Bosch [Robert Bosch GmbH] Business Report FY ended Dec. 2016

Financial Overview |

(in million EUR) |

| FY ended Dec. 31, 2016 | FY ended Dec. 31, 2015 | Rate of Change (%) | Factors | |

| Overall | ||||

| Net Sales | 73,129 | 70,607 | 3.6 | 1) |

| EBIT | 3,335 | 4,587 | (27.3) | 2) |

| Mobility Solutions | ||||

| Sales | 43,936 | 41,657 | 5.5 | 3) |

| EBIT | 2,047 | 3,216 | (36.3) | 4) |

Factors

1) Net Sales

-In the fiscal year ended December 31, 2016, the Company’s net sales were EUR 73,129 million, an increase of 3.6% over the previous year. Excluding negative currency effects during the year, the Company’s sales increased by 5.5% for the year, as the negative currency effects accounted for a loss of EUR 1.3 billion. In addition, changes in consolidation increased sales by approximately EUR 130 million. The Company had increased sales in Europe and Asia Pacific regions, which was partially offset by slightly decreased sales in North America and South America.

2) EBIT

-The Company’s EBIT in the fiscal year ended December 31, 2016 was EUR 3,335 million, a decrease of 27.3% from the previous year. The decrease in earnings was primarily a result of an increase in upfront investments including higher research and development costs, higher depreciation on capital, restructuring costs, and negative currency effects compared to the previous year.

3) Mobility Solutions Sales

-The Company’s Mobility Solutions business sector’s sales increased by 5.5% in the fiscal year ended December 31, 2016 to EUR 43,936 million. The first-time effect of a full year of consolidation of the Automotive Steering division had a positive effect of approximately EUR 320 million. Sales were positively impacted by increased demand for advanced gasoline direct injection systems, engine management systems, transmission control systems, sensors, driver assistance systems, exhaust gas treatment systems, and active and passive safety systems.

4) Mobility Solutions EBIT

-The Mobility Solutions business sector had EBIT of EUR 2,047 million in the fiscal year ended December 31, 2016, a decrease of 36.3%. The decrease was primarily caused by higher depreciation from the remeasurement of assets, as well as increased investments in research and development and capital expenditure.

Acquisitions

-The Company signed an agreement to acquire ITK Engineering AG, a development services company headquartered in Rulzheim, Germany. ITK Engineering employs more than 800 people and is a major service provider in the field of model-based system and software development, specializing in the automotive engineering industries. ITK Engineering will be run as a wholly owned subsidiary within the Company and controlled by Bosch Engineering. (From a press release on October 13, 2016)

Business Partnership

-Siemens PLM Software announced that the Company’s Electrical Drive Division will introduce Siemens' integrated suite of software solutions, including its mainstay NX CAD software and Teamcenter product lifecycle management (PLM) software, in summer 2016. The Company has already been using the same software from Siemens in other business units. Expanding the use of the solutions is expected to lead to efficient data sharing, faster innovation, accelerated time-to-market, and broader support for the Industry 4.0 strategy. (From an article in the Nikkan Jidosha Shimbun on March 23, 2016)

-Anhui Quanchai Engine Co., Ltd. announced it signed a basic agreement with Bosch Automotive Diesel Systems Co., Ltd., setting the framework to enter into a full-scale partnership. Their areas of partnership will include engine fuel systems compliant with China V or stricter standards, diesel exhaust aftertreatment systems that meet China V or higher standards, and non-road engine fuel systems that meet China III or higher standards. The Company expects the collaboration will accelerate the development and sales of high-end diesel engines for the Chinese market. (From a press release on January 25, 2016)

-The Company announced that Bosch Engineering Technology Co., Ltd. and CH-AUTO Technology Co. Ltd. have signed an agreement to form a strategic partnership to collaborate on the development of electronic stabilizer programs for CH-Auto’s Event. (From news releases issued by multiple sources on January 19, 2016)

Recent Developments

-The Thailand 4.0 initiative has provided a tremendous business opportunity for the Company to deploy its smart solutions to all key industries. Following global trends, the Company is focusing on three "S" strategies: sensors, software and services, as pillars for a connected strategy. The Company was one of the leaders in making micro-electromechanical system (MEM) sensors, while its software is designed to analyze data collected from sensors. The Company acknowledged that while Thailand was in the early stages of adopting these new technologies, it was encouraging to hear the government announce its support of a digital economy by encouraging all business sectors to get involved with the developing trend. The Company aims to create automated valet parking in 2018 and expects to launch autopilot in the near future. (From The NATION article on November 28, 2016)

-The Company’s Bosch India subsidiary hosted the Bosch Smart Manufacturing Conclave (BSCM) in Mumbai, targeting primarily customers, suppliers and other relevant stakeholders. The outcome of the conclave determined that a digitally driven India will lead to the overhauling of manufacturing facilities. The Company is equipped to offer India a broad range of technology solutions and services in smart manufacturing, such as drives, automation, sensors, software and predictive maintenance. These solutions are suitable for the automotive manufacturing industry and tier 1 component manufacturing organizations. The Company believes that smart manufacturing can improve India’s productivity and optimize operations. India is one of the frontrunners when it comes to the adoption of the Internet of Things (IoT) in the Asia Pacific region. The Company has a dual approach as a lead supplier and user of Industry 4.0 in its own manufacturing plants. This strategy enables the Company to be a leader in this sector. The Company focuses on offering software solutions with intuitive human machine interface (HMI) and user experience which results in full grade connectivity, final transparency and reduced complexity. (From a press release on November 11, 2016)

-The Company announced that it has resumed operations at its plant in Jaipur, India, following the Rajasthan State Pollution Control Board issuing a notice to close the plant in abeyance for a period of one month. The Company also announced that there was no material impact because of the suspension of plant operations for one day. On October 28, the Company announced that the plant was served with an order by the board over alleged non-fulfillment of certain conditions with respect to waste water treatment and the reuse of the treated water. The Company was compelled to close the operations at the Jaipur Plant immediately upon receipt of the order. (From a Bosch Limited Stock Exchange filing on October 28, 2016)

-The Company’s Bosch India subsidiary announced that it is planning to start manufacturing an anti-lock braking system (ABS) for two-wheelers at its Chakan plant from next fiscal year. The Government of India recently announced fitment of antilock braking systems (ABS) as a mandatory requirement beginning April 2018. This move will help the Company to meet future demand for ABS in the country. (From Bosch India press release on August 2, 2016)

Contracts

-The Geely Boyue that is equipped with the Company’s new AB12 airbag ECU has obtained a five-star safety rating in the third China-New Car Assessment Program (C-NCAP) 2016, which is run by the China Automotive Technology and Research Center. The airbag ECU used in the Boyue is the first of its kind developed in China and mass produced for the global market. Compared with the previous generation, the new ECU offers higher levels of chip integration and operating speeds. With acceleration sensors in the front and on the side, the ECU can precisely control the airbag deployment and belt pretensioners to reduce impact and prevent injuries from impacts during collisions. (From a press release on October 28, 2016)

-The Company’s CRSN4 common-rail injection system is used in the Freightliner Cascadia Evolution truck, which is powered by a Detroit DD15 engine with six cylinders. The high-pressure pump and rail come from the Jihlava plant in the Czech Republic, while the extremely precise injector is manufactured in Homburg, Germany. The pump provides system pressure of up to 1,200 bar, while the injector features an integrated hydraulic pressure amplifier that can more than double the maximum injection pressure. (From a press release on July 20, 2016)

-The Company is developing and testing the brake control system of Pagani's Huayra BC under icy and snowy conditions in the Arctic Circle. The Pagani Huayra BC boasts 12 cylinders and more than 750 hp. The Company makes the Huayra BC’s ABS antilock braking system, traction control system, and ESP electronic stability program. The vehicle will be tested on a track just a few kilometers south of the Arctic Circle. Pagani and Bosch Engineering have been technology partners for a number of years. (From a press release on May 10, 2016)

Awards

-The Company’s Bosch India subsidiary received multiple awards from Indian OEM in the 2015-16 fiscal year. Bosch India received the Supplier Excellence Award from Mahindra & Mahindra for Best Cost Management Performance. Bosch India also received an Award for Delivery from Tata Motors and was a Winner in the 'Delivery and Performance' category at the Escorts Partner Meet. Bosch India won a Quality award from Ford. SML Isuzu Ltd. awarded Bosch India for Product Upgradation through Innovation.

-The Company’s Bosch India subsidiary announced that it has received four awards at the Mahindra & Mahindra Annual Vendor Meet 2016. The achievements included the Mahindra Supplier Excellence Award and awards for valuable contribution towards building Mahindra's latest range of SUVs and tractors. (From Bosch India press release on July 10, 2016)

Outlook for FY ending Dec. 31, 2017

-Ignoring currency effects, the Company expects to have sales growth between 3% and 5% in the fiscal year ending December 31, 2017, led by the Mobility Solutions and Consumer Goods business sectors.

-In the long term, the Company expects to achieve an average annual sales growth of 8%, with up to 3% stemming from acquisitions. The Company also aims to achieve an EBIT margin from operations of approximately 7%.

-The Company forecasts that Asia Pacific will remain a significant driver of its growth for 2020. The market for the internet of things (IoT) is growing rapidly in the region, while investments and government schemes including “Made in China 2025” initiative and “Make in India” program, offer a wealth of opportunities for businesses with connected solutions. The Company plans to invest EUR 1.2 billion in the Asia Pacific region. The Company is also aiming to utilize local engineering and intensify partnerships in the region. The Company plans to employ up to 120,000 associates in the Asia Pacific region by the end of 2016. (From a press release on November 3, 2016)

-On June 8, the Company forecasted that its global sales to Japanese OEMs will grow at an average annual rate of at least 10% over the next six years through 2021. Its sales are forecast to increase in three business areas: electrification, autonomous driving, and connectivity (between vehicle and the external environment). (From an article in the Nikkan Jidosha Shimbun on June 9, 2016)

Corporate Strategy

Regional planning

-The Company's capital expenditure was distributed across its regions of operations as follows:

- Europe: EUR 2.8 billion

- Asia Pacific: EUR 1.0 billion

- North and South America: EUR 460 million

-The Company’s capital expenditure in Europe was primarily focused on increasing production capacity for semiconductors, sensors and gasoline direct injection systems, as well as new facilities at the Company’s location in Reutlingen, Germany. Another portion of the capital expenditure in the region was used towards expanding development activities in Abstatt, Germany.

-The Company’s capital expenditure in the Asia Pacific region was focused primarily on China, India, and Southeast Asia. In China, the investment was used towards expanding production locations of gasoline direct injection systems. The Company also used the investment for a new engineering center in Suzhou. In India, the Company expanded its plants in Bidadi and Nashik. The Company also began construction of a facility in Thailand for gasoline direct injection systems, while expanding capacity at sites in Malaysia and Vietnam.

-The Company’s capital expenditure in North and South America focused on primarily expanding locations in the U.S. and Mexico.

Avenues of development in the automotive market

-In its Mobility Solutions business sector, the Company’s goal is to become one of the world’s leading suppliers in electrified, automated, and connected driving. The Company is also aiming to become one of the world’s leading companies in the Internet of Things.

-The Company announced that it would consolidate its electromobility operations in a dedicated unit, as part of the Company’s new Powertrain Solutions division. By the beginning of 2018, the Powertrain Solutions division will encompass the Company’s electromobility activities, its Gasoline Systems division, and its Diesel Systems division. The Powertrain Solutions division will focus on three segments: passenger cars, commercial vehicles, and fully electric vehicles.

-In the fiscal year ended December 31, 2016, the Company invested approximately EUR 400 million in the field of electromobility. One main focus of the investments into electromobility was research and development related to batteries, power electronics and electric motors.

-The Company, in order to focus its operations on electrification, autonomous, and connectivity trends, announced several divestitures.

- The Company has spun off its Starter Motors and Generators division as an independent unit and has begun the sales process of the division.

- In conjunction with the Mahle Group, the Company is aiming to sell the turbocharger joint venture Bosch Mahle Turbo Systems (BMTS). While the turbocharger market is projected for further growth, a company’s success in the market is dependent on achieving a certain site. As both the Company and Mahle have decided against further expansion of BMTS, the next best course of action is the sale of the joint venture.

- The Company will discontinue the operations of a Bosch Emission Systems plant in Neunkirchen, Germany due to a difficult economic environment.

- The Company will sell its transmission components business in Japan for on-highway commercial vehicles to Knorr-Bremse AG.

R&D Expenditure |

(in million EUR) |

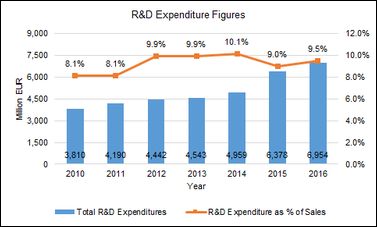

| FY ended Dec. 31, 2016 | FY ended Dec. 31, 2015 | FY ended Dec. 31, 2014 | |

| Overall | 6,954 | 6,378 | 4,959 |

| -Mobility Solutions | 5,285 | 4,784 | 4,066 |

-One part of the Company's mission statement focuses on the Company playing an active role in influencing changes occurring in both technology and various markets. These changes represent opportunities for the Company to take advantage of. In order to take advantage of these opportunities, the Company has continued to invest an increasing amount in research and development. This holds true especially in the Mobility Solutions business sector, where vehicle technologies are trending towards electrification, connectivity, and autonomous driving.

-One part of the Company's mission statement focuses on the Company playing an active role in influencing changes occurring in both technology and various markets. These changes represent opportunities for the Company to take advantage of. In order to take advantage of these opportunities, the Company has continued to invest an increasing amount in research and development. This holds true especially in the Mobility Solutions business sector, where vehicle technologies are trending towards electrification, connectivity, and autonomous driving.

-The Company's research and development expenditures in the fiscal year ended December 31, 2016 grew 9.0% to EUR 6,954 million, while the ratio of R&D expenditure to total sales increased from 9.0% to 9.5%. The increase in both R&D expenditure and ratio of R&D expenditure to total sales was due to the increased investments in the Mobility Solutions business sector. Specifically, the Company made heavy investments in driver assistance systems, automotive multimedia, and sensors. In the fiscal year ended December 31, 2016, the Mobility Solutions business sector accounted for 76% of the Company's total R&D expenditure.

R&D Structure

-As of December 31, 2016, the Company has approximately 58,700 employees working in research and development, an increase of 2,900 over the previous year. Over half of the employees working in research and development work in locations outside Germany.

R&D Facilities

-The Company has opened a new powertrain engineering center at its existing site in San Luis Potosi, Mexico. Between 2015 and 2018, the Company will invest roughly EUR 72 million in both the center and in expanding production capacity at the location. (From a press release on October 25, 2016)

-The Company announced that it is investing EUR 43 million (THB 1.7 billion) for the construction of a new factory and R&D center in Thailand which are expected to be completed later in 2016 and begin operations in 2017. (From a Bangkok Post article on October 6, 2016)

-The Company is strengthening its research and development activities in the U.S. In Pittsburgh, Pennsylvania, the Company has opened its expanded development center at a new, central location after outgrowing its previous facilities. Measuring almost 5,000 square meters, the technology center offers space for 200 employees. Approximately 130 employees now work at the new location. The location focuses on developing internet and security technologies for the Internet of Things (IoT). In addition to basic research, the new location also houses the Company’s subsidiary, Akustica, which develops and markets MEMS microphones. (From a press release on September 16, 2016)

-The Company inaugurated the first phase of expansion of its development center in Adugodi, Bengaluru, India. Since 2014, the Company has invested INR 3.5 billion (EUR 47 million) in revamping the facility into a technology and development center. The two newly inaugurated buildings have state-of-the-art laboratory facilities and can accommodate over 3,000 employees. Adugodi will house the majority of the local development, including R&D centers, of Bosch Limited. The new facility has an open work space, more discussion rooms and a collaborative work space on each floor. The Company announced that for the second phase of expansion, it will further invest in the coming years to develop Bosch Adugodi into a state-of-the-art R&D facility. The Company also announced that it will invest INR 11.7 billion in India in 2016. (From a press release on September 2, 2016)

-The Company held a ribbon-cutting ceremony at the 220,500-square-foot expansion of its technical center in Plymouth Township, Michigan, U.S. The expansion approximately doubles the size of the existing technical center, which opened in 2007. The total site, located on 75 acres, has more than 445,000 square feet and capacity for 1,400 employees. The expansion enables further growth of several key technologies, including automotive electronics, electrical drives, and a variety of safety and driver assistance systems that will advance automated driving. (From a press release on August 24, 2016)

-The Company announced that it has established a research and technology office in Tel Aviv, Israel. Its associates aim to work more closely with scientific institutions and universities and, at an early stage, to identify innovative start-ups working in fields such as machine learning (deep learning), robotics, cybersecurity, connectivity, and the internet of things (IoT). (From a press release on June 22, 2016)

-The Company announced that it has opened a new engineering center in Lund, Sweden. The new center already employs 50 experts, who are working on new software and hardware in areas such as vehicle connectivity, automotive security systems, and motorized two-wheelers. (From a press release on May 2, 2016)

R&D Activities

-Bosch Corporation, the Company’s Japanese unit, will accelerate development of automated driving systems. A new division committed to systems development was established at the Chassis Systems Control Division in February 2016, which will allow engineers to work as one comprehensive unit without being limited to the existing component framework. The systems development organization consists of more than 60 experts with different engineering backgrounds. Testing on Japanese public roads began in October 2015, with a second test vehicle developed in Japan shown to the media on September 28. The new test car was developed to realize highway pilot capabilities, which allows cars to drive autonomously on highways without driver supervision. (From an article in the Nikkan Jidosha Shimbun on September 29, 2016)

-The Company announced that it has begun on-road testing of autonomous driving in Japan. Test drives are being conducted on Tohoku Expressway in Tochigi Prefecture and Tomei Expressway in Kanagawa Prefecture, as well as on two Company proving grounds in Nasushiobara, Tochigi Prefecture and Memanbetsu, Hokkaido. The Company aims to help Japanese automakers introduce autonomous driving technology by carrying out tests on public roads. (From an article in the Nikkan Jidosha Shimbun on January 25, 2016)

-In 2016, the Company began collaborating with China’s Development Research Center of the State Council (DRC) on a study into connected manufacturing.

-The Company joined the IoT Acceleration Lab in Japan in 2016, an organization which promotes smart mobility and connected manufacturing.

-In the fall of 2016, the Company and Daimler launched a community-based parking project in the greater Stuttgart area in Germany. The project utilizes vehicles with ultrasonic sensors to detect available parking spaces as they drive and create a digital parking map. This information is then made available to other vehicles through the cloud. The solution developed by the Company and Daimler runs on an open platform which can be used by other partners.

Technological Alliance

-The Company’s subsidiary, Bosch Automotive Diesel Systems Co., Ltd., and Anhui Hualing Automobile Co., Ltd. signed an agreement to collaborate on developing products that meet the China VI emissions standard. Anhui Hualing will develop its Hanma engines by using the Company’s high-pressure common rail systems and aftertreatment systems, while following the Company’s roadmap for exhaust gas recirculation (EGR) systems, diesel oxidation catalysts (DOC), diesel particulate filters (DPF), selective catalytic reduction (SCR) systems, and acceleration slip regulation (ASR). According to Anhui Hualing, its CM6D30 60 Hanma engine with the Company’s newest High Power Density (HPD) engine brake offers more than 50% greater braking power than previous engines, while contributing to a 5% reduction in fuel consumption. (From news releases issued by multiple sources on November 3, 2016)

Product Development

eCall automatic emergency call service

-On June 8, the Company announced that it will start the eCall cloud-based automatic emergency call service in Japan at the end of 2016. This service is scheduled to be provided as original equipment hardware or an aftermarket add-on. The Company currently offers eCall in 41 countries worldwide and will set up a facility in Japan to start the cloud-based service. This service comes with a feature that enables a vehicle to automatically notify a Company call center when the sensor detects an accident through indicators like airbag deployment. An operator at the call center confirms the emergency call and notifies the nearest ambulance service and the police. The driver can also make an emergency call manually. (From an article in the Nikkan Jidosha Shimbun on June 9, 2016)

Home zone park assist autonomous parking technology

-The Company announced its newest autonomous parking technology, Home zone park assist, which is expected to make its North American market debut by 2019. With Home zone park assist, drivers can remotely control the parking process by smartphone, even from outside the vehicle. The technology will guide the car, autonomously if needed, to parking spaces up to 100 meters away, where it can then maneuver the car into the space. (From a press release on June 6, 2016)

Advanced car navigation software

-The Company announced that it has developed advanced car navigation software. The new software displays visible changes in terrain height by using integrated satellite imagery and produces an almost photorealistic look. It will allow the driver to easily locate the position of the vehicle, even when surrounded by high-rise buildings. This is made possible by the Company’s advanced navigation software, which takes data compliant with the new Navigation Data Standard (NDS) and processes it in a 3D rendering module to turn it into a photographic map. (From an article in the Nikkan Jidosha Shimbun on February 29, 2016)

Intelligent Transport Management System (iTraMS)

-The Company will be presenting its Intelligent Transport Management System (iTraMS) at the Bosch’s Technology Exposition in Noida, India. Its features include vehicle location tracking, condition monitoring, and performance analysis. The flexible new solution works in passenger cars, commercial vehicles, and off-highway vehicles. Another example of local development is e-Call, which was developed with contributions by the Bosch India engineering team. Vehicles equipped with the safety system trigger an automated emergency call whenever a crash happens. In 2015, Bosch India filed for more than 200 patents. (From a press release on February 2, 2016)

Active gas pedal

-The Company has developed a technical aid in the shape of the active gas pedal. The pedal vibrates to tell drivers if they are applying too much pressure. If the vehicle has an assistance system, the pedal also becomes a warning indicator. Coupled with a navigation system or sensors that recognize road signs, the pedal gives drivers a haptic warning if, for example, they are approaching a dangerous bend at too high of a speed. The active gas pedal encourages drivers to be light-footed on the accelerator. The feedback from the pedal allows drivers to reduce fuel consumption by as much as 7%. (From a press release on January 25, 2016)

Electric axle drive system

-The Company unveiled its new electric axle drive system (e-axle) at the 2017 North American International Auto Show in Detroit. As opposed to current powertrains for electric or hybrid vehicles consisting of individual components, the e-axle integrates the transmission, electric motor and power electronics together in a compact housing. This reduces the complexity of the electric powertrain and makes it smaller, less expensive, and more efficient, thus lowering production costs.

Patents

-In 2015, the Company filed approximately 5,400 patent applications.

Capital Expenditure |

(in million EUR) |

| FY ended Dec. 31, 2016 | FY ended Dec. 31, 2015 | FY ended Dec. 31, 2014 | |

| Overall | 4,252 | 4,058 | 2,585 |

| -Mobility Solutions | 3,300 | 3,100 | 2,200 |

-In the fiscal year ended December 31, 2016, the Company’s Mobility Solutions capital expenditure totaled EUR 3.3 billion, an increase from EUR 3.1 billion in the previous year. The increase in capital was primarily due to an increase in requirements of gasoline direct injection systems, driver assistance systems, infotainment and display systems. In addition, the Company expanded production capacity for semiconductors, sensors, and control units in response to increased demand.

Investments in Germany

-The Company is enhancing connectivity in its manufacturing operations, with more than 100 projects successfully running worldwide. Among other benefits, this increases the availability of its machinery, thus improving its productivity and competitiveness. In less than one year, the Company improved its productivity in the manufacture of ABS/ESP braking systems by nearly 25% by deploying Industry 4.0 solutions throughout its international manufacturing network. One reason for this productivity increase is the data collected from the thousands of installed sensors along the plant's production lines. The sensors record the movement of cylinders, the cycle times of grippers, and the temperature and pressure levels in the manufacturing process. This wealth of information is entered into massive databases. Through RFID (radio frequency identification) technology, the plant can also digitally map its internal flows of goods. The result is a computer-generated virtual representation, or "digital twin," of the actual factory. This digital representation facilitates transparency across the entire value stream, thus enabling many more Industry 4.0 solutions possible. (From a press release on March 10, 2016)

Investments outside Germany

-The Company announced that it will hire 500 workers in 2017 for its manufacturing sites in Juarez, Mexico to accommodate new purchase orders. The additional workers will bring the total workforce to 4,500 people by the end of 2017. The Company has several manufacturing plants in Juarez, including its largest electronic control device manufacturing plant in North America. The Company’s plants in Juarez currently produce more than 50 products including sensors, distance control units, anti-lock braking system (ABS) devices, electrical power steering controls, sunroof motors and window lifters. (From a Mexico-Now article on December 20, 2016)

-Between 2015 and 2018, the Company will invest roughly EUR 72 million in developing its powertrain engineering center and expanding capacity at San Luis Potosi. The plant in San Martin Obispo has also been expanded through an investment of EUR 9 million, with an additional building creating extra space for the production of hydraulic systems. The Company is planning to invest more than EUR 90 million in Mexico in 2016. (From a press release on October 25, 2016)

-The Company announced that it will establish a new facility in Queretaro, Mexico. This new plant will be the first location that the Company’s Automotive Steering division will have in the country. Construction of the facility will begin shortly, with completion scheduled for the end of 2016. The Company is investing approximately USD 80 million over the next four years to establish the 15,000-square-meter (160,000-square-foot) facility. Production lines will be installed beginning in January 2017, with production scheduled to begin in December 2017. The Company plans to hire approximately 600 employees by the end of 2019, with further growth planned. The facility will initially assemble three products for passenger cars: manual-adjust steering columns, Servolectric column type electric power steering and Servolectric dual pinion electric power steering systems. (From a press release on April 25, 2016)

-The Company announced that it is investing nearly EUR 400 million in 2016 for expansion purposes in the U.S., an increase of approximately 20% compared to 2015. The Company also announced its plans to continuously expand its Charleston, South Carolina plant. The Charleston plant employs more than 1,700 associates and manufactures components for ABS and ESP automotive safety systems. The Company’s U.S. headcount is expected to increase to more than 18,800 by 2017, from the 17,800 associates currently present, 2,300 of who are researchers and engineers. From 2011 to 2015, the Company invested a total of nearly EUR 1.2 billion in the U.S. The Company is also pursuing its expansion strategy in the U.S. with acquisitions. (From a press release on November 16, 2016)

-The Company announced that it is investing EUR 43 million (THB 1.7 billion) for the construction of a new factory and R&D center in Thailand due to be completed later in 2016 and begin operations in 2017. The plant will produce fuel injectors with an annual capacity of 1 million units. The investment is a part of a EUR 80 million package that the Company plans to invest in the ASEAN region in 2016. The remaining budget is slated for an expansion of the Company's manufacturing and sales facilities in Indonesia, Malaysia and the Philippines. (From a Bangkok Post article on October 6, 2016)

-The Company announced that it is planning to invest around EUR 80 million in Southeast Asia in 2016. In the first half of 2016, the Company opened new offices in the Philippines and Indonesia. The Company is also strengthening its manufacturing capacity in the region and plans to expand its Mobility Solutions plants in Malaysia and Vietnam, while planning a new plant in Thailand. In the past ten years, the Company has invested almost EUR 500 million in the expansion of its manufacturing and development locations in Southeast Asia. (From a press release on September 19, 2016)

-The Company announced it is entering the Japanese market for mobility services through the opening of its first service center in Shiki, 30 km north of Tokyo. Operations will begin by the end of 2016. The service center is expected to create approximately 50 jobs by the end of 2020. The Company will initially offer its eCall emergency service, while other mobility services such as its Concierge Service, Stolen Vehicle Tracking and Breakdown Call are in the planning phase. (From a press release on August 25, 2016)

-Robert Bosch Motor (China) Co., Ltd., a wholly owned subsidiary of the Company, began operations in the Changsha National High-Tech Industrial Development Zone on August 1, 2016. The subsidiary was established in April 2016 to develop and produce starter motors and alternators. Prior to the establishment, Bosch China produced starter motors, alternators, and electric drivetrain systems at two facilities: Bosch Automotive Products (Changsha) Co., Ltd. and Bosch Automotive Components (Changchun) Co., Ltd. (From news releases issued by multiple sources on August 3, 2016)

-On July 11, 2016, the Company began constructing a car multimedia plant in the Jiujiang Economic and Technological Development Zone, Wuhu. A total of USD 30 million will be invested in this facility, which will be located on a 61,333-square-meter-plot. The facility will develop, produce, and sell automotive instrument meters, navigation systems, and connecting control units, and will also offer related services to customers. Sales at this plant are expected to reach CNY 8 billion in five years after full-scale production begins. (From news releases issued by multiple sources on July 14, 2016)

-The Company is opening a new regional presence in Tehran, Iran. All of the Company’s business sectors will have operations in the country. By the end of 2016, the Company will employ approximately 50 associates in Iran. (From a press release on May 9, 2016)

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India