Gestamp Automocion S.A. Business Report FY ended Dec. 2017

Financial Overview |

(in million EUR) |

| FY ended Dec. 31, 2017 | FY ended Dec. 31, 2016 | Rate of change (%) | Factors | |

| Net Sales | 8,201.6 | 7,548.9 | 8.6 | 1) |

| EBITDA | 889.9 | 841.1 | 5.8 | 2) |

| Sales by business unit | ||||

| Body-in-White and Chassis | 6,439.3 | 6,067.4 | 6.1 | 3) |

| Mechanisms | 1,015.9 | 902.4 | 12.6 | 4) |

Factors

1) Net Sales

-The Company’s net sales in the fiscal year ended December 31, 2017 increased by 8.6% over the previous year to EUR 8,201.6 million. Excluding currency effects, the Company’s sales increased by 11.0% over the previous year. The increase in sales was due to improved sales in South America, Europe and Asia. The gains in those regions were partially offset by a decrease in revenue in North America.

2) EBITDA

-The Company had an EBITDA of EUR 889.9 million in the fiscal year ended December 31, 2017, an increase of 5.8% over the previous year. Sales growth in South America, Europe and Asia contributed to the increase in earnings, while a decline in North America and negative currency effects partially offset those increases.

3) Body-in-White and Chassis

-Sales in the combined Body-in-White and Chassis business units totaled EUR 6,439.3 million in the fiscal year ended December 31, 2017, an increase of 6.1% over the previous year. Sales primarily increased in Europe and South America.

4) Mechanisms

-In the fiscal year ended December 31, 2017, the Mechanisms business unit had sales of EUR 1,015.9 million, an increase of 12.6% over the previous year. Sales in the business unit primarily increased in China, Germany, Brazil, Spain, Czech Republic, Russia and North America.

Acquisitions

-On March 1, 2017, the Company's subsidiary, Beycelik Gestamp, acquired majority of a Romanian company which located on the outskirts of Pitesti, has more than 200 employees and had sales of EUR 17 million in 2016. The Romanian plant currently supplies small and medium-sized stamped components, as well as assemblies. The new plant will enable Gestamp to serve the Romanian production plants of both Renault-Nissan Group and Ford Motor Co.

-On November 24, 2016, the Company’s subsidiary, Gestamp Metalbages, acquired 60% of the share capital of ESSA Palau for EUR 23.4 million. As a result of the transaction, ESSA Palau became a wholly owned subsidiary of Gestamp Metalbages. ESSA Palau is based in Barcelona, Spain, and stamps and manufactures components for passenger cars.

R&D Expenditure |

(in million EUR) |

| FY ended Dec. 31, 2017 | FY ended Dec. 31, 2016 | FY ended Dec. 31, 2015 | |

| Overall | 361.2 | 298.5 | 240.9 |

R&D Structure

-The Company has a total of 13 research and development facilities and approximately 1,500 employees working on research and development activities.

R&D Facilities

-As of March 1, 2017, the Company has 13 research and development centers located in the following nine countries along with an additional research and development center under construction in Asia:

- Spain

- Germany

- France

- U.K.

- Sweden

- U.S.

- Brazil

- China

- Japan

R&D Activities

-The Company’s research and development efforts for body-in-white products primarily involve collaboration with OEMs to improve vehicle characteristics such as passive safety, NVH, architecture, crash performance, deformation monitoring and energy absorption.

-In the Chassis business unit, the Company focuses its research and development efforts on improving qualities such as stiffness, strength, durability, and crash effects while also considering themes of weight reduction and cost savings.

-In the Company’s Mechanisms business unit, research and development focuses on weight reduction, ease of use and safety.

Product Development

Products shown at IZB trade fair

-The Company displayed a variety of products and technologies at the IZB suppliers’ trade fair:

- Battery box prototype for electric vehicles: The prototype was developed in collaboration with Volkswagen and consists of modules that support the battery cells. If a cell fails, the design of the box enables the module to be changed in a faster and safer manner, by avoiding contact with the cells. The prototype is also scalable, thus allowing it to be used in a variety of vehicle models.

- Front lower control arm: The control arm features an integrated ball joint. The ball joint is integrated with a plastic overmolding process, which reduces the weight of the component and enables greater precision in the components characteristics. Additionally, the ball joint is directly integrated into the welded assembly, without the use of additional components.

- Aluminum door with electric opening: Edscha presented an aluminum door that utilizes electric opening mechanisms, with hinges that are made from high-strength aluminum.

- Stopped door: Edscha presented a door which combines a doorstop with various sensors to detect objects in the door’s path, and prevents the door from colliding with various obstacles.

- Soft-zone hot stamping technology: The Company has developed a hot stamping process in which different attributes can be integrated into a single part. The method is suited to create lighter structures with controlled deformation in electric vehicles to compensate for increased battery weight.

Patents

-As of December 31, 2016, the Company held more than 960 patents, utility models and applications related to its business and products.

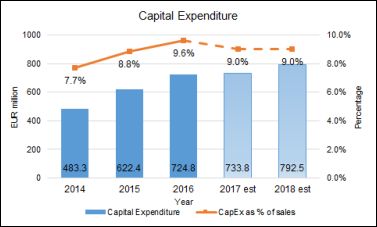

Capital Expenditure |

(in million EUR) |

| FY ended Dec. 31, 2017 | FY ended Dec. 31, 2016 | FY ended Dec. 31, 2015 | FY ended Dec. 31, 2014 | |

| Total | 796.0 | 724.8 | 622.4 | 483.3 |

-A key aspect to the Company’s growth is its capital expenditure, as it is used primarily to construct new manufacturing plants or to increase production capacity in existing plants. The Company expects that its capital expenditure as a percentage of net sales for the fiscal years ending December 31, 2017 and 2018 to be similar to the capital expenditure percentage average from 2013 through 2016. Assuming net sales growth of approximately 8% per year in future years, as well as a capital expenditure totaling 9% of total net sales, the Company’s capital expenditure is estimated to be approximately EUR 800 million in the fiscal year ending December 31, 2018.

-A key aspect to the Company’s growth is its capital expenditure, as it is used primarily to construct new manufacturing plants or to increase production capacity in existing plants. The Company expects that its capital expenditure as a percentage of net sales for the fiscal years ending December 31, 2017 and 2018 to be similar to the capital expenditure percentage average from 2013 through 2016. Assuming net sales growth of approximately 8% per year in future years, as well as a capital expenditure totaling 9% of total net sales, the Company’s capital expenditure is estimated to be approximately EUR 800 million in the fiscal year ending December 31, 2018.

-Most of the Company’s capital expenditures have been dedicated towards increasing the production capacities at various production facilities due to an increase in orders from the Company’s customers.

-The Company invested EUR 1,830.5 in capital expenditures from 2014 through 2016. Of the capital expenditure during the three-year period, approximately EUR 850 million was invested towards growth projects. Of the EUR 850 million, approximately 52% was used for greenfield projects, 31% was used for major plant expansions, and 17% was used for new processes and technologies in existing plants.

-As of March 1, 2017, the Company has ten additional production facilities under construction. In addition, the Company expects to have 13 new manufacturing facilities and 10 plant expansions fully operations by 2019.

Investments outside Spain

-The Company chose to locate a new manufacturing facility in Chelsea, Michigan, U.S. The new facility will contain a chassis assembly line, electronic coat paint line, and a remote laser welding 3-D technology line. The Company will invest USD 68 million into the new plant, which is expected to create 195 new jobs over the next four years. Additional support for the plant came from the Michigan Economic Development Corporation, the Ann Arbor SPARK organization and the City of Chelsea. (From a press release on October 25, 2016)

-The Company plans to build a new manufacturing facility in Four Ashes near Wolverhampton in the UK. The new plant will entail an investment of more than GBP 70 million, with the Company investing GBP 56.3 million for the construction of the new factory. The new West Midlands plant spans 50,000 square meters and is designed to safeguard the 800 jobs at the Company's Cannock plant by progressively relocating production to the facility. The plant is expected to provide improved service to local customers, including BMW, Honda, Jaguar Land Rover, Renault-Nissan and Toyota. Production is scheduled to begin before the end of 2017. Once completed, the annual turnover of the new West Midlands plant will surpass GBP 140 million. Part of the existing facilities in Cannock may be retained to accommodate future training and development requirements. The Company has already invested over GBP 180 million in its UK plants since 2011, including over GBP 30 million in the Cannock facility. (From a press release on September 6, 2016)

-Edscha AG, a subsidiary of the Company, has laid the cornerstone for its new plant in the city of San Luis Potosi, Mexico. The production line is expected to operational as early as December 2016. The first products will be door hinges, door checks, liftgate hinges and hood hinges. Local production of powered systems for the automatic opening and closing of rear lids and liftgates is planned in the future. During the first construction phase, the new Edscha plant will occupy approximately 3,800 square meters. Approximately 60 persons will be employed at Edscha in Mexico by the end of 2016. The plant is scheduled to expand, spanning 10,000 square meters and employing 300 workers in the future. (From a press release on June 22, 2016)

-The Company announced that its subsidiary, Edscha, has opened its fourth plant in Russia in Togliatti. Approximately 50 employees have started assembling and manufacturing door hinges, liftgate hinges and rear door hinges for the Russian market, with an expected total production of 2.5 million hinges in 2016. In the medium term, Edscha plans to employ more than 150 employees in Togliatti. The plant has a production area of approximately 5,000 square meters. An additional 6,000 square meters is available for future expansion. (From a press release on March 10, 2016)

-The Company announced that it opens a new R&D center in Shanghai to strengthen its collaboration with the OEMs based in China. The new R&D building will host more than 40 highly skilled jobs by the end of 2017. The Company has invested EUR 2.5 million in this new facility. This new space, that sizes 2,550 square meters, enhances R&D footprint of the group that includes Edscha, the mechanisms subsidiary that develops its R&D activities in Kunshan. The Company also announced the start of its operations in a new tooling factory located in Kunshan. (From a press release on November 22, 2017)

-The Company announced that it opens a new plant specializing in aluminum in Nitra, Slovakia. The company is investing EUR 133 million into the new opening which will provide service to automotive plants, including the Jaguar Land Rover plant to be launched in the country. Gestamp will undertake this investment until 2021, in turn creating 229 jobs. The new plant will embark on production in 2018 on a surface area covering 42,400 square meters. The components that are manufactured are intended to reduce the weight and enhance the safety of vehicles and will mainly, over 80%, be made from aluminum. (From a press release on January 12, 2017)

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India