertrain division will be transformed into an independent legal entity with a new name at the beginning of 2019. Powertrain will continue to be in charge of all future business involving hybrid and electric drive systems and all current battery activities, in addition to the combustion engine business. (From a press release on July 18, 2018)

-On April 18, 2018, the Company’s ContiTech AG Shanghai Office was officially converted to ContiTech’s headquarters in China. The ContiTech Shanghai Office will become a holding company of the ContiTech business group’s companies in China, allocate resources in cooperation with its 12 plants in China, and be responsible for ContiTech's construction investment and business development strategy in China. (From a press release on April 19, 2018)

Joint Ventures

-Osram and the Company have successfully concluded their negotiations on the Osram Continental GmbH joint venture. The joint venture, in which each of the partners has a 50% stake, aims to combine the Company’s and Osram’s respective expertise in lighting, light control and electronics. The joint venture scheduled to begin operations in the second half of 2018. The joint venture will be based within the region of Munich but will operate globally to ensure rapid development cycles with customers in their local areas. The product portfolio will feature semiconductor-based lighting modules such as LED modules for front and rear headlights, laser modules and light control units. (From a press release on April 3, 2018)

-Osram Continental GmbH, a 50:50 joint venture set up by the Company and Osram, has successfully launched. Osram Continental will initially employ around 1,500 people at 16 locations worldwide, basing its headquarters in Munich, Germany. The headquarters will eventually move to Garching, Germany. The joint venture aims to generate annual sales in the mid-triple-digit-million-euro range. Osram Continental is aiming towards annual double-digit growth rates over the next five years. This is based on strong growth in the market for LED and laser-based lighting modules and solutions and associated electronics. The first products developed by the joint venture are expected to be ready for series production by 2021. (From a press release on July 3, 2018)

-The Company and Chinese automotive supplier and battery manufacturer CITC (Sichuan Chengfei Integration Technology) announced a joint venture for the development and production of 48-volt battery systems for the automotive industry. The Company will hold 60% while CITC holds 40% of the joint venture’s shares. The joint venture will operate globally and supply customers in Europe, North America, China and other Asian markets. The planned location of the joint venture’s headquarters is Changzhou, near Shanghai, with operations expected to begin in the middle of 2018. The new joint venture will develop and produce a battery platform for all conventional 48-volt topologies (P0, P2, Px) up to 25kW. The battery cells will be provided by CITC's subsidiary CALB, while the Company’s contribution comes in the form of the battery management system. (From a press release on March 7, 2018)

Recent Developments

-The Company recently inaugurated its Continental Training Center (CTC), located in its San Luis Potosi plant, having invested USD 600,000 into the center. This campus is designed to develop specific technical skills, including pneumatics, electronics, hydraulics, robotics and automation. The CTC is approximately 280 square meters and is equipped with a management simulation system, pneumatic simulators, numerical control simulators, robots, control cabinets, training rooms, and collaboration spaces that focus on quality issues and staff development. (From Mexico-Now article on December 3, 2018)

-The Company is beginning construction of its new headquarters in Hanover. The first development phase for the building complex will be completed by the end of 2020 and provide space for 1,250 employees. According to the plans, a future expansion to accommodate 1,600 employees is possible. Relocation of the employees should be completed in 2021, in time for the Company's 150th anniversary. The new headquarters will consist of a total of eight buildings, which will be connected to each other by four bridges. (From a press release on July 31, 2018)

-Continental Automotive Japan K.K., a subsidiary of the Company, held a press conference at its head office, where President Bert Wolfram indicated the its plans to strengthen the Japanese unit's structure with an objective to achieve sales of JPY 540 billion or higher in 2019 from its operations targeting Japanese OEMs. The 2019 target is an increase of more than 30% from the 2016 level. At present, the Japanese unit employs 1,600 people. The supplier will increase the number of personnel in charge of business targeting Japanese OEMs by 150 to 200 each year through new hires or redeploying personnel within the Company over several years in an effort to expand operations. The Company will also boost investment to expand its operations. (From an article in the Nikkan Jidosha Shimbun on May 15, 2018)

-The Company will start production of ABS brakes with electronic stability control (ESC) in Brazil in the first quarter of 2019. The component will be manufactured at the Varzea Paulista facility and initially supplied to one of the four major automakers in Brazil. Local production of the component fulfills legislation requiring that, all new cars and commercial vehicles up to 3,500 pounds built in Brazil be equipped with ESC starting in 2020. By 2022, all vehicles up to 3,500 pounds operating on the roads in Brazil will need to be equipped with ESC. (From multiple sources on May 8, 2018)

Business Partnership

-The Company and Turo announced a collaboration to bring instant mobility to users through the new application, Turo Go. This feature will provide a seamless car booking experience to users that don’t always have time to deliver keys in person. Turo Go will be launched in Los Angeles during the LA Auto Show and expand to new markets in future months. The Company’s Key as a Service (KaaS) aftermarket solution offers a seamless user experience for secure vehicle access, start authorization and accurate car data. KaaS is also offered as a solution which is already embedded into the vehicle's architecture. (From a press release on November 27, 2018)

-The Company and Knorr-Bremse have entered into a partnership to develop a complete system solution for highly automated driving in commercial vehicles. The system includes environment recognition, driving planning and decision-making capabilities, control of the actuator systems in the vehicle such as steering and brakes, and human-machine interfaces. The cooperation will initially involve automated convoy driving through platooning. Later development work will deal with automated driving on the freeway in a Highway Pilot system. Knorr-Bremse will offer the complete system to commercial vehicle manufacturers in Europe, North America and Asia. At the beginning of 2019, a joint platooning demonstrator, consisting of a convoy of three coupled trucks from different manufacturers, will demonstrate its capabilities to selected customers. (From a press release on September 19, 2018)

-The Company’s Continental Korea subsidiary signed a memorandum of understanding with a Korean in-vehicle infotainment manufacturer, Motrex Co., Ltd., regarding a plan to jointly develop electric components. The two companies are planning to make automotive intelligent key cards with push buttons, smart key system solutions, and digital clusters. (From some releases on May 23, 2018)

Contracts

-Sono Motors, a German mobility provider, announced that it was entering into a contract with the Company. The Company’s Powertrain Division will build the electric drive unit for the Sion, the first series-produced e-vehicle with integrated solar cells. Beyond the engine, the Sion’s drive unit consists of power electronics and the transmission. The integration into a single system unit reduces the size and weight of the drive system, thereby boosting the vehicle’s performance. The drive system, which has already been validated, can be incorporated into the Sion without the need for any additional significant development work. (From a press release on November 22, 2018)

-The Company’s subsidiary, Elektrobit, will now offer Classic and Adaptive AUTOSAR-compliant software specifically developed for NXP Semiconductors’ scalable S32 Automotive Processing Platform. By utilizing tailored software tools for the S32 platform in combination with S32 Virtual Development Kits, automakers can develop future automotive applications like those needed for connected and highly automated driving more quickly and efficiently. (From a press release on November 13, 2018)

-The Company has developed a power electronics system solution for Jaguar Land Rover that is specifically adapted to the requirements of sporty, performance-oriented powertrains. This innovative power electronics solution, which first went into production in the Range Rover Sport Plug-in Hybrid, is designed for application across the entire future EV line-up of the two British premium brands. The power electronics converts the AC current produced by the electric motor into DC current, which is then used to charge the battery. The IGBT (insulated gate bipolar transistor) power modules help in enabling the system to achieve such an excellent combination of performance, long life and compact dimensions. The Company is the first to use this technology in an automotive electronics application. (From a press release on October 22, 2018)

-The Company announced that its PremiumContact6 sporty comfort tire has been adopted as original equipment for the all-new Volvo V60. (From an article in the Nikkan Jidosha Shimbun on October 10, 2018)

-The Company’s subsidiary, Continental Tire Japan Co., Ltd. announced that its ContiSportContact 5 tires have been selected as original equipment for Volkswagen’s all-new Polo GTI. The tire is a premium sport tire featuring excellent stability while cornering, grip performance, and handling performance. The tire size is 225/45R17 91W XL. (From an article in the Nikkan Jidosha Shimbun on August 20, 2018)

-The Company announced that its ContiSportContact 5 tires have been adopted as original equipment for Nissan's new Leaf Nismo. The size of the tire adopted for the new model is 225/45R18 95Y XL. (From an article in the Nikkan Jidosha Shimbun on August 9, 2018)

-The Company’s 48-volt belt starter generator with integrated power electronics is standard on the new Audi A8. It has a continuous power rating in generator mode of up to 5 kW, with peak output of up to 15 kW for short periods. The combination of zero-emission coasting, earlier engine shutdown by the stop-start system and improved braking energy recuperation results in fuel savings of up to 0.7 L/100 km. (From a press release on January 15, 2018)

Awards

-The Company’s intelligent door system has been recognized as a CES 2019 Innovation Award honoree in the Vehicle Intelligence and Self-Driving Technology category. With the power door control function, Continental supports autonomous opening and closing of vehicle doors and avoids crushing fingers, hands or belongings with its anti-pinch protection system. The smart autonomous door continuously communicates with the integrated static obstacle detection system. If the sensors detect an obstacle while the door is opening, then the door stops. The continuously variable gap angle provides other benefits. The intelligent door supports smooth opening in any position without locking into place. Despite this, the door can be securely stopped by the control system in any position. (From a press release on December 5, 2018)

-The Company won a 2018 Automotive News PACE Award for its Digital Micromirror Head-Up Display technology. Audi and the Company were also presented with an Innovation Partnership Award for the Safety Domain Control Unit. The recognition marks the 10th PACE Award and third Innovation Partnership Award wins for the Company. The Continental DMD HUD provides vivid colors, a large field of view and the ability to be seen through polarized sunglasses. It was first made available on the 2017 Lincoln Continental and 2018 Lincoln Navigator. (From a press release on April 12, 2018)

-The Company was awarded the CES 2018 Best of Innovation Award in the In-Vehicle Audio/Video category, the highest awarded honor, for the world's first touchscreen featuring a 3D surface. The innovative 3D touch surface display can be operated instinctively, enhancing the user experience and increasing safety. The Company’s haptic technology also means that the display can provide haptic feedback, allowing drivers to operate the display instinctively without having to take their eyes off the road. (From a press release on January 8, 2018)

R&D Expenditure by Divisions |

(in million EUR) |

| FY ended Dec. 31, 2018 | FY ended Dec. 31, 2017 | FY ended Dec. 31, 2016 | |

| Chassis & Safety | 1,023.2 | 913.8 | 773.4 |

| Powertrain | 672.6 | 699.0 | 701.5 |

| Interior | 1,064.7 | 1,062.7 | 956.0 |

| Tires | 299.4 | 289.8 | 260.9 |

| ContiTech | 149.1 | 138.4 | 119.7 |

| Total | 3,209.0 | 3,103.7 | 2,811.5 |

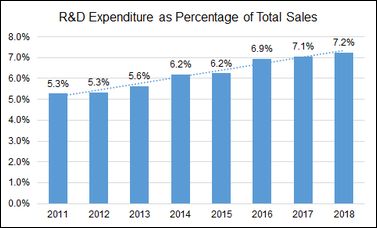

-In recent years, the Company has invested approximately 7% of its sales in research and development each year.

-In recent years, the Company has invested approximately 7% of its sales in research and development each year.

-The Company has increased the percentage of its total sales invested into research and development due to its increased focus on business areas such as electric mobility, automated driving, connectivity, digitalization and urbanization.

R&D Structure

-The Company intends to increase its team of experts in artificial intelligence by 2021 from approximately 400 employees to approximately 700 employees. The Company cited this figure during its first international AIR Days (Artificial Intelligence and Robotics). The AIR Days are part of the Company’s strategy to bolster it as a technology company that utilizes artificial intelligence in all areas. Experts from ten countries and three continents exchanged ideas, including ideas about the opportunities and potential for AI in production and logistics. Joint research activities with research facilities such as Oxford, Berkeley and German Research Center for Artificial Intelligence were also planned. (From a press release on November 12, 2018)

R&D Facilities

-As of December 31, 2018, the Company has 82 locations in which research and development take place.

-The Company officially inaugurated its research laboratory named Taraxagum Lab Anklam in Anklam, Mecklenburg-Western Pomerania, Germany. After the groundbreaking ceremony in November 2017, the 30,000-square-meter laboratory is ready for occupation. The lab is a base for research on the farming and extraction process of Russian dandelions as an alternative material source to tropical rubber trees. If positive test results are received, the Company is planning to introduce the raw material into serial production within ten years. In the medium term, approximately 20 employees with backgrounds in agricultural sciences, chemistry, production and process technology will work on plant cultivation and develop, set up, and operate machines for processing Russian dandelions at the new lab. (From a press release on December 6, 2018)

-The Company’s Continental India subsidiary has inaugurated a new research and development facility within its plant premises in Manesar, Gurgaon. The facility will cater to global and regional R&D requirements for its brake systems businesses. The new center will include design and testing for brake systems, and offshore engineering activities for Italy and Japan. (Based on updates from Continental India)

-The Company has opened its third research and development building in Singapore. The new building aims to meet the demand of growing engineering capacities driven by the worldwide business expansion, particularly in Asia. The new seven-story building has a floor space of approximately 11,000 square meters. It will accommodate employees from the Company’s Interior and Powertrain division. The location will hire more than 500 employees within the next few years. (From a press release on June 6, 2018)

-The Company inaugurated its new research and development center in Queretaro, Mexico, after an investment of USD 59 million. With an initial staff of 160 employees, the new center is expected to have 1,000 employees by 2022. Teams will focus on developing software and hardware for obstacle detection, environmental tracking at crossroads, and detection of objects surrounding the vehicle, among other applications. The research and development enter will partner with public and private universities in the region, giving students the opportunity to combine academic knowledge with experience. (From a Mexico-Now article on May 15, 2018)

-The Company and SAIC-GM-Wuling Automotive Co., Ltd. announced the opening of a new joint chassis and safety research and development center on April 2, 2018. The two companies also signed an alliance agreement for active and passive safety solution development. (From some releases on April 3, 2018)

-The Company opened the Center for Research and Development in Novi Sad, Serbia. Its two business units will develop electronic control systems for vehicle interiors and for vehicle safety. The Company has hired 100 engineers for projects and product development in Novi Sad. The Company expects to employ 500 workers in Novi Sad in the future, primarily in software and system engineering positions. (From Development Agency of Serbia press release on March 7, 2018)

-The Company announced the opening of a deep machine learning competence center in Budapest in May 2018. The company intends to expand its expertise in deep machine learning to enable automated driving and to support its Vision Zero goal. The new center will create 100 new jobs in the field of artificial intelligence. The Hungarian Investment Promotion Agency (HIPA) supports the settlement. (From a press release on January 30, 2018)

-The Company is investing USD 62 million to establish a technical center in Queretaro, Mexico, for the research and development of autonomous vehicles, connected and electric cars, according to Jorge Vazquez Murillo, director of the facility. Murillo noted that the Company chose the Queretaro location because of the concentration of universities and number of researchers per capita, which is among the highest in Mexico. (From a Mexico-Now article on January 29, 2018)

R&D Activities

-The Company commissioned the first driverless tire testing vehicle used on a wide range of road surfaces at its testing site in Uvalde, Texas. The aim is to provide additional test results for the Company’s passenger and light truck tires and minimize the impact of the test procedure on the results. The new test vehicle is based on the Company’s automated Cruising Chauffeur, which was developed for freeways, and is controlled using a satellite-based navigation system. Equipped with camera and radar sensors, the car can react immediately to unexpected objects on the track, even without a driver. (From a press release on December 19, 2018)

-According to the Company’s 2018 Continental Mobility Study, approximately two-thirds of motorists in Germany, the U.S. and China would use a system to help navigate narrow road-construction zones. Across Germany, Japan, the U.S. and China, 58% of respondents expressed anxiety about the reliability of autonomous technology. Approval rates have remained fairly stable in Germany and the U.S. over the last five years, and have risen from 55% to 68% in China. The Company commissioned infas, the market and social research institute, to conduct a representative survey of drivers in Germany, the U.S., Japan and China for the study. Experts from scientific, research and automotive fields were also interviewed. The study is one of the most comprehensive of its kind worldwide on the acceptance of advanced driver assistance systems and automated driving. (From a press release on December 12, 2018) (From an article in the Nikkan Jidosha Shimbun on November 17, 2018)

-The Company announced that the work will continue on completing the test facilities at Taraxagum Lab Anklam. The first machines that will be used to extract rubber from dandelion roots were installed just a few days ago. The aim is to use the first plant to obtain rubber from the dandelion roots in late fall 2018. The extraction unit has a 50-square-meter footprint and weighs approximately 40 tons. The Company is researching the industrialization of rubber from the Russian dandelion plant in the Taraxagum Lab Anklam laboratory. (From a press release on August 28, 2018)

-The Company has signed a five-year agreement to be members of the UC Berkeley DeepDrive (BDD) center. The research partnership focuses on optimizing the speed of neural networks and protecting AI systems in safety-critical applications. Both parties are driven by the goal of implementing AI research results into series production as quickly as possible. In the first year of program membership, the Company and BDD are focused on two fields of research. One field involves the testability of AI algorithms in safety-relevant systems. Researchers at the center are also looking at how to operate AI applications in a memory-efficient way to accelerate and optimize neural networks. This will allow easier implementation of AI methods in a vehicle. (From a press release on July 30, 2018)

-The Company will strengthen its development of autonomous driving technologies in Japan. Continental Automotive Corp., a Company subsidiary, started development of a second-generation autonomous driving test car which should be completed by 2018. The Company also implemented test operations of its unmanned vehicle CUbE in Japan. The Company will test a driverless system featuring its latest technologies to support Japanese automakers in their development of autonomous driving technologies. (From an article in the Nikkan Jidosha Shimbun on May 30, 2018)

-The Company will increase its investment in DigiLens Inc., a Silicon Valley-based leader in holographic waveguide projection technology. With its additional investment, the Company will own close to 18% of DigiLens after the Series C financing round. DigiLens’ AutoHUD waveguide product doubles the field of view for an HUD, creating a much larger display required for augmented reality applications, while reducing the component volume to one-sixth of the traditional size. (From a press release on May 17, 2018)

-The Company is expanding its global development activities for the safe launch of automated driving. Engineers are now testing prototypes in real traffic conditions on autobahns in Lower Saxony. The prototypes are always monitored and operated by a development expert in the driver's seat. Having concentrated on automated driving on the autobahn in recent years, the Company is focusing on autonomous driving development for complex highways. Lower Saxony is suitable for the test drives of the Cruising Chauffeur test vehicle. The planned routes include sections of the autobahn and routes through the city for subsequent test intervals. The Company’s final development goal is achieving production readiness of highly automated driving systems. The Company is working achieving fully automated driving on the autobahn by 2025. (From a press release on April 26, 2018)

-The Company, the Frankfurt transport authority (VGF) and the Frankfurt University of Applied Sciences (Frankfurt UAS) are launching a three-day, autonomous trial on the Frankfurt UAS campus. The purpose of the trial is to share knowledge between the Company, EasyMile and VGF to determine future requirements for driverless vehicles and realistic usage models. From April 17 to April 19, 2018, students at Frankfurt UAS will test a driverless shuttle service with the Continental CUbE. The shuttle service will drive to various campus buildings, replacing existing walking routes. (From a press release on April 18, 2018)

Technological Alliance

-The Company announced that a joint research and development team formed with EasyMile will commence work on solutions for driverless mobility at the Singapore corporate building. EasyMile is a pioneer in driverless technology and smart mobility solutions. EasyMile has a team in Singapore dedicated to deep learning and artificial intelligence. The new joint team’s work focus will be to develop new technology centered on perception and deep learning and to prepare autonomous vehicle technology for tests towards safe deployments on private and public areas in the Singaporean metro area. Singapore has identified three towns for pilot deployment of autonomous vehicles for public transport by the early 2020s. (From a press release on November 15, 2018)

-The Company and the Indian Institute of Technology (IIT) Madras have signed a Memorandum of Understanding for joint research of a computing platform and cyber security for powertrain applications. The joint research addresses an industry weakness, cyber security for conventional drivetrains. The research will focus on intrusion detection and reporting on powertrain applications. As inter- and intra-vehicle networks become more complex and multi-nodal, they become more vulnerable to threats, thus necessitating the need for secure communication. (From multiple sources on August 28, 2018)

-The Company and the German Research Center for Artificial Intelligence (DFKI) have agreed to enter into a partnership for future mobility. As part of the collaboration, the Forschungslabor Intelligente Technologien (FIT) will be established at the DFKI location in Kaiserslautern. Company employees will research the fundamentals of AI technology and address specific problems. In 2020, the Company plans to produce neural networks on a larger scale with its fifth-generation cameras for faster object recognition. By the end of 2018, the Company will employ around 400 engineers worldwide with specific AI expertise. (From a press release on June 20, 2018)

-The Company is announcing a new partnership with Vodafone to drive innovation. Their objective is to improve the safety of German roads with smart vehicle connectivity by collaboratively developing innovations to protect all road users. The two partners are already working on application scenarios at Vodafone’s 5G mobility lab. A digital shield for pedestrians and a traffic jam warning system are two focal projects. These systems will be implemented with 5G, cellular V2X and mobile edge computing. (From a press release on June 10, 2018)

-The Company has signed a Memorandum of Understanding with the Indian Institute of Technology Madras for Advanced Research in machine learning. IIT Madras with its capability in machine learning and bio-inspired neural networks will contribute to the Company’s ADAS business. The collaboration, named Project NeuroMotive, will aid the Company’s long-term global strategy towards Vision Zero – a future with zero accidents – through innovations and ongoing improvement of components and systems. (From some releases on May 4, 2018)

-Elektrobit, a subsidiary of the Company, and IPG Automotive entered into a technological partnership for the development of automated driving functions. The interface between the simulation software CarMaker by IPG Automotive and Elektrobit’s EB Assist Automotive Data and Time-Triggered Framework (ADTF) used for the development, testing, visualization, and validation of driver assistance systems and autonomous functions is already an established product feature of the CarMaker product family. The newly formed technological partnership now facilitates an optimized joint support provided by IPG Automotive and Elektrobit for customers who use both tools. (From a press release on March 1, 2018)

-Infineon Technologies announced that it is teaming up with the Company’s subsidiary, Elektrobit, to work closely together on vehicle cybersecurity. The companies offer a perfectly coordinated hardware-software solution that boosts the performance of on-board communication and satisfies current and future security requirements. It is based on the second generation of the multicore microcontroller family AURIX (TC3xx) from Infineon and, Elektrobit’s zentur HSM solution. (From a press release on February 27, 2018)

-TomTom announced that it will collaborate with the Company’s Elektrobit subsidiary to demonstrate an Electronic Horizon system for driver assistance functions and autonomous vehicles, combining TomTom AutoStream, and Elektrobit’s EB robinos Predictor. TomTom AutoStream is a Cloud to Car map delivery system which streams the latest map data from the TomTom Cloud to the vehicle. EB robinos Predictor is an in-vehicle Electronic Horizon solution that uses this map data to provide accurate and up-to-date information about the road ahead for predictive driver assistance functions. The joint project will combine TomTom AutoStream and EB robinos Predictor to establish an easy-to-use demonstrator, evaluation and development platform for the automotive market. (From a press release on February 26, 2018)

-The Company and NVIDIA announced that they are partnering to create AI self-driving vehicle systems based on the NVIDIA DRIVE platform, with a planned market introduction in 2021 for level 3 features. The partnership will enable the production of AI computer systems that scale from automated level 2 features through full level 5 self-driving capabilities. The Company and NVIDIA will initially develop highly automated driving features, including 360-degree perception, automatic lane changing on highways, and lane merging in traffic. In addition, the system will integrate HD maps, enabling the vehicle to localize themselves and provide mapping updates. (From a press release on February 5, 2018)

Product Development

See-through Virtual A-Pillar

-The Company has developed a Virtual A-Pillar to help remove forward blind spots by making wide A-pillars virtually see-through. The Virtual A-Pillar is designed to address the growing problem on vehicles that need widened front pillars to meet mandatory safety testing. New flexible OLED displays and advanced head tracking are used to provide increased visibility to the driver. The system tracks movements using an interior camera mounted just above the steering wheel. At the same time, the Company’s SurroundView camera, mounted on the vehicle’s exterior, feeds a live video of the vehicle’s external environment to the OLED displays embedded in the A-pillars. (From a press release on October 25, 2018)

Machine-learning vehicle support system

-The Company has jointly developed a machine-learning vehicle system with TU Darmstadt to support drivers in urban traffic and have installed it in a prototype for the fourth stage of the PRORETA research project. Data from radar sensors helps drivers assess traffic situations when turning left, entering a roundabout or at right-before-left intersections. Through machine-learning, the system adapts to the driver’s style of driving, assesses the driver’s behavior and level of attention and gives appropriate recommendations. During the course of PRORETA 4, various methods for reducing the number of test cases for learned algorithms were identified and will be subject to further research. One component of PRORETA 4 was a camera-based system for automatically mapping landmarks such as prominent points on buildings or infrastructure. (From a press release on October 17, 2018)

EcoContact 6 summer tire

-The Company’s new EcoContact 6 tire is a high-tech summer tire that delivers substantial improvements in terms of rolling resistance, mileage, steering precision and braking distances. Compared to its predecessor, the new tire offers 20% higher mileage, 15% lower rolling resistance, more precise handling and shorter braking distances on wet and dry roads. The Company has already received approvals from 12 European vehicle manufacturers for factory-fitting of the EcoContact 6 on subcompact to mid-range cars. The Company has begun volume production of the first tires for the replacement market. By March 2019, 112 items for 13 to 22 inch rims are to be available. (From a press release on October 15, 2018)

AR-HUD based on waveguide technology

-The Company revealed an industry-first full-color demonstrator of an automotive-specific HUD based on waveguide technology. This demonstrator is the result of the joint development with DigiLens Inc. The new AR-HUD with waveguide technology significantly reduces the packaging size. With this new technology, the device achieves an augmentation area of 15° x 5° (equivalent to 2.60 meters x 0.87 meters at a projection distance of 10 meters) while reducing the device size to a mere 10 liters in magnitude. (From a press release on October 10, 2018)

Technologies showcased at 27th Aachen Colloquium

-At the 27th Aachen Colloquium, the Company will demonstrate how 48V hybrid technology can be used to deliver reduced NOx emissions for both diesel and gasoline engines. The Company’s approach combines engine-integrated technology packages with electrically assisted exhaust aftertreatment functions. These new functions, powered by the additional electrical energy generated by a 48V hybrid vehicle, enable further advances in both emissions and fuel consumption. The Company will demonstrate that fuel-efficient diesel engines are capable of achieving real-driving NOx emissions below 35 mg/km, with simultaneous reductions of up to 10 g/km in CO2 emissions. Combined with optimized injection, 48V hybridization also enhances gasoline particulate filter regeneration. (From a press release on October 8, 2018)

Technologies showcased at Global Future Mobility Conference 2018

-The Company announced that it will be showcasing intelligent thermal management solutions for future vehicles at the Global Future Mobility Conference 2018 in Hangzhou, China. New multi-port valves called Coolant Flow Control Valves serve to flexibly switch heating and cooling circuits in a way to route available heat or cold. Thermal management solutions enhance electric vehicle range in extreme temperatures and speeds up the vehicle charging process. The Company’s first thermal management products are already in production. The start of production of the first thermal management volume order for an electric vehicle is scheduled to take place in China towards the end of 2019. (From a press release on September 20, 2018)

Technologies showcased at IAA Commercial Vehicles

-The Company is expanding its range of solutions for automated driving of commercial vehicles. It is currently developing an environmental model that captures the vehicle environment using various sensors. The data from sensors such as cameras, radars and lidars is combined with additional information such as the profile of the route ahead and collected, evaluated and interpreted by the Assisted and Automated Driving Control Unit. A complex and detailed environment model is then created from the resulting data. This model can be used to implement a wider range of advanced driver assistance functions. Visitors to the IAA Commercial Vehicles exhibition can see how the environment model works. (From a press release on September 17, 2018)

Dynamic eHorizon system

-The Company will unveil the dynamic eHorizon to the public at IAA Commercial Vehicles, which will enable drivers of commercial vehicles to optimize driving strategies based on real-time traffic condition data. As a result, they will be able to save more fuel in slow-moving traffic, up to 2% compared with the previous static eHorizon. The dynamic eHorizon is the next generation of the electronic horizon. The static eHorizon system already uses detailed topographic route data and a GPS signal to send information on the road ahead to control units in the vehicle. The control units then automatically adjust the vehicle’s driving style and speed. The dynamic eHorizon provides more data thanks to real-time information. (From a press release on September 12, 2018)

WinterContact family of winter tires

-The Company offers various winter tires for a variety of cars. WinterContact TS 860 S tires are designed for more powerful vehicles and SUVs, while WinterContact TS 860 tires are aimed at smaller vehicles and mid-range models. The WinterContact TS 860 S delivers top performance in terms of braking distances and handling on dry roads and snow. This tire is available in 14 sizes for 18- to 21-inch rims. Compared to its predecessor, WinterContact TS 860 delivers improvement across all properties. When braking on wet wintry roads, it performs five percent better than the WinterContact TS 850. The WinterContact TS 860 is currently available in 66 sizes for 13- to 17-inch rims. The Company has also winter tires for SUVs and 4WD models in sizes from 15 to 22 inches and for vans, light commercial vehicles and recreational vehicles in sizes from 14 to 17 inches. (From a press release on September 11, 2018)

AllSeasonContact premium all-season tire

-The Company presented its premium all-season tire AllSeasonContact, which combines strong handling characteristics on winter and summer roads with the best fuel efficiency in its class. As a result of new tread design, compound, tire contour and construction, the AllSeasonContact improves upon the weaknesses previously demonstrated by tires intended for all-year use in terms of winter and wet-weather performance. The Company manufactures this tire in widths from 165 to 245 millimeters for 14 to 20-inch rims. (From a press release on September 11, 2018)

AllSeasonExpert 2 all-season tire

-The Company unveiled its all-season tire, AllSeasonExpert 2. Compared to its predecessor, the AllSeasonExpert 2 tire features improved performance in dry conditions and decreased rolling resistance while maintaining strong braking performance on wet and snow-covered roads. The improvements are due to a new tread pattern, while a compact central rib provides additional stability. The AllSeasonExpert 2 will be produced in more than 50 sizes fro 13- to 18-inch rims. (From a press release on September 11, 2018)

DTCO 4.0 smart tachograph

-The Company has developed the smart tachograph DTCO 4.0, which is able to record, validate and process acquired data based on the most stringent security criteria and then exchange it with clearly defined and authorized third parties. Countless services and even new business models can now be created based on data from DTCO. Its Intelligent Transportation Systems interface, which is implemented as a standard feature, assists in transport planning and enables cooperating services. The Company is presenting the DTCO 4.0 to address fleet management challenges at the IAA Commercial Vehicles in Hanover, Germany. (From a press release on September 10, 2018)

ContiConnect digital tire monitoring platform

-The Company will showcase the further development of ContiConnect, its digital tire monitoring platform, at IAA Commercial Vehicles. The portfolio will be enhanced by a new solution that can be integrated into existing systems. This integrated solution provides operators of truck fleets and bus companies with proven transparency regarding temperature and tire inflation pressure in combination with other vehicle data. The updates to ContiConnect are a highlight among the products and solutions that the Company will be showcasing in response to the challenges of long-haul transportation. (From a press release on September 3, 2018)

Exhaust aftertreatment technologies showcased at IAA Commercial Vehicle

-The Company announced that it will be presenting solutions to support even more efficient exhaust aftertreatment in trucks at IAA Commercial Vehicles. The primary aim is to ensure more efficient conversion of NOx into harmless emissions. At IAA, the Company will present solutions like close-coupled systems and, also an architecture based on an innovative combination of diesel injection into the exhaust stream and an electric heating element mounted upstream of the catalyst. For the selective catalytic reduction of NOx emissions in the exhaust gas, an aqueous urea solution is injected into the exhaust stream. A fifth-generation pump offers an optional purge function which empties the urea line when the vehicle is shut down, to avoid frost problems at the nozzle. (From a press release on August 29, 2018)

Modular driver workplace

-The Company’s modular driver workplace (mDWP) has integrated advanced technology into the bus cockpit. In city and intercity buses, the mDWP makes the daily work of bus drivers more ergonomic, comfortable and safer. The mDWP enables fleet operators to operate more flexibly and vehicle manufacturers to stock fewer parts. The digital displays give manufacturers complete freedom in the arrangement and programming of the various displays and control panels, providing driver workplaces that can be adapted to their individual requirements. The first units are already being delivered to bus manufacturers and serial production will start in early 2019. In addition to bus manufacturers, manufacturers of electrically driven municipal vehicles, agricultural machinery and construction vehicles are also showing interest in the mDWP. (From a press release on August 21, 2018)

Ultrasonic height and pressure sensor

-The Company has developed a sensor that is able to measure the height and pressure of air springs using ultrasound. Using the Ultrasonic Height and Pressure Sensor (UHPS) will enable vehicle height to be adjusted electronically, thereby improving the efficiency of urban buses. Thanks to their extremely heat-resistant material, the air springs featuring the sensor technology are equipped for use with current and future engines. The Company is presenting the UHPS for the first time at the 67th IAA Commercial Vehicles in Hanover. Due to the larger exhaust systems of the low-emission Euro 6 engines, the air springs in urban buses are closer to the engine or other heat sources than before and are therefore exposed to extreme temperatures. (From a press release on August 16, 2018)

Right-hand turn assistant

-The Company will show visitors the future of the right-hand turn assistant for trucks at the 67th IAA Commercial Vehicles exhibition. The second generation of the right-turn assistant will distinguish dangerous and non-hazardous situations with greater accuracy. In order to achieve this, the radar-based system will be expanded to include cameras. Artificial intelligence will help right-turn assistance systems to assess pedestrians’ and cyclists’ behavior, providing more safety in the future. In the future, the right-turn assistant will be able to interpret complex and unpredictable traffic situations accurately and warn the driver. (From a press release on August 1, 2018)

End-to-end cyber security and OTA software update solutions

-The Company is offering end-to-end cyber security and over-the-air software update solutions from Argus Cyber Security and Elektrobit pre-integrated into its connected vehicle electronics products such as telematics units, infotainment systems and gateways. The Company’s cybersecurity philosophy is based on three critical pillars of prevention, understanding and response. The solutions from Elektrobit and Argus provide vehicle manufacturers an end-to-end offering to secure their fleets from current and future cyber threats. The Company’s Gateway integrates state-of-the-art security features from Argus and enables basic vehicle diagnostics and over-the-air software update capabilities via Elektrobit to monitor the vehicle's health and allow for immediate updates if needed. (From a press release on July 24, 2018)

EB cadian Sync software solution

-Elektrobit has announced EB cadian Sync. Together with Argus Cyber Security, this modular solution allows automakers to safely and securely keep their fleets up to date, regardless of size. The new software product forms the basis for automated and connected cars and minimizes the risk of security threats. EB cadian Sync opens the door to offering software as a product or software as a service over a vehicle’s lifecycle. With these new business models, car makers can offer upgradeable vehicles equipped with the hardware needed for a variety of exclusive features. EB cadian Sync offers automakers a non-intrusive method for maintaining their fleets and having the latest software version installed. (From a press release on July 19, 2018)

Technologies showcased at CES Asia

-The Company is presenting intelligent products for safety, efficiency, and vehicle networking at CES Asia. Continental will present the fifth generation of its multifunction camera, which relies on neural networks, smart algorithms and traditional computer vision processes to understand pedestrians' intentions and gestures. The intelligent camera, which will go into production in 2020, stands out with its eight megapixel resolution and aperture angle of up to 125 degrees. The Company will also present a digital companion capable of learning. To enable a normal conversation between driver and vehicle, a cloud-based voice-service is coupled to various functions, such as an interactive user guide. The innovative AllCharge system will celebrate its premiere in China. The system combines an electric motor and an inverter for a complete charging system. (From a press release on June 13, 2018)

Emission control technologies showcased at International Vienna Motor Symposium

-The Company will be presenting its latest advances in the field of emissions control at the 39th International Vienna Motor Symposium. Its focus is on system solutions for enhanced combustion and aftertreatment control. Highlights include the new XL5 injector, which reduces manifold-wall fuel condensation during cold-starting, a gasoline particulate filter, an active purge pump and a heated catalyst with a wide range of applications. (From a press release on April 25, 2018)

Aquaplaning warning system

-The Company has begun to develop new sensor-based concepts that can warn drivers about aquaplaning. The system under development is all encompassing, and includes tires, tire sensors-, cameras, algorithms, brake actuation, and a human-machine interface. Utilizing signals from surround view cameras and tire-mounted electronic-tire information system sensors, an early warning concerning possible aquaplaning is given to the driver. Aquaplaning conditions can also occur unexpectedly with no opportunity for advance warning. In such cases, the potential risk to other vehicles on the road can be mitigated by early communication via V2X technology and eHorizon. According to the Company, an initial version of the technology is conceivable in the next-generation of vehicles. The hardware and software for the aquaplaning warning is being developed by engineers in Frankfurt, Hanover and Toulouse. (From a press release on April 12, 2018)

Virtual testing system for AR-HUD

-Elektrobit, a wholly owned subsidiary of the Company, and OPTIS, the leading global virtual prototyping company, announced a partnership for the virtual testing of augmented reality head-up display (AR-HUD) systems in a dynamic driving experience. OPTIS and Elektrobit will combine their expertise in automotive solutions to provide a unique, commercial off-the-shelf solution that can be used by carmakers to develop and assess sensor fusion and augmented reality content. OPTIS’ VRX makes it possible to virtually test several driving scenarios in real-life driving conditions to anticipate the detection of these dangers in a virtual environment. (From a press release on April 10, 2018)

Integration of mobile standards for telematics systems

-The automatic emergency call system, eCall, must be installed in all new cars receiving type approval after April 2018 in the European Union, and connectivity will now be standard in every vehicle in Europe. To further expand and enhance its telematics business, the Company is already working on integrating the new mobile network standards LTE-Advanced and 5G into the vehicle. The Company has eCall-based telematics systems ready for production. These can be adapted to the requirements of individual vehicle manufacturers and delivered at short notice. (From a press release on March 28, 2018)

Cyber security solutions

-The Company uses cyber security technology to ensure comprehensive protection against possible hacker attacks on both safety-relevant vehicle components and in production plants. All of the Company’s future products will contain cryptographic functions that can be used to introduce security keys. These keys are individually generated for each product, which ensures maximum security because one car being hacked will not affect others. The Company has also introduced an incident response management system, which is an additional layer of security that responds immediately if an attack occurs. The Company is implementing cyber security solutions on multiple levels and layers. These offerings have been significantly augmented with the multiple end-to-end solutions provided by recently acquired Argus Cyber Security. (From a press release on March 20, 2018)

Telematics platform for commercial vehicles

-On March 5, 2018, the Company and FAW Jiefang Automotive signed an agreement on a project for a new Telematics platform. The two companies will launch an operating platform for a telematics ecosystem for commercial vehicles to individual users. The platform will use the businesses and resources of the Company’s Commercial Vehicles and Repair Market Division and Intelligent Transport Systems Division and be managed by FAW Jiefang Automotive. (From a press release on March 8, 2018)

Third-generation ABS

-The Company’s third generation anti-lock braking system (ABS3) now responds with even greater speed and precision thanks to enhanced brake pressure control. Optimum brake performance is ensured thanks to the more adaptive controller design. Test drives conducted in Sweden on different road surfaces confirm that the ABS3 performance is maintained in critical situations such as when braking on roads with varying levels of friction. These benefits mean that the third-generation ABS is much easier than ABS2 to apply in different vehicle models. (From a press release on March 5, 2018)

Predictive data and connectivity management solution

-The Company has developed a predictive data and connectivity management solution to allow maximum utility of existing network coverage. It is an add-on to handle connectivity issues when they arise, and to develop intelligent data management and download strategies for a more anticipatory drive. The project is an evolution of the Smart Telematics solution that the Company developed with Carnegie Technologies. In order to calculate the reception quality along the road, the connectivity manager collects data on the availability and quality of the communication channels from vehicles traveling along the same route. This data is then processed and analyzed in the backend using Continental.cloud. (From a press release on February 26, 2018)

ContiSense tire monitoring system and ContiAdapt adaptable tire characteristic system

-The Company introduced two new tire technology concepts that will further improve road safety and comfort in the future. ContiSense will provide continuous monitoring of the tire’s condition, while ContiAdapt will provide situation-matched adaptation of tire performance characteristics to prevailing road conditions. (From a press release on February 23, 2018)

Anti-vibration product portfolio

-The Company features an anti-vibration element product portfolio to prevent vibrations being transmitted to the electronics units of autonomous transport units. The product portfolio includes mounting components such as rubber-metal components fitted at the transition point between the chassis and switchgear unit. They isolate sensitive electronics from vibrations and thus protect against damage and failure. Another advantage is that the additional mountings can also provide protection for materials being conveyed that may be sensitive to vibration. (From a press release on February 19, 2018)

Solid tires for industrial trucks

-The Company is optimizing its solid tire portfolio for industrial trucks with the new Plus range which has been available since January. The four solid tire types: SC20+, CS20+, CSEasy SC20+ and SH12+ are equipped with the new Plus compound which combines the advantages of high mileage with low rolling resistance. Tires equipped with the Plus compound have recorded mileage increases of up to 20% on hard abrasive surfaces. The Company will showcase its latest products and developments from the tire segment at Hannover Messe instead of at CeMat. Together with intelligent key technologies and other highlights, the new solid tire portfolio and tire pressure management system for pneumatic tires will be on display. (From a press release on February 12, 2018)

Technologies showcased at Mobile World Congress

-The Company will unveil innovative solutions and services at the Mobile World Congress in Barcelona. The Company will demonstrate how it is shaping the transformation of vehicles through holistic connectivity. The Company will also bring its Multifunctional Smart Device Terminal to MWC 2018. The terminal enables wireless charging for all smartphones that meet the Qi standard. The Company will also highlight its portfolio of end-to-end security solutions. (From a press release on February 8, 2018)

Exhaust gas sensor technology

-The Company introduced its latest innovations in exhaust gas sensor technology to the Chinese market to lower vehicle emissions. Its smart High Temperature Sensor (HTS) and Differential Pressure Sensor (DPS) are designed to quickly provide accurate measurements. The second-generation HTS is based on thermocouple technology which sends a digital signal based on the temperature to the Engine Control Unit to achieve the optimal catalytic conversion process. The Company’s DPS can be used to infer the exhaust gas flow through the particulate filter by measuring the differential pressure across the filter. The technology will provide an analog or digital output voltage proportional to the differential pressure across the filter. (From a press release on January 30, 2018)

Software framework for autonomous driving

-Elektrobit Automotive, a Company subsidiary, annoucned that EB robinos, its hardware-agnostic software framework for automated driving, now includes convoy tracks and free space. Convoy tracks is part of EB robinos Road Fusion, deriving lanes from the tracks of preceding vehicles to overcome gaps or erroneous detections of lane markings. Free space describes the vehicle’s surroundings in an innovative polygon description that is easy to interpret and small enough to be distributed throughout a network. Both complete the EB robinos perception modules to provide a 360-degree view of the vehicle’s environment. (From a press release on January 24, 2018)

Updated electronics architecture

-The Company is adding an additional level of safety to highly automated driving through a new electronics architecture. In addition to a central Assisted & Automated Driving Control Unit for automated driving, the Company uses a Safety Domain Control Unit (SDCU) as a fallback path in order to stop the vehicle safely, even in a functional failure in the primary automation path. Both the central control unit and the SDCU continuously monitor each other in regards to availability and functionality. If one path is no longer capable of controlling the vehicle or performing the minimum risk maneuver safely, the other path initiates the safe stop in an emergency. The Company already uses this architecture for its Cruising Chauffeur function for highly automated freeway driving. (From a press release on January 10, 2018)

Charging technologies shown at CES 2018

-The Company showcased an inductive charging system which will permit fully automated battery charging without cables at CES 2018. It is accompanied by a new micro-navigation solution that allows the vehicle to be positioned precisely over the ground-based charging pad. The Company’s second innovative system– AllCharge – has the potential to revolutionize cable-based charging. The technology can utilize any charging point, regardless of charging rate, current type or voltage level. (From a press release on January 8, 2018)

Flexible computing platform for autonomous driving systems

-The Company will showcase a highly flexible computing platform for automated driving systems and the processing of the huge amount of data at CES 2018. When automated driving is activated, the data from vehicle surroundings sensors such as cameras, radar and LiDAR are analyzed in a central control unit, the Assisted & Automated Driving Control Unit. The data can be processed in either the individual sensor or on a central control unit to construct a high-precision environmental model of the vehicle’s surroundings. The platform provides heterogeneous computing options such as a Central Processing Unit, Graphics Processing Unit, Digital Signal Processor, and now through Xilinx's All Programmable technology, a customizable hardware acceleration solution. This provides developers the ability to optimize software for the appropriate processing engine or to create their own hardware accelerators. (From a press release on January 3, 2018)

Capital Expenditure |

(in million EUR) |

| FY ended Dec. 31, 2018 | FY ended Dec. 31, 2017 | FY ended Dec. 31, 2016 | |

| Chassis & Safety | 749.7 | 682.5 | 523.7 |

| Powertrain | 691.0 | 653.7 | 544.4 |

| Interior | 578.4 | 453.3 | 428.9 |

| Tires | 837.1 | 847.0 | 882.1 |

| ContiTech | 250.2 | 213.2 | 212.0 |

| Other/Consolidation | 18.0 | 4.7 | 1.9 |

| Total | 3,124.4 | 2,854.4 | 2,593.0 |

-The Company expects to invest approximately 8% of its sales, or EUR 3.7 billion, in capital expenditures for the fiscal year ending December 31, 2019.

Investments outside Germany

<India>

-The Company began construction of a plant to manufacture premium surface materials in Pune with a EUR 22 million investment. A 12,000-square-meter facility with an initial annual production capacity of 5 million square meters will be built on the four-hectare plot. The factory is scheduled to begin production in 2020 with an initial workforce of up to 110 employees. Materials produced from Pune will supply local Indian markets. The Acella Eco artificial leather that will be produced in Pune from 2020 has been popular in India as a replacement for real leather. The facility will also manufacture the environmentally compatible Yorn and Yorn Light expanded foils. The plant, which offers space for further expansion, will include production, warehousing, research and development labs, sales, logistics, product development facilities, and local purchasing. (From a press release on December 11, 2018)

-The Company inaugurated two new lines for ABS and ESC assembly at its plant in Gurgaon, India. This capacity increase is to address market requirements stemming from government legislations for ABS entry in April 2019 for passenger cars and 2-wheelers. In 2016, the Company set up a line for ABS assembly and ESC systems, in Gurgaon. In 2018, another new line was set up in the Bangalore plant, for production and assembly of ECUs for 2-wheeler and passenger car ABS and ESC systems. Recently, the Company had announced investments of several INR billion within the next two years in India, and a plan to increase employees to 10,000 in the same period. (From a press release on November 22, 2018)

<U.S.>

-The Company hosted the grand opening for its new Employee Training Center in Clinton, Mississippi, U.S. The Center is the Company’s first completed structure on the future Truck Tire Plant site. The total investment for the entire manufacturing site in Mississippi is USD 1.45 billion. The Training Center is equipped with classrooms, computer labs and technical equipment that will be used for job interviews, new employee orientation, and training. The tire plant, expected to begin production in 2020, will have approximately 400 employees for initial operations. Approximately 2,500 jobs will be created by 2028. (From a press release on November 8, 2018)

<Mexico>

-The Company unveiled plans to build a USD 60 million manufacturing plant in Aguascalientes, Mexico, dedicated to production of electronic components. Construction work on the 8,000-square-meter facility will begin in early 2019 followed by the installation of equipment in the second half of the year. The first production tests will begin at the end of 2019 with the aim to formally start operations in 2020. The plant will manufacture ECUs, door control unit, lighting control boards and smart antenna modules. It will be the Company’s sixth plant of its kind in North America and 30th worldwide, and its 25th location overall in Mexico. (From Mexico-Now article on November 2, 2018)

<Brazil>

-The Company is preparing its plant in Guarulhos, Brazil, to produce digital instrument panels. The Company is currently in discussion with two OEMs to introduce digital panels in models that will be released between the end of 2019 and 2020. Since 2017, Volkswagen has been importing the Company’s digital instruments for high end versions of the Brazilian-made Polo and Virtus, and has announced that the T-Cross will also have this option. The Company’s engineers in Brazil are working to develop digital instrument panels with reduced functions that would be produced locally to lower costs. (From multiple sources on October 30, 2018)

<China>

-The Company announced that its new plant in Qingdao has been relocated to the Qingdao Sino-German Ecopark and now officially opened. With a total investment of approximately CNY 240 million and spanning an area of approximately 84,000 square meters, the new plant manufactures high quality hose products and mobile fluid system solutions for passenger cars and commercial vehicles. The new plant in Qingdao has introduced technologies including advanced air conditioning hoses using the new HFO-1234yf refrigerant, lightweight cooling water hoses suitable for electric vehicles and GPF hoses meeting the National IV standards. (From a press release on October 18, 2018)

-The Company has invested approximately EUR 10 million in a new 3D blow molding plant in Changshu, China, which is now open. In the future, the plant will produce 3D blow molded hoses used in high performance turbochargers for automotive OEMs. The new plant will begin series production in the third quarter of 2018. Its production workshop is equipped with multiple state-of-the-art production lines for highly automated and intelligent production. The plant will rely on the Company’s global hose and duct expertise and adopt internationally advanced 3D blow molding technology to provide Chinese automakers with high performance turbocharger ducts. (From a press release on August 30, 2018)

-On August 8, 2018, the Company completed the third-phase of its expansion of its Changshu plant that produces hydraulic brake systems. The new plant will primarily produce motor gear units. The investment in the expansion was EUR 70 million, resulting in a floor space exceeding 42,000 square meters after the expansion. (From a press release on August 8, 2018)

-The Company celebrated the groundbreaking of its greenfield facility in Wuhu, China, dedicated to powertrain components. The new production facility is located in the Wuhu Economy and Technology Development Zone, and covers an area of 80,000 square meters. With an initial investment of approximately EUR 28 million for land and building, the first phase of the construction project will cover approximately 20,000 square meters, providing approximately 8,000 square meters of shop floor, more than 9,000 square meters of storage space, 700 square meters of office area, and 1,500 square meters for other supporting facilities. Construction will start in the second quarter of 2018 with production scheduled to begin in the third quarter of 2019. The facility will have a total of 24 production lines installed to produce various drivetrain products including sensors, actuators and fuel and exhaust management components. (From a press release on April 13, 2018)

<Hungary>

-The Hungarian Investment Promotion Agency (HIPA) informed that the foundation stone has been laid for an automotive electronic component manufacturing plant in Debrecen. The new plant will cover 7,000 square meters. The Company has made a greenfield investment of EUR 100 million in the establishment to create 450 jobs. The new manufacturing plant in Debrecen reaffirms the Company’s expectations to begin production of sensor technology and gearbox systems by the end of 2020. (From HIPA press release on September 17, 2018)

-The Hungarian Investment Promotion Agency (HIPA) announced that the Company’s new EUR 100 million plant in Debrecen will manufacture sensors and transmission control units to satisfy the growing demand for electronics. The investment will create 450 new jobs. Construction on the site will begin in the third quarter of 2018, while operations are scheduled to begin in the third quarter of 2020. (From HIPA press release on February 21, 2018) (From a press release on February 22, 2018)

-ContiTech Magyarorszag, a Company subsidiary, has expanded production in Nyiregyhaza, Hungary. The expansion utilized an investment of EUR 20 million and created 600 new jobs. The expansion increases air bellow manufacturing capacity, starts the production of automotive cooling and heating pipes, and adds a second rubber mixing lines. Other additions include a 2,000-square-meter warehouse complex and a 4,500-square-meter logistics hall. (From Hungarian Investment Promotion Agency press release, on January 23, 2018) (From a press release on January 23, 2018)

<Czech Republic>

-The Company celebrated the official opening of the new production hall of their molds and container manufacturer A-Z Formen- und Maschinenbau (AZ) in Horsovsky Tyn, Czech Republic. The Company invested approximately EUR 11 million on the new production hall, which spans 7.500 square meters, new tire manufacturing technologies and equipment. (From a press release on September 12, 2018)

-The Company has opened a combined production and storage facility for NOx sensors in Trutnov, Czech Republic. The facility will create 200 new jobs. Approximately 3,000 square meters of the new hall will be dedicated to nine new production lines while another 2,220 square meters will provide storage space. Two SMT lines for the production of printed circuit boards complement the sensor manufacturing. With this investment, the Company will be in position to meet the increasing demand for advanced NOx sensors. (From a press release on June 15, 2018)

<Lithuania>

-The Company is continuing to expand its European production capacities, celebrating the groundbreaking ceremony for its first plant in Kaunas, Lithuania. Starting from the second half of 2019, electronic components for the European market will be manufactured at the new electronics plant. The Company will invest EUR 95 million over the next five years and will create around 1,000 new jobs. (From a press release on July 20, 2018)

<Thailand>

-The Company’s subsidiary, Continental Tires Thailand, is confident its sales will surge once its new plant opens in March 2019. The Company installed its first machine at its new tire manufacturing plant in Rayong. The Company invested USD 250 million into the new plant. The plant is expected to annually manufacture 4 million tires for passenger cars and light trucks after the first phase of construction. The site spans 750,000 square meters, potentially allowing capacity expansion of up to 25 million tires a year. The Company has a 3% share of Thailand’s overall tire market and is aiming to become a leading international brand in the Thai market by 2025. (From an article of Bangkok Post on March 16, 2018)

Future Investments

-The following is a planned list of projects that the Company expects to invest in during the fiscal year ending December 31, 2019:

- Global expansion of production capacity for new generations of electronic brake systems in the Vehicle Dynamics business unit.

- Global expansion of production capacity for sensors.

- Development of a new plant in China for the Powertrain division.

- General development of the Hybrid Electric Vehicle business unit

- Construction of new plants in Eastern Europe, North America and China for the Interior division.

- Industrialization of new display technologies.

- Expansion of production capacity for passenger vehicle tires in Asia, North America, Southern Europe and Eastern Europe for the Tire division.