Miba AG

Company Profile

Business Overview

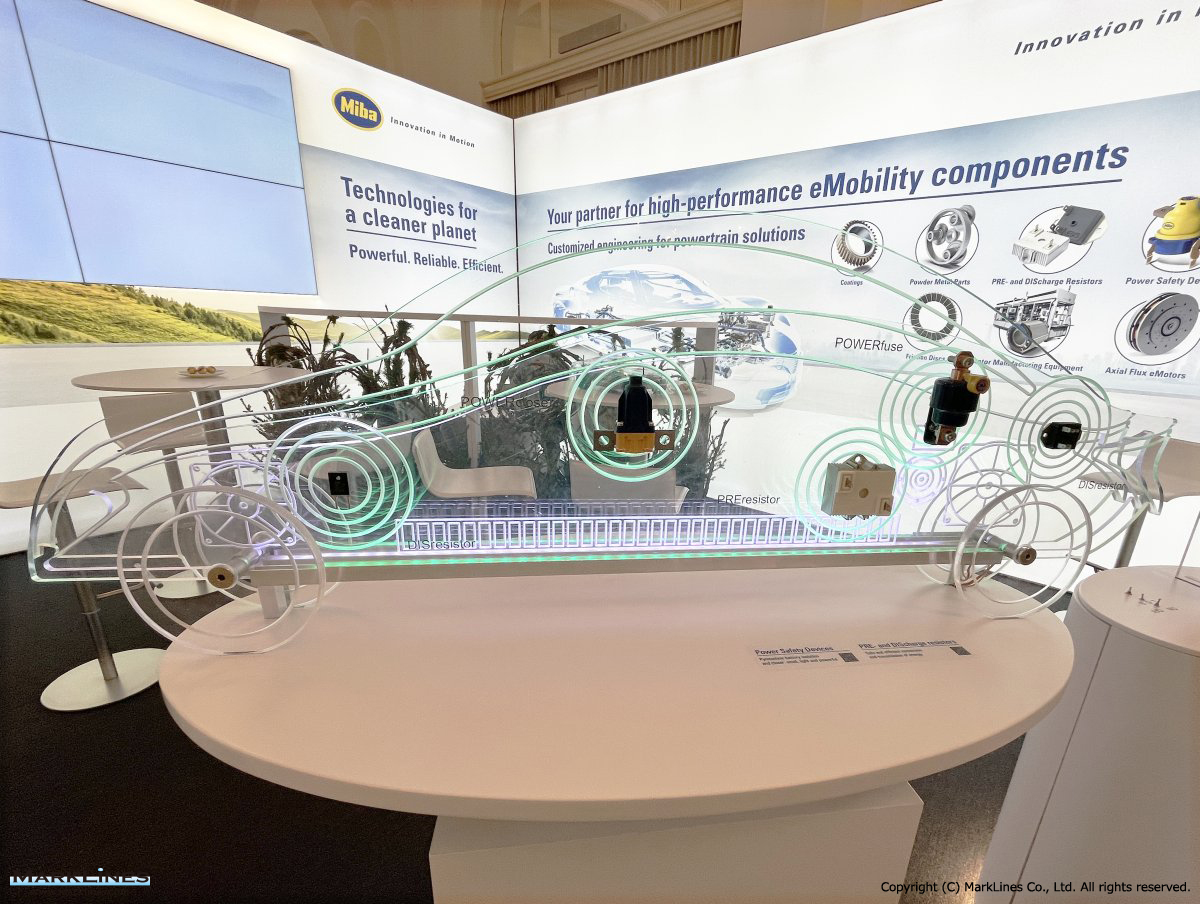

-The Company develops and manufactures components and systems for the entire energy value chain, enhancing the efficiency and sustainability for the generation, transmission, storage and use of energy for engines and powertrains. The Company serves several markets, including the automotive and commercial vehicle markets.

-The Company is organized into the following divisions:

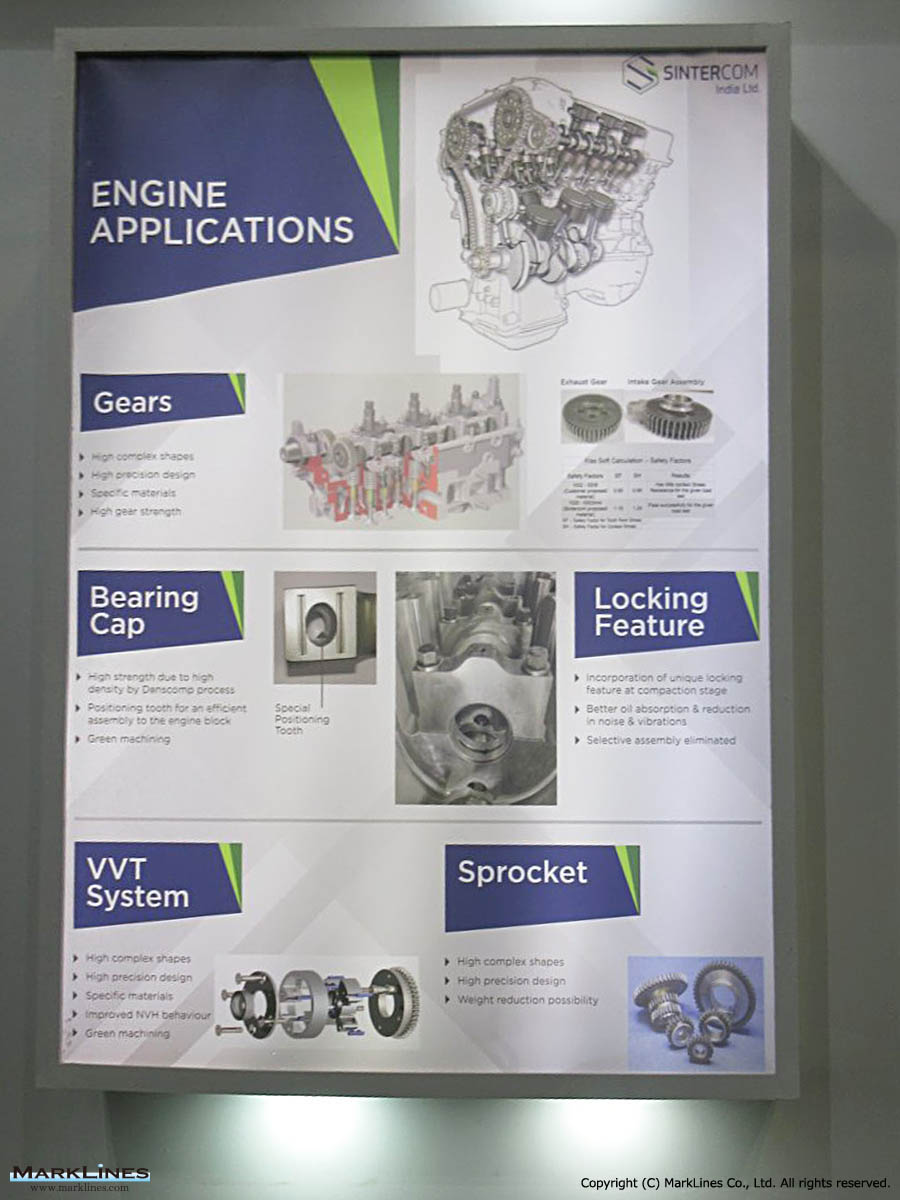

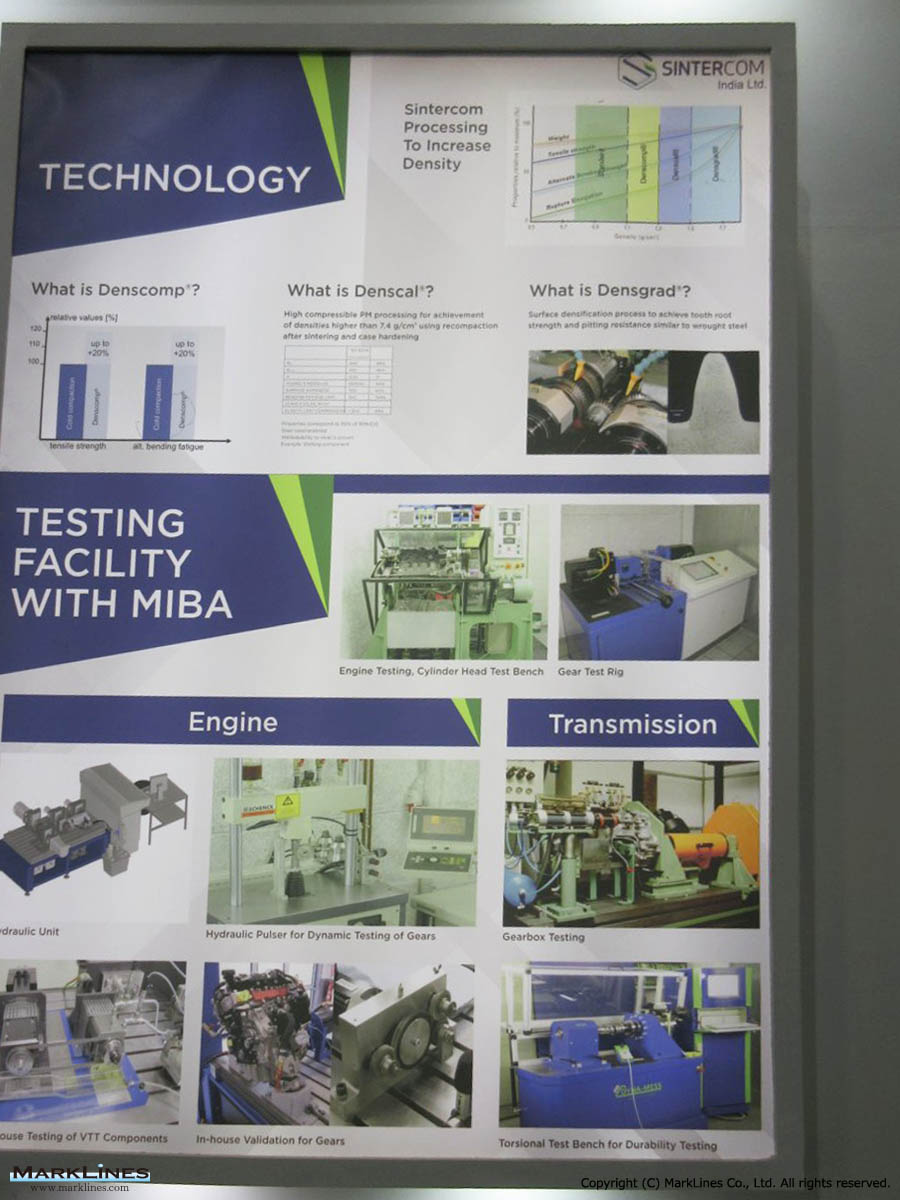

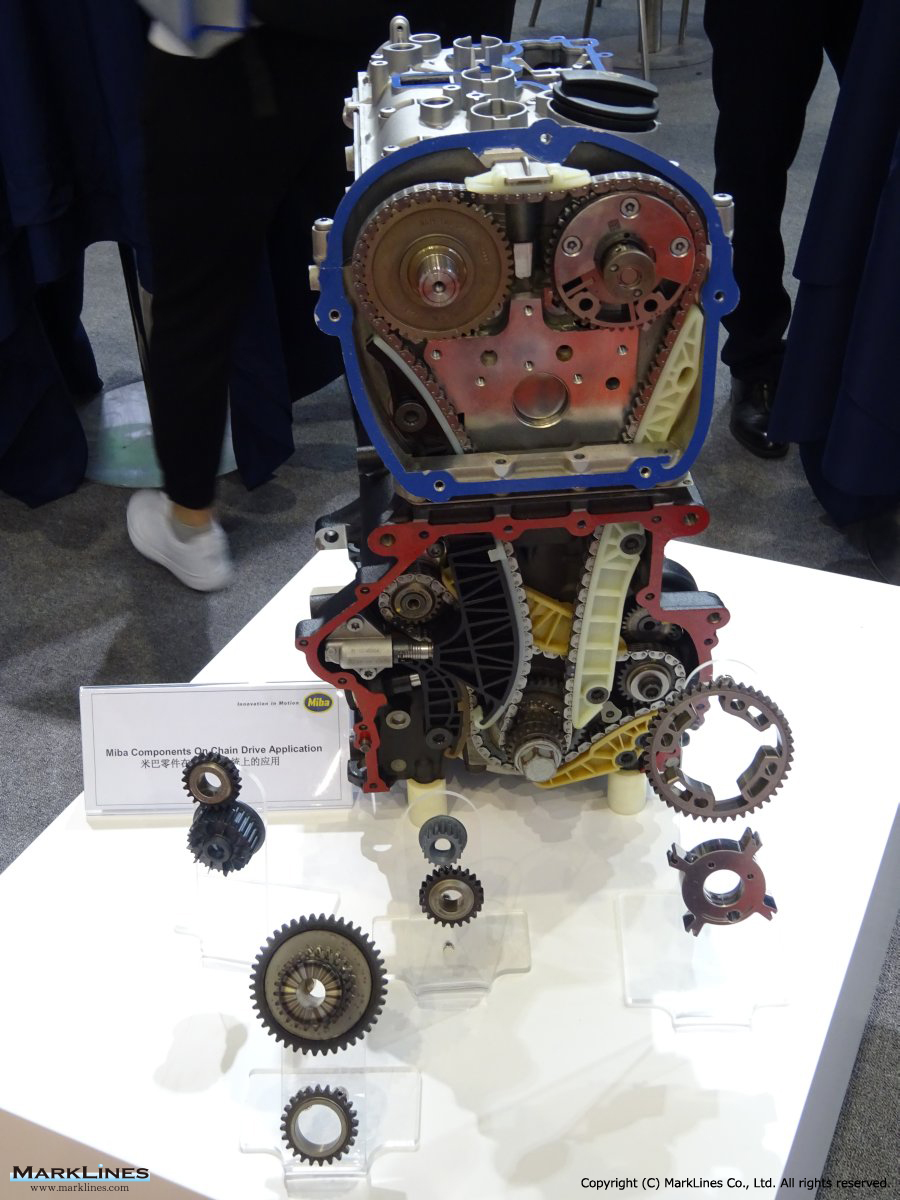

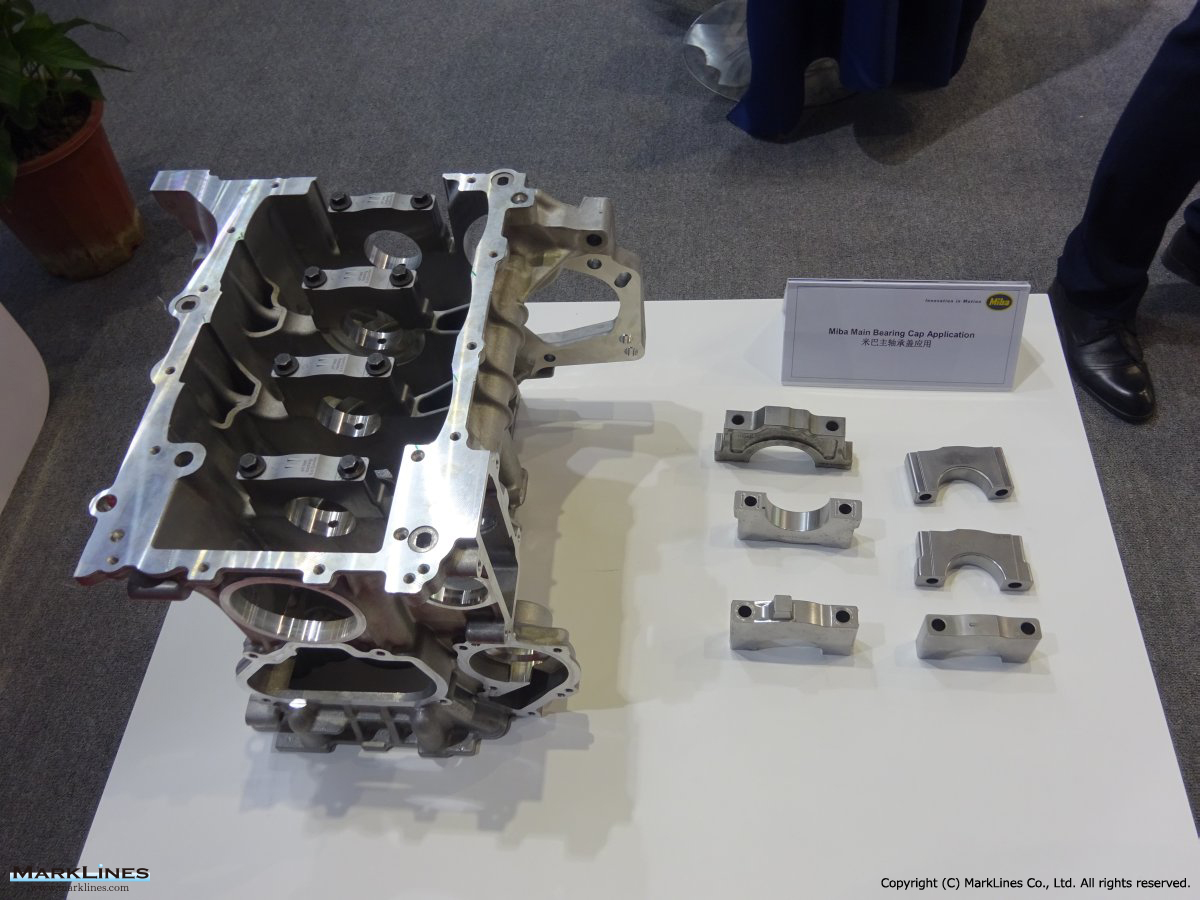

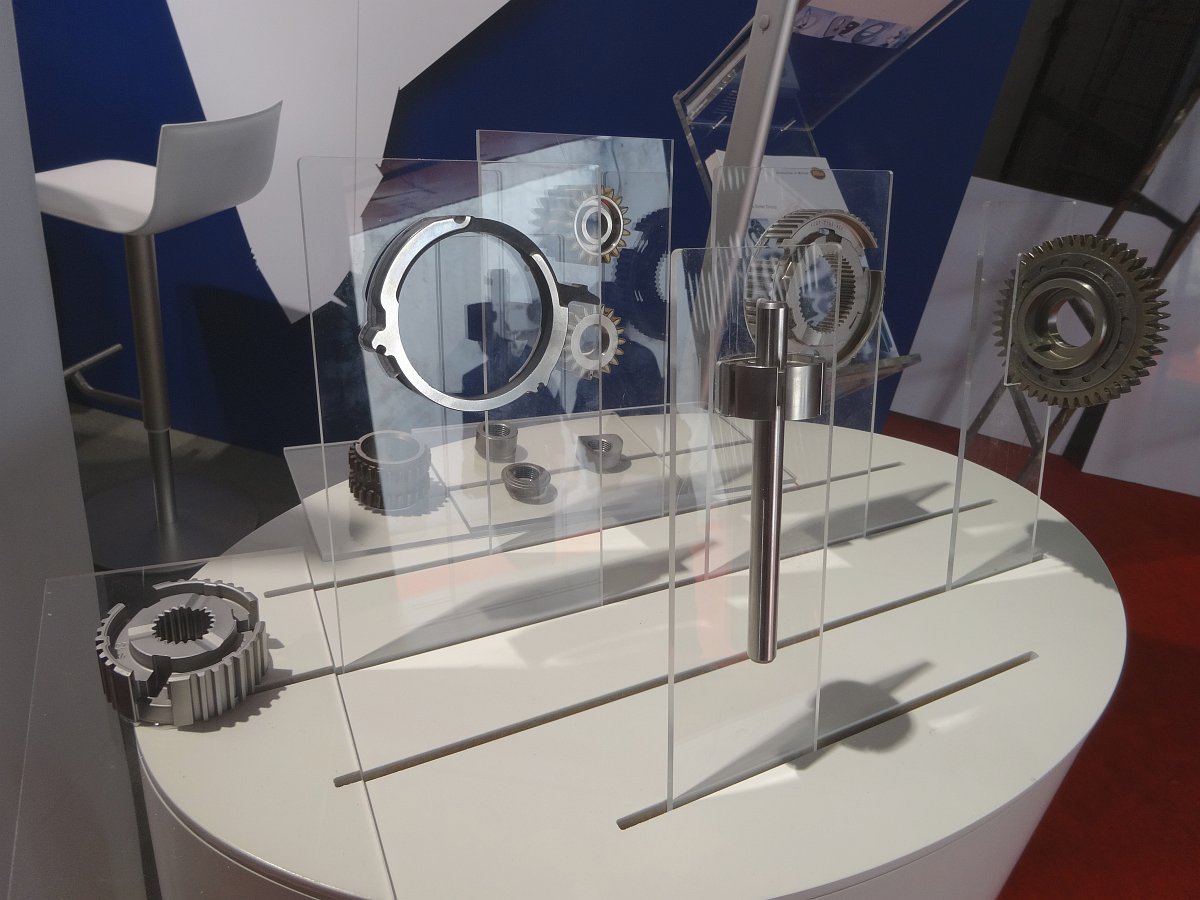

- Miba Sinter Group – Produces sintered components primarily for car engines, transmissions and electrical steering systems

- Miba Bearing Group – Produces engine bearings for trucks, ships, locomotives and power plants; also produces industrial bearings for turbomachinery such as compressors, gas and steam turbines, generators, and pumps

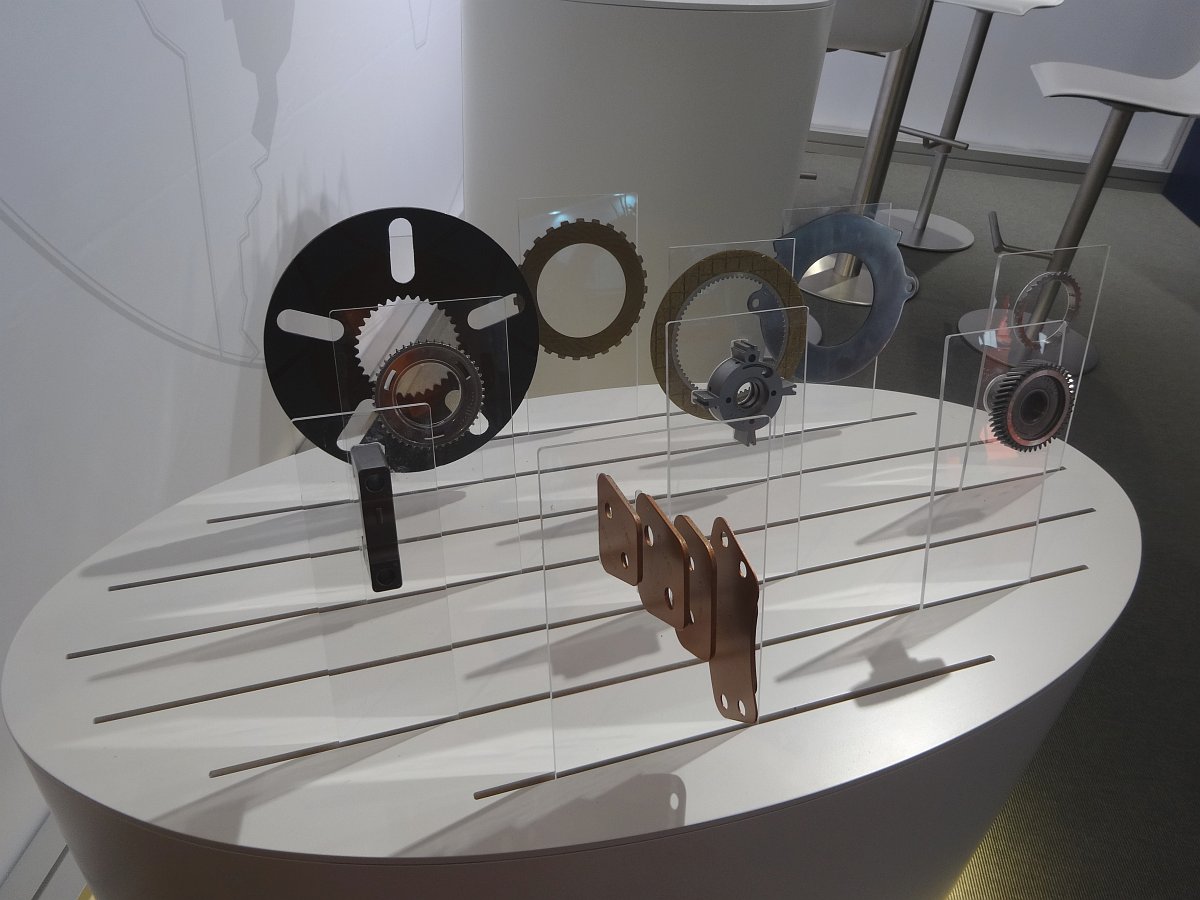

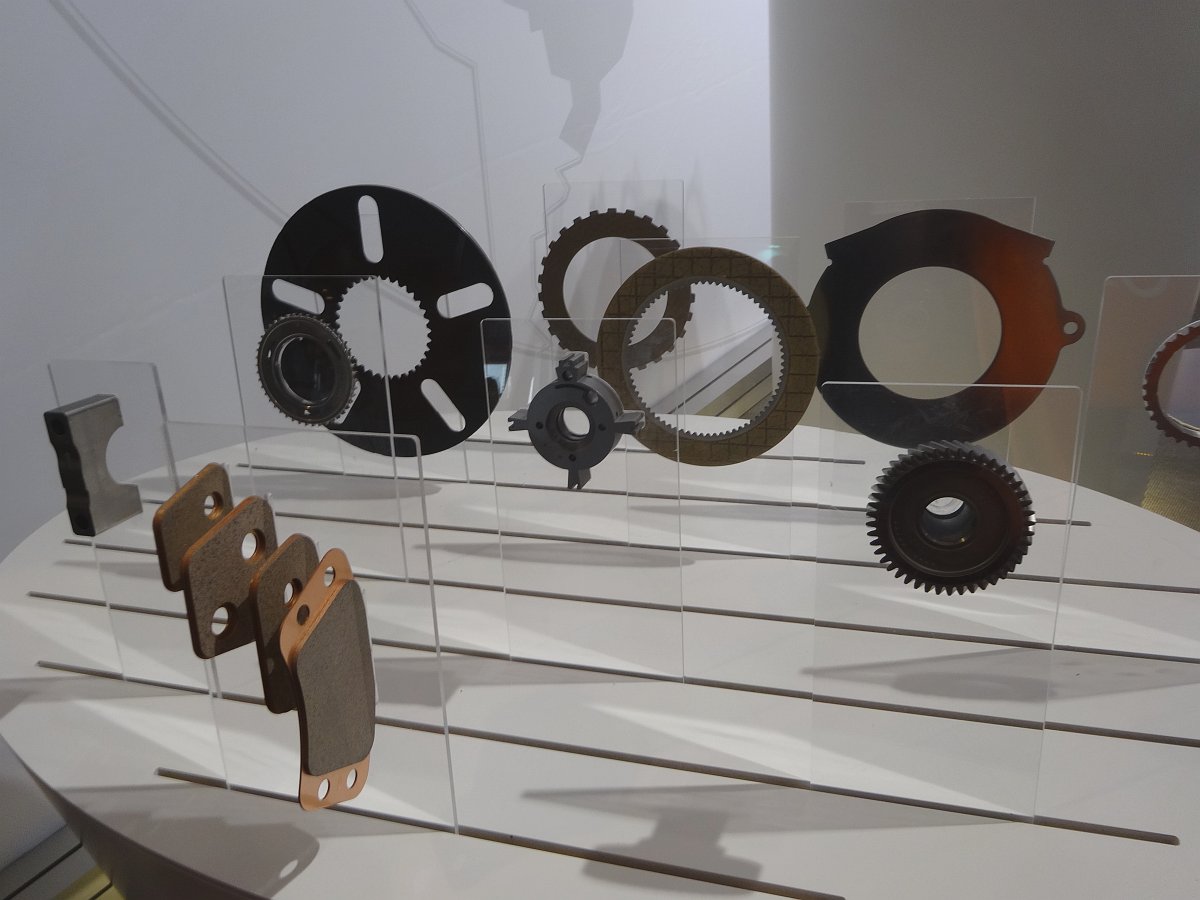

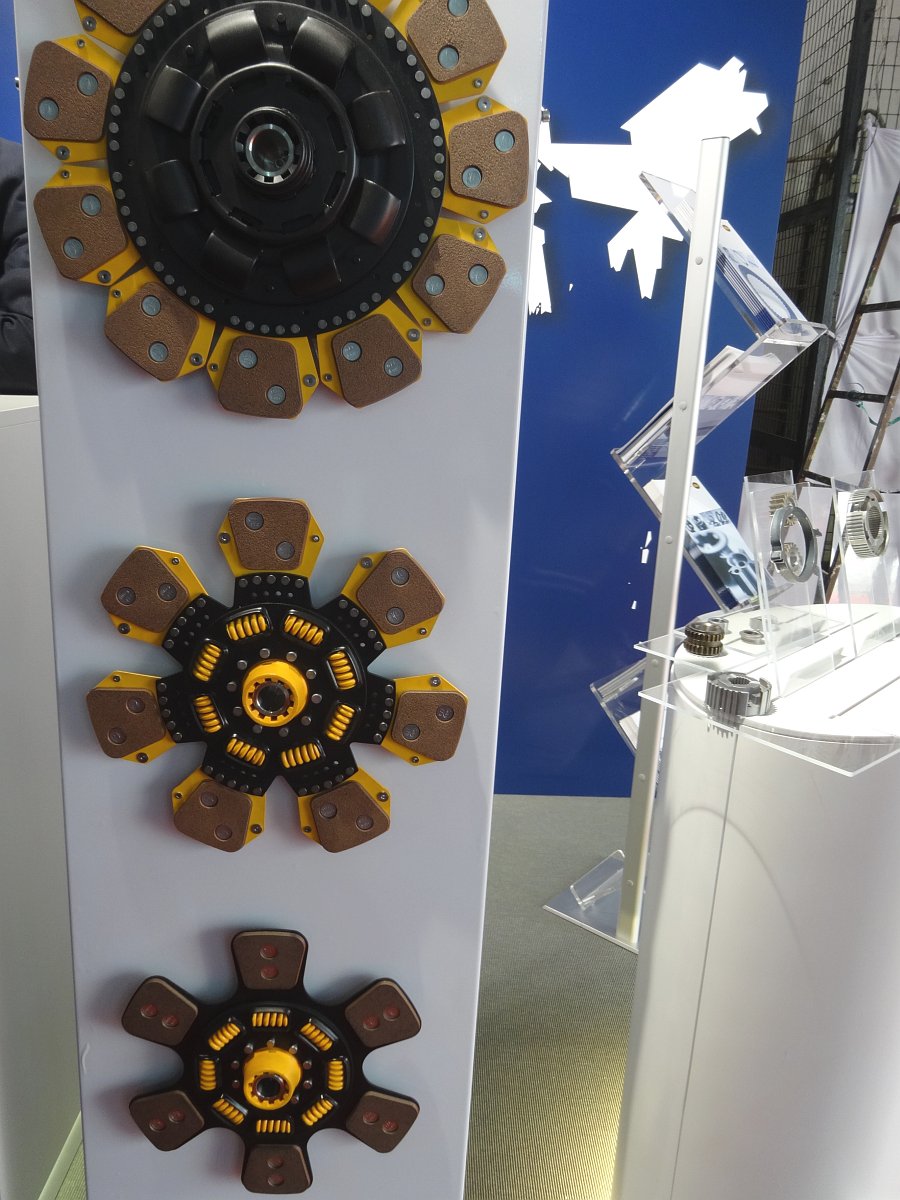

- Miba Friction Group – Produces friction materials for passenger vehicles, commercial vehicles, motorcycles, construction vehicles, trains, tractors, aircraft, and wind power plants

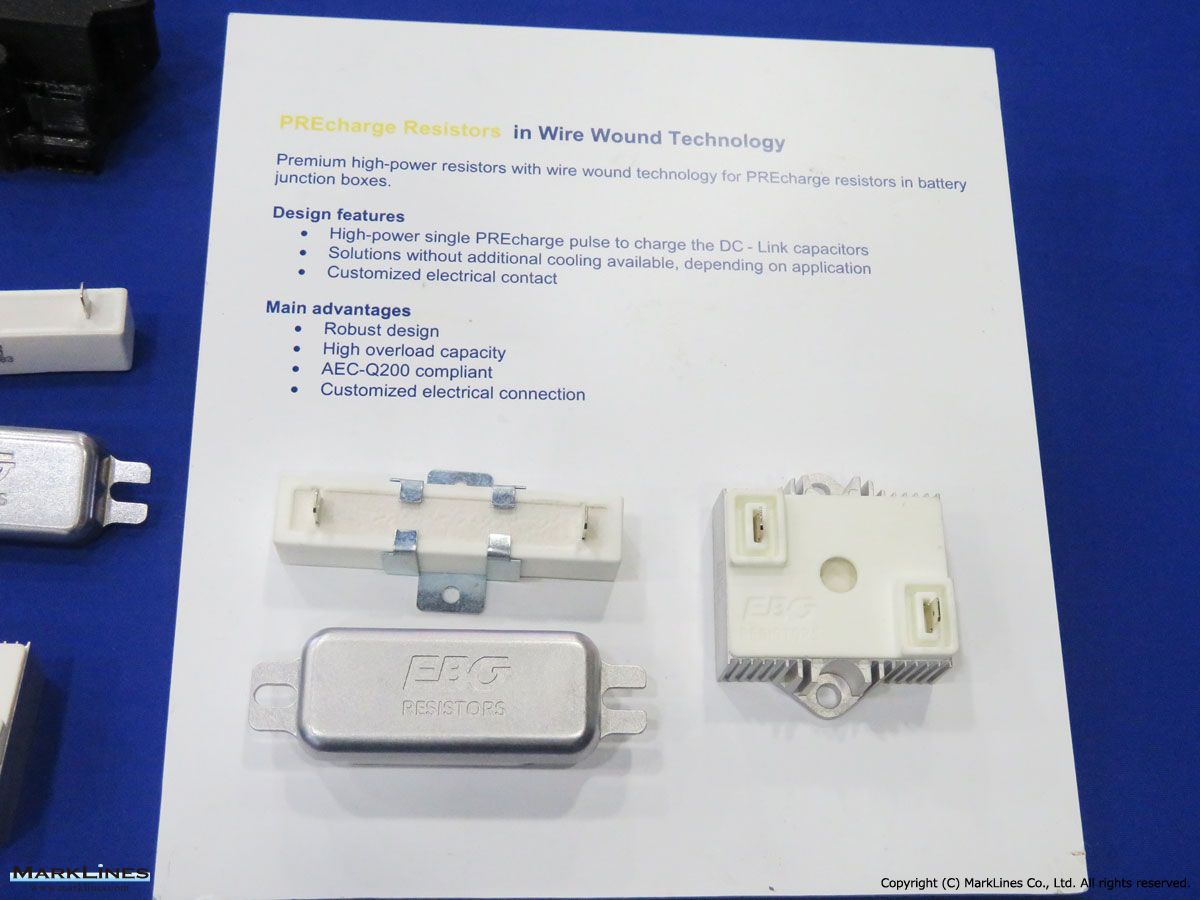

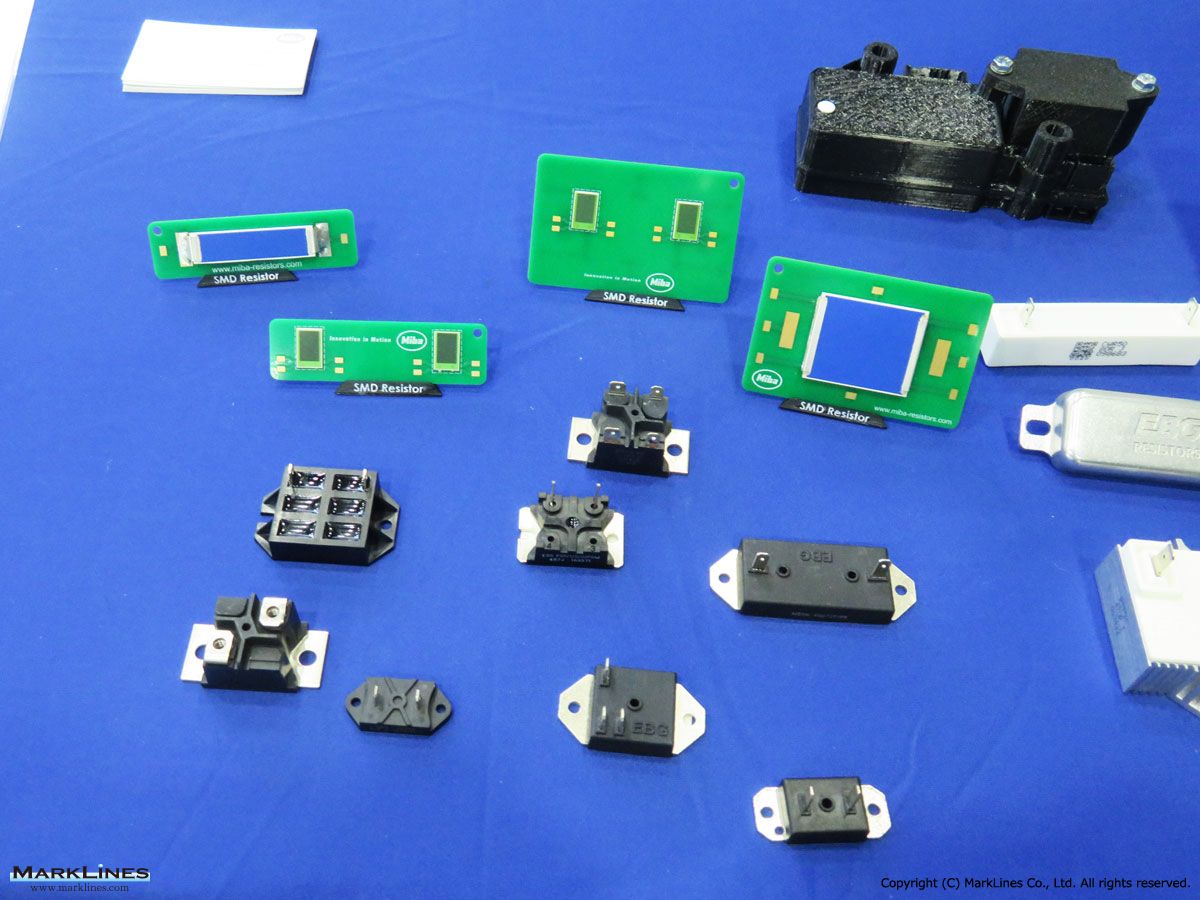

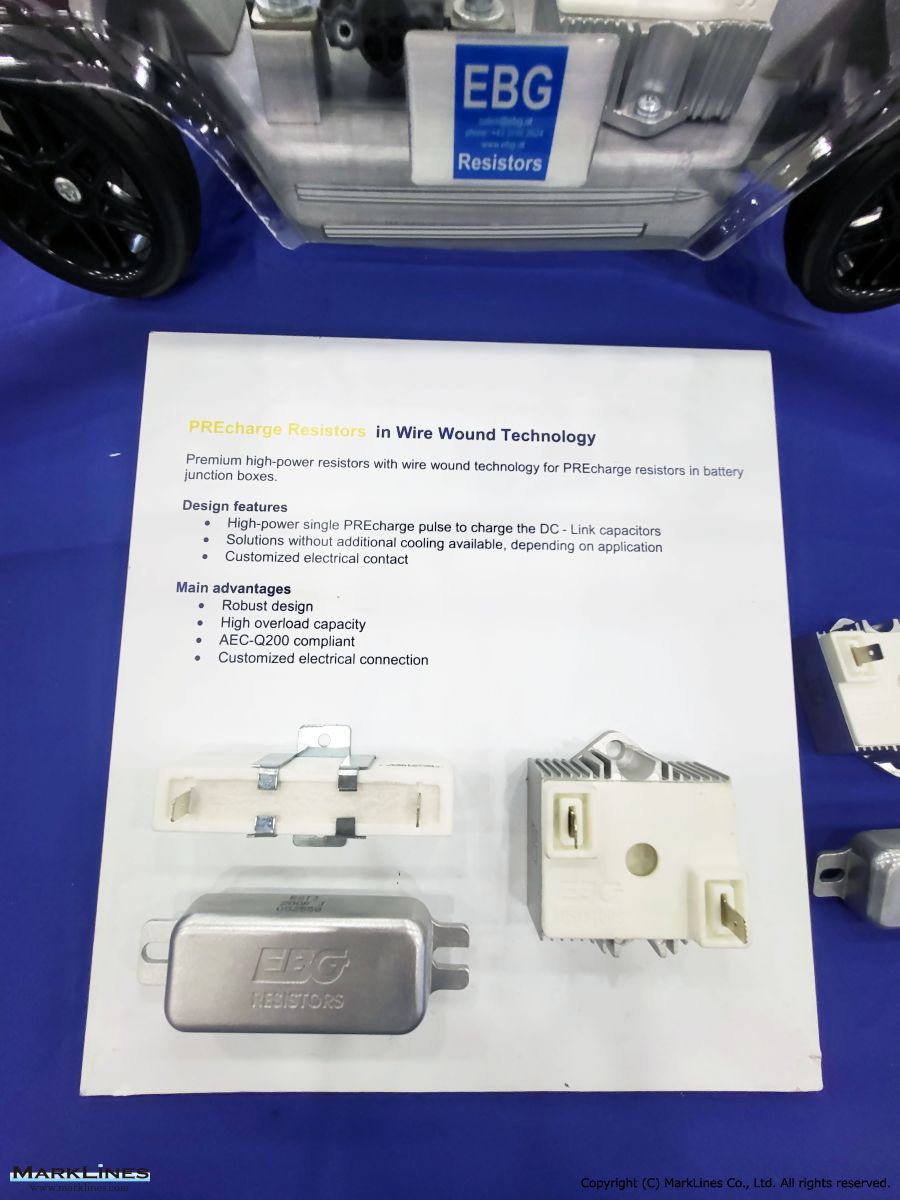

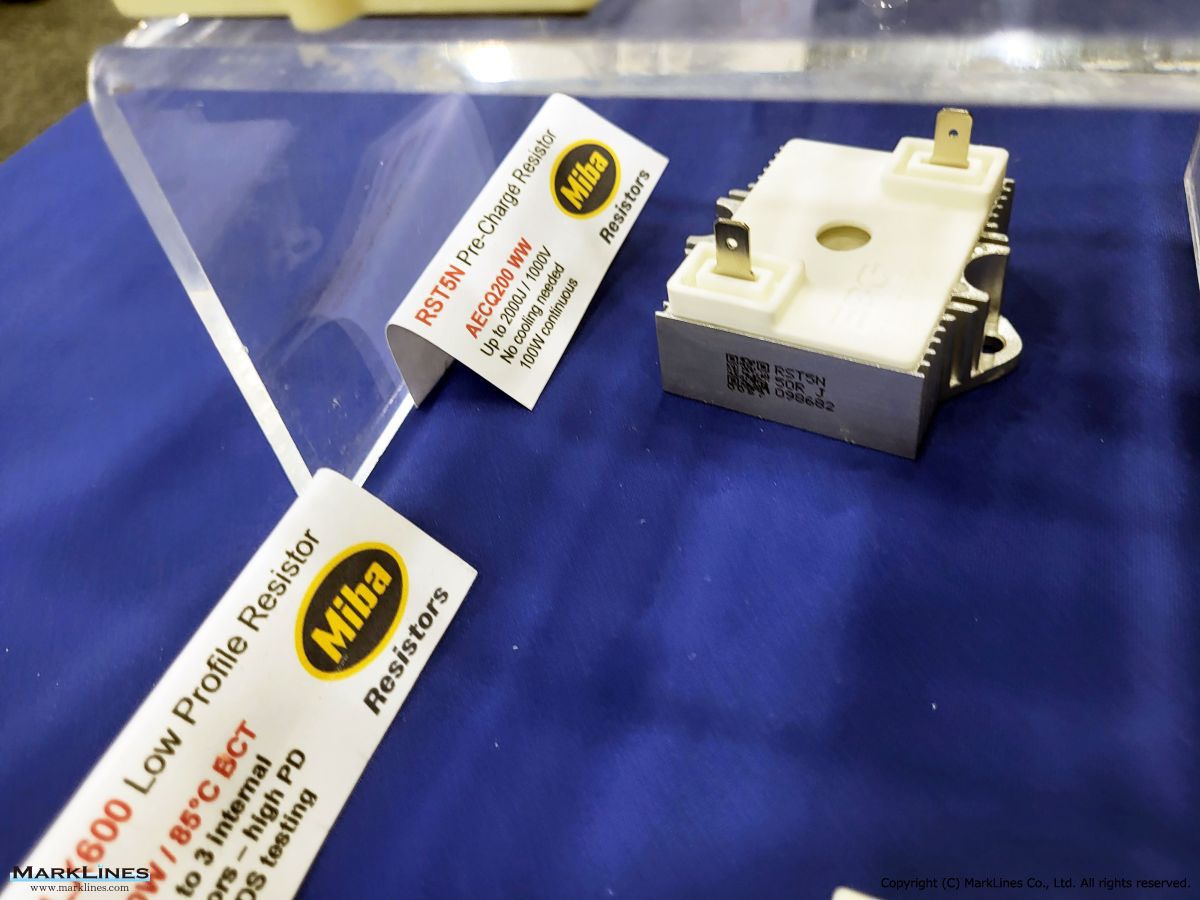

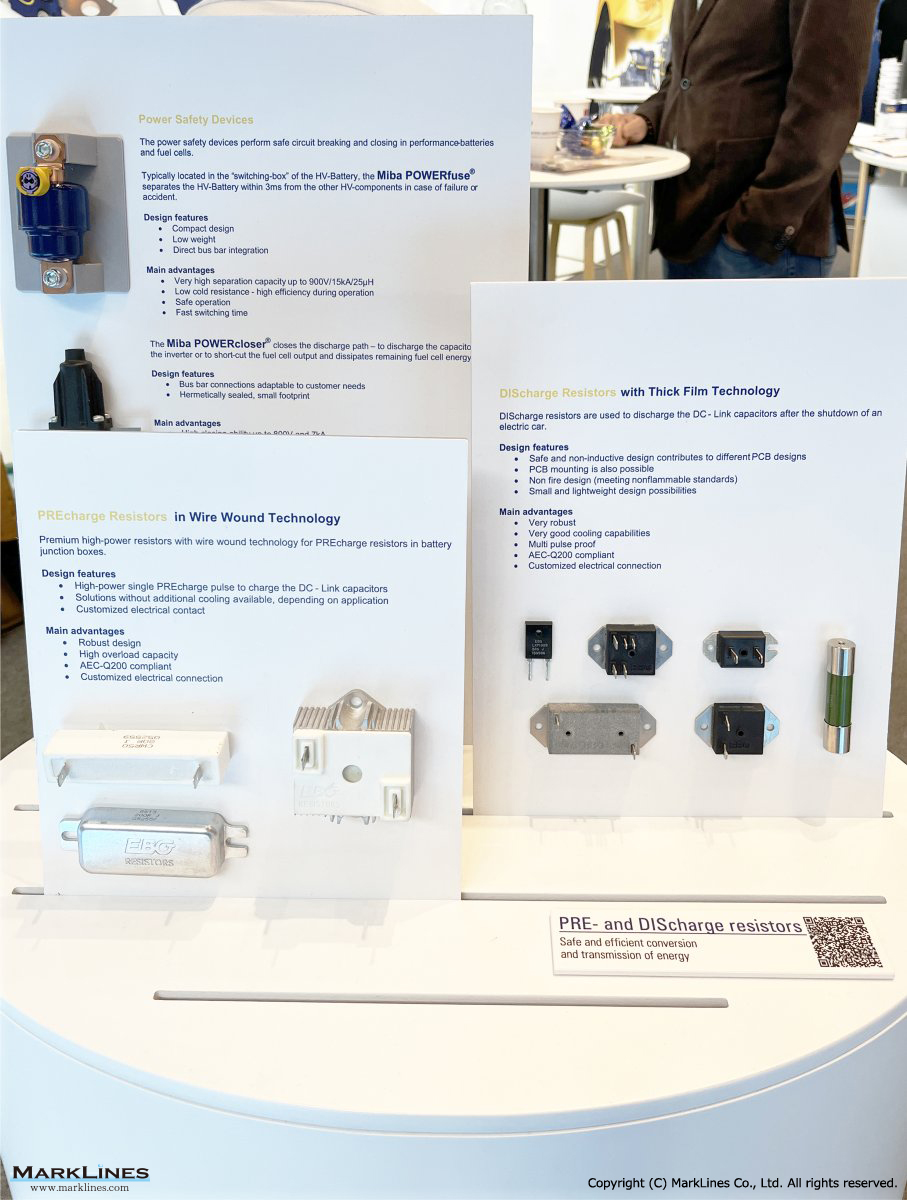

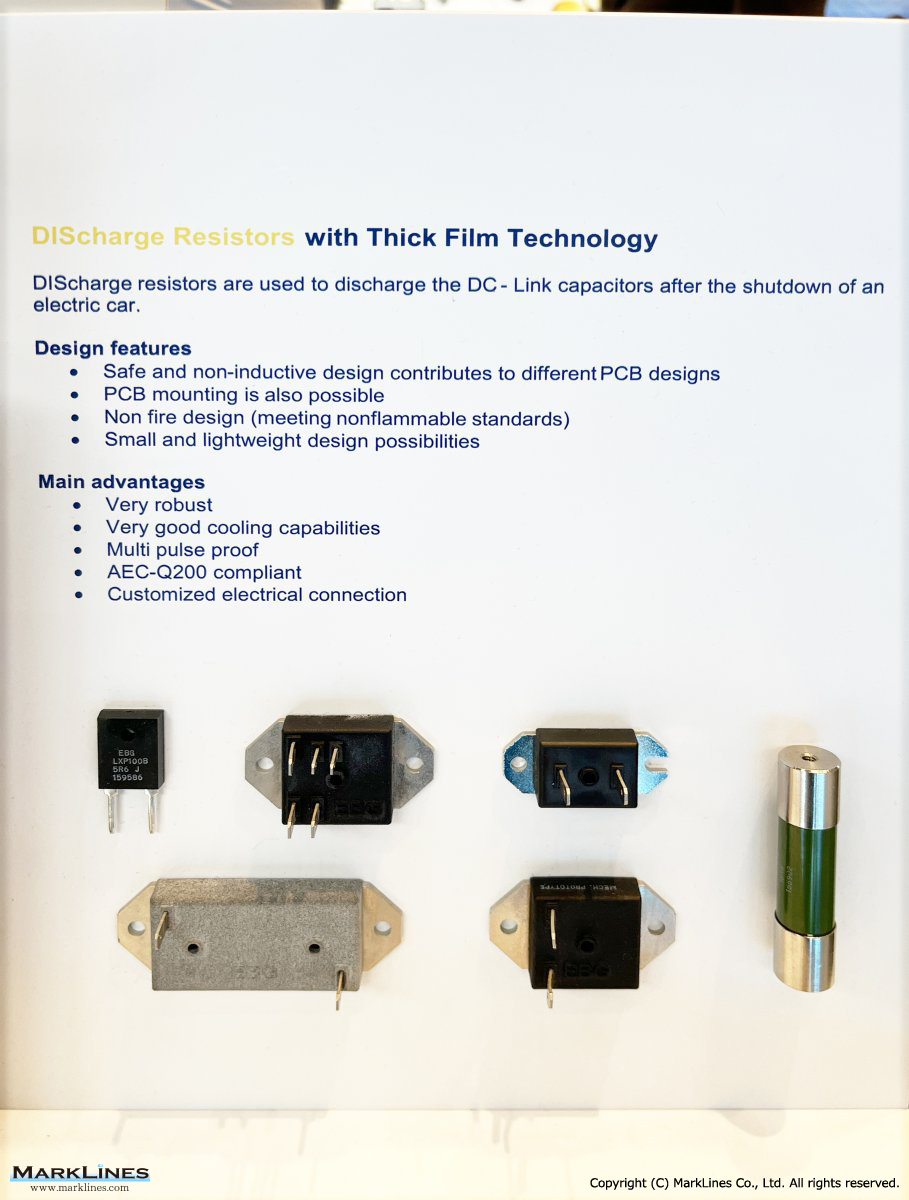

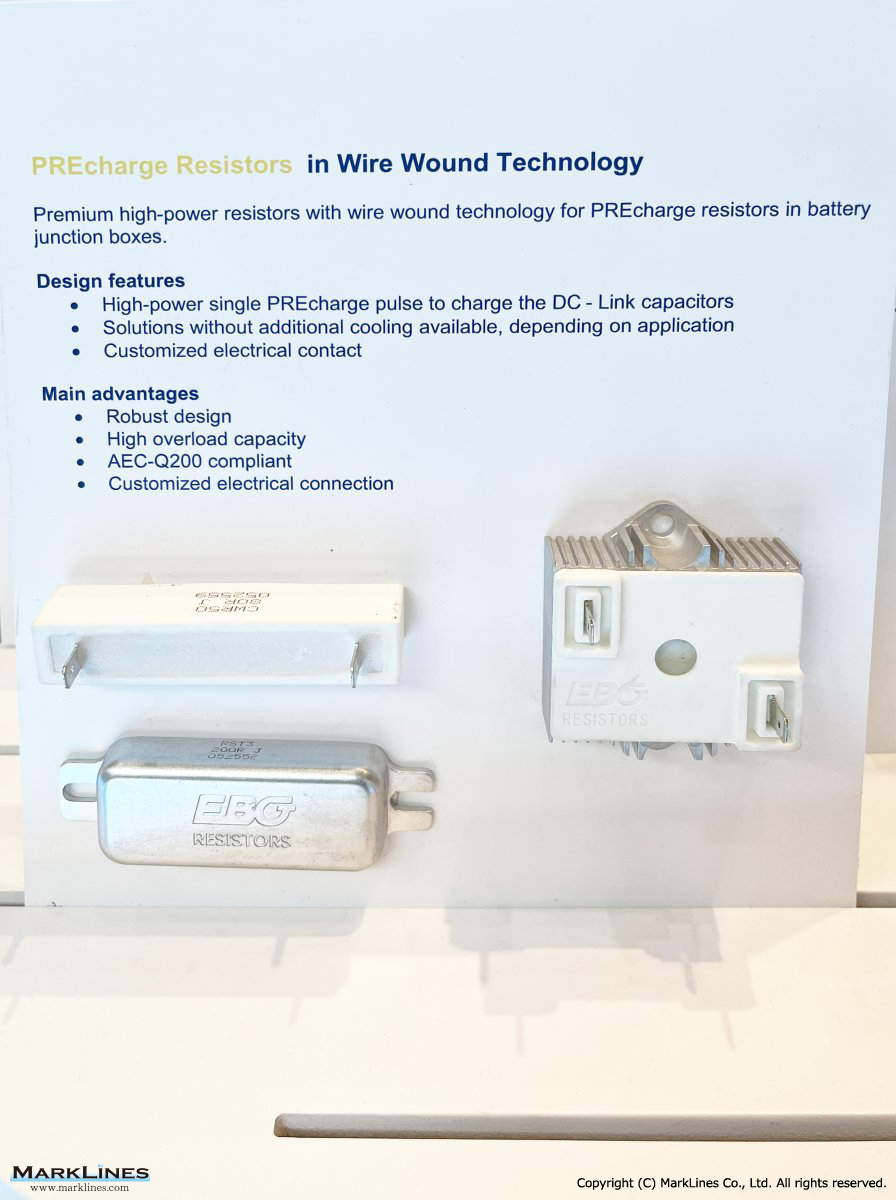

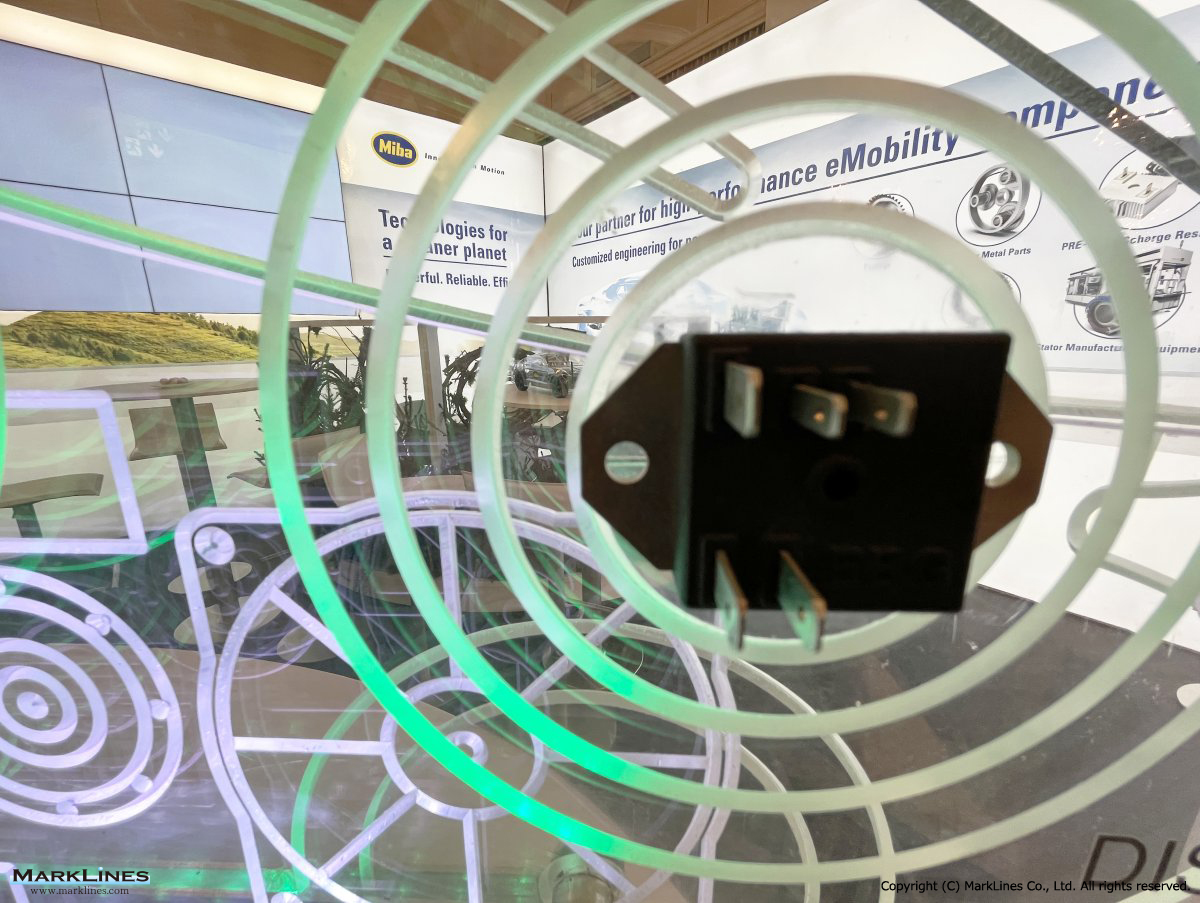

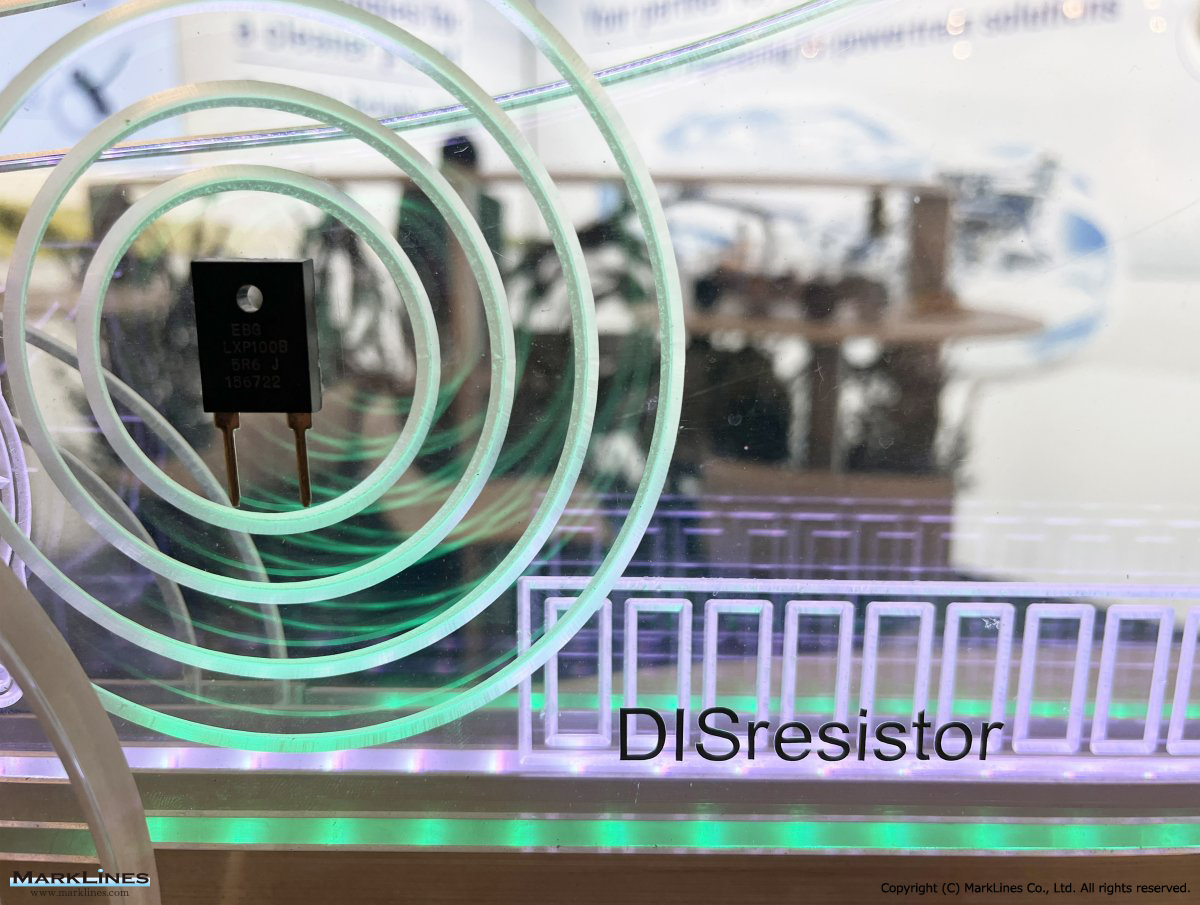

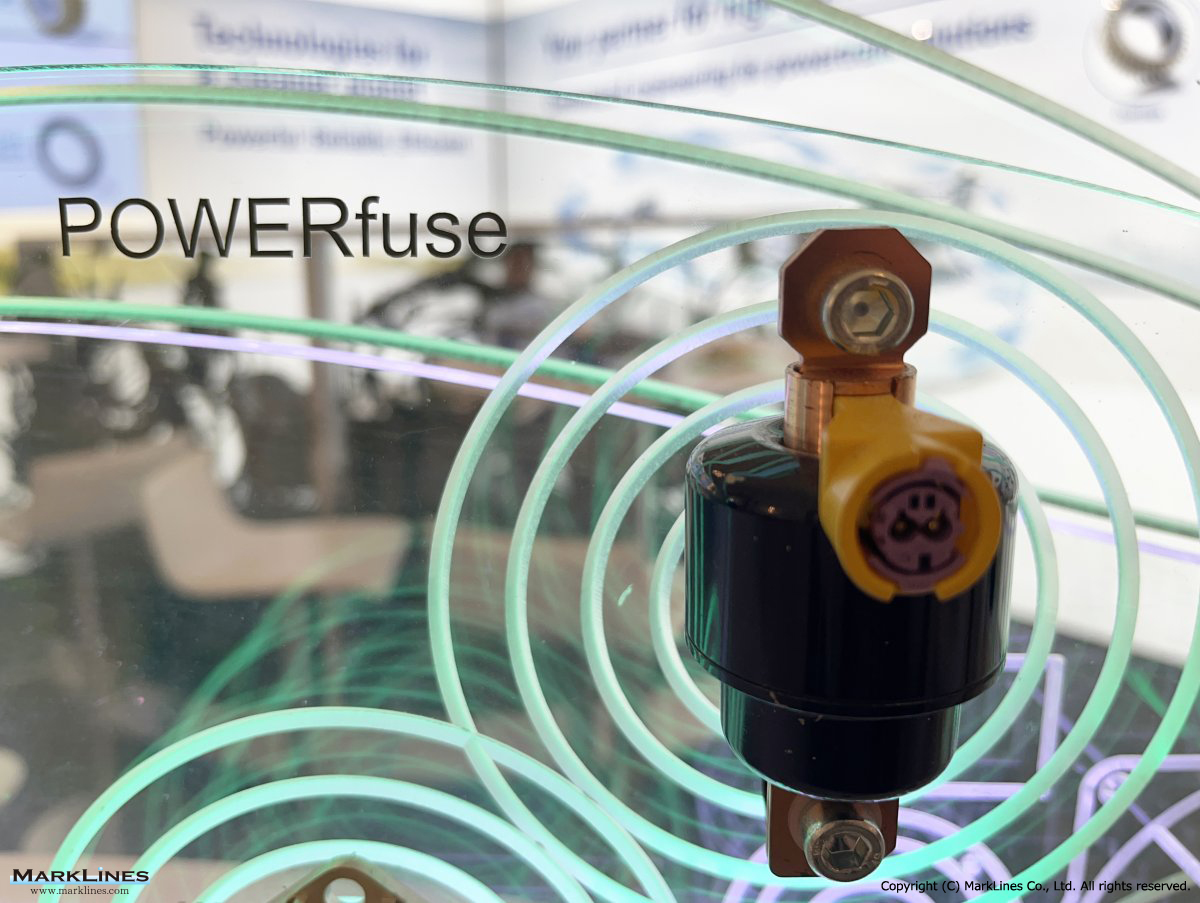

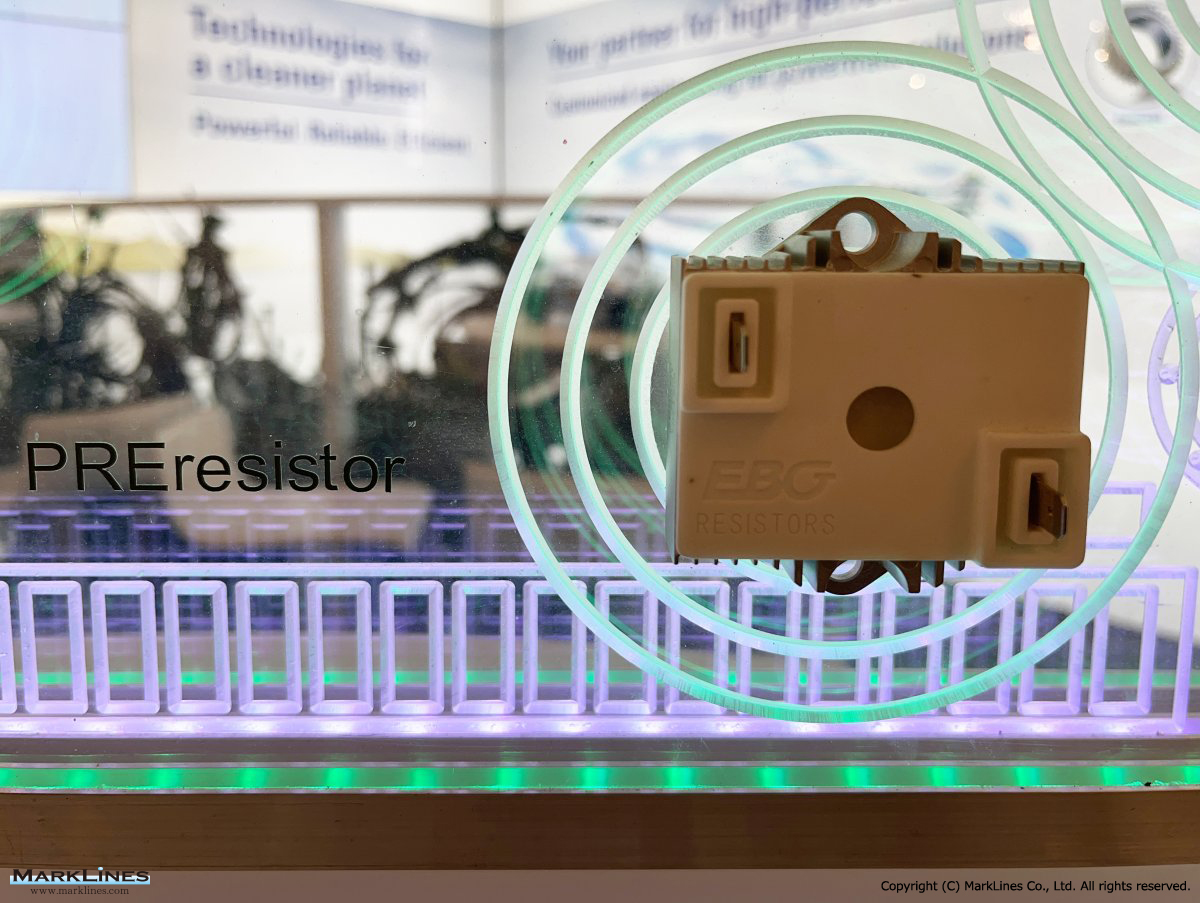

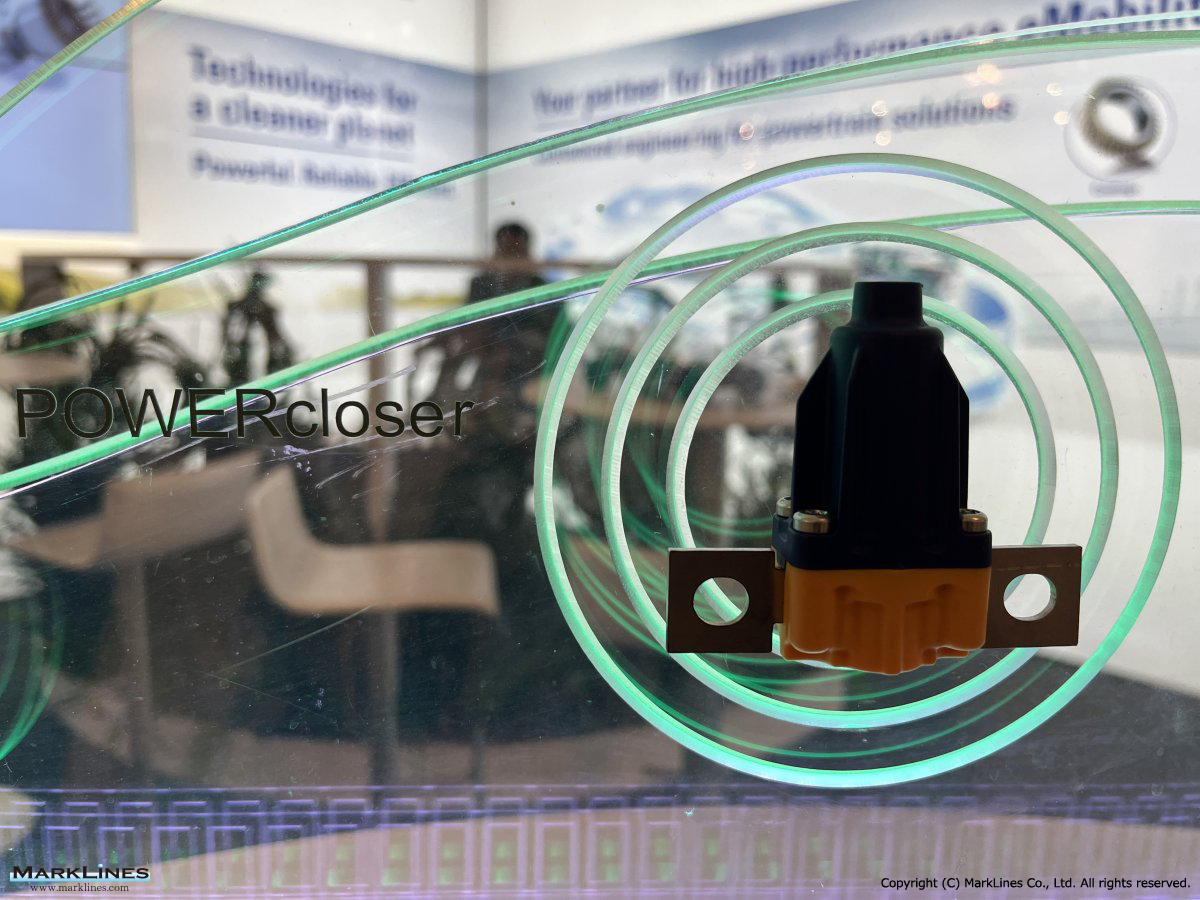

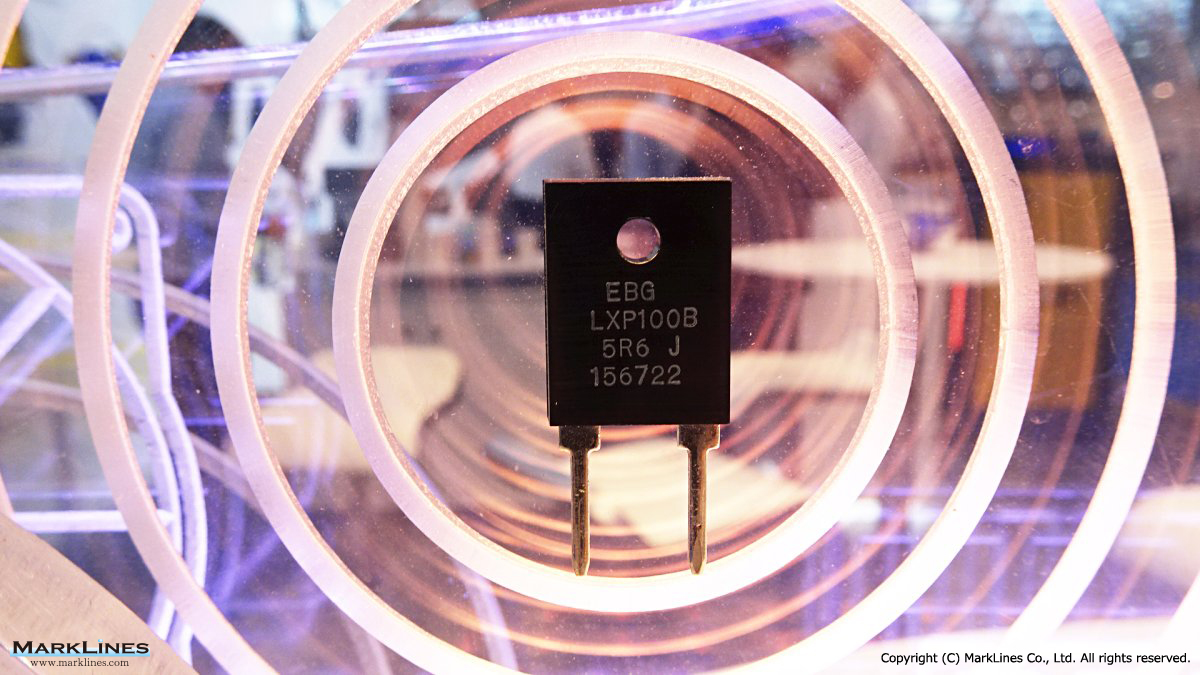

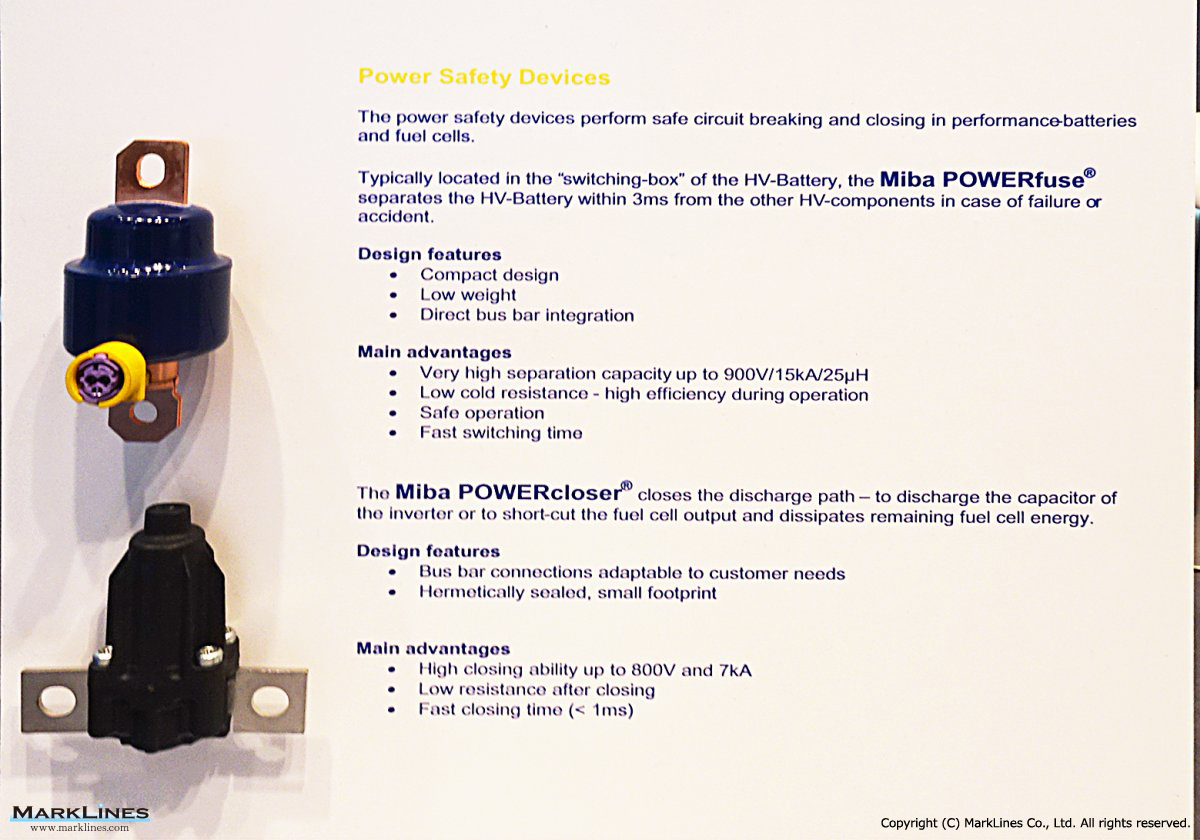

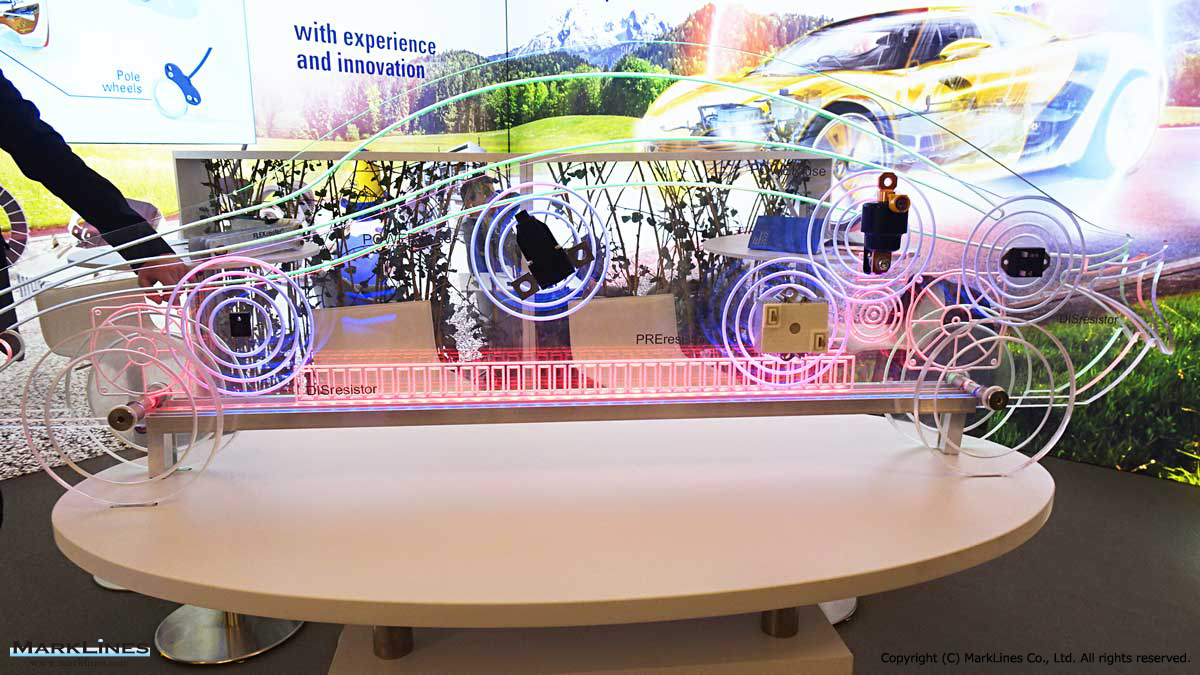

- Miba Power Electronics Group – Develops customer-specific solutions such as resistors and heat sinks for more efficient generation, transmission and utilization of electrical energy

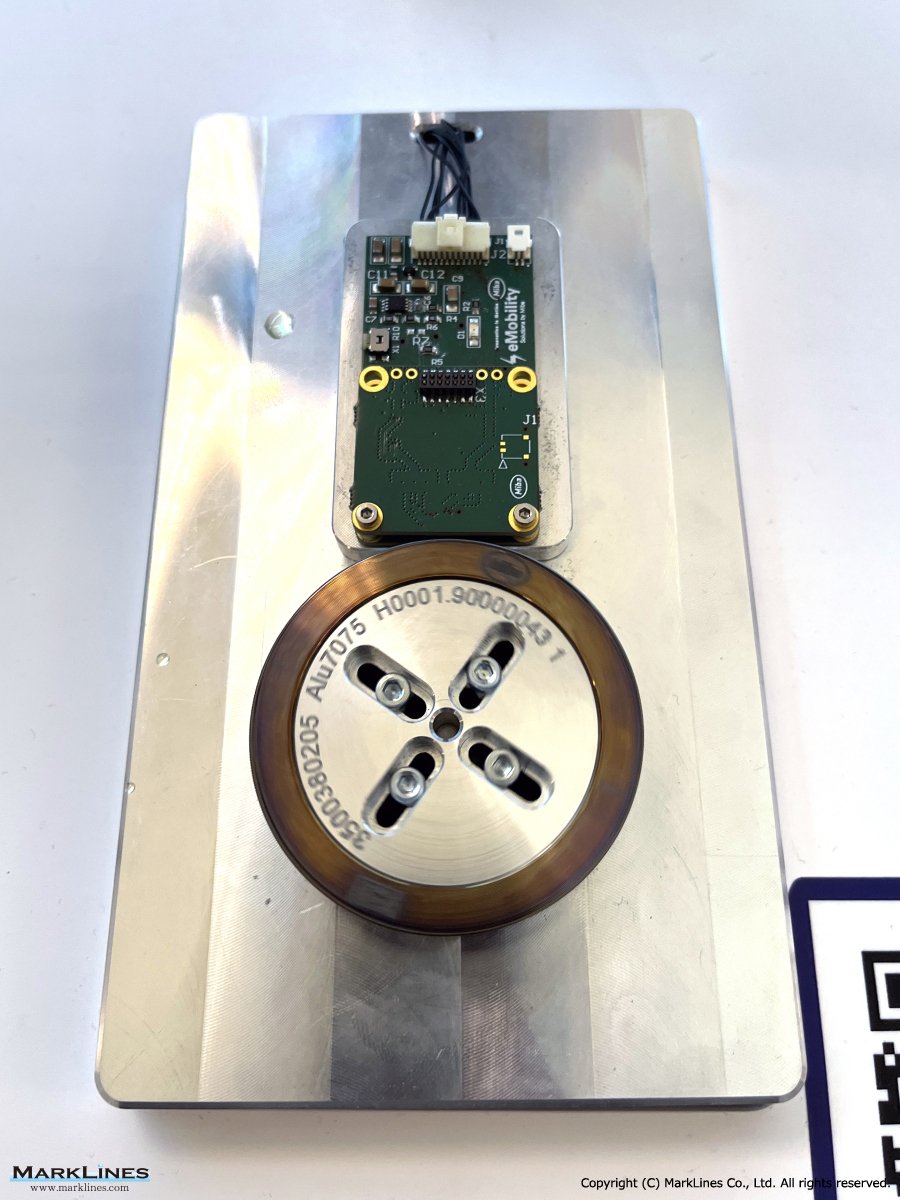

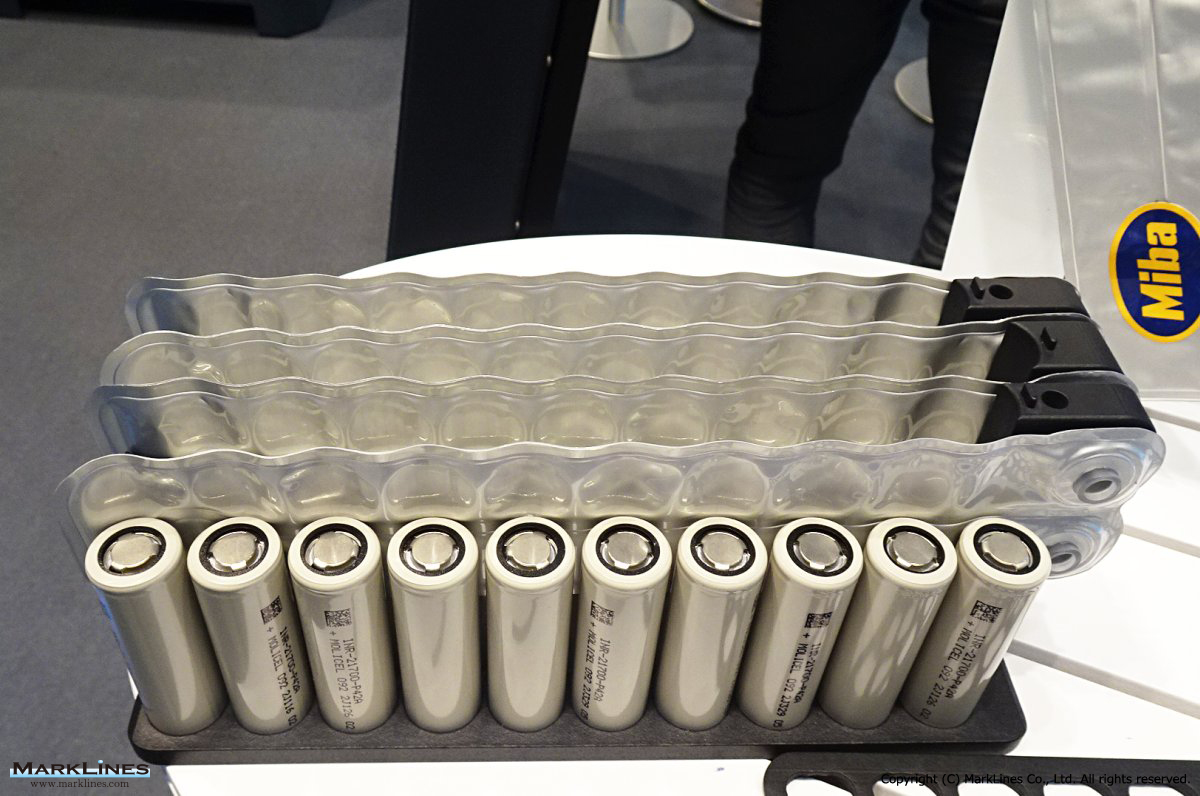

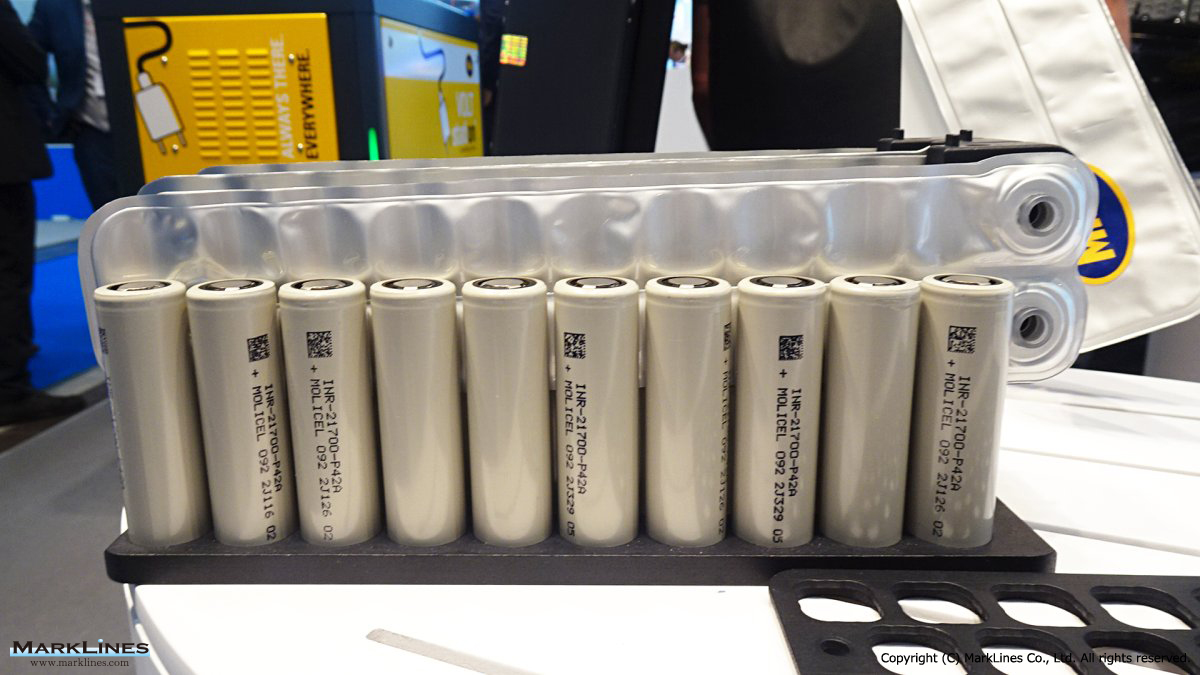

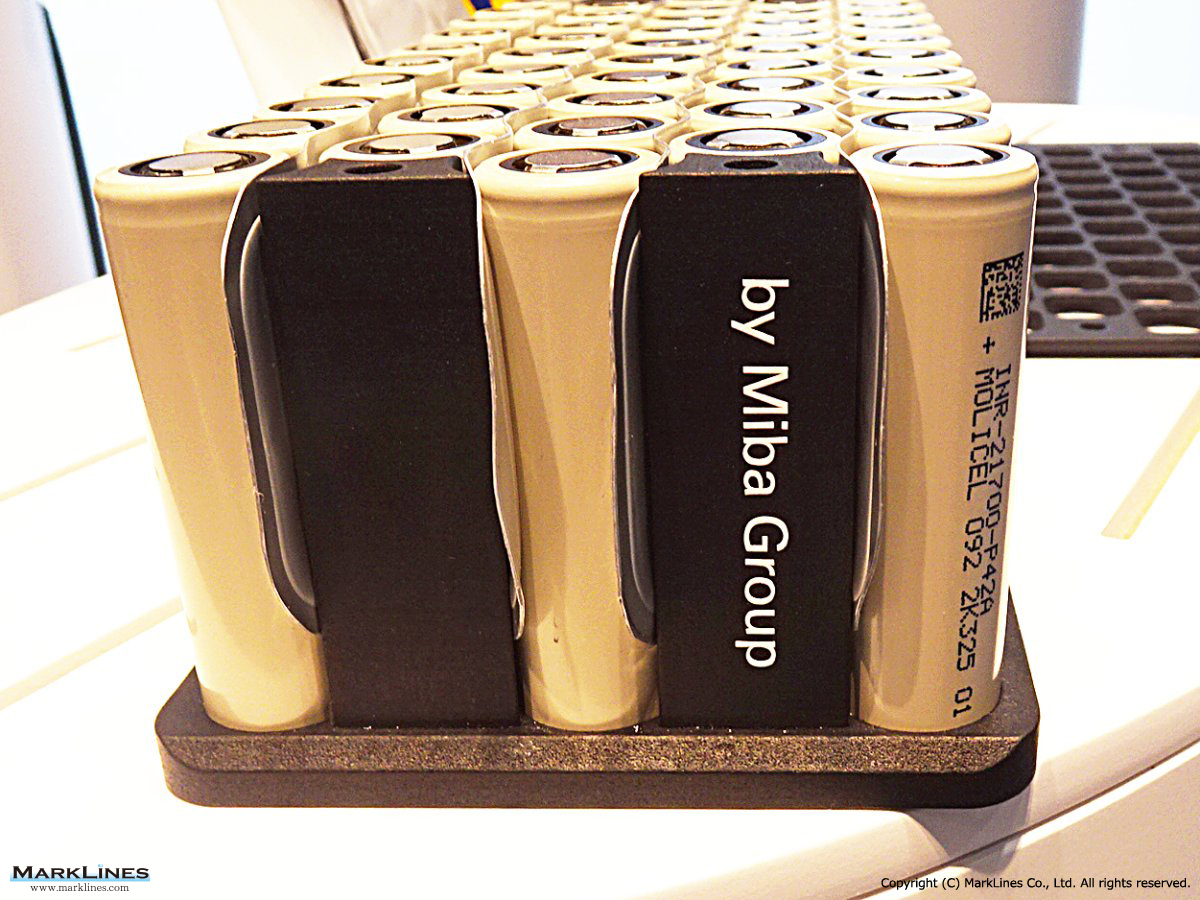

- Others – Comprised of three miscellaneous business units: Miba Automation Systems, which provides robotics, automation, mobile, and stationary special machines for various processing applications, assembly lines, and measurement systems; eMobility, which provides a variety of solutions such as resistors, sintered components and friction materials targeted towards electric vehicle; and Battery Systems, which provides battery systems and solutions for vehicle batteries as well as mobile and stationary energy storage applications

-In the fiscal year ended January 31, 2025, the Company's sales in the automotive market accounted for 39% of total sales.

Shareholders

-The Company is a family-owned entity. It was delisted from the Vienna Stock Exchange on December 3, 2015, following the registration of the exclusion of shareholders.

Products

Powder metal parts

Engine components

-Belt pulleys

-Chain sprockets

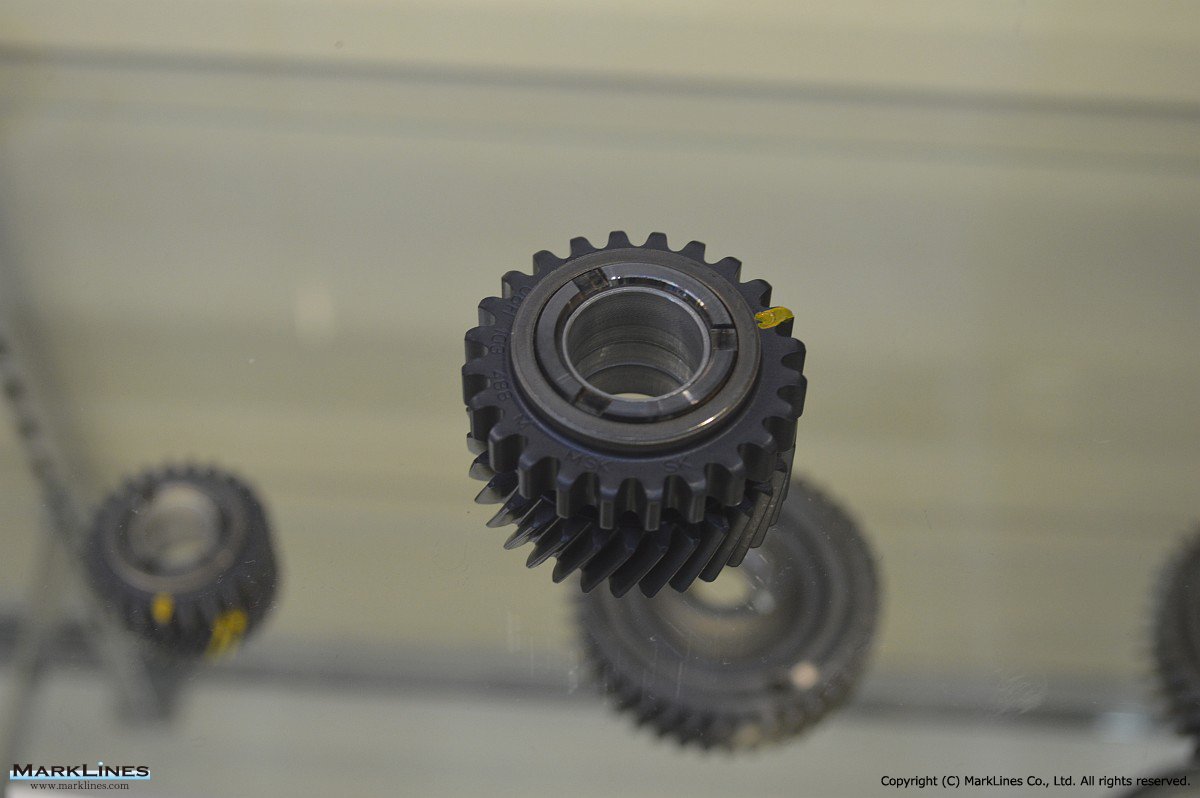

-Gears

-Components for hydraulic cam phasers

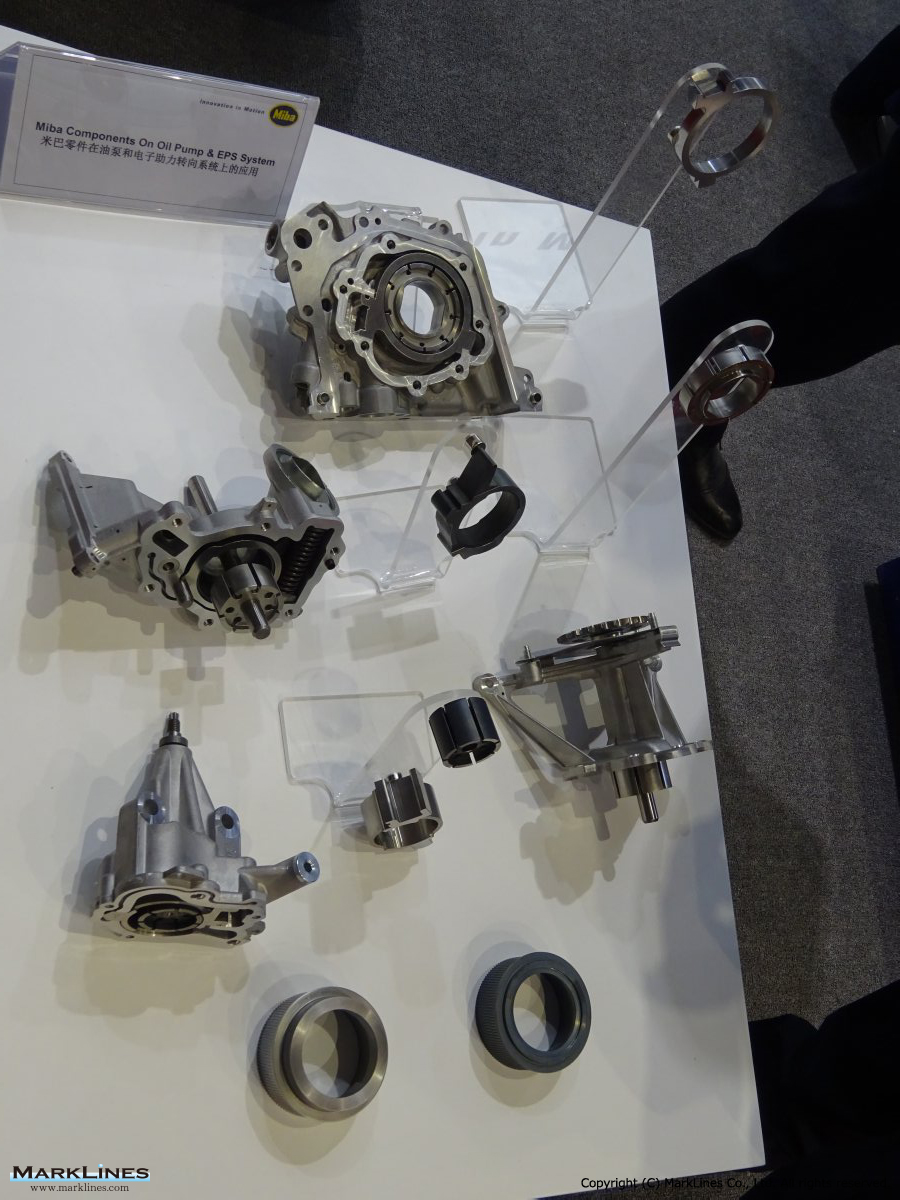

-Oil pump gears

-Water pump gears

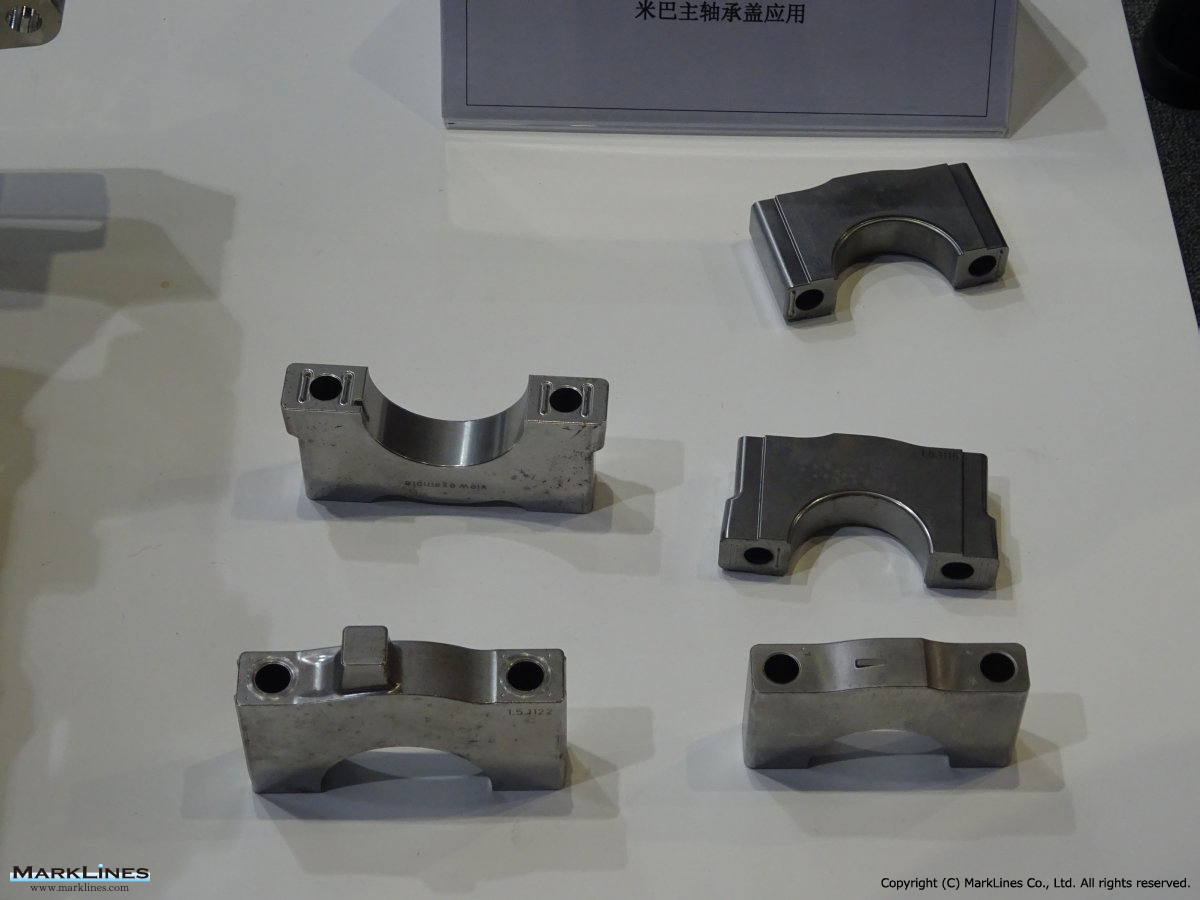

-Main bearing caps

-Variable valve timing components

Transmission components

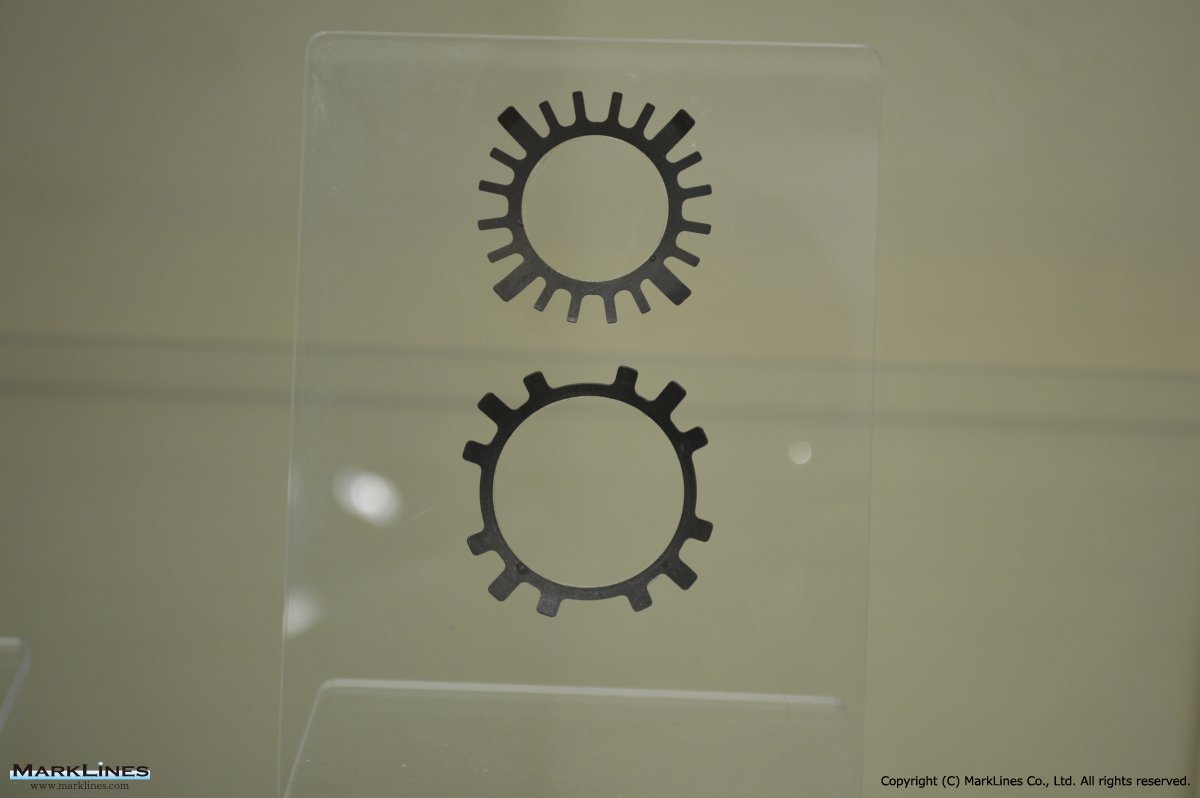

-Synchronizer hubs and rings

-Friction rings

-Dog rings

-Clutch bodies

-Coupling rings

-Ball ramp rings

-Pressure plates

-Shift fingers

-Shift forks

-Sliding sleeves

-Fully assembled synchronizer units

Shock absorbers

-Pistons

-Rod guides

-Cylinder ends

Body, Chassis, Pumps, e-Drive components

-Hydraulic system parts

-Oil pump stators and rotors

-Exhaust system parts

-Steering parts

-Brake parts

-Car body parts

-Helical belt pulleys for electrical steering systems

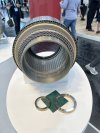

Engine bearings

-Half-shafts

-Bearings

-Bushings

-Bimetal engine bearings

-Thrust washers

-Sputter coatings

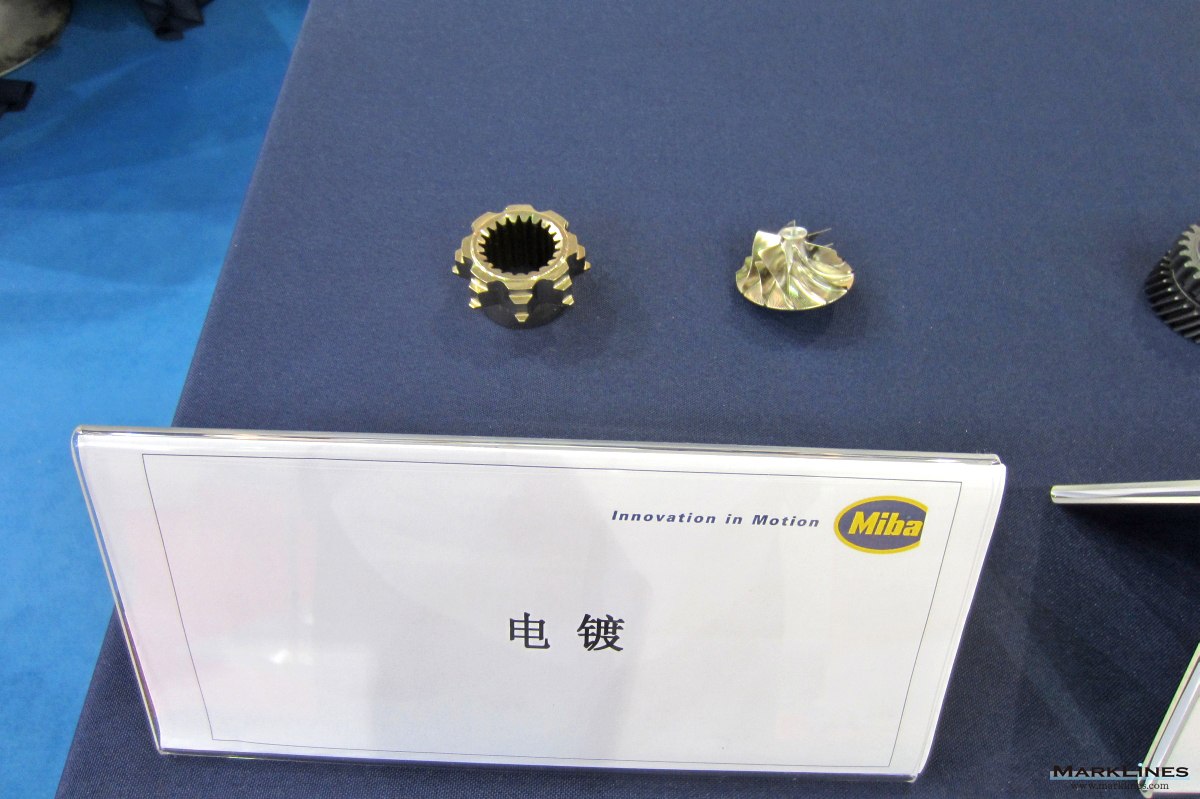

-Electroplated coatings

Friction materials

Friction and steel discs

-Wet-running fiber composite friction discs

-Carbon friction discs

-Sintered friction discs

-Carbon friction materials

-Fiber composite materials

-Steel mating discs

-Disc carriers

-Molybdenum discs

Clutch buttons

-Main clutches

Coatings

-Polymer coatings

-Electroplated coatings

-PVD coatings

-Anti-friction coatings

-Noise reduction coatings

-Friction enhancing coatings

-Wear-resistant coatings

-Corrosion-resistant coatings

Power electronic components

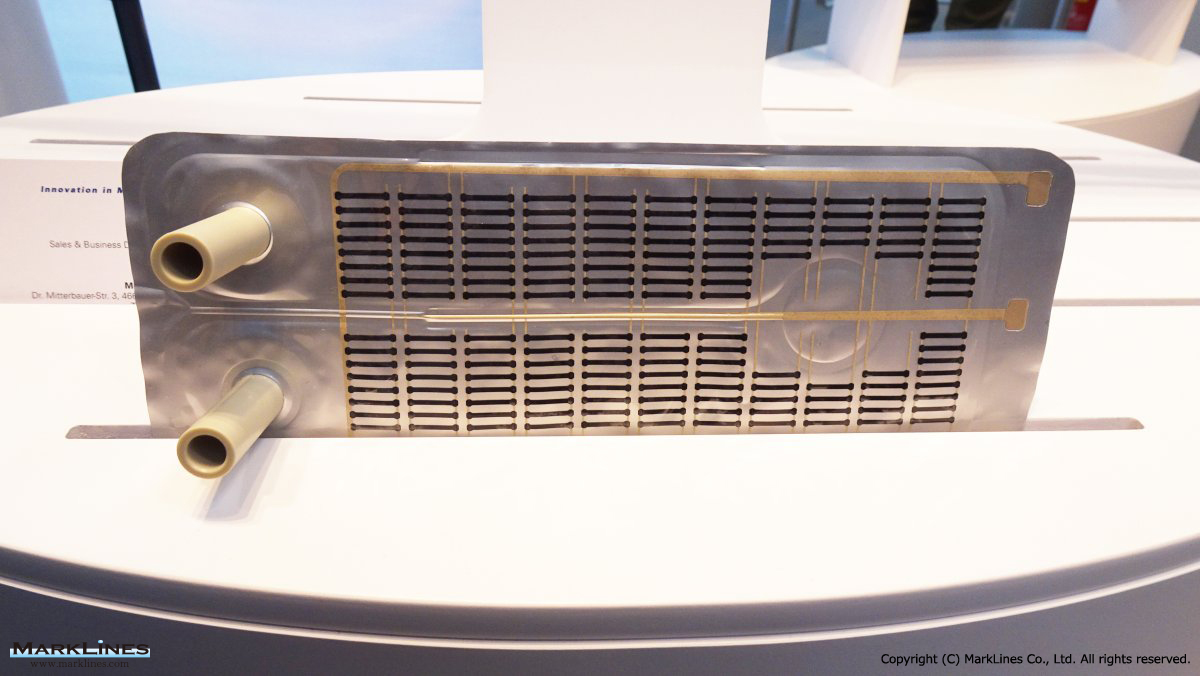

-Air-cooled heat sinks

-Liquid-cooled heat sinks

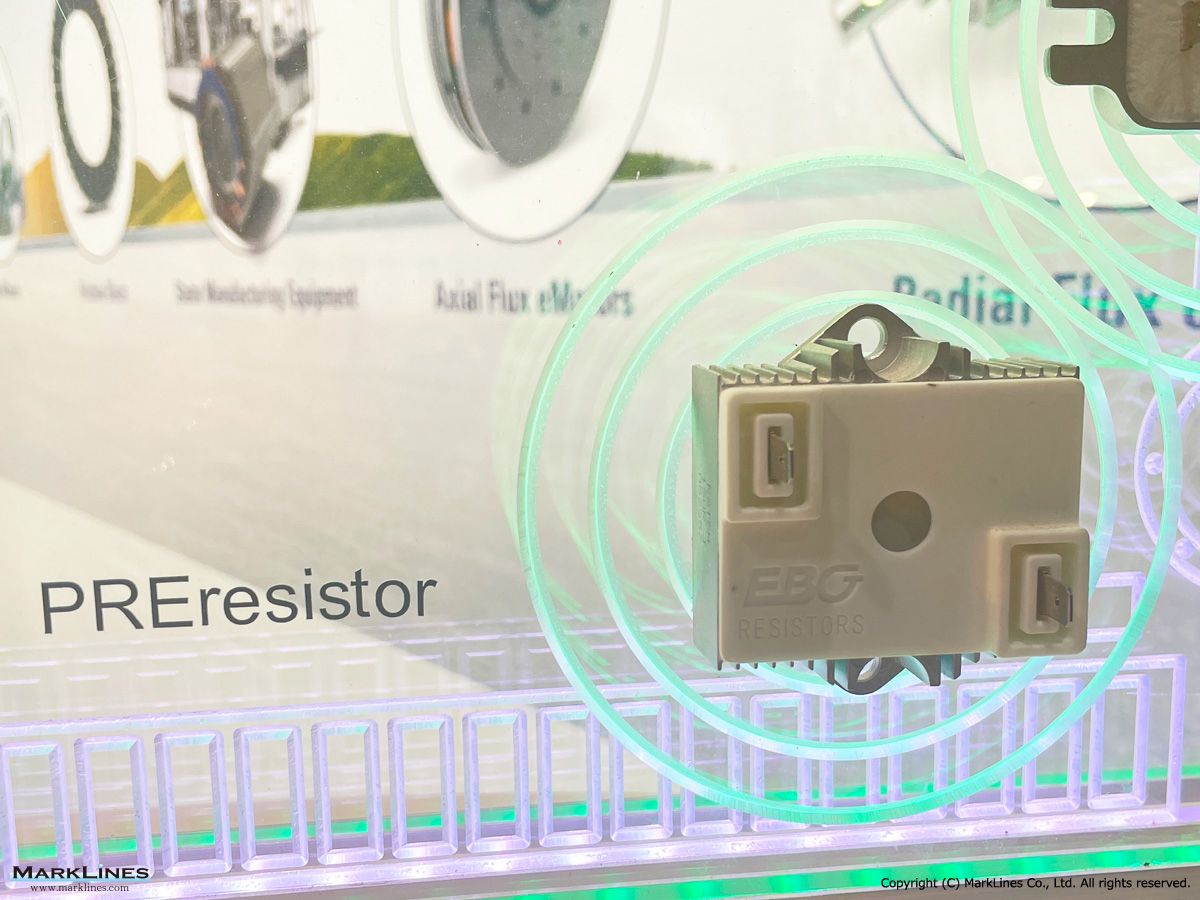

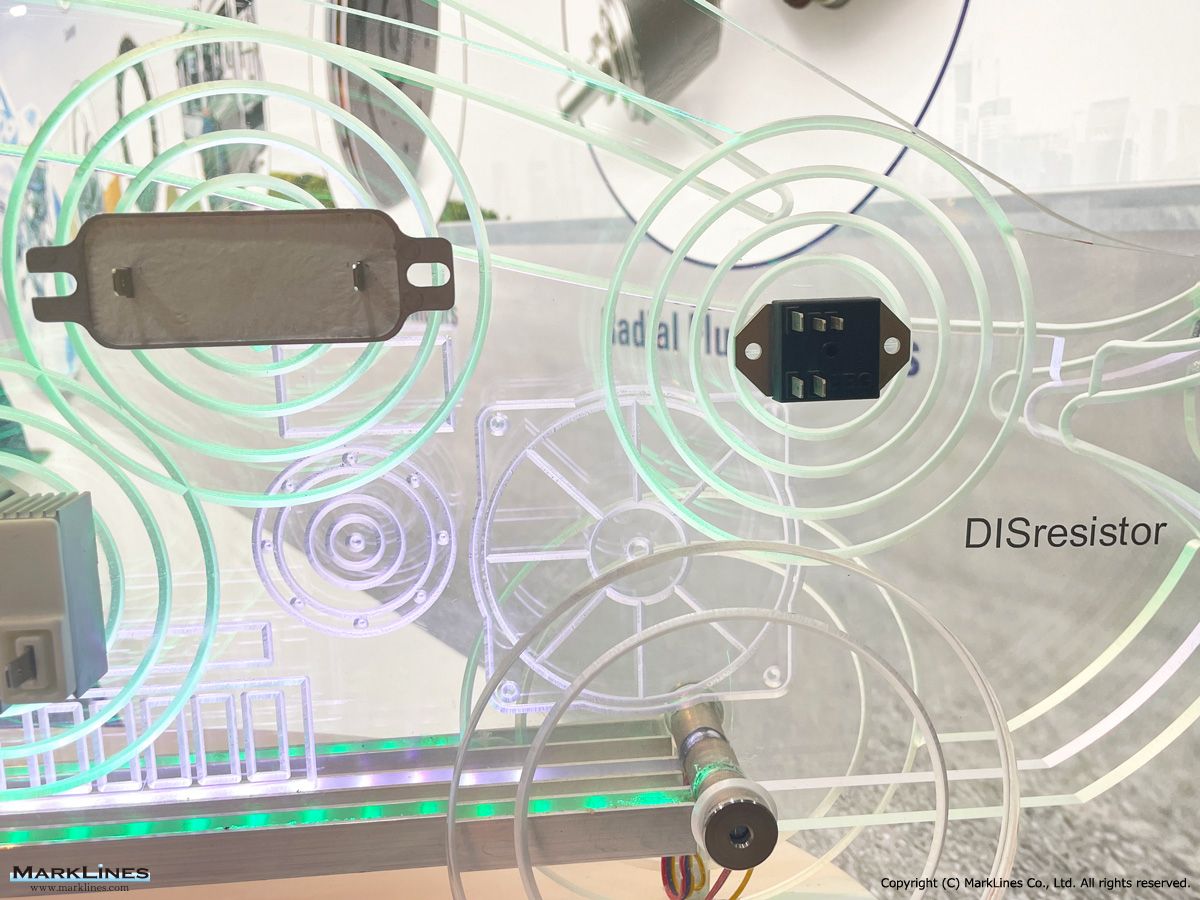

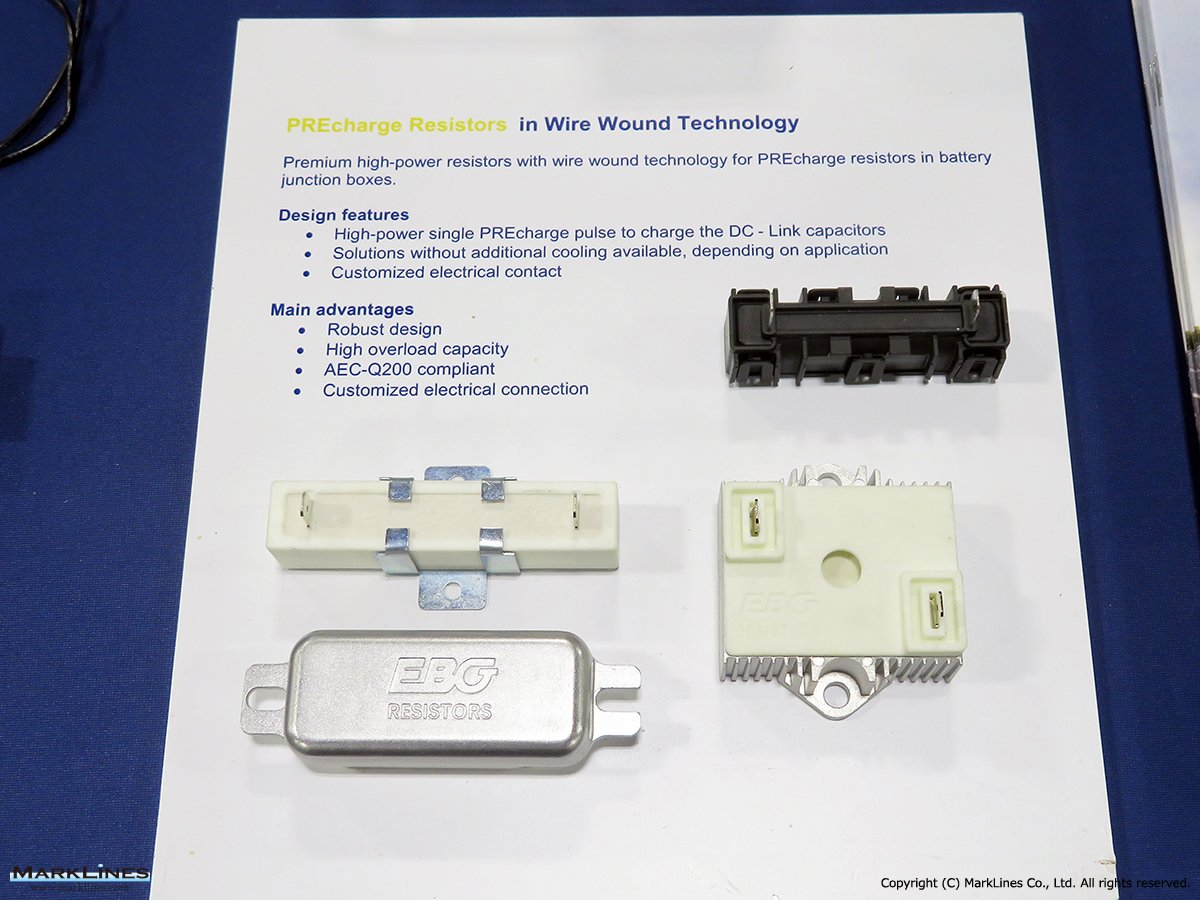

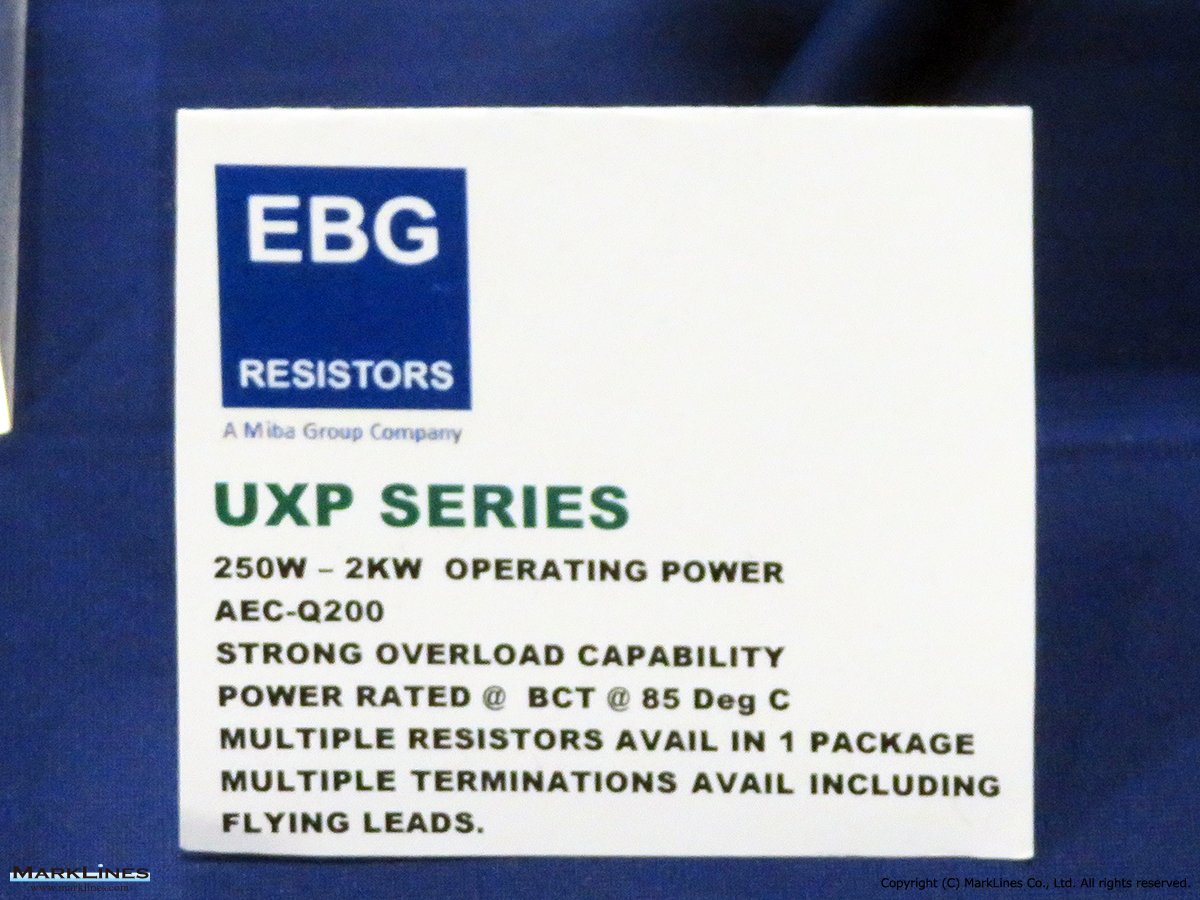

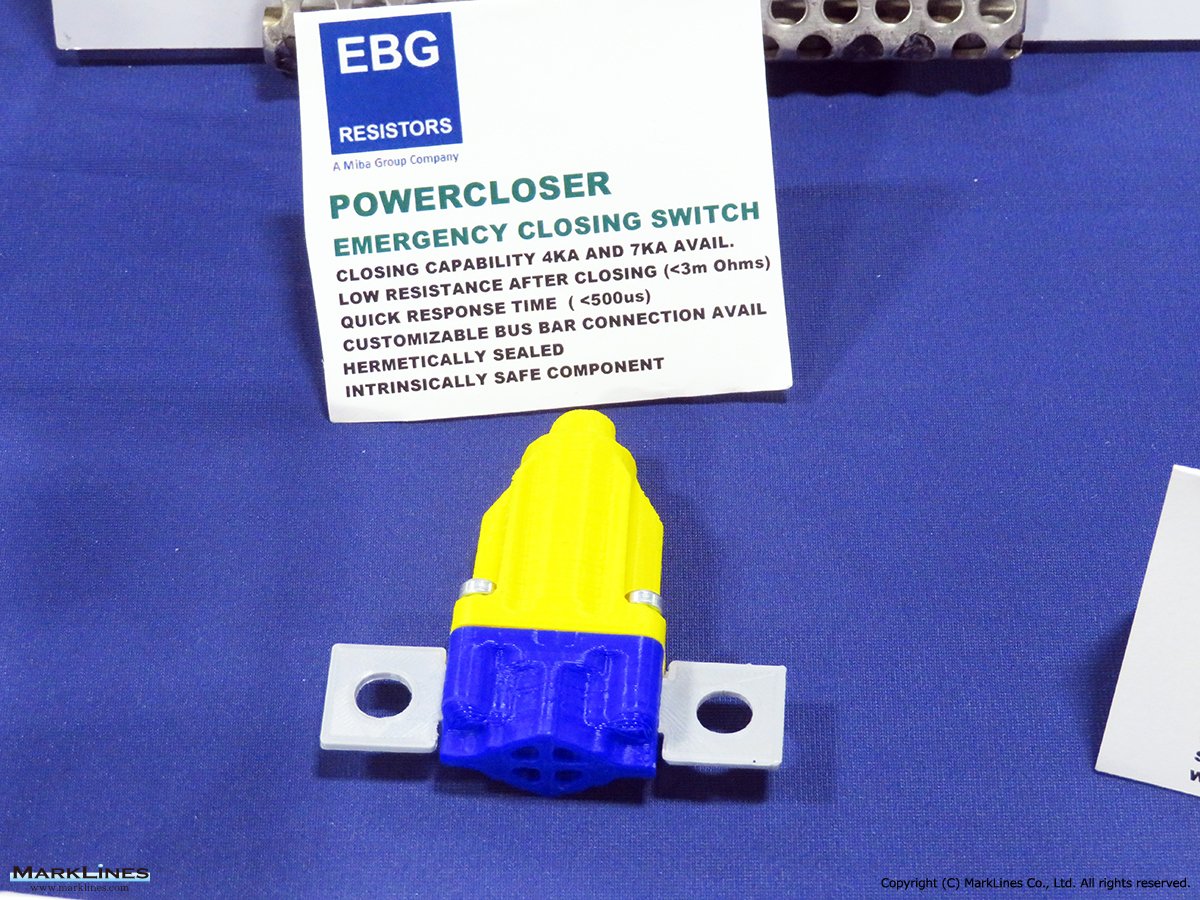

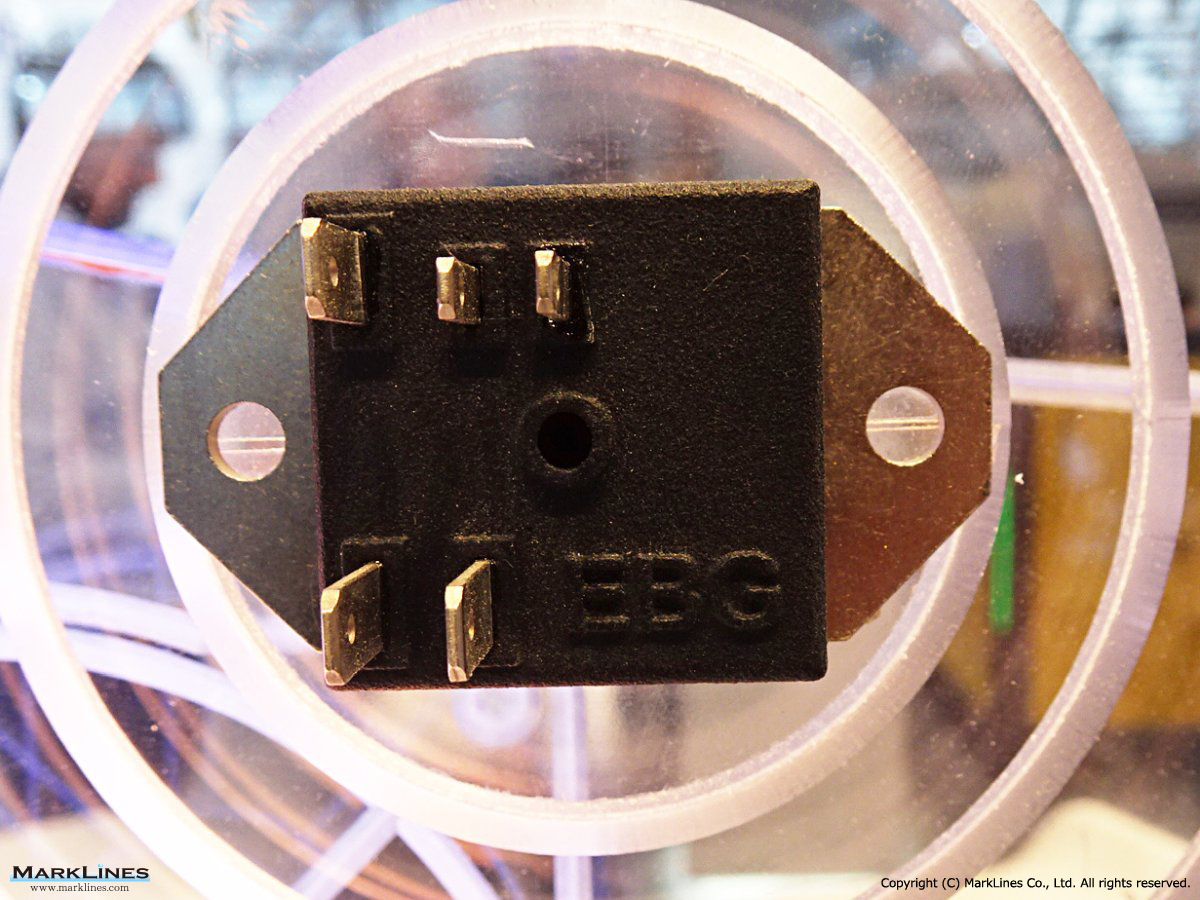

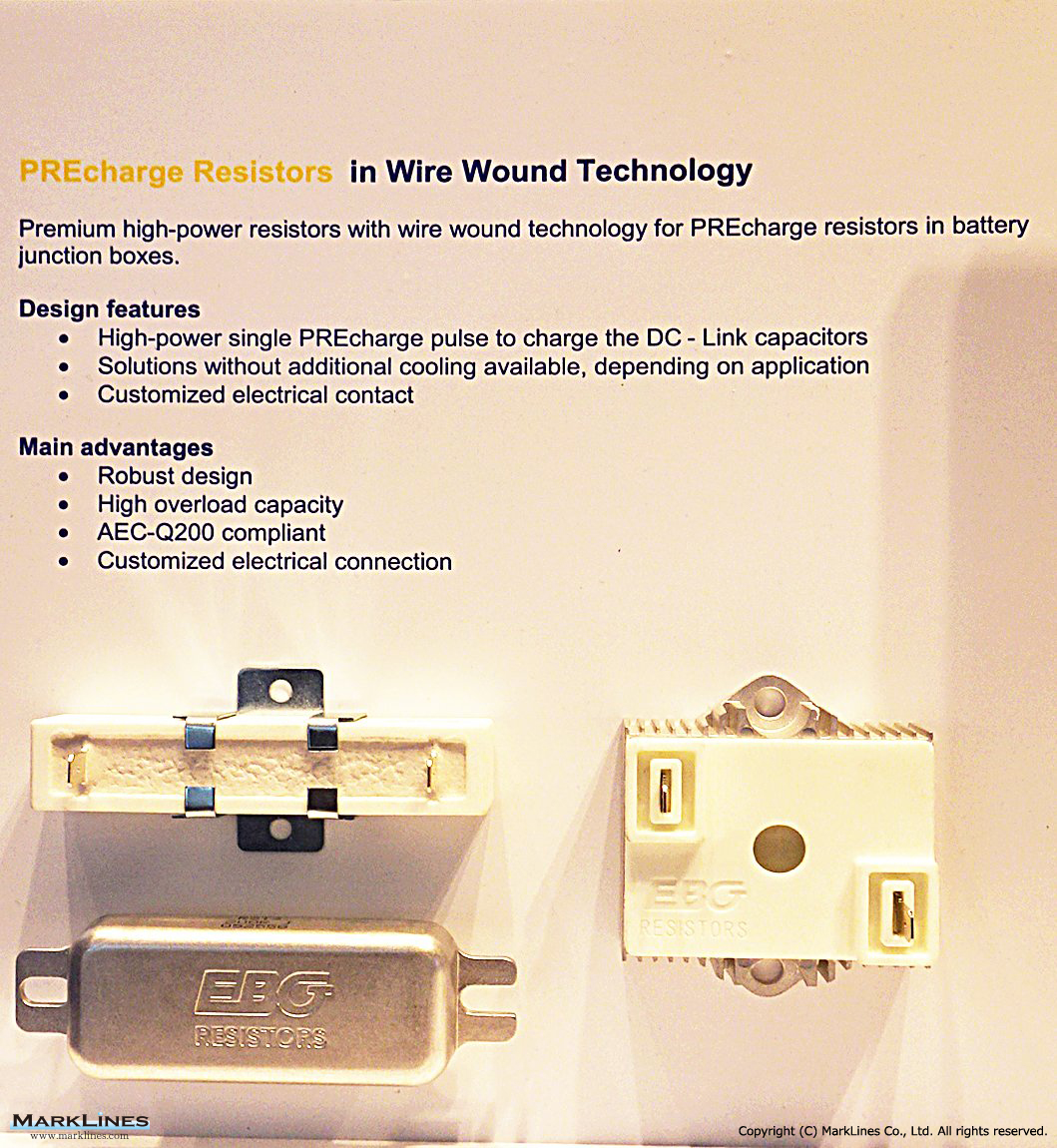

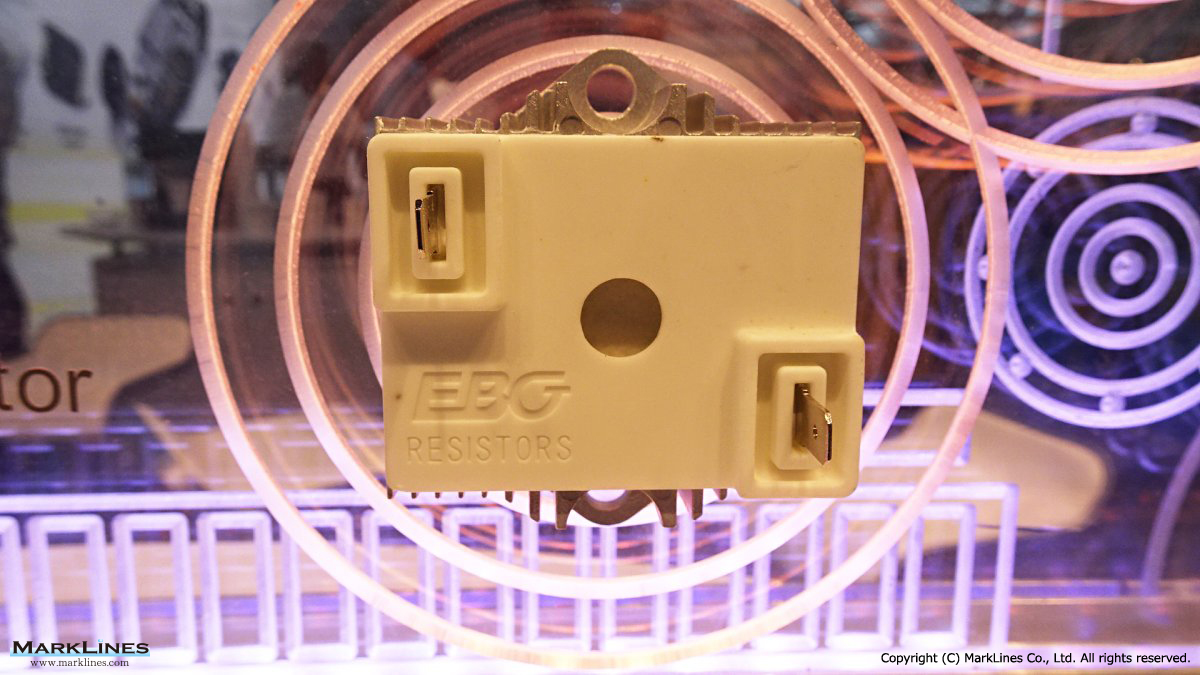

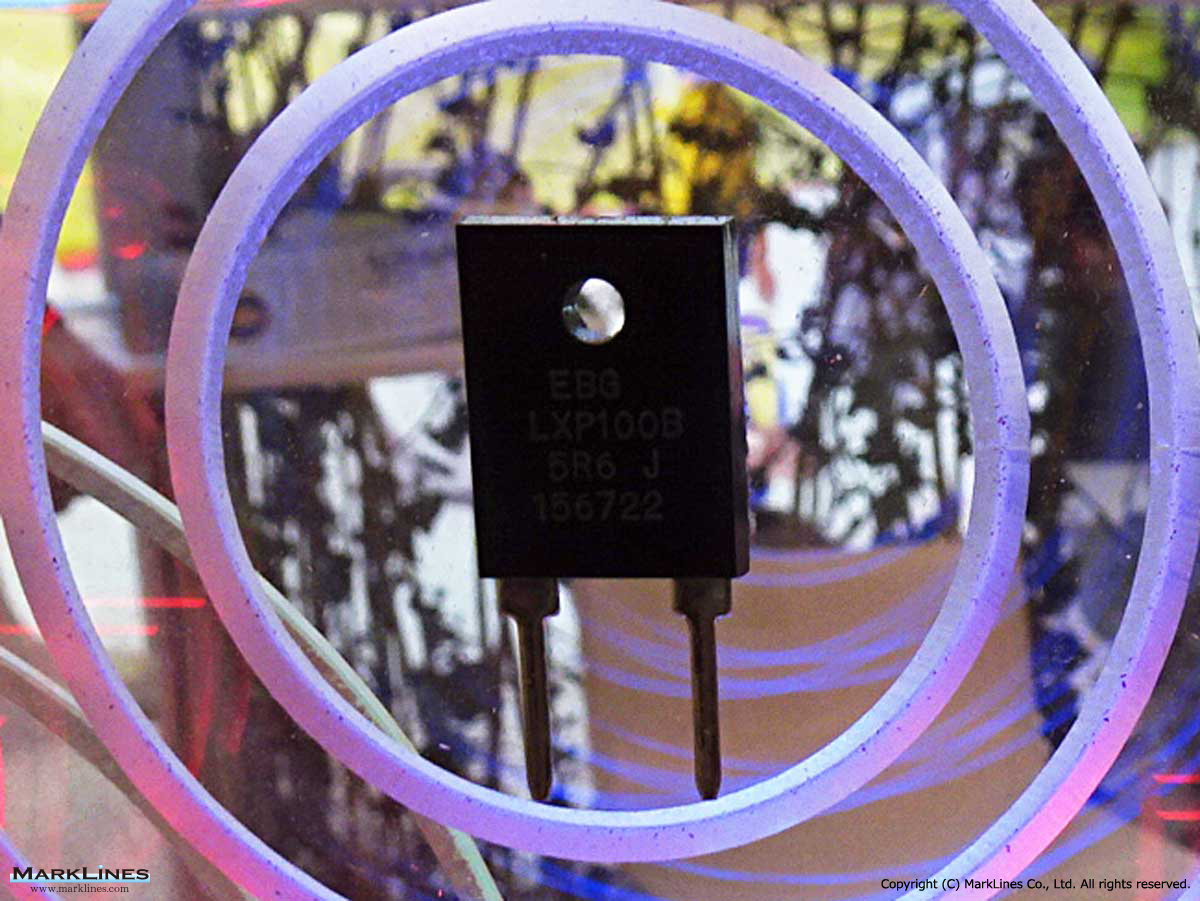

-Resistors

-Heat pipes

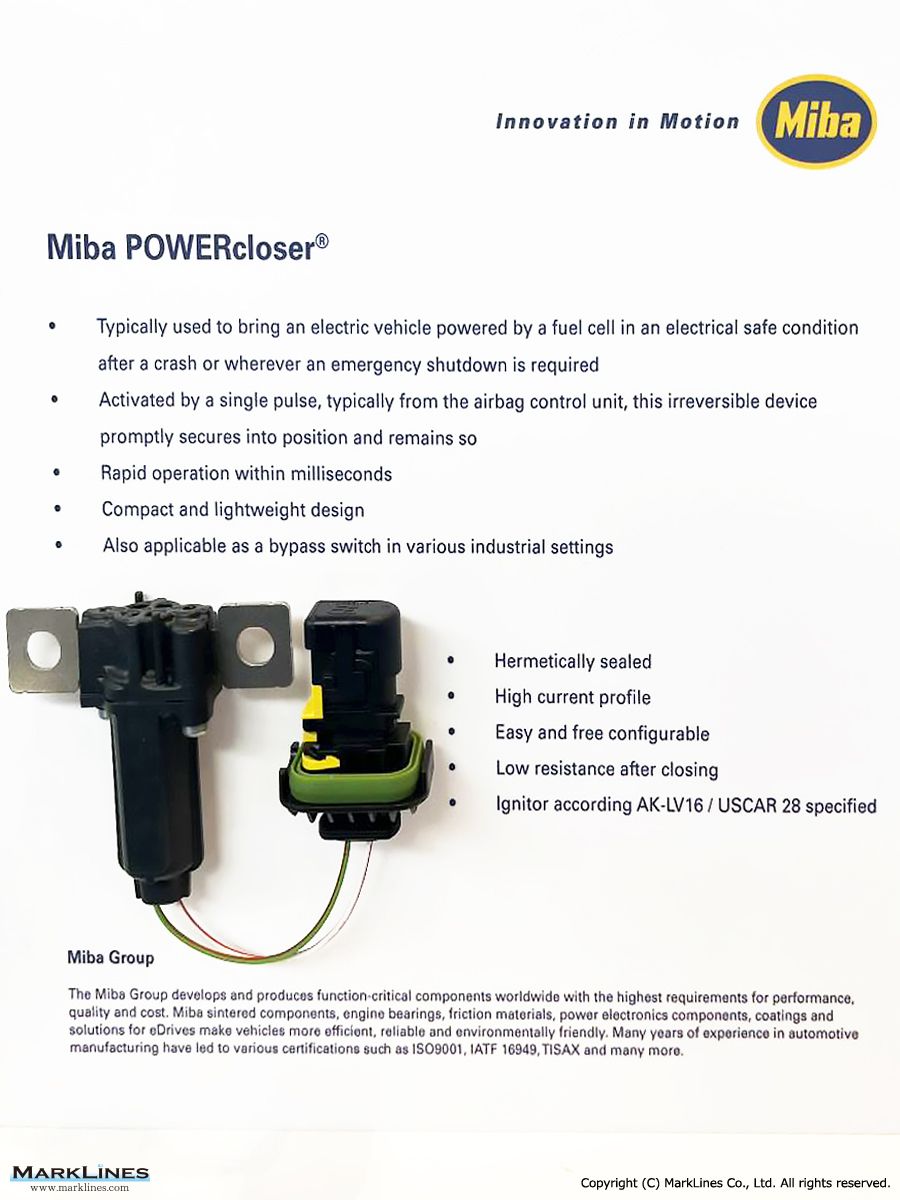

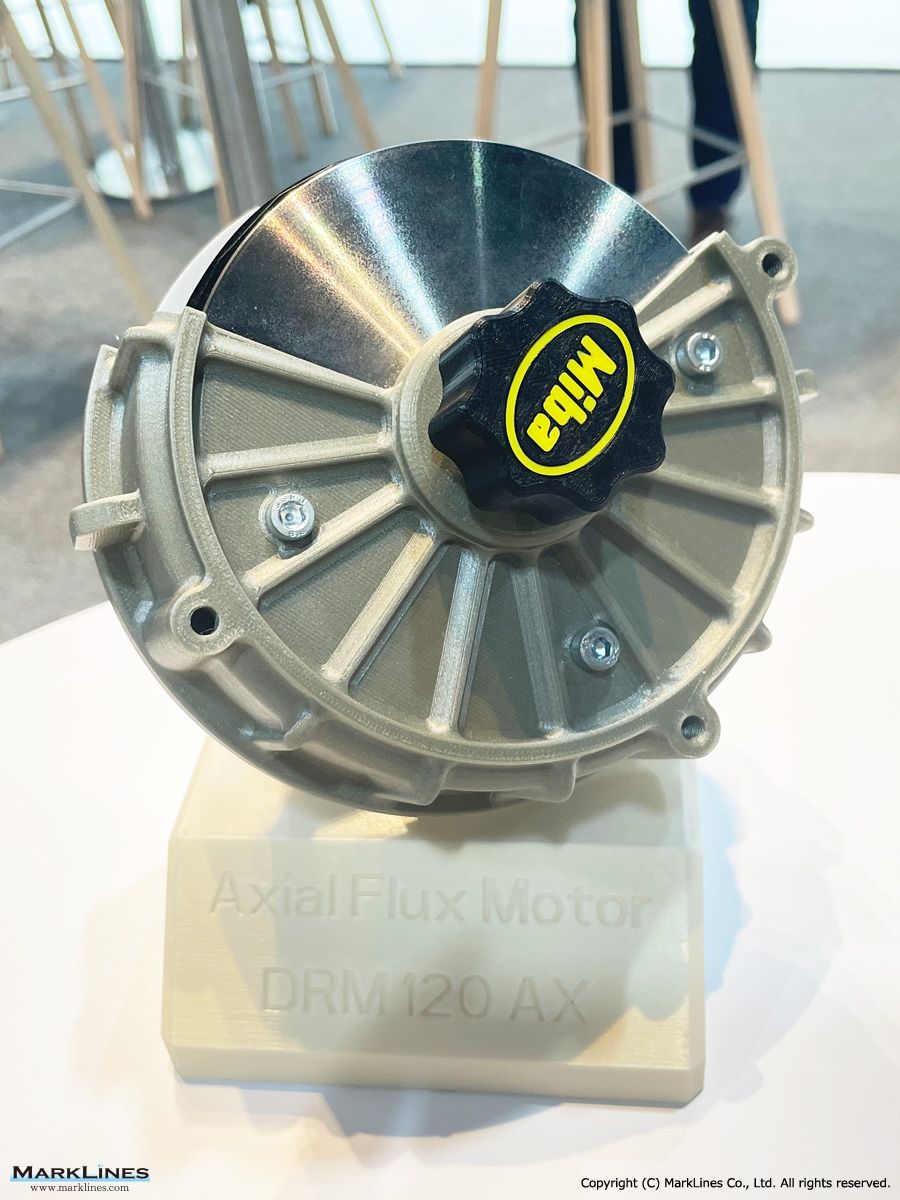

eMobility

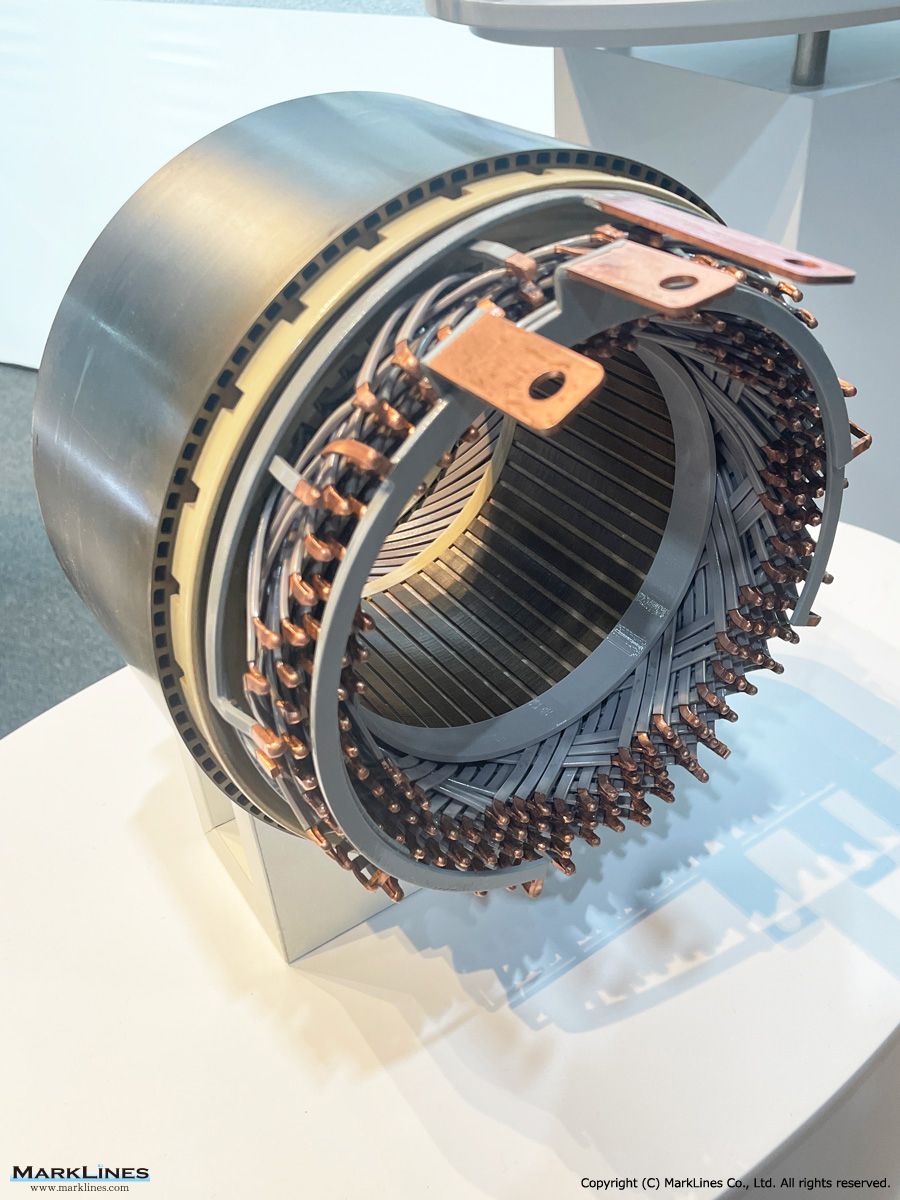

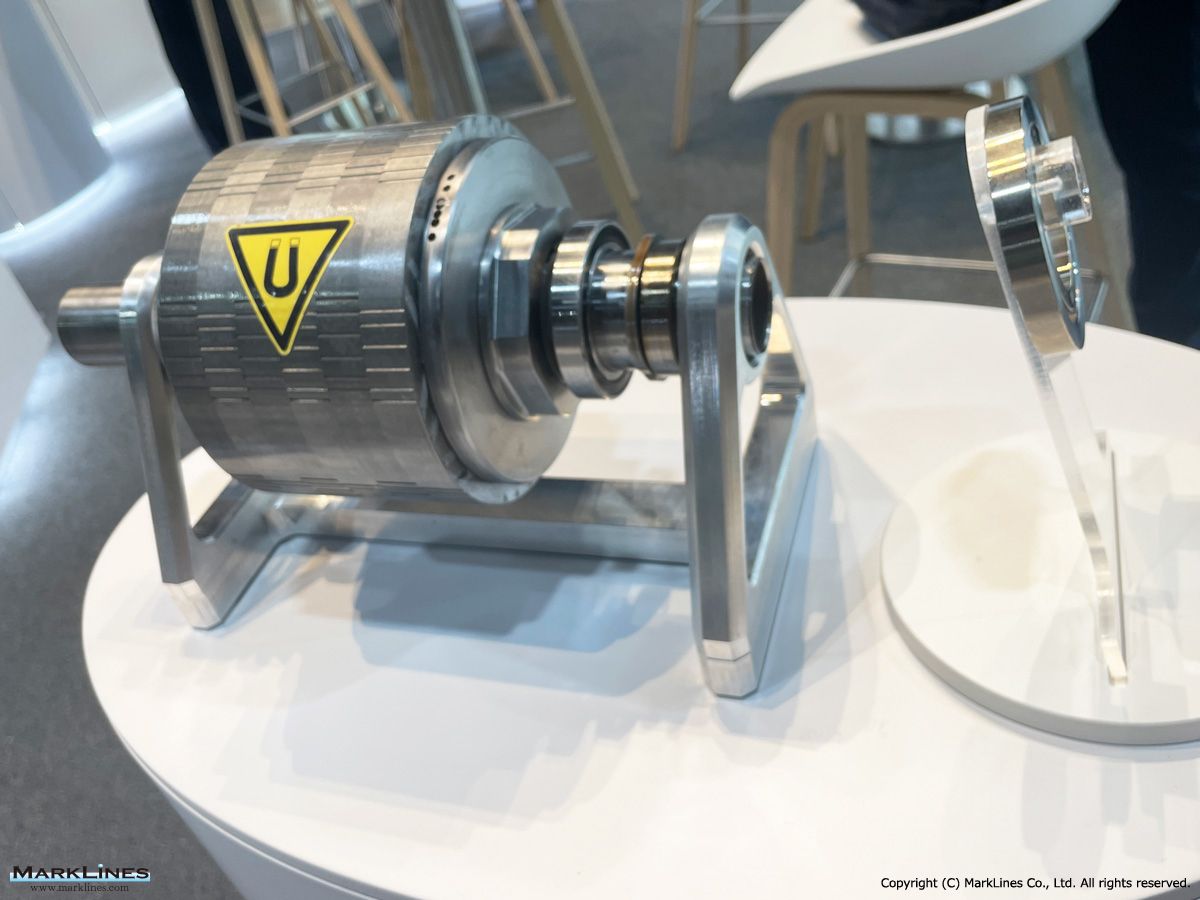

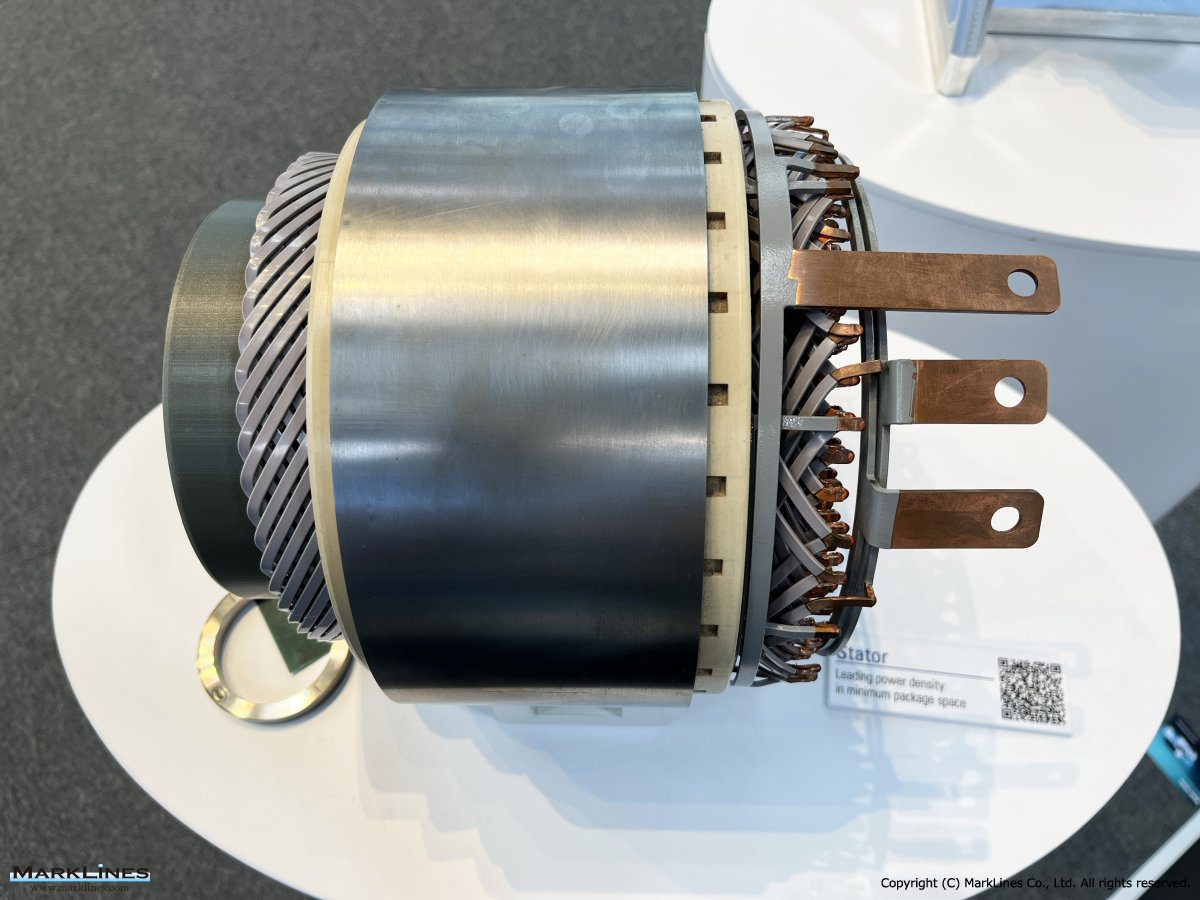

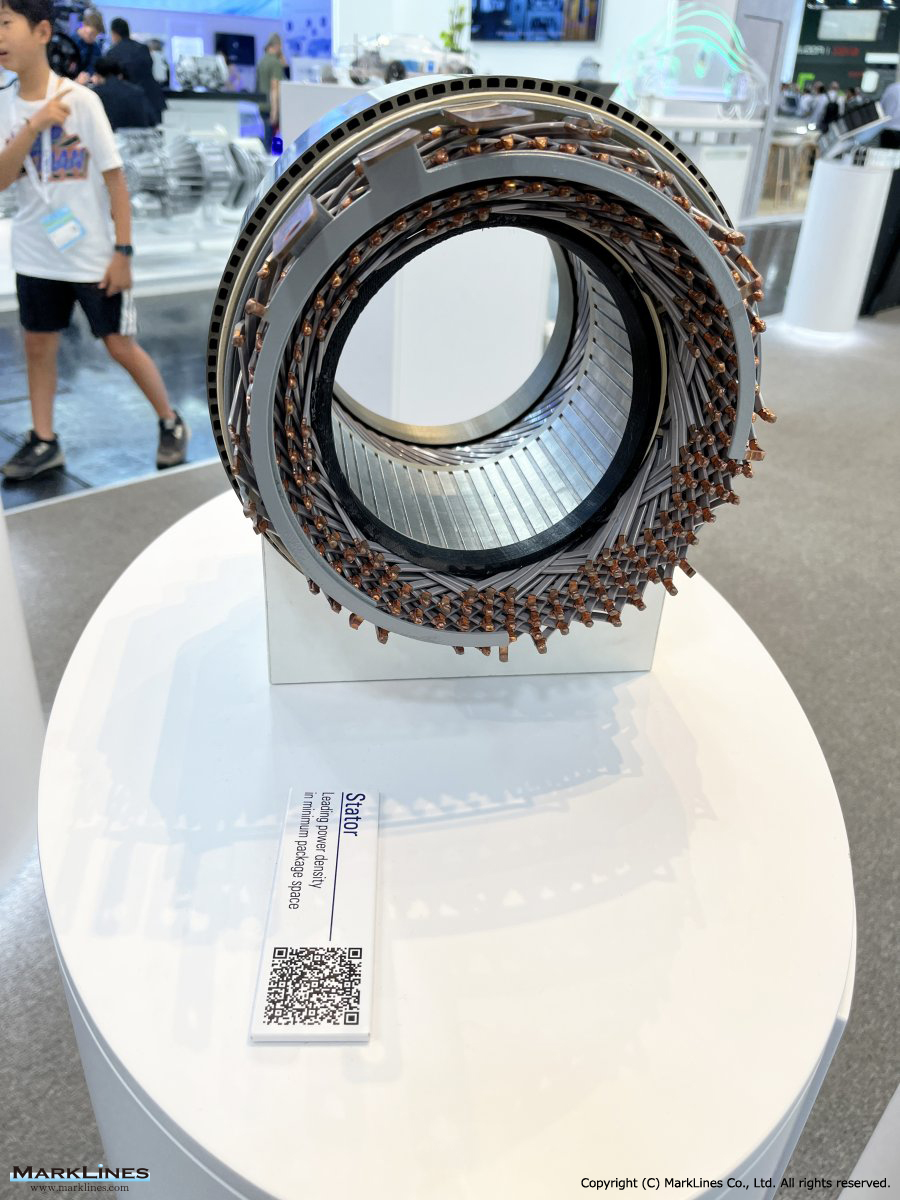

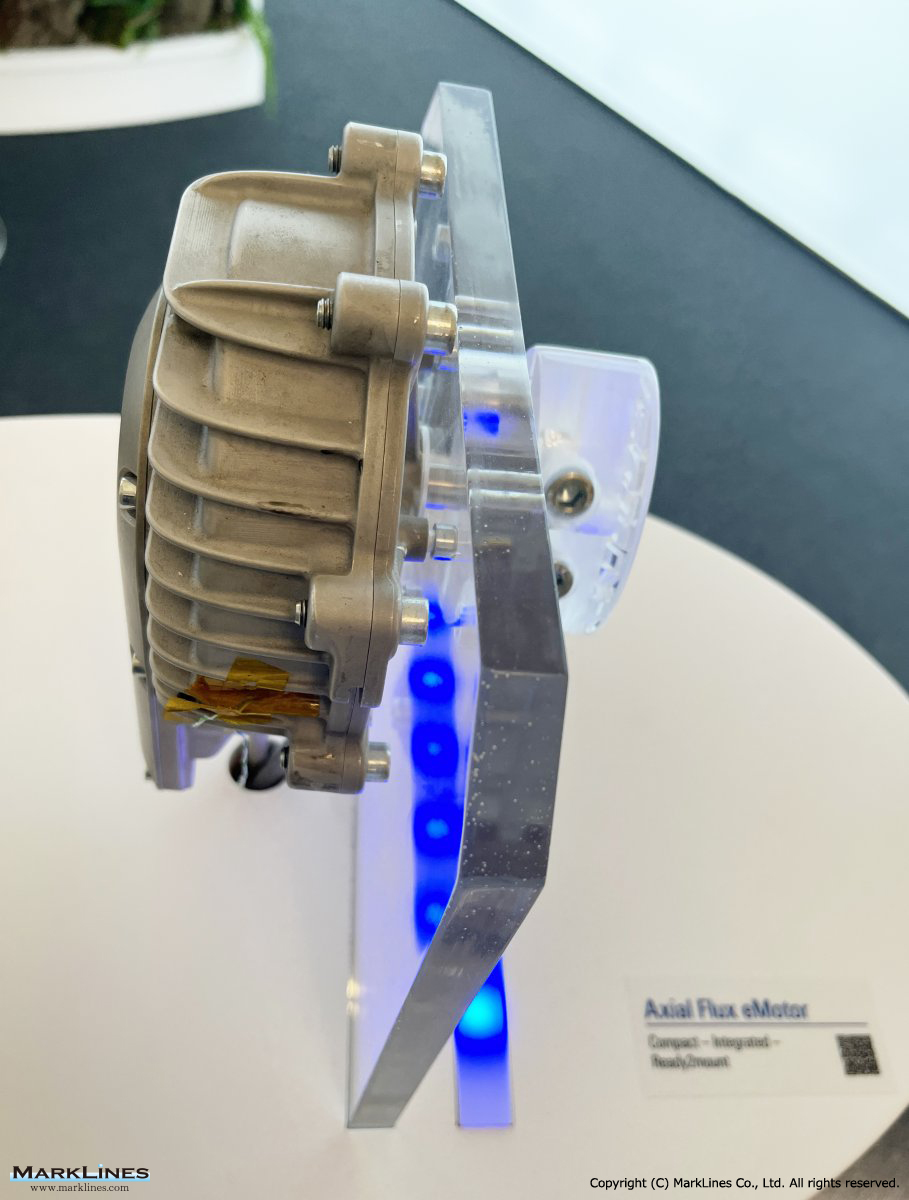

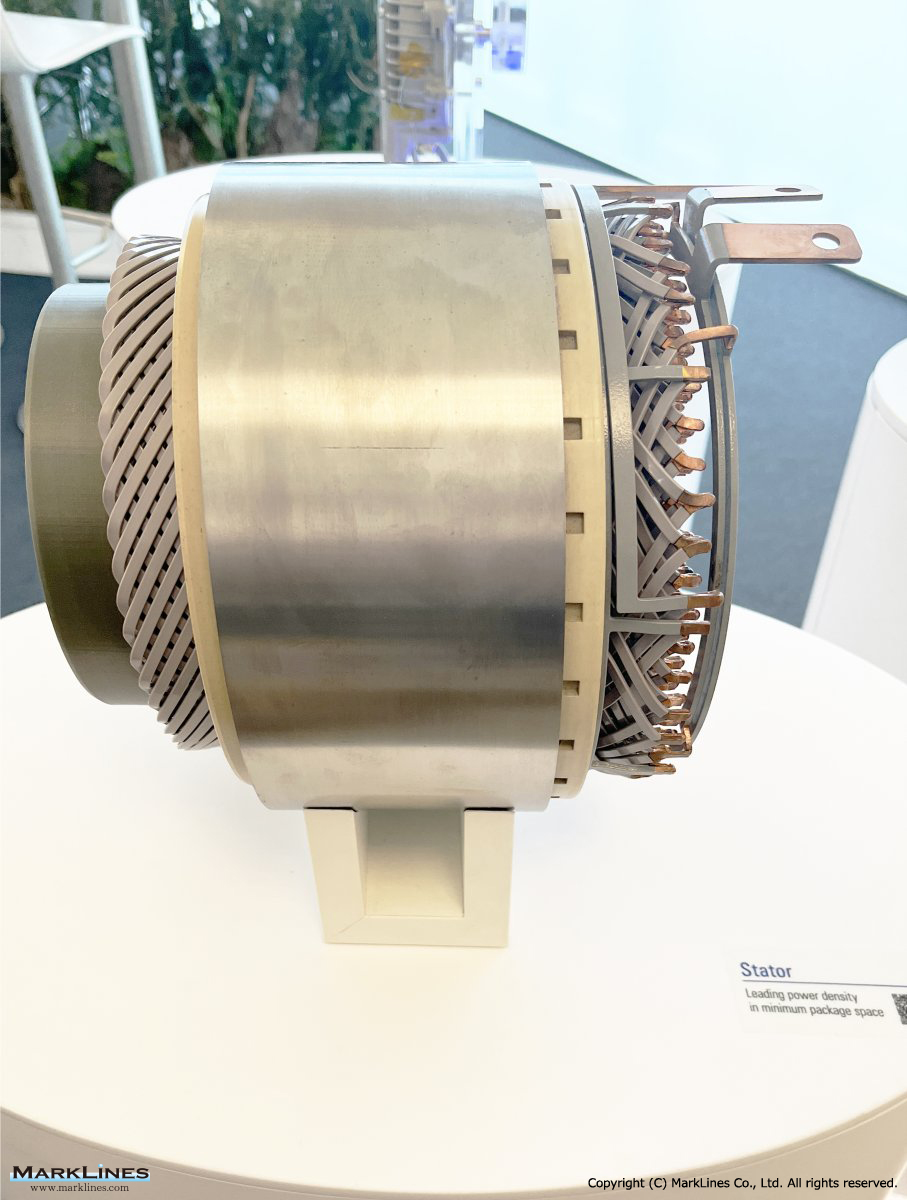

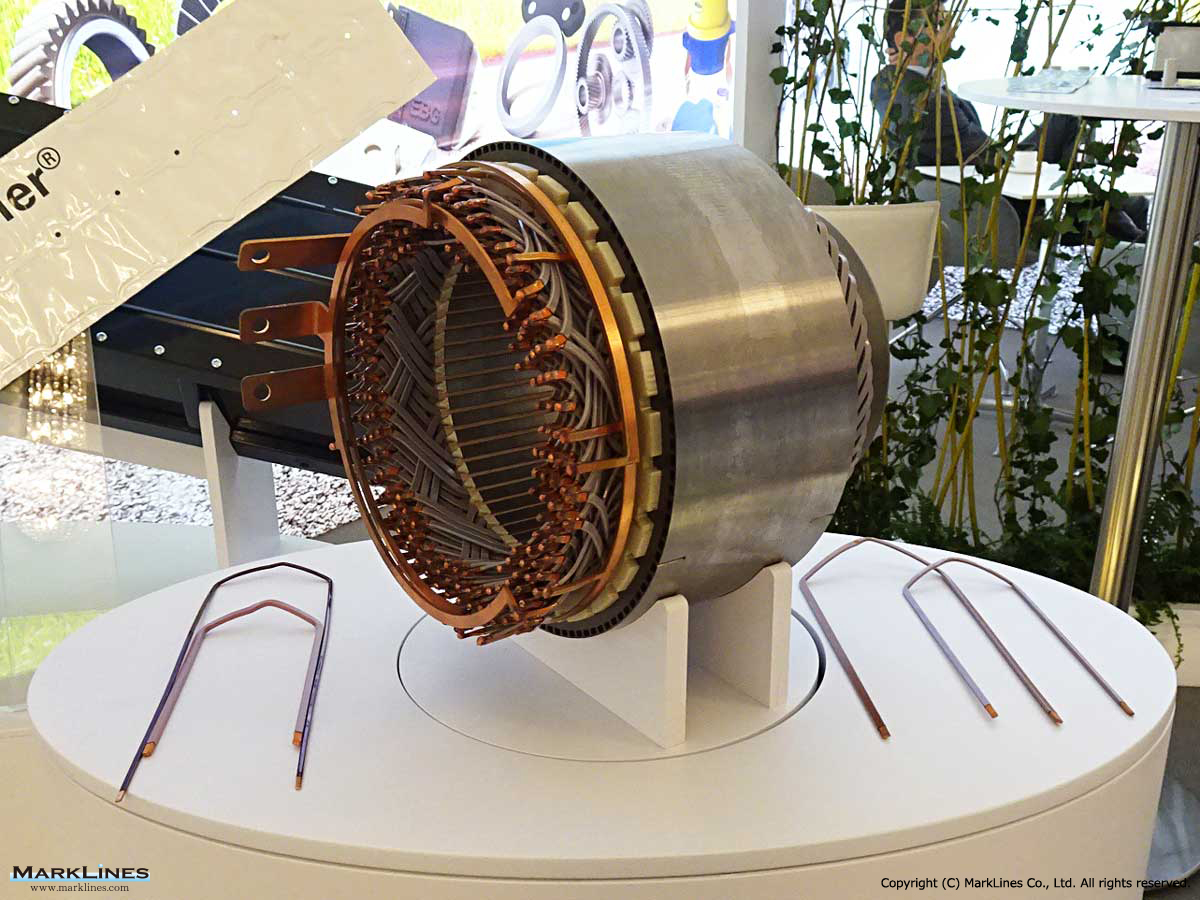

-Winding and assembly systems for electric motors

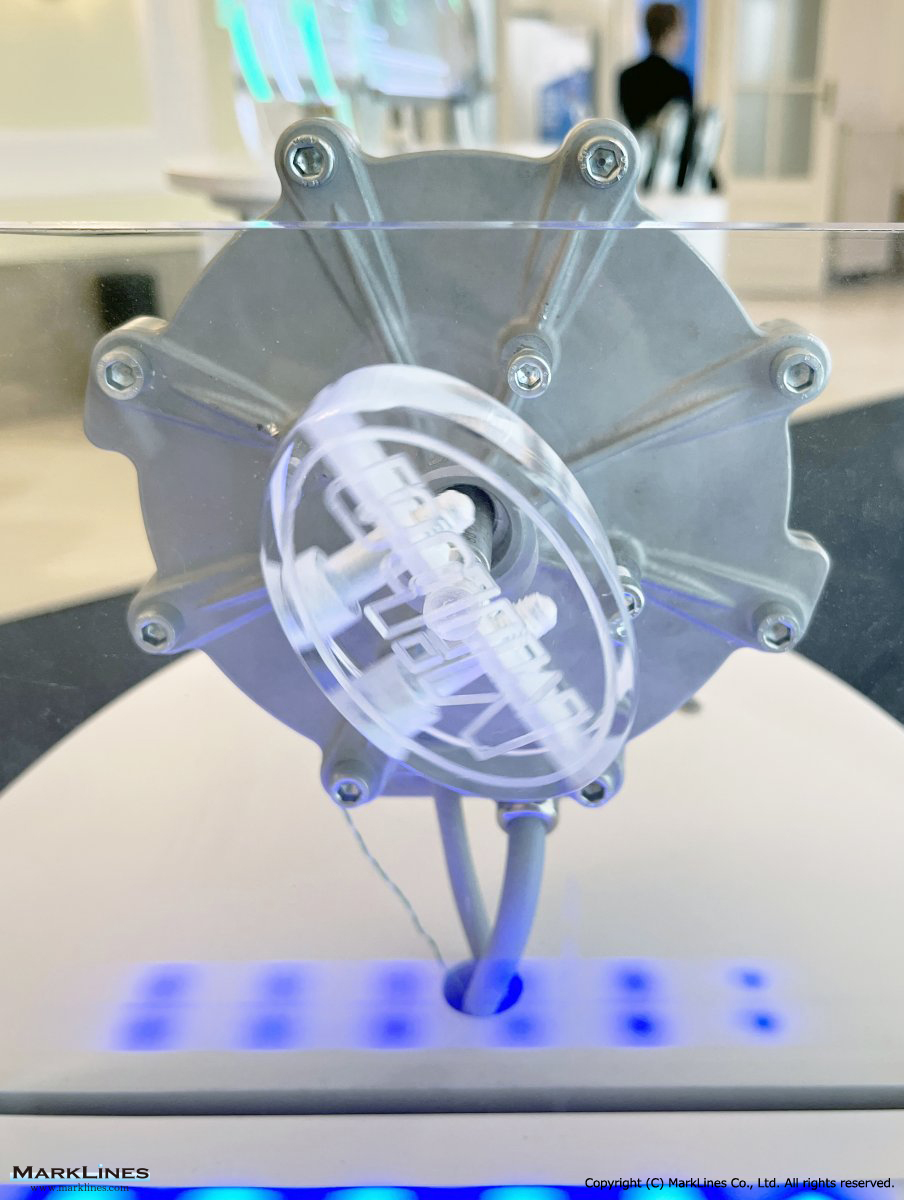

-Soft Magnetic Composite materials for electric motors

-Powder-metal gears

-Self-energizing synchronizers

-Powder metal components for clutch actuation and parking lock devices

-Noise reduction coatings

-Adaptive coatings

-Gripcoat process to directly apply friction-enhancing coating to components

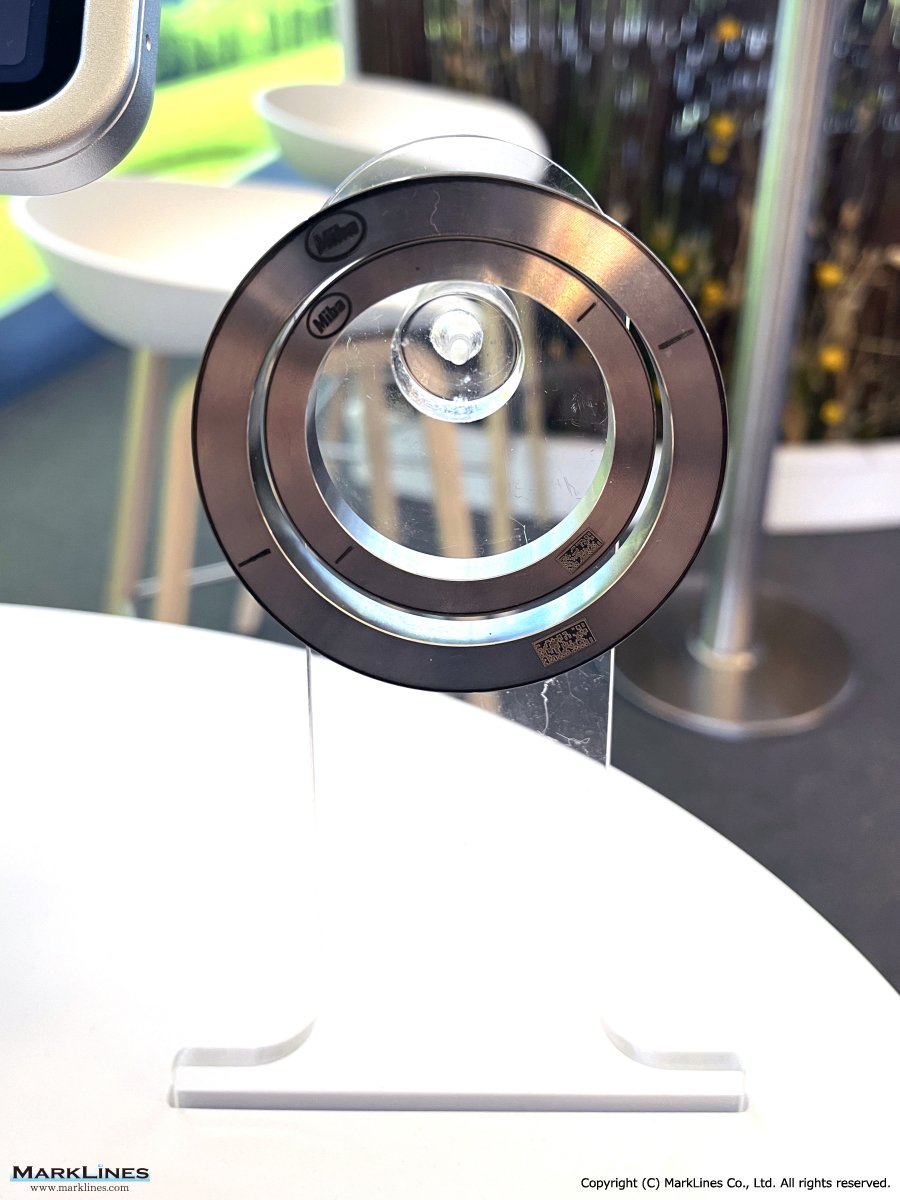

-Pole wheel for magnetic encoders

-Bipolar plate coatings

-Resistors

-Heat sinks

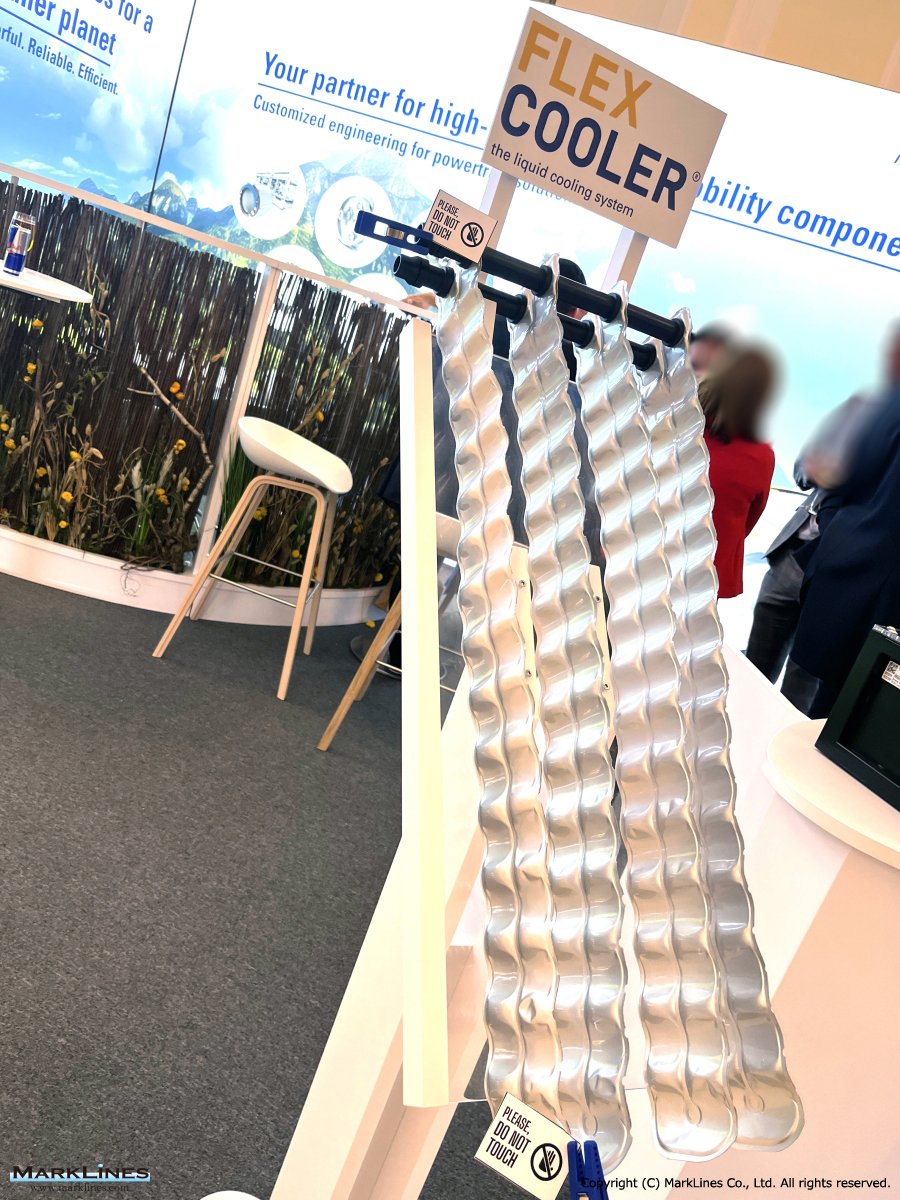

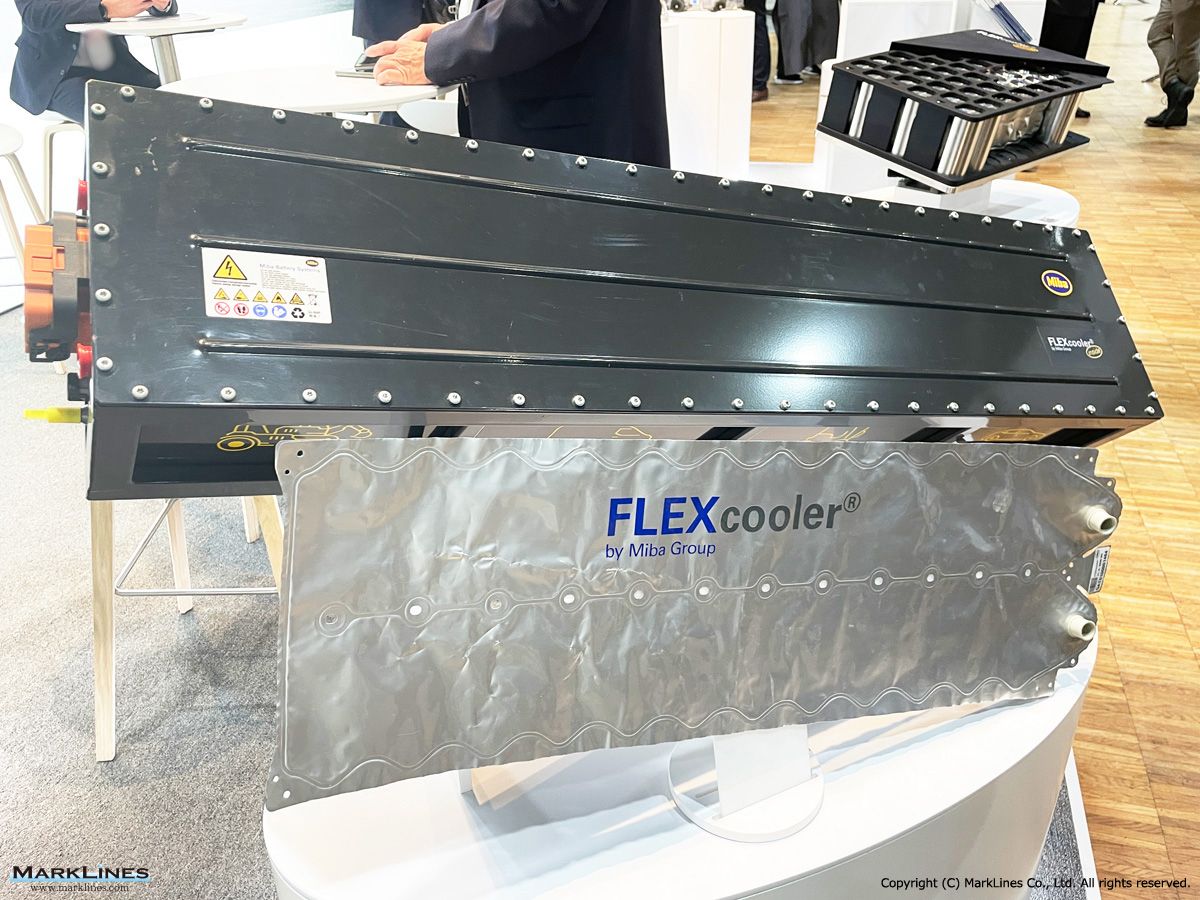

-Liquid cooling components for battery modules

-Heat pipe assemblies

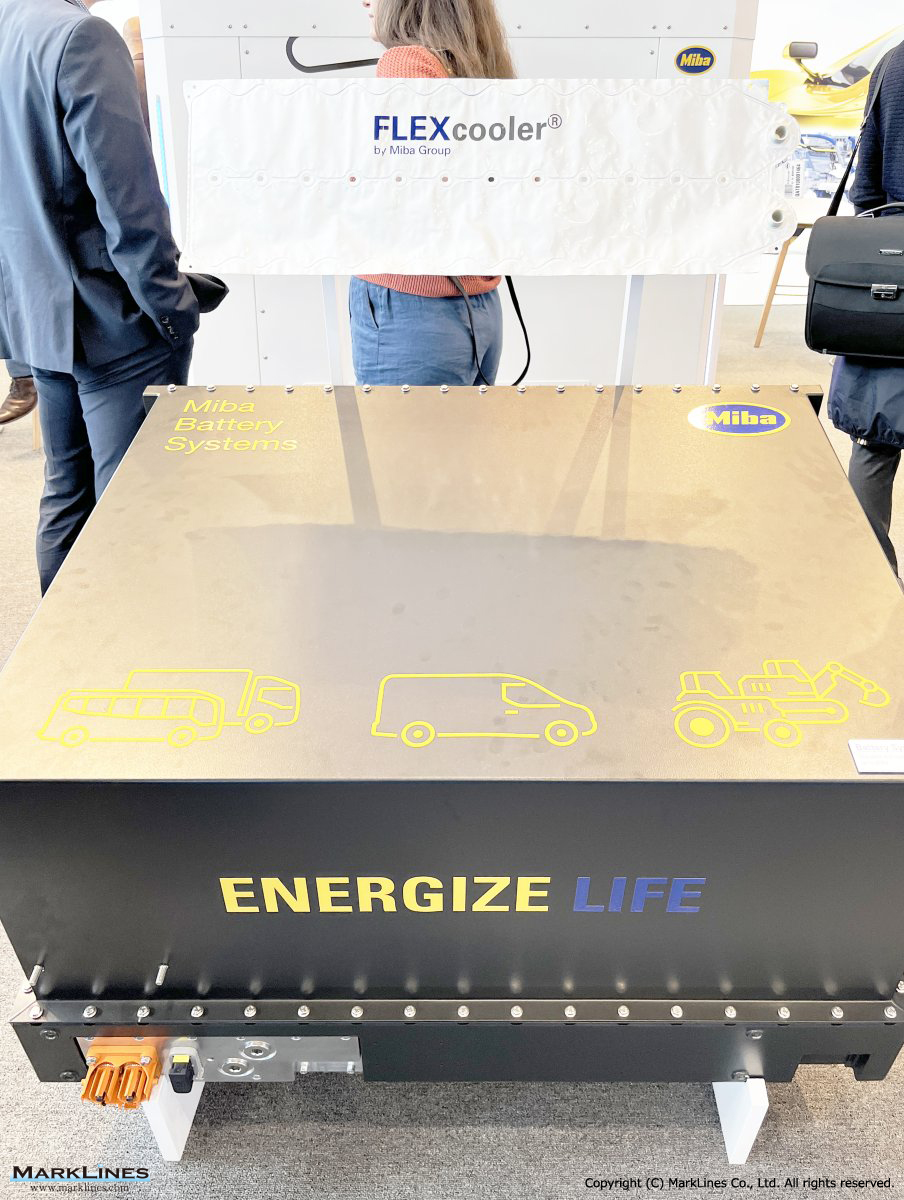

-Battery cooling systems

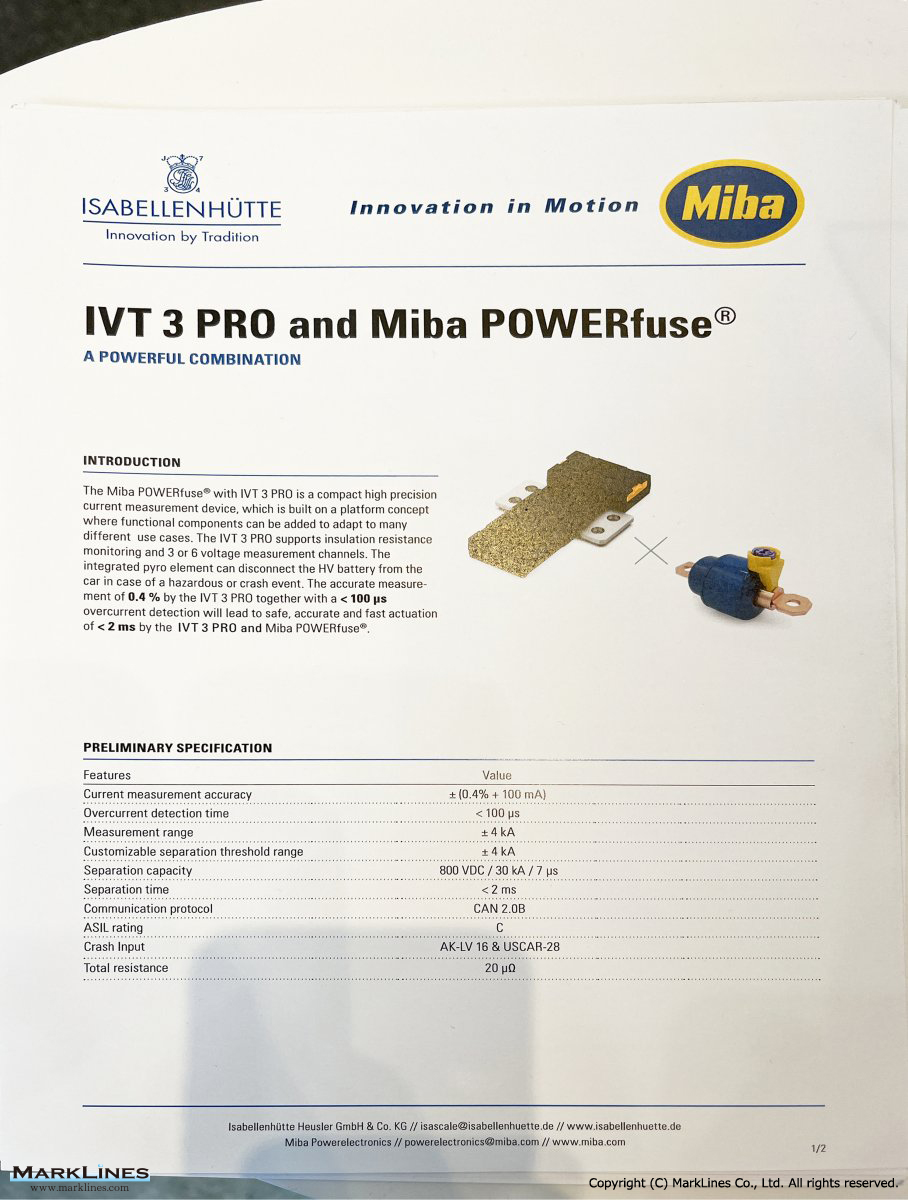

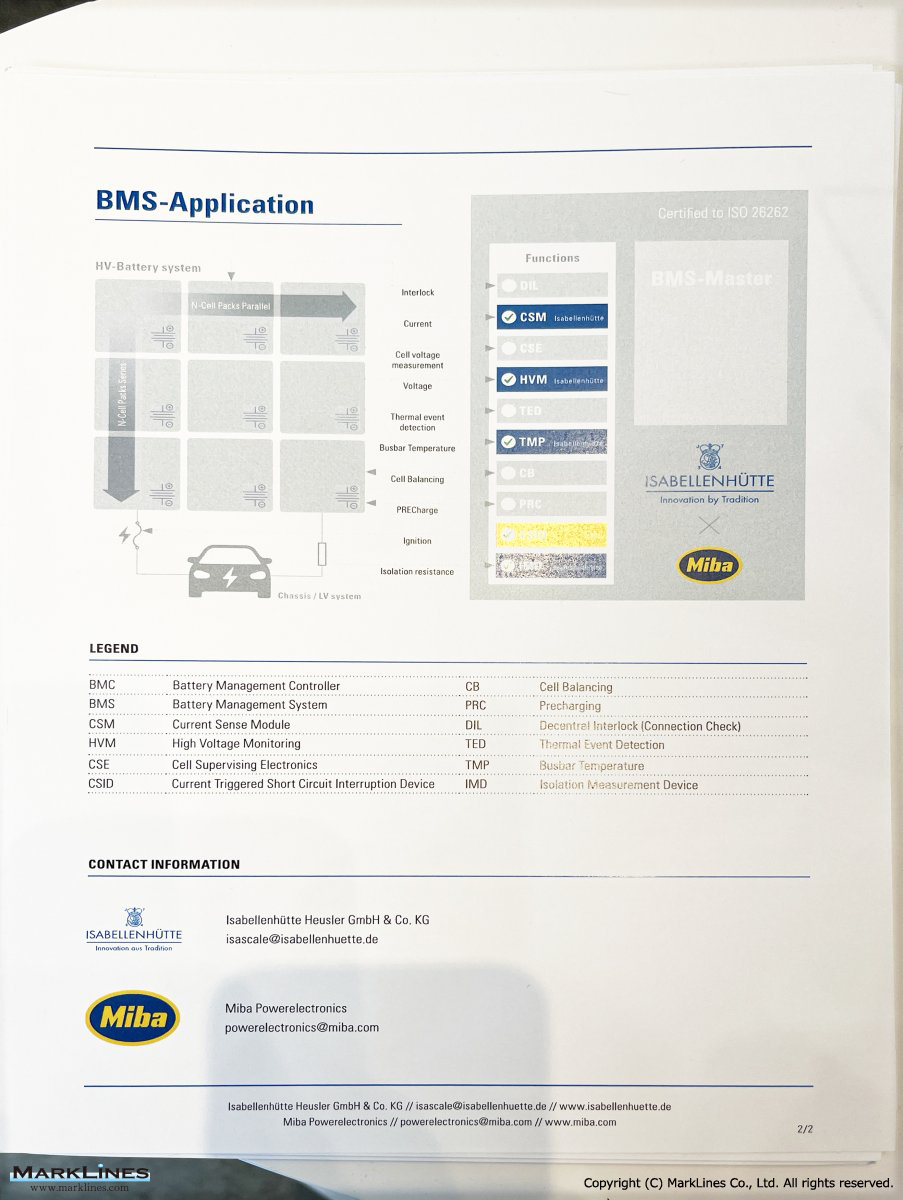

-Battery management systems

-TERRA battery platform for on- and off-highway commercial vehicle applications

-FLEXOOLER non-rigid liquid cooling component for EV battery cells

History

| 1927 | Franz Mitterbauer took over the metalworking shop of his employer, a master craftsman, and expanded it into an automobile workshop. |

| 1935 | Franz Mitterbauer started to specialize in engine maintenance and repairs. |

| 1949 | The Company started the production of engine bearings. |

| 1955 | First exports of bearings; introduction of the "Miba" brand. |

| 1963 | The first sintered components were produced. |

| 1975 | Started producing friction materials. |

| 1986 | Listed on the Vienna stock exchange. |

| 1991 | Acquired Tyzack Transmission Components Ltd. |

| 1991 | Acquired Miba Handelsgesellschaft mbH-Motor-Center Mitterbauer GmbH. |

| 1991 | Acquired an 80% interest in Terrecorp, United States. |

| Jan. 1992 | Constructed Miba Motor-Center Kft. in Budapest, Hungary. |

| 1993 | Increased its interest in HydraMechanica Corp., a manufacturer of friction materials in the US, from 50% to 100%, and at the same time disposed of Friction Masters Inc. |

| 1994 | Acquired Nuova Merisinter Group, Italy. |

| Oct. 1998 | Acquired a 30% interest in Metal Leve Produtos Sinterizadors Ltda. and started its expansion in South America. |

| 1999 | Disposed of Motor-Center Mitterbauer. |

| Jul. 1999 | Acquired Sintermetal S.A., Spain. |

| Oct. 1999 | Opened Miba Training Center, in Laakirchen, Austria. |

| Jul. 2001 | Miba-Bearings of the US, a subsidiary of the Company, Acquired the heavy wall bearing business of Federal-Mogul Corporation. |

| Oct. 2006 | The sinter plant in Napels (Italy) sold to an Italian investor. |

| 2007 | Miba Precision Components (China) in Suzhou, China opens |

| 2007 | Miba Steeltec, Vráble, Slovakia opens |

| 2008 | High Tech Coatings opens a second plant in Vorchdorf |

| 2010 | Miba Sinter USA, McConnelsville opens Acquisition of the british coating specialist Teer Coatings Ltd. in Droitwich, UK Acquisition of the friction materials business off-highway applications from Hoerbiger and acquisition of a production site in Pune, India Acquisition of the Styrian specialist for power electronic components EBG and DAU |

| 2011 | Acquisition of minority stake in Maxtech Sintered Product Pvt. Ltd. in Pune, India F. Peter Mitterbauer joins the Miba Board and takes over the responsibility for Miba Friction Group Formation of Miba’s new business division, New Technologies Group |

| Dec. 2013 | Signed an agreement to increase its interest in Mahle Metal Leve Miba Sinterizados Ltda in Indaiatuba, Brazil, by 10% from 30% to 40%. |

| Jun. 2017 | Increased its interest in Mahle Metal Leve Miba Sinterizados (MMLMS) from the current level of 40% to 100% as of June 30, 2017. |

| May 2018 | -The Company built two new production sites in Suzhou and Qingxi, China. -Acquired the industrial bearing segment of the John Crane Group with three production sites in the US and one plant in Germany. |

| Jul. 2019 | Acquired a 25.1% stake in the Upper Austrian company Voltlabor, a sister company of Nordfels GmbH. |

| Nov. 2019 | Opened the new production site in Miba Drivetec India (MDI) in Pune, India. |

| Jan. 2020 | Miba Automation Systems (MAS) has taken over a 49 percent share in the Burgenland machine builder "SEP Automation". |

| May 2022 | Acquired a majority stake in battery specialist Voltlabor, which is now rechristened as "Miba Battery Systems". |

| Sep. 2022 | The Company’s first battery plant, VOLTfactory #01, located in Bad Leonfelden, Upper Austria has officially been opened. |

Supplemental Information 1

>>>Business Report FY ended Jan. 31, 2008

>>>Business Report FY ended Jan. 31, 2009

>>>Business Report FY ended Jan. 31, 2010

>>>Business Report FY ended Jan. 31, 2011

>>>Business Report FY ended Jan. 31, 2012

>>>Business Report FY ended Jan. 31, 2013

>>>Business Report FY ended Jan. 31, 2014

>>>Business Report FY ended Jan. 31, 2015

>>>Business Report FY ended Jan. 31, 2024

Note: A figure in brackets ( ) indicates a loss

AI Navigator

AI Navigator

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India