Bosch [Robert Bosch GmbH] Business Report FY ended Dec. 2018

Financial Overview |

(in million EUR) |

| FY ended Dec. 31, 2018 | FY ended Dec. 31, 2017 | Rate of Change (%) | Factors | |

| Overall | ||||

| Net Sales | 78,465 | 78,066 | 0.5 | 1) |

| EBIT | 5,502 | 4,944 | 11.3 | 2) |

| Mobility Solutions | ||||

| Sales | 47,567 | 47,384 | 0.4 | 3) |

| EBIT | 3,531 | 3,346 | 5.5 | 4) |

Factors

1) Net Sales

-In the fiscal year ended December 31, 2018, the Company’s net sales were EUR 78,465 million, an increase of 0.5% over the previous year. Excluding negative currency effects during the year, the Company’s sales increased by 3.2% for the year, as negative currency effects accounted for a loss of EUR 2.1 billion. Sales increased in the Americas and Europe by 0.2% and 1.5%, respectively, despite significant negative currency exchange rate effects. Sales decreased in the Asia Pacific region by 1.1%.

2) EBIT

-The Company’s EBIT in the fiscal year ended December 31, 2018 was EUR 5,502 million, an increase of 11.3% from the previous year. The Company’s earnings benefited from a non-recurring special effect of approximately EUR 430 million to the changed reporting of its pension scheme. General weakness in the automotive market and in China led to a smaller increase in earnings than expected. This effect was amplified by increased raw material prices.

3) Mobility Solutions Sales

-The Company’s Mobility Solutions business sector’s sales increased by 0.4% in the fiscal year ended December 31, 2018 to EUR 47,567 million. Excluding exchange-rate effects as well as the divestiture of the Starter Motors and Generators, sales in the business sector increased by 5.8%. Sales related to commercial vehicles and off-highway powertrains, electrification, exhaust-gas treatment, exhaust sensors and transmissions all increased. These gains offset losses caused by declining demand for diesel powertrains and a weaker Chinese market. Other segments showing significant growth include driver assistance systems, electric steering systems, thermal systems, and display systems. Sales of control units, sensors and security also increased.

4) Mobility Solutions EBIT

-The Mobility Solutions business sector had EBIT of EUR 3,531 million in the fiscal year ended December 31, 2018, an increase of 5.5%. Earnings in the business sector increased despite weakness in the automotive market as well as increased investments for future projects.

Acquisitions

-At the beginning of 2019, the Company announced that it would acquire EM-motive GmbH, a joint venture which the Company originally had set up with Daimler in 2011. EM-motive is a manufacturer of electric motors, having produced approximately 450,000 motors in the company’s lifetime.

-The Company is entering the ridesharing business through the acquisition of Splitting Fares Inc. (SPLT), a U.S. start-up based in Detroit, Michigan. SPLT operates a platform that allows companies, universities, and municipal authorities to offer their workforces ridesharing services. Founded in 2015, SPLT has approximately 140,000 users in the U.S., Mexico, and Germany. The Company has employees in Mexico currently using the app, and plans to extend its use across the entire Company. SPLT will remain an independent entity as a wholly owned subsidiary within the Company. (From a press release on February 21, 2018)

Restructuring

-The Company and Mahle Group announced that they have successfully completed the sale of the Bosch Mahle Turbo Systems joint venture to FountainVest Partners as planned. Effective immediately, the former joint venture is operating under the new name of BMTS Technology. FountainVest Partners, a private equity investor based in Hong Kong, wants to build on the joint venture’s previous successes and further expand BMTS Technology. (From a press release on March 12, 2018)

-The Company’s new connected mobility solutions division will bring together over 600 employees to develop and sell digital mobility services. These include vehicle sharing, ridesharing, and connectivity-based services. In 2022, the market for mobility services and associated digital services is expected to be worth EUR 140 billion. The Company aims to use the new division to further extend its existing service portfolio. Its recently acquired Splitting Fares startup has developed a platform that companies, universities, or municipal authorities can use to arrange ridesharing for their staff. The Company’s COUP subsidiary has provided e-scooters for rent in Berlin since 2016. (From a press release on February 21, 2018)

-The Company successfully consummated the scheduled sale of its subsidiary SEG Automotive Germany, formerly the Robert Bosch Starter Motors Generators Holding, together with all subsidiaries, to the purchaser consortium Zhengzhou Coal Mining Machinery Group (ZMJ) in Zhengzhou, China and China Renaissance Capital Investment (CRCI) in Hong Kong, China. ZMJ is a major Chinese automotive supplier for starter motors and generators and engine components for commercial vehicles and passenger cars. As a ZMJ’s long-standing business partner, the financial investor CRCI will support the ZMJ in this acquisition. (From a press release on January 2, 2018)

Business Partnership

-The Company announcing that it is patnering with the German website clever-tanken.de. With over 20 million visits a month (IVW/Google Analytics August 2018), clever-tanken.de is the market leader for fuel-price information in Germany. The result of this collaboration is Clever Laden, a new feature of the price-comparison website’s app. The app will feature prices for gasoline, diesel, and LPG, and also show the locations of charge spots throughout Germany. Clever Laden helps drivers across Germany locate some 11,500 charge spots operated by various companies. The app will notify users which charge spots are unoccupied, what connector a customer has to have, what charge capacity is available, and what the total electricity price will be. It covers various regional power suppliers, charge spot providers and partner services, such as for payment transactions. (From a press release on November 29, 2018)

Recent Developments

-The Company’s Bosch India subsidiary will suspend all manufacturing operations at the plant in Bidadi, Karnataka on December 28 and December 29, 2018, due to downward shift in demand. The Bidadi plant manufactures single-cylinder, common-rail pumps and conventional fuel injection pumps. (From a press release on December 20, 2018)

-Robert Bosch Venture Capital (RBVC), the corporate venture capital entity of the Company, completed a follow-on investment in ABAX Sensing. ABAX is developing a full solid-state chip lidar for consumer and automotive applications, specifically for advanced driver assistance systems and autonomous vehicles. ABAX is starting to conduct small-scale production testing and relevant customer trials on its first-generation Lidar products. ABAX’s enhanced chip-level solution intrinsically enables low costs and small product design, combined with functional requirements and safety. Its proprietary anti-interference technology eliminates mutual interferences among different Lidar devices and disturbance problems caused by ambient light. (From a press release on September 18, 2018)

-The Company’s Bosch Mexico subsidiary reported sales growth of 10%, reaching USD 3.2 billion during 2017, including sales of non-consolidated companies and internal deliveries to affiliated companies. During the same period, the Company’s sales in the Mexican market increased 4.5% to USD 1.3 billion. The Company aims to continue to expand its presence in Mexico, noting its USD 120 million investment to build an electronic components production plant in Celaya. (Mexico-Now article on August 29, 2018)

-The Company plans to take a 4% equity stake in Ceres Power. A collaboration and license agreement for the development of fuel-cell technology, and the establishment of small-volume production operations at the Company, as well as a share purchase agreement, was signed by the two companies on August 20, 2018. SOFC technology uses an electrochemical reaction in the fuel cell stack to convert fuel such as natural gas or hydrogen into electricity. Together with Ceres Power, the Company will work on making SOFC technology available for various applications. SOFC systems will be used in cities, factories, and data centers, and also as a power supply for electric charging stations. (From a press release on August 21, 2018)

-Robert Bosch Venture Capital GmbH (RBVC), the Company’s corporate venture capital entity, has completed an investment in DeepMap Inc, a U.S. startup based in Palo Alto, California. DeepMap is a software company focused on solving the mapping and localization challenge for autonomous vehicles. DeepMap is taking a novel approach within the mapping industry, allowing different companies to create custom HD maps, which contain different characteristics and data structures. HD maps are complete and accurate volumetric reconstructions of a 3D environment and provide a critical set of pre-information to autonomous vehicles. The company has assembled a 75-person team with experience at launching maps at massive scale. Prior to founding DeepMap, some members of the executive team previously co-founded Apple Maps, led numerous aspects of Google Maps and Google Earth, and led the Baidu HD Mapping initiative. RBVC joins investors Andreessen Horowitz, Accel Partners, and GSR Ventures as backers of DeepMap. (From a press release on August 9, 2018)

-The Bosch Corporation, a subsidiary of the Company, held its annual press conference in Tokyo on June 6. Klaus Meder, President of Bosch Corporation, announced that the company will start full-scale business operations for state-of-the-art technologies like autonomous driving in the Japanese market. The company is preparing for the commercialization of its automatic valet parking system in the country, and started joint development with its partner companies. It is also considering starting mobility service businesses like ride-sharing in the country. (From an article in the Nikkan Jidosha Shimbun on June 7, 2018)

-The Company and the Antenne Bayern radio station formed a partnership aiming to eliminate road fatalities caused by wrong-way drivers. This partnership will allow Antenne Bayern to integrate the Company’s cloud-based wrong-way driver warning into its app for radio listeners. This beneficial solution rapidly warns both wrong-way drivers and all other road users in the vicinity. German radio broadcasts warn listeners of approximately 2,000 wrong-way drivers annually. On average, wrong-way drivers kill 20 people in Germany each year. With the help of the Antenne Bayern app and its 250,000 active unique users, the nationwide radio station can immediately warn listeners throughout the country of hazardous situations caused by wrong-way drivers. (From a press release on March 16, 2018)

-The European Commission announced that it has confirmed a price fixing agreement formed for automotive spark plug sales from 2000 to 2011 among Denso Corporation, NGK Spark Plug Co., Ltd., and the Company. Denso reported the cartel to the commission and therefore was exempted from fines. The commission imposed a fine of approximately EUR 30 million on NGK Spark Plug, and EUR 46 million on the Company. The commission started the investigation on the three companies' infringement of the European Competition Law on July 2011. (From an article in the Nikkan Jidosha Shimbun on February 23, 2018)

-HERE Technologies announced that the Company and Continental have signed a definitive agreement to acquire indirect ownership stake in HERE Technologies from HERE’s indirect shareholders AUDI AG, BMW Group, and Daimler. The Company is acquiring a 5% indirect ownership stake in HERE Technologies. The acquisition gives a boost to the Company’s services business. It also helps HERE take a further step toward its goal of becoming a global provider of data-based real-time location services to customers inside and outside the automotive industry. Continental has also signed a definitive agreement to acquire a 5% indirect ownership stake. (From a press release on January 4, 2018)

Contracts

-The 2019 Volksagen Touareg features a curved instrument cluster produced by the Company. This curved instrument cluster is the first such unit available on a mass-production vehicle model. (From a press release on November 14, 2018)

-The Company announced that its electric mirror has been adopted for the first time ever for Daimler AG’s Actros heavy-duty truck. The Actros will be mass produced from 2019 for the European market. It will be the first truck model equipped with electric mirrors. The Digital Side Mirror captures right and left rear images with cameras, and displays them on a monitor. The mirror not affected by weather, and offers high visibility. The Company aims to adopt the system for different models, and enhance the system’s functionality. (From an article in the Nikkan Jidosha Shimbun in October 1, 2018)

Awards

-On March 23, 2018, Zhejiang Asia-Pacific Mechanical & Electronic Co., Ltd. awarded the Company with the excellent supplier award at the 8th suppliers meeting of SAIC MAXUS Automotive. The Company formed a strategic partnership agreement with SAIC MAXUS in 2010. (From a press release on March 26, 2018)

Outlook for FY ending Dec. 31, 2019

-For the fiscal year ending December 31, 2019, the Company expects that its sales will remain level compared to the previous fiscal year, excluding any currency exchange rate effects. In the best case scenario, its sales will slightly increase. Its EBIT in the Mobility Solutions business sector is expected to decline due to both decreased automotive production and increased investments for future projects.

-In the long term, the Company expects to achieve an average annual sales growth of 8%, with up to 3% stemming from acquisitions. The Company also aims to achieve an EBIT margin from operations of approximately 7%.

Corporate Strategy

Regional planning

-The Company’s capital expenditure for the fiscal year ended December 31, 2018 was distributed across its regions of operations as follows:

- Europe: EUR 3.0 billion

- Asia Pacific: EUR 1.4 billion

- North and South America: EUR 470 million

<Europe>

-The Company increased its capital expenditure in Germany from EUR 1.5 billion to EUR 1.8 billion in the fiscal year ended December 31, 2018. The increased investment in Germany has been used in projects including the development of a new wafer fab in Dresden and expanding capacity of automotive electronics in Reutlingen. The Company is also investing in camera systems, braking systems and the general expansion and modernization of locations in the country.

-Outside of Germany, the Company also made significant investments in Hungary, expanding manufacturing capacity of power electronics in Hatvan and expanding the size of the engineering center in Budapest. The Company also expanded capacity for exhaust gas treatment systems in Ceske Budejovice, Czech Republic, increased capacity for automotive electronics in Cluj, Romania and invested in the manufacturing of head-units and automotive display systems in Braga, Portugal.

<Asia Pacific>

-As with recent years, the Company’s investment in the Asia Pacific region was primarily focused on China, aimed towards expanding production capacity. The Company also invested in new engineering centers in Suzhou and Nanjing. In India, the Company expanded its production facilities at Bidadi and Naganathapura while expanding its engineering center in Adugodi. Another area of focus for investment was Long Thanh, Vietnam, where the Company produces push belts for continuously variable transmissions.

<Americas>

-In the U.S., the Company invested in facilities in Charleston, Anderson and Florence, South Carolina. The Company’s investment in Brazil was primarily dedicated to its Campinas facility.

Avenues of development in the automotive market

-In its Mobility Solutions business sector, the Company’s goal is to become one of the world’s leading suppliers in electrified, automated, and connected driving. The Company is also aiming to become one of the world’s leading companies in the Internet of Things.

-The Company is focusing on two paths of development in the field of autonomous driving. The first path involves developing and evolving partial and conditional autonomous driving technologies, that is, level 2 and level 3 technologies, from currently available driver assistance systems. These technologies would be implemented in private vehicles to ease the stress of a general commute. The Company’s second path involves implementing limited application driverless vehicles such as robotaxis or roboshuttles in dense urban areas. These vehicles would serve to ease congestion issues in larger cities.

-In regards to vehicle powertrains, the Company’s long term goal is to reduce carbon dioxide and other emissions as much as possible. Under its Powertrain Solutions division, the Company is developing technologies across a wide range of powertrains, including diesel and gasoline ICEs, hybrid powertrains and fully electric powertrains.

-The Company is aiming to lead the mass market in electromobility. In 2018, the Company acquired 30 electromobility projects worth several billion euros. It aims to increase its sales in the segment to EUR 5 billion a year by 2025.

-The Company is also focused on industrial and consumer applications of AI. In 2017, the Company announced that it would invest EUR 300 million over a five year period into expanding the Bosch Center for Artificial Intelligence. In 2018, the Company announced plans to quadruple the number of experts in AI from 1,000 to 4,000 by 2021.

-In 2018, the Company completed the divestitures of the following:

- Its Starter Motors and Generators division

- The Bosch Mahle Turbo Systems joint venture in conjunction with the Mahle Group

- Repair shop equipment suppliers Beissbarth GmbH and Sicam SrL

-The Company is also restructuring its steering columns business to increase its focus on electric steering systems over conventional steering systems.

R&D Expenditure |

(in million EUR) |

| FY ended Dec. 31, 2018 | FY ended Dec. 31, 2017 | FY ended Dec. 31, 2016 | |

| Overall | 5,963 | 7,045 | 6,911 |

| -Mobility Solutions | 5,284 | 5,739 | 5,285 |

-The decrease in research and development expenditure in the fiscal year ended December 31, 2018 was due to the first-time application of IFRS 15 standards. Excluding the effect of IFRS 15, the Company’s research and development expenditure increased compared to the previous year.

-The Mobility Solutions business sector investment in research and development during the fiscal year ended December 31, 2018 was focused on electrification, driver assistance systems, autonomous driving technologies, display and infotainment systems, and sensors.

R&D Structure

-As of December 31, 2018, the Company has approximately 68,700 employees working in research and development, an increase of approximately 4,300 employees over the previous year. The increase in employees was driven by expansion of research and development facilities in the Asia Pacific region. 56% of the Company’s employees working in research and development are located outside of Germany, with 37% working in the Asia Pacific region.

R&D Facilities

-The Company recently opened its USD 10 million technology and innovation hub along with new corporate offices in Guadalajara, Mexico. The first floor of the ten-story hub is occupied by an area called the Connectory which functions as a shared space, or co-working offices, aimed at promoting the exchange of ideas among professionals, entrepreneurs and creators. The new offices are designed to bring together specialists and engineers focused on software development, artificial intelligence, augmented reality, mobility and connectivity, and engineering solutions. (From Mexico-Now article on December 5, 2018)

-On September 6, 2018, the Company’s subsidiary, Bosch Automotive Products (Suzhou) Co., Ltd. began operation of its new R&D center. The Company invested CNY 330 million into the 34,000-square-meter center. This new lab is one of the Company’s largest R&D centers in the world. Approximately 1,500 employees are expected to work in the new center in the fields of smart transportation and connected industries by the end of 2018. (From a release on September 7, 2018)

-In an investor conference call, the Company’s Bosch India subsidiary announced that it has set up Agile Project House on mobility solutions. The project house will enable the company to respond better to local requirements while making use of global solutions. The project house will work in close cooperation with the software division in Bosch India and Engineering Services. (From Bosch Limited conference call Q1, FY 2018-19)

-The Hungary Investment Promotion Agency (HIPA) announced that the Company will expand its Budapest engineering center with a EUR 120 million investment. The expanded building complex will feature creative spaces, innovation zones, and relaxation areas. In the center, engineers will develop self-driving systems and play a considerable role in the Company's electromobility research and development activities. The first phase of the investment is set to be finished by 2021. (From HIPA press release on July 10, 2018)

-The Company opened a new technology center in Braga, Portugal. The new center will create 100 new jobs. Approximately 100 more employees have already moved from the Company's headquarters four kilometers away to the new technology center, which covers an area of 4,500 square meters. In total, approximately 200 engineers are expected to work on the development of sensors and software functions for automated driving by the end of 2018. The new technology center is also working on a long-term collaborative joint project with the University of Minho to investigate sensors for automated driving. The team is expected to start work on this new project this year, which will run for three years. (From a press release on May 29, 2018)

-According to local media reports, the Company will invest USD 12 million in a new 10-story, 10,000-square-meter building in Guadalajara to house the 400 employees currently working at the Company's operations center in the Ciudad Creativa Digital, located in the same city. The move is due to the fact that the Company’s operations expanded significantly in its four years of operations, going from 14 employees in 2014 to 400 by the end of 2017. The center is expected to have 1,000 employees by 2020. The innovation center includes a coworking space for other companies. Centraal, a company that operates shared work spaces in these types of facilities in Mexico City, will also occupy space in the new building. (From a Mexico-Now article on April 6, 2018)

-The Company has moved to a larger location in Silicon Valley, opening a new Research and Technology Center (RTC) in Sunnyvale. The previous RTC was located in Palo Alto. The Company has invested EUR 36 million in the new location, which will consolidate 200 employees in the RTC. Covering almost 10,000 square meters, the new location offers 40% more space in total and room for up to 300 associates. Roughly half of the company’s associates in Sunnyvale work in basic research and advance engineering to develop processes and solutions in fields such as data mining, sensors, artificial intelligence, and automated driving. (From a press release on April 5, 2018)

-The Company announced its plans to significantly increase the extent of localization of its electrified portfolio in India. It will soon offer end-to-end solutions including drive components and intelligent charging infrastructures. In order to better respond to local requirements, the Company has set up an Agile Project House at its operations in India. The project house is working on prototype development and system integration to feasibly deploy electric vehicles and electromobility solutions on Indian streets. With this approach, the Company is demonstrating its indigenously developed, fully electric high-voltage vehicle systems with the 400 V, 85 kW powertrain at the Bosch Technology Exposition 2018. (From a press release on February 6, 2018)

R&D Activities

-The Company is continuing to research and develop measures to reduce emissions for gasoline engines. This includes the development of systems which utilize varying injection pressures, the development of systems which utilize multiple injections, and additional exhaust treatment systems.

-At the start of 2018, the Company discontinued research into current and future battery cell technologies as the original goal of the research was to determine the feasibility of in-house battery cell production. As such, the Company dissolved the Lithium Energy and Power GmbH & Co. KG joint venture held with GS Yuasa and Mitsubishi Corporation, which focuses on the development of next-generation lithium-ion battery technology. The Company will also end operations of Seeo, Inc., which focuses on the research of solid-state battery technology, in 2019.

-The Company and Daimler announced that they have chosen San Jose, California as the pilot city for an autonomous ride-hailing service that will launch in the second half of 2019. The Company and Daimler plan to deploy the service, offered through a Daimler Mobility Services ride-hailing app, with a fleet of highly and fully automated driving (SAE Level 4 and 5) Mercedes-Benz S-Class sedans to a selected user community in a corridor between downtown and west San Jose. The two companies had previously announced plans to launch a self-driving car pilot in Silicon Valley, but had not announced the location. Engineers for Daimler and the Company have been collaborating on autonomous vehicle technology development with the goal of delivering a self-driving car by 2021. Daimler specializes in delivering the vehicle's driving system, while the Company provides key components, such as sensors. (Daimler press release on November 8, 2018) (Detroit Free Press article on November 8, 2018)

-The Company, Vodafone and Huawei are the first companies to performing live field tests of Cellular-V2X technology in Europe. The companies have been testing 5G test modules on the A9 freeway in Bavaria. For the first time, the companies are demonstrating that driver assistance systems such as adaptive cruise control also benefit from direct, instantaneous exchange of information between vehicles. Until now, Cellular-V2X has been used as a real-time alert system when changing lanes on the freeway or when the car ahead suddenly brakes. Driver assistance systems are different in that they have limited vehicle control capability, and can use the information from Cellular-V2X to make decisions. (From a press release on January 24, 2018)

Technological Alliance

-The Company has multiple collaborations in relation to the use of fuel-cell technologies for commercial vehicles. The Company is collaborating with Weichai to develop fuel-cell powertrains for commercial vehicles. The Company is also working with the Nikola Corporation to develop an electric axle for heavy trucks featuring fuel-cell powertrains, as well as an efficient electrical powertrain with a fuel cell acting as both a power generator and storage medium.

-PowerCell Sweden AB has signed a term sheet with the Company, regarding a joint development cooperation regarding the PowerCell S3 automotive fuel cell stack and PowerCell’s fuel cell systems. The parties have also agreed that PowerCell will start supplying the Company with fuel cell stacks for use in the Company’s prototype automotive fuel cell systems. The two parties aim to finalize these negotiations in the first half of 2019. (From a press release on December 18, 2018)

-Cinemo announced that the Company’s Car Multimedia division will showcase an engaging solution for Android Automotive systems that energizes in-vehicle digital media consumption at CES 2019. Both companies will also detail additional cooperation potential for further automotive commercial projects. For the second consecutive year at CES, the Company will utilize Cinemo’s multimedia and connectivity framework to demonstrate the performance and universal control of its Android Automotive based infotainment and telematics hardware. Both the Company and Cinemo will leverage their technological strengths with future commercial projects that enrich the cockpit experience. (From a press release on December 13, 2018)

-The Company and Huawei announced a partnership to accelerate the development of IoT in China. Huawei is developing IoT hardware gateways that will be pre-configured with Company IoT Gateway software and managed through the Company’s IoT Remote Manager to run on the Huawei Cloud. The Bosch software platform connects web-enabled objects to facilitate data sharing across a multitude of digital services and business models. A leading Chinese automaker has chosen to deploy the Bosch IoT Suite on Huawei Cloud for its vehicles’ over-the-air firmware updates. The solution is expected to be deployed in the coming years. The Bosch IoT Suite enables vital services such as the Vehicle Management Solution, which is available locally on Huawei Cloud. This solution connects vehicles throughout their service life, providing the technological foundation for cloud-based services such as predictive diagnostics and over-the-air software updates. (From a press release on October 10, 2018)

-The SiTime Corporation and the Company announced a strategic technology partnership focused on innovative microelectromechanical systems (MEMS). SiTime will work with the Company to develop new processes and procedures for next-generation MEMS resonators. These MEMS resonators are the key to 5G, IoT and automotive electronics, and will enable the higher speeds of 5G, longer battery life of IoT devices and increased reliability of driver assistance systems in automotive applications. SiTime has produced more than a billion MEMS timing applications for numerous segments across the electronics industry. (From a press release on September 4, 2018)

-The Company has formed an alliance with Foreca, a leading provider of weather information, to develop predictive road condition services to increase the safety and availability of automated driving functions. The service will be deployed worldwide in 2020 based on weather data. As the number of networked cars in the market increases, the service will be supplemented with vehicle data. Foreca supplies the Company with global, constantly updated road weather data. (From a press release on July 25, 2018)

-The Company and electric vehicle company NIO signed a strategic cooperation agreement focused on sensor technology, automated driving, electric motor controls, and intelligent transport systems. NIO began delivering its seven-seat high-performance electric SUV, ES8, to customers in China in June. The vehicle contains key components from the Company, such as driver assistance systems, control units, sensors and the iBooster electromechanical brake booster. The components will be developed further for NIO’s future models. (From a press release on July 9, 2018)

-The Company announced a strategic investment in Canada-based startup Mojio, a technology platform and software-as-a-service (SaaS) provider for connected cars, as well as an innovation agreement to co-develop connected car services that include vehicle communication, diagnostics, crash detection and notification. Founded in 2012, Mojio has teams in Vancouver, Canada; Palo Alto, California, U.S.; and Sofia, Bulgaria. Mojio has gathered real-world data from more than 7 billion miles of driving as part of its platform service that delivers connected car experiences to subscribers of network operators in North America and Europe, including Deutsche Telekom, T-Mobile US and TELUS. (From a press release on June 27, 2018)

-The Company’s Bosch China subsidiary and Changjiang Automobile held a ceremony to commemorate the signing of a strategic partnership agreement in April 2018. The two companies will fully cooperate in the fields of intelligent drive, IoV, intelligent transportation and electrification. (From some releases on April 13, 2018)

-The Company and the Aachen-based automaker, e.GO, have agreed to collaborate on automated valet parking. The Company will manage the infrastructure technology in the parking garage and will work with e.GO to integrate the startup’s vehicles into the automatic valet parking service. The first stage will see automated valet parking implemented using up to 12 of e.GO’s Life electric cars. These cars are part of e.GO’s fleet. In the second stage of development, the Company and e.GO aim to improve parking-space utilization in the parking garage with the help of automated valet parking. The new parking garage for the production engineering cluster on the RWTH Aachen campus, built in 2018, is equipped with the Company’s automated valet parking infrastructure. (From a press release on April 11, 2018)

Product Development

Electrification components and systems for Chinese market

-At the end of 2018, the Company began production of a new 48-volt battery for entry-level hybrid vehicles in China. The Company also provides a standardized 48-volt system for two-wheeled vehicles and small four-wheeled vehicles, featuring a motor, control unit, charger, display and smartphone app connectivity. In 2019, the Company will also begin production of its e-axle in China, which integrates a motor, power electronics and transmission in a single module.

Highway assistant system

-In 2018, the Company launched a new highway assistant which combines the capabilities of adaptive cruise control with stop-and-go traffic handling and lane-keeping support. Through the optimization of longitudinal and lateral assistance during in-lane travel, the highway assistant is capable of providing level 2 autonomous driving for the vehicle.

Perfectly Keyless entry system

-The Company’s Perfectly Keyless system revolutionizes keyless entry systems. The technology utilizes a virtual key stored in a smartphone. Built-in sensors in the car recognize the owner's smartphone as securely as a fingerprint and opens the door for the owner. The system features Bluetooth as a transmission technology and can be used with private cars, sharing fleets and commercial vehicles. If the smartphone and its app are lost, the digital key can be deactivated online, thus blocking access to the vehicle through the system. (From a press release on December 19, 2018)

Technologies showcased at CES 2019

-The Company will present its solutions in a demonstration vehicle based on an Audi A3 e-tron at CES 2019. The integrated charging and navigation solution increases the everyday benefits of electromobility by enabling the electric car to know when it runs out of power and where to recharge. The mySPIN smartphone integration system allows drivers to safely use smartphone apps while driving, and now supports the MirrorLink standard. The Company has developed a cloud-based solution that warns wrong-way drivers and vulnerable road users within ten seconds. The electronic horizon provides data on inclines and curve radii of roads to complement navigation data, enabling the vehicle to think ahead, thus increasing both comfort and safety. (From a press release on December 13, 2018)

Mobility services showcased at concept shuttle in CES 2019

-The Company will provide mobility services in future, bundling them into a smart, seamlessly connected ecosystem. That will include booking, sharing, and networking platforms, parking and charging services, and software solutions for managing and maintaining vehicles, and infotainment options during the trip. The Company will present its mobility solutions with a concept shuttle at CES 2019. The concept shuttle features technology ranging from an electric powertrain and 360-degree surround sensors to connectivity management and vehicle computers. (From a press release on December 12, 2018)

Central control unit for V2X communication

-In order to enable connected and automated driving in the future, vehicles must be able to easily communicate with other vehicles and their surroundings. Currently, there is no global standard for V2X communication. Instead, in the future, vehicles will communicate using a wide variety of different standards implemented by countries and vehicle manufacturers around the world. The Company has combined connectivity and telematics units, which individually, are capable of a single transmission technology, to create an all-in-one central control unit for V2X communication. Cars can then use Wi-Fi networks while commuting in cities, while using cellular networks elsewhere. The task of managing the diverse communication options is handled by a software solution from Veniam, a startup based in Silicon Valley. The unit continuously searches for the best transmission technology that suits specific requirements and switches automatically between available alternatives, therefore maintains continuous and seamless vehicle connectivity. (From a press release on December 5, 2018)

Vehicle motion and position sensor

-The Company has developed a vehicle motion and position sensor that allows automated vehicles to precisely determine their position. The new sensor includes a high-performance receiver unit for global navigation satellite system (GNSS) signals, which an automated vehicle needs to determine its absolute position. The vehicle motion and position sensor combines GNSS position signals, correction data, inertial sensor data, the wheel-speed sensor data, and steering-angle sensor data. The Company also provides Bosch road signature, a map-based localization service based on the sensors in vehicles. The Company ensures safety redundancies by combining the satellite- and vehicle motion and position sensor-based approach with the road signature’s map-based localization service. (From a press release on November 27, 2018)

Curved instrument cluster

-The Company is putting the world’s first curved instrument cluster in the cockpit of a mass-production vehicle. The curved instrument cluster will debut in the Innovision Cockpit of the new Volkswagen Touareg. A new manufacturing process enables the instrument cluster to reflect more than four times less light, even in the sunlight, providing increased sharpness and contrast. The optical bonding process uses a thin liquid to bond the instrument display and glass directly to each other. The displays curvature mimics the natural curvature of the human eye. Thus, the driver is able to more easily detect indicator lights and warning signals, even at the edge of the screen. (From a press release on November 14, 2018)

Electric van sharing service

-The Company announced that it is launching a new sharing service for electric vans. Together with toom, a subsidiary of the German retail group Rewe, the Company will be testing the service at hardware stores in Germany. The van-sharing service will initially be offered at hardware stores in Berlin, Frankfurt, Leipzig, Troisdorf, and Freiburg. These stores already feature charge spots for small electric vans, which are provided by StreetScooter. The Company supplies the powertrain components for these vehicles. If the new sharing service proves popular, the Company plans to expand it to include other partners, such as other toom stores, furniture stores, supermarkets, or electronics stores. (From a press release on October 9, 2018)

Electrified axle that can be integrated into semitrailers

-At the 2018 IAA Commercial Vehicles in Hannover, the Company will present an electrified axle that can be integrated into semitrailers. The Company supplies an inverter and the relevant vehicle control unit. The separate motor generator is available for installation as a complete electric motor, or the active components consisting of a rotor, stator, and resolver, can be integrated into the axle. A battery system is also required. The Company calculates that the electric axle can save up to 9,000 liters of diesel a year. An electrical start and acceleration boost function can help save additional fuel, which in turn reduces CO2 emissions. The Company offers this technology for new trailers and as a retrofit solution. (From a press release on August 28, 2018)

Digital vehicle key for commercial vehicles

-The Company has developed a digital vehicle key which uses a smartphone. The Company anticipates a large market for the solution, which is celebrating its world premiere at the IAA Commercial Vehicles in Hanover. The heart of the new system is an app that both dispatchers and truck drivers have on their smartphones. Access authorizations for vehicles are allocated through the cloud via the app. When the driver with their smartphone, gets to the truck, the sensors built into the truck detect the key via a radio link. The sensors also determine once the driver is in the car. At which point, once the driver presses the start-stop button, the truck will start. In the future, digital key management will be fully integrated into the dispatching and planning system of freight forwarders. (From a press release on August 23, 2018)

Connectivity, electrification and autonomous technologies showcased at IAA Commercial Vehicles

-The company is presenting its innovations for tomorrow's freight traffic at the 67th IAA Commercial Vehicles in Hannover. Using technology to automate, connect, and electrify commercial vehicles, the Company is improving efficiency and safety in logistics. For connected services, the Company will showcase a connectivity platform for cloud-based services, predictive diagnostics, and other features. Its driver assistance systems for commercial vehicles, including turn warning, blind-spot recognition, predictive emergency braking and lane assistant, will also be presented. (From a press release on August 2, 2018)

Electronically controlled windshield wiper

-The Company will start mass-producing an electronically controlled wiper with a new structure around the end of 2018. The new wiper will offer improved cost performance by having a simplified structure while featuring advantages found in electronically controlled wipers such as wiping capacity, noise, and retractability. The new wiper system has a structure that allows one motor to operate two arms. The decrease in the number of motors will provide improved cost perofrmance. Although the new wiper system uses a linkage to transmit power to two wiper arms, the linkage is simpler in structure than mechanical link arms due to an ECU that controls the repetitive motion of the wiper arms. The new wiper will achieve a 30% reduction in cost and weight compared to mechanical wipers equipped with link arms. The Company will gradually increase production through the middle of 2019. (From an article in the Nikkan Jidosha Shimbun on July 31, 2018)

EV route optimization system and energy management system

-The Company is developing new solutions to enhance the convenience of EVs on a full-scale basis. The Company has developed technologies that provide optimal route information by predicting the vehicle’s possible travel distance and charging locations, as well as an energy management system that efficiently utilizes power. Some of these technologies have been already commercialized in Europe. The Company is planning to cooperate with other industries to develop a service for optimizing time used for fast charging. The Company will actively develop EV-related services in addition to EV parts in order to take the lead in electrification. It introduced the system!e electric mobility services at the Bosch ConnectedWorld 2018 event held in Germany in February. One of the system's three main services is precise prediction of travel distance. Battery consumption fluctuates depending on factors like the use of air conditioning and audio systems, road conditions, and driving styles. The service is able to predict a vehicle’s remaining range by utilizing hardware that monitors battery consumption. (From an article in the Nikkan Jidosha Shimbun on June 25, 2018)

Diesel technologies which reduce nitrogen oxide emissions

-The Company’s new developments in diesel technology could enable vehicle manufacturers to reduce emissions of nitrogen oxides (NOx) to the point that they comply with future limits. Vehicles equipped with the new diesel technology can achieve approximately one-tenth of the prescribed NOx emission limit that will apply after 2020. A combination of advanced fuel-injection technology, a newly developed air management system, and intelligent temperature management has resulted in significantly lowered NOx emissions. The new diesel system is based on components that are already available in the market. It is available to customers effective immediately and can be incorporated into production projects. The Company also aims to use artificial intelligence to build on these latest advances. This will mark another step toward a major landmark: the development of a combustion engine that, excluding CO2 emissions, has virtually no impact on the ambient air. (From a press release on April 25, 2018)

Redundant braking and steering solutions for autonomous vehicles

-The Company is working on redundant brake solutions across all levels of autonomy. The Company solution for a redundant braking system consists of the combination of the iBooster electromechanical brake booster and the Electronic Stability Control. In the rare case of a failure of one of the two components, the other component can assume braking functions without driver intervention. The Company is also promoting redundant steering for automated driving. This allows the driver or autopilot to maneuver the vehicle to a safe location in the event of a fault, a necessary prerequisite for automated driving. (From a press release on January 16, 2018)

Technologies showcased at NAIAS 2018

-The Company will present several innovations that will make vehicles more efficient, more context-aware and much safer at the 2018 North American International Auto Show. One year after its debut, the Company’s eAxle has achieved significant momentum. The Company’s braking and steering solutions will make automated driving a reality. Connected solutions will also be essential in future vehicles. (From a press release on January 16, 2018)

Smart cockpit technology

-At CES 2018, the Company will showcase smart cockpit technology that lets drivers concentrate on driving. In the future, the Company will run the entire human-machine interface through a cockpit computer and will integrate more functionality in a single central processor. That will enable the convergence and synchronization of the infotainment system, instrument cluster, and other displays so that any information can be managed, and displayed anywhere in the vehicle at any given time. (From a press release on January 8, 2018)

HMI voice assistant

-The Company has developed a HMI voice assistant that is by nature multilingual and does not require an external data connection for support. The voice recognition system understands and speaks 30 different languages with 44 female and 9 male voices. The newly developed technology frees drivers from distractions so that they can concentrate on driving. The voice recognition system understands natural sentence structures as well as accents and dialects. (From a press release on January 3, 2018)

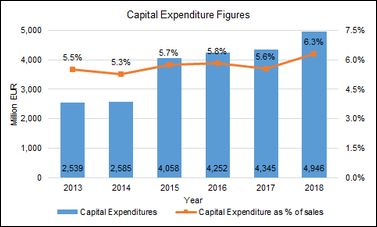

Capital Expenditure |

(in million EUR) |

| FY ended Dec. 31, 2018 | FY ended Dec. 31, 2017 | FY ended Dec. 31, 2016 | |

| Overall | 4,946 | 4,345 | 4,252 |

| -Mobility Solutions | 3,800 | 3,300 | 3,300 |

-In the fiscal year ended December 31, 2018, the Company’s Mobility Solutions business sector had capital expenditure totaling EUR 3.8 billion, representing a 15.1% increase over the previous fiscal year. The Company’s capital expenditure in the Mobility Solutions business sector focused on gasoline direct injection systems, electric drive systems, e-axles, CVT units, iBoosters, integrated power brakes, electric bikes and automated driving systems.

-In the fiscal year ended December 31, 2018, the Company’s Mobility Solutions business sector had capital expenditure totaling EUR 3.8 billion, representing a 15.1% increase over the previous fiscal year. The Company’s capital expenditure in the Mobility Solutions business sector focused on gasoline direct injection systems, electric drive systems, e-axles, CVT units, iBoosters, integrated power brakes, electric bikes and automated driving systems.

Investments in Germany

-The Company has begun construction of its semiconductor plant in Dresden on a 100,000-square-meter plot. The construction of the semiconductor factory is the largest single investment in the Company's history, with an investment of more than EUR 1 billion. The chips that will be manufactured in Dresden will be tailored for use in the IoT and automated driving. The new factory will employ more than 700 employees. (From a press release on April 24, 2018)

Investments outside Germany

<India>

-In an investor update, the Company’s Bosch India subsidiary declared a capital expenditure of INR 17 billion over the next three years. The Company will use the investment to transform its headquarters at Adugodi into one of the smartest campuses in India by 2022. The investment will also be used for its 100-acre greenfield property in Bidadi for its second phase of construction, as well as a scheduled shift of production from the Bangalore plant into Bidadi by the middle of 2019. (Based on Bosch investor conference call Q2, FY 2018-19)

-The Company expects to see business continue to develop positively in India in the medium term. Beginning in April 2020, India is planning to switch from the BS-IV to the BS-VI standard. The government is also pressing ahead with the development of electromobility solutions adapted to the Indian market. The Company aims to provide technology to support both initiatives. In order to meet rising demand in the Indian market, the Company will invest approximately EUR 220 million over the next three years. Apart from modernizing manufacturing plants in India, the bulk of the investments will go towards further expanding the Company’s new Adugodi smart campus. India also plays a key role within the Company regarding artificial intelligence. In 2017, the Company invested approximately EUR 300 million in the Bosch Center for Artificial Intelligence, which has locations on three continents, including Bengaluru, India. (From a press release on June 20, 2018)

<Mexico>

-The Company inaugurated its new USD 16 million production facility in Aguascalientes, Mexico. The new 36,000-square-meter facility will manufacture the second-generation brake booster known as iBooster 2, along with G9 ABS systems and other components for its electronic stability programs (ESP). The plant will have 220 employees by the end of 2018, and will add an additional production line in 2021. (From a Mexico-Now article on August 29, 2018)

-The Company officially broke ground in Celaya, Guanajuato to build its USD 120 million plant dedicated to electronic automotive components. The Company plans to hire 1,200 employees at the 21,000-square-meter facility to manufacture ECUs for the U.S. market. Friedrich Dreler, plant project leader, said, “This plant is a sister of our plant in Juarez, we need more space and that is why we are building the new plant here, the plant in Juarez has reached its limit with more than 4,000 employees, we’re starting the first phase of construction in October with 24,000 square meters of floor production and 11,000 square meters for the logistics center.” (From a Mexico-Now article on August 27, 2018)

-Dr. Michael Schmitt, senior vice president and plant manager at Bosch-Toluca, announced that the Company is investing USD 150 million throughout 2018 for various projects in Mexico. The Toluca facility manufactures a wide range of components including comfort systems, braking systems, thermal systems, fuel pumps, and low pressure sensors. The plant has the capacity to produce 125,000 electric motors per day. In 2017, total sales from the Bosch Toluca unit approached USD 1 billion. More than 80% of the production from Bosch Toluca is used by North American customers. (From a Mexico-Now article on August 7, 2018)

-The Company is investing EUR 100 million in a new plant in Celaya, Guanajuato, Mexico. The Company plans to build a new smart factory for electronic components in the central Mexican city by 2020, with the goal of creating more than 1,200 additional jobs at the new Industry 4.0 plant in the coming years. The new 21,000-square-meter facility in Celaya will manufacture ECUs for the U.S. market. Covering a total surface area of 170,000 square meters, the site has the capacity for future expansion. (From a press release on April 17, 2018)

<Austria>

-ABA – Invest in Austria informed that the business of the Company’s Austrian subsidiary is going so well that an additional 95 developers will be hired in 2018. Its revenue is expected to rise by at least 5% in 2018, with demand remaining high, especially in the field of mobility. It is witnessing high level of demand for injection systems for large engines and exhaust aftertreatment systems. In addition to the core business, the Company aims to grow within the country through Internet-based technologies. (From ABA press release on June 13, 2018)

<Thailand>

-The Company is optimistic that Thailand’s healthy economic growth will spur further development of the local automotive industry. The Company believes that the positive outlook for 2018 and better circumstances in terms of overall car output will make growth likely for the Company this year. The Company is also optimistic that Thailand’s Eastern Economic Corridor scheme is coming together with the Industry 4.0 initiative and that the two policies are showing progress in upgrading Thailand as an investment destination. The Company concluded its fiscal 2017 with THB 12.8 billion in consolidated sales in Thailand, registering growth of 7.5% compared to the previous year. In 2017, the Company recorded investment of THB 1.6 billion across all business sectors in Thailand. The Company also revealed that it is making significant investments in electric powertrains while it continues to develop innovations in combustion engines to increase efficiency and reduce emissions. (From an article of Bangkok Post on June 6, 2018)

<China>

-The Company announced that it has opened a new plant for infotainment systems in Wuhu, China. The plant is located on an 18,000-square-meter plot, and will manufacture infotainment systems, instrument clusters and connectivity control units for vehicles for the Chinese market. By the end of 2018, the new plant will employ 900 people, 160 of which in research and development. (From a press release on May 23, 2018)

-On March 27, 2018, the Company held a groundbreaking ceremony for China’s first 48V automotive battery plant. In September 2017, the Company signed a memorandum of understanding with the Wuxi High-tech Industrial Zone regarding a full-scale strategic partnership agreement in the areas of automotive battery production, electric vehicle development and IoT applications. The batteries will be used in both electric vehicles and ICE vehicles. Sales from the new plant are expected to reach CNY 8.7 billion in 2021. (From some releases on March 29, 2018)

<Vietnam>

-The Company’s powertrain solutions plant in the Dong Nai province, Vietnam, has manufactured more than 25 million CVT pushbelts for automakers in the Asia Pacific and North America regions. Over the past ten years, the production capacity of the factory has continuously expanded. As of December 2017, the plant successfully runs 18 production lines. The number of associates working at Dong Nai facility has grown from less than ten in 2008 to more than 1,900 by the end of 2017. Since 2015, the plant has invested around USD 1 million to build and operate a wastewater recycling system. At the end of 2017, the Company announced an additional investment of USD 67 million into the plant to continue increasing its production capacity and to transform it into a smart factory. By the end of 2018, the Company will have invested a total of USD 372 million into the plant. (From a press release on March 15, 2018)

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India