Continental AG Business Report FY ended Dec. 2016

Financial Overview |

(in million EUR) |

| FY ended Dec. 31, 2016 | FY ended Dec. 31, 2015 | Rate of change (%) |

Factors | |

| Overall | ||||

| Sales | 40,549.5 | 39,232.0 | 3.4 | 1) |

| EBITDA | 6,057.4 | 6,001.4 | 0.9 | - |

| Chassis & Safety | ||||

| Sales | 8,977.6 | 8,449.7 | 6.2 | 2) |

| EBITDA | 954.6 | 1,160.3 | (17.7) | - |

| Powertrain | ||||

| Sales | 7,319.5 | 7,068.5 | 3.6 | 3) |

| EBITDA | 756.2 | 730.7 | 3.5 | - |

| Interior | ||||

| Sales | 8,324.7 | 8,154.8 | 2.1 | 4) |

| EBITDA | 904.2 | 1,082.2 | (16.4) | - |

| Tires | ||||

| Sales | 10,717.4 | 10,408.8 | 3.0 | 5) |

| EBITDA | 2,828.7 | 2,604.3 | 8.6 | - |

| ContiTech | ||||

| Sales | 5,462.5 | 5,367.8 | 1.8 | 6) |

| EBITDA | 730.9 | 577.2 | 26.6 | - |

Factors

1) Net Sales

-The Company’s net sales for the fiscal year ended December 31, 2016 increased by 3.4% over the previous year to EUR 40,549.5 million. Excluding changes in the Company’s scope of consolidation or currency exchange effects, sales increased 4.7% over the previous year. While changes in the scope of consolidation increased sales, negative currency exchange effects offset those gains. The growth in sales was primarily due to increased production of passenger cars, station wagons and light commercial vehicles combined with a vehicle mix that shifted favorably towards the Company. Within the Automotive division, Asia and China specifically exhibited significant growth.

2) Chassis & Safety sales

-The Chassis & Safety division had sales of EUR 8,977.6 million in the fiscal year ended December 31, 2016, an increase of 6.2% from the previous year. Contributions to the increase in sales came from improved sales of electronic brake systems, brake boosters, and airbag control units. Sales for brake calipers integrated in electric parking brakes increased by 48% over the previous year, while sales of advanced drive assistance systems increased by 36%.

3) Powertrain sales

-Sales for the Company’s Powertrain division increased by 3.6% to EUR 7,319.5 million during the fiscal year ended December 31, 2016. Product lines in the Powertrain division with increased sales include engine control units, injectors, pumps, turbochargers and exhaust gas sensors. Sales of battery systems increased slightly, while sales for power electronics and on-board power supply systems decreased from the previous year. In terms of business units, both the Transmission and Fuel & Exhaust Management business unit had increased sales during the fiscal year.

4) Interior sales

-In the fiscal year ended December 31, 2016, the Interior division had sales of EUR 8,324.7 million, an increase of 2.1% over the previous year. The division experienced sales decreases in its Infotainment & Connectivity business unit as well as its Commercial Vehicles & Aftermarket business unit due to discontinued products and weaker markets. In contrast, sales of the Body & Security business unit and Instrumentation & Driver HMI business unit increased.

5) Tires sales

-The Company’s Tire division’s sales in the fiscal year ended December 31, 2016 were EUR 10,717.4 million, an increase of 3.0% from the previous year. Sales of both original equipment and replacement tires increased for passenger vehicles and light trucks, while sales for commercial vehicle tires increased by approximately 4.0% from the previous year. The fiscal year ended December 31, 2016 was the first time that the Tire division sold more than 150 million tires in a single year.

6) ContiTech sales

-Sales for the ContiTech division increased by 1.8% over the previous year to total EUR 5,462.5 million in the fiscal year ended December 31, 2016. While sales increased in the areas of automotive original equipment and replacement systems, sales decreased in the division’s industrial business areas, due primarily to weakening conditions in mining and the oil production sectors.

Acquisitions

-Benecke-Kaliko, a subsidiary of the Company, will expand its industrial business further and open up new sales markets, particularly in North America. A corresponding agreement on the purchase of the Hornschuch Group, based in Weissbach, Germany, has been brokered. The Hornschuch Group is one of major manufacturers of design, functional and compact films, foam laminates, and artificial leather for industrial and automotive applications. Hornschuch generated sales of EUR 410 million in the 2015 fiscal year, with more than 1,800 employees working at four production sites in Germany and the U.S. Hornschuch will be integrated into Benecke-Kaliko as part of the ContiTech division. (From a press release on October 15, 2016)

-The Company has acquired a majority stake in Zonar Systems Inc., a company specializing in fleet management solutions. With a total of 330 employees, Zonar provides solutions for managing private and public commercial vehicle fleets in the North American market. The purchasing contract gives the Company a stake in Zonar amounting to approximately 81% of the total shares. Daimler AG retains its existing share, which amounts to more than 19%. The share acquisition is expected to be completed in the middle of the fourth quarter of 2016. (From a press release on October 4, 2016)

-The Company announced the acquisition of the Hi-Res 3D Flash LIDAR business from Advanced Scientific Concepts, Inc. (ASC) based in Santa Barbara, California, U.S. This technology will further enhance the Company’s Advanced Driver Assistance Systems product portfolio with another future-oriented solution needed to achieve highly and fully automated driving. One advantage of Hi-Res 3D Flash LIDAR sensor technology is that it provides both real-time machine vision and environmental mapping functions. This technology will help provide a significantly more detailed and accurate field of vision around the entire vehicle, independent of time of day and adverse weather conditions. With the acquisition, ASC employees will join the Chassis & Safety Division of Continental as a business segment within the ADAS Business Unit based in Santa Barbara, California. Over the long term, the company is planning to have over 100 engineers in this segment. (From a press release on March 3, 2016)

Restructuring

-The Company and Yokohama Rubber Co., Ltd. announced that they have agreed to dissolve their Japanese joint venture, Yokohama Continental Tire Co., Ltd. (YCC), by the end of March 2016. YCC was established in 2002 to help Japanese and Korean automakers procure tires on a global basis. For 14 years, the Company and Yokohama Rubber have been expanding their global production networks and have made solid progress. Both companies will now individually focus on further expanding their businesses. (From a press release on March 8, 2016)

Recent Developments

-The Company is favoring the location near the Pferdeturm in Hanover as the site for its future headquarters. The Company has now officially entered concrete, detailed negotiations about this with the city of Hanover. The focus here is on the possible acquisition of two areas north and south of Hans-Bockler-Allee. The plots have a combined surface area of around 37,600 square meters. Both parties hope to conclude the negotiations by the end of the year. The transfer of ownership is planned for the first quarter of 2017, and the move to the new headquarters is to be completed in 2020. The company is expecting its capital expenditure for the complete project to reach into the high double-digit million euro range. (From a press release on June 14, 2016)

Business Partnership

-The Company has entered into a strategic partnership with DigiLens Inc., a Silicon Valley-based company specializing in holographic optical waveguide technology and materials. Together, the two companies have developed ultra-thin Augmented Reality (AR) Head-up Displays (HUD) that will increase market penetration in cars across multiple segments. The ultra-thin holographic HUD will be a third as large as currently available systems and will ease drivers into accepting automated driving faster. The AR HUD will be displayed for the first time at CES 2017. (From a press release on December 16, 2016)

-Switzerland-based telematics provider LOSTnFOUND is integrating the Company’s tire pressure monitoring system ContiPressureCheck into its existing telematics system. As part of the collaboration between the two companies, the tire pressure and temperature data collected in real time by ContiPressureCheck is shown on the LOSTnFOUND user interface. Thanks to the telematics system's network connection, the data can be received on mobile devices. (From a press release on March 23, 2016)

Contracts

-The Company announced that it is supplying the new “PSA Connect” infotainment system to the Peugeot, Citroen, and DS brands. The system, which offers online services and broad smartphone integration solutions, uses a Linux open-source operating system and complies with the GENIVI software standard. (From a press release on November 28, 2016)

-The Company announced that it supplies its Multifunctional Smart Device Terminal (MFST) for the Mercedes-Benz E-Class. The MFST enables any device placed in the compartment in the center console to be charged inductively. It also offers automatic wireless Bluetooth pairing of the phone along with support from the vehicle’s external antenna and the vehicle’s head unit. These functions can be enabled through the system’s Near Field Communication (NFC) function. In addition, NFC technology allows the smartphone to be used as a digital vehicle key for secure authentication. (From a press release on November 22, 2016)

-The Company announced that it is supplying its 48-volt hybrid drive system to one diesel variant of the new Renault Scenic and Grand Scenic models by the end of 2016. The system, offered as a "Hybrid Assist", is the first use of a 48-volt hybrid drive in a production vehicle. (From a press release on October 21, 2016)

-The Company announced that it has restarted its cooperation with Borgward, which returned to the automotive market after a hiatus in March 2015. The Company developed a 4.2" color TFT cluster for the new BX7, launched in April 2016. The high-resolution cluster provides high contrast ratios and a wide angle of view, and is connected with various audio/video entertainment modules in the BX7. (From a press release on August 4, 2016)

-The Company announced that VDO has expanded its range of multibrand tire pressure monitoring sensors with a fifth REDI-Sensor that can be installed in new Hyundai, Ford, BMW and Mercedes-Benz models. The sensor has also been designed to cover future BMW and Mercedes-Benz model changes. The sensor is an ideal TPMS solution for models including the Tucson and i20 from Hyundai, the new Ford Galaxy and S-Max models, the current BMW 7 Series and the Mercedes Benz E-Class. (From a press release on July 27, 2016)

-The Company supplies Alfa Romeo with its MK C1 brake system for the Integrated Brake System (IBS) of the new Giulia, the first model worldwide with a series-produced MK C1. With the MK C1, the brake actuation feature, brake booster and control systems (ABS and ESC) are combined into a compact, weight-saving braking module. The system weighs up to three to four kilograms less than a conventional braking system. (From a press release on June 22, 2016)

-The first Company turbocharger with RAAX turbine technology is used on the Audi A3’s new 2.0-liter turbocharged gasoline engine. The technology results in up to 3% greater efficiency in the engine-relevant operating range. (From a press release on June 20, 2016)

-The Company supplies its Advanced Radar Sensor ARS 410 as original equipment for the new Volkswagen Tiguan. This new radar differentiates between static and moving objects and detect objects and pedestrians at a distance of up to 170 meters. One major advantage of the ARS 410 is its robustness in adverse weather conditions such as fog, drizzle, or glare from the sun. The system can initiate automatic braking in an emergency. (From a press release on June 15, 2016)

-The lightweight transmission adapter featuring the Ultramid polyamide from BASF, is being used for the first time in new Mercedes-Benz E-Class models. It is a central component of the bearing in the 9G-TRONIC transmission and is planned for future use in the Mercedes-Benz C- and S-Class. (From a press release on April 4, 2016)

-The Company announced that MAN and a major European truck maker have integrated the Company’s electronic horizon system (eHorizon) into their vehicles in 2015. Several production launches in Europe and North America are being prepared for both the coming year. MAN is offering a system comprising eHorizon and solutions of its own under the name Efficient Cruise. Tests verified by TUV have shown that it achieves fuel savings of more than 6%. The Company estimates that the technology has made it possible to save more than 195 million liters of diesel fuel since 2012, when it first went into series production. This corresponds to more than EUR 260 million and more than 515,000 metric tons of carbon dioxide. In developing the sensor systems, the Company cooperated with the location cloud developer HERE, which supplied mapping data. (From a press release on January 19, 2016)

-The Company announced that seven of the 2016 Ward’s 10 Best Engines feature its powertrain technologies. Below is a list of the technologies included in the award-winning engines:

- BMW 340i 3.0L 6-cylinder: Natural vacuum leak detection (NVLD), canister purge gauge pressure sensor, electronic throttle control (ETC)

- Chevrolet Camaro/Cadillac ATS 3.6L V-6: direct injection engine control unit, coolant temperature sensor, oil level switch, and voltage stabilization system (Cadillac ATS)

- Chevrolet Volt EREV 1.5L 4-cylinder: coolant temperature sensor, knock sensor, exhaust gas recirculation actuator, and fuel delivery module

- Ford Shelby GT350 Mustang 5.2L V-8: engine control unit, knock sensor, and temperature manifold absolute pressure sensor

- Hyundai Sonata PHEV 2.0L 4-cylinder: direct injection powertrain control unit, gasoline direct-injection XL3.1 200bar solenoid injector, coolant temperature sensor, and natural vacuum leak detection (NVLD) sensor

- Nissan Maxima 3.5L V-6: knock sensor

- Volvo XC90 2.0L Turbo/Supercharged 4-cylinder: oil level switch, fuel delivery module, and close coupled substrate catalytic converter

(From a press release on January 14, 2016)

Awards

-The Company announced that a vehicle using its new AdBlue dosing system was the winner of both laboratory and real driving emission tests of 36 diesel models by Deutsche Umwelthilfe, a non-profit environmental and consumer protection organization. The four-cylinder diesel engine of the test winner uses SCR technology, in which an injector adds the AdBlue urea to the exhaust pipe to trigger a chemical process in the catalytic converter. The result is a significant reduction in nitrogen oxide emissions. The main components of the AdBlue system are the injector, a tank flange module which includes the pump, and a dedicated electronic control unit. This electronic control unit controls the injector, regulates the pump pressure, and diagnoses the fill level of the AdBlue tank. A sensor on the tank flange module measures the urea concentration of the fluid. The SCR system is placed directly on the engine where the water-cooled AdBlue injection valve is located. To prevent the urea solution from freezing, the Company offers a heatable line for the tank flange module and the injector. (From a press release on December 8, 2016)

-The Company received the 2016 Volkswagen Group Award as one of Volkswagen Group’s best suppliers. (From a press release on June 2, 2016)

-The Company announced that Toyota Motor Corporation presented it with the Annual Technology & Development Award in recognition of its development contribution towards Toyota's active safety package "Toyota Safety Sense C." The Company received the award for the development of the Multi-Function Camera with Lidar (MFL) which integrates a camera and an infrared Lidar (Light Detection and Ranging Sensor) into a single compact unit. (From a press release on May 20, 2016)

-The Company received an Award of Excellence from Toyota Motor Corporation for its anti-lock brakes. (From a press release on March 16, 2016)

Outlook

-The Company expects that its consolidated sales will total more than EUR 43 billion in the fiscal year ending December 31, 2017. Of the EUR 43 billion in expected sales, the Company’s Automotive Group will comprise approximately EUR 26 billion while the Rubber Group will generate more than EUR 17 billion.

R&D Expenditure by Divisions |

(in million EUR) |

| FY ended Dec. 31, 2016 | FY ended Dec. 31, 2015 | FY ended Dec. 31, 2014 | |

| Chassis & Safety | 773.4 | 691.2 | 629.5 |

| Powertrain | 701.5 | 708.7 | 635.1 |

| Interior | 956.0 | 697.3 | 570.9 |

| Tires | 260.9 | 244.9 | 216.9 |

| ContiTech | 119.7 | 107.5 | 85.3 |

| Total | 2,811.5 | 2,449.6 | 2,137.7 |

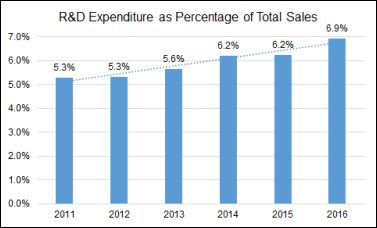

-In recent years, the Company has invested more than 6% of its sales in research and development each year.

-In recent years, the Company has invested more than 6% of its sales in research and development each year.

-The Company has increased the percentage of its total sales invested into research and development due to its increased focus on business areas such as electrification, automated driving, and connectivity.

R&D Structure

-As of December 31, 2016, the Company has 146 locations in which research and development takes place.

-Frank Jourdan, a member of the Company’s Executive Board, Chassis & Safety Division, gave an interview to Nikkan Jidosha Shimbun. In the interview, Jourdan said the Company will increase its software development engineer headcount. The Company currently has 13,000 software engineers worldwide, but needs more to accelerate technological development for Advanced Driving Assistant Systems (ADASs) and autonomous driving. In order to maintain its position as a leader in the fields of ADAS and autonomous driving, the Company will hire skilled employees by strengthening its collaboration with universities. (From an article in the Nikkan Jidosha Shimbun on November 28, 2016)

R&D Facilities

-On August 8, 2016, the Company’s new office in Shangpu Center, Yangpu District, Shanghai was inaugurated. The new office is a four-story building that covers approximately 8,000 square meters and includes meeting rooms and testing laboratories to accommodate approximately 730 employees in total. The Company's Tire Division has already relocated to the new building. This will be followed by the relocation of the Hybrid and Electric Vehicle Components Division under the Powertrain business in the third quarter of 2016, and that of the Intelligent Traffic System Division under the Body and Electronic business in the fourth quarter. The Company's China headquarters on Dalian Road, Yangpu District, Shanghai will continue to serve as the main office for China operations. (From news releases issued by multiple sources on August 9, 2016)

-The Company announced that its test center in Yancheng, Jiangsu Province, China has officially opened. In cooperation with the China Automotive Technology & Research Center (CATARC), the test center will support the testing and validation of safety products and systems, such as electronic and hydraulic brake systems, advanced driver assistance systems (ADAS) and tires. The Test Center Yancheng occupies 2,500 square meters in phase one of its development. (From a press release on July 11, 2016)

-The Company announced that it will establish an R&D center in Chongqing, China to develop new products and solutions in the areas of in-vehicle electronics, new energy vehicles, and industrial products. The center will begin operations at the beginning of 2018, and is expected to employ 400 engineers by 2020. (From news releases issued by multiple sources on June 30, 2016)

Technological Alliance

-In November, the Company announced that it commenced a research partnership with Oxford University in artificial intelligence. The Company expects the partnership to yield findings on the use of artificial intelligence methods, focusing on the areas of automated and autonomous driving, future vehicle access systems, accident minimization through intelligent warning systems, and future interactions between drivers and vehicles. The partnership is initially planned for a three-year period, though the research scope and time frame may be extended in the future. (From a press release on November 11, 2016)

-The Company’s Chinese regional subsidiary, Continental Group (China), and China Automotive Technology & Research Center (CATARC) announced that they have signed an agreement to closely collaborate in areas including automotive security, environmental protection, and energy saving systems. (From news releases issued by multiple sources on January 12, 2016)

Product Development

Biometric access system

-The Company announced that it will demonstrate an access system using biometrics at the Consumer Electronics Show 2017 in Las Vegas. The Company will combine the PASE (Passive Start and Entry) keyless entry and start system with biometric elements for authentication and vehicle personalization purposes. A two-fold authentication process whereby the driver provides a fingerprint and the vehicle key can significantly increase the vehicle's anti-theft measures. A camera system can recognizes the driver's face and then allow the access system to automatically personalize vehicle settings, such as seat and mirror position, music, temperature, and navigation. The Company's Intelligent Glass can also be integrated, enabling the vehicle’s windows to gradually darken and lighten automatically as the driver approaches. (From a press release on December 15, 2016)

UltraContact UC6 and ComfortContact CC6 tires

-The Company released the UltraContact UC6 and ComfortContact CC6 tires for Asia Pacific markets. The two tires will be released in Japan on a date yet to be determined. The UltraContact UC6 has been developed to provide increased grip, reduced braking distances in all road conditions and low noise levels. It is available for rims with diameters between 15 and 19 inches. The ComfortContact CC6 prioritizes comfort and is available for rims with diameters between 14 and 18 inches. (From an article in the Nikkan Jidosha Shimbun on October 25, 2016)

48-volt hybrid drive system

-The Company’s 48-volt hybrid drive system is featured in the Renault Scenic and Grand Scenic. Company engineers have been working with Renault since 2013 on a hybrid drive which is cost-efficient to produce. The ready-to-install 48-volt drive is manufactured at the Company’s plant in Nuremberg, which specializes in complex electronic modules. The hybrid drive uses an electric motor with a continuous output of 6 kW to power the crankshaft. The electric motor, operated as a generator, converts a large proportion of braking energy into electricity, which is temporarily stored in a small battery. This electricity can then be used to relieve the internal combustion engine. Benefits to the hybrid drive system include a reduction of NOx emissions and exhaust particles. Furthermore, the system is similar in size to a conventional starter generator, thus enabling it to be easily combined with preexisting internal combustion engines. The electric motor can also be placed between the engine and transmission, allowing purely electric driving in inner city areas. (From a press release on October 21, 2016)

Emission-reduction solutions for China

-The Company will offer two new emission-reduction solutions to the Chinese market. The new products achieve improved control over evaporative emissions and meet the China VI standards. One of the modules is a leak detection system that can eliminate unnoticed fuel evaporation. The other module is an Active Purge Pump (APP) which flushes accumulated volatile organic compounds that are contained in a storage canister during re-fueling. Since the purging action is independent of the engine vacuum, the capability is available under nearly all engine operating conditions. (From a press release on October 11, 2016)

eTIS tire load and tread depth measuring function

-The Company announced that it has developed a new "eTIS" function that measures tire loads and tread depths for its tire pressure monitoring systems (TPMS). The eTIS function estimates tire loads and tread depths from ground contact area size and tire rolling movement. The Company will start mass production of new TPMS as original equipment in 2018 to 2019. The Company's current TPMS measures the pressure and temperature of tires. With the additional monitoring functions, eTIS can warn drivers of overloading and the need to replace tires in a timely manner by automatically measuring tread depths. The data can then be sent to tire distributors through vehicle telematics or other systems. (From an article in the Nikkan Jidosha Shimbun on October 4, 2016)

HMI system utilizing LED lights

-The Company plans to put a human machine interface (HMI) system using LED lights into practical application by 2020. The system arranges LED lights around the dashboard to communicate information to the driver such as indicating a switch from human operation to autonomous driving mode in cases like level 3 autonomous driving. In combination with an in-vehicle camera, the system is also capable of prompting inattentive drivers to focus on the road. It was developed for use in autonomous vehicles where drivers are required to switch between manual and autonomous driving modes. The Company will offer this system together with its interior camera, which detects the direction of a driver's eyes and how they open and close them. The camera uses infrared rays to monitor the driver and is expected to be put into practical use by 2018. (From an article in the Nikkan Jidosha Shimbun on September 28, 2016)

Long-range radar for commercial vehicles

-The Company has developed a new long-range radar system for commercial vehicles. The high-resolution long-range radar (Advanced Radar Sensor) distinguishes between static and moving objects. With a sensor range of up to 250 meters and a wide field of view, it can warn the driver about dangerous situations and enable automatic braking if necessary. The radar can detect pedestrians who are partially obscured by a vehicle and detect objects in poor visibility due to fog, drizzle or dazzling sunlight. (From a press release on September 5, 2016)

Steering-wheel based gesture detection system

-The Company announced that it has unveiled an innovation project that focuses on the detection of gestures on the steering wheel. This is possible due to a time-of-flight sensor integrated into the instrument cluster. Previous gesture-based control systems in the area of the center console forced drivers to take their hands off the steering wheel or take their eyes off the road. With gestures in a clearly defined area on the steering wheel, the new system can minimize distraction and improve safety. It uses two transparent plastic panels without any electronic components behind the steering wheel, which a driver can operate with his or her thumbs, similar to a touchpad. The system can currently detect four different gestures: setting navigation, browsing through apps and starting music, answering calls, and controlling the on-board computer. (From a press release on May 10, 2016)

Lightweight transmission adapter

-ContiTech, a subsidiary of the Company has now launched a new transmission adapter for cars. The transmission adapter uses the glass-fiber-reinforced polyamide, Ultramid by BASF, making the component 55% lighter than the aluminum version previously used. (From a press release on April 4, 2016)

Software Defined Radio platform

-The Company has developed a progressive vehicle radio platform, the Software Defined Radio (SDR), which allows control of numerous individual functions on one processor, ultimately reducing hardware to a minimum. The main approach behind the radio platform is to replace cost intensive hardware with software wherever possible. To achieve this reduction the radio platform is built on a highly optimized system on chip (SoC). It has a multi-core processor that manages all human machine interface, connectivity and audio-post processing related functions, as well as an integrated vehicle controller and a digital signal processor (DSP) that enables the core radio technology of the new SDR platform. (From a press release on February 12, 2016)

Urea sensors

-The Company announced that it has started producing urea sensors for more efficient exhaust gas aftertreatment in diesel engines. This sensor will help further optimize selective catalytic reduction (SCR). The urea sensor can measure quality, level and temperature of the urea solution in the tank. Several vehicle manufacturers intend to install the sensor in their vehicles. (From a press release on February 4, 2016)

Capital Expenditure |

(in million EUR) |

| FY ended Dec. 31, 2016 | FY ended Dec. 31, 2015 | FY ended Dec. 31, 2014 | |

| Chassis & Safety | 523.7 | 470.3 | 411.6 |

| Powertrain | 544.4 | 468.4 | 428.0 |

| Interior | 428.9 | 336.0 | 286.1 |

| Tires | 882.1 | 658.2 | 724.3 |

| ContiTech | 212.0 | 245.2 | 190.6 |

| Other/Consolidation | 1.9 | 0.7 | 4.8 |

| Total | 2,593.0 | 2,178.8 | 2,045.4 |

Investments in Germany

-The Company announced the start of production for the world's first hybrid drives that run on 48-volts at its plant in Nuremberg, Germany. While the Company currently is electrifying one diesel variant of both the new Renault Scenic and Grand Scenic models, the hybrid assist system used is a modular design that facilitates applications for other OEMs. The Company invested EUR 15 million in production equipment for the plant, which will yield an annual production capacity of 200,000 48-volt drive systems. The production facility for the 48-volt drives is divided into three lines. The rectifier is produced on the first line, the stator is manufactured on a second line, and final assembly is completed on a third line. (From a press release on December 15, 2016)

Investments outside Germany

-The Company announced that it inaugurated an electronic braking system manufacturing facility for four-wheelers at its Manesar Plant in India. This line produces a combined 600,000 ABS and ESC units a year for passenger cars. The Company is planning to increase production by 1.2 million units in the next fiscal year. The Company also plans to manufacture ABS for two-wheelers in the existing Brake Systems plant in Manesar. In 2018, the Bangalore plant will begin production of ECUs. (based on interview with Continental representatives)

-The Company announced that its Chassis & Safety Division will start the production of Anti-lock Brake Systems (ABS) and Electronic Stability Control (ESC) units in India in 2016. A new assembly line for passenger car ABS and ESC units will be located in the existing Automotive Brake Systems plant in Gurgaon, Haryana. A production line for ABS for two-wheeled vehicles will be added in the future. Production of ECUs in Bangalore are planned to begin in 2018. (From a press release on January 21, 2016)

-Mississippi Governor Phil Bryant and executives from the Company’s subsidiary, Continental Tire the Americas, LLC, broke ground at the site of its future commercial vehicle tire manufacturing plant near Clinton, Mississippi. The project, announced in February, represents a USD 1.45 billion corporate investment and will create 2,500 jobs. Construction of the multi-million-square-foot plant is scheduled to begin in January 2018. On February 4, the Mississippi Legislature approved a USD 263 million grant for the project. (From a press release on November 4, 2016)

-The Company has selected a site near the city of Clinton, Mississippi for a new plant to drive the future growth of its tire business in the North American market. Continental Tire the Americas, LLC (CTA) has reached an agreement with the state of Mississippi to purchase a site for the construction of a commercial vehicle tire plant. The Company has committed a long-term investment totaling approximately USD 1.4 billion and will employ 2,500 people when the plant reaches full capacity in the next decade. The Company will begin site development in 2016 and expects to start construction of the plant in 2018. The production of commercial vehicle tires is planned to begin by the end of 2019. The site is more than 400 hectares in size. (From a press release on February 9, 2016)

-The Company is expanding the presence of its advanced driver assistance systems business unit in Asia. To meet the growing demand of Asian vehicle manufacturers for surrounding sensors, production of short-range radar sensors launched in Calamba, Philippines towards the end of 2015. Additionally, production of the Multi Function Cameras with Lidar will begin in Calamba in Fall 2016. The plan is to produce over ten million short range radar sensors and one million camera systems in Calamba in the future. In Shanghai, China, the production of long-range radar sensors for various customers is planned to begin in 2018. The goal is to produce several million sensors annually. (From a press release on August 29, 2016)

-ContiTech AG, a subsidiary of the Company, announced that it has signed a memorandum of understanding on a new plant in Qingdao, Shandong Province, China, mainly for automotive hoses. The company plans to invest more than EUR 20 million (approximately RMB 200 million) in the first construction phase to set up a greenfield with an initial floor space of approximately 15,000 square meters. In the next few years, existing production of heating and cooling hose lines will be moved to the new location, which has a projected annual output of about 15 million low pressure pipes in its first full-capacity phase. Depending on market development, ContiTech intends to expand the new plant further within a five-year timeframe. Construction of the first phase is expected to be complete by 2020. Currently, ContiTech produces and sells rubber hoses and hose assemblies for the automotive industry, with more than 500 employees in downtown Qingdao, mainly for domestic car manufacturers in China and in the Asian Pacific region. (From a press release on July 19, 2016)

-Trutnov in the Czech Republic is the Company’s sole manufacturing site for its first turbocharger with RAAX turbine technology. However, a further facility is already under construction in China. In 2017, this plant will manufacture turbochargers for a number of volume production projects. Another facility is also under construction in North America. Production orders are already lined up for this new plant, which is due to open in 2018. (From a press release on June 20, 2016)

-Benecke-Kaliko, a subsidiary of the Company, officially opened a new plant in Changzhou, Jiangsu Province, China to manufacture Acella Eco and Acella Eco green interior materials. Series production began since the end of 2015 with a workforce of approximately 100 employees. The plant will add 50 more jobs over the next few months. The company has invested EUR 40 million in the first phase of the expansion. The new plant operated by Benecke Changshun Eco Trim (Changzhou) Co., Ltd. will produce around 10 million square meters of the surface material Acella Eco annually. It is mainly used for vehicle seats and arm rests. The new plant has doubled the company’s production capacity for Acella in China. A second expansion phase for the new facility is planned if demand continues to rise. (From a press release on March 10, 2016)

-ContiTech Fluid Ltd., a Company subsidiary, announced that it will construct a plant in Cheonan City, Chungcheongnam-Do, Korea to produce automotive air conditioning hoses. The company will invest USD 19 million in this plant by 2020, which will be built on 53,762 square meters of land. (From a press release on March 9, 2016)

Future Investments

-The following is a planned list of projects that the Company expects to invest in during the fiscal year ending December 31, 2017:

- Global expansion of production capacity for MK 100 and MK C1 brake generations in the Vehicle Dynamics business unit

- Global expansion of production capacity for long-range and short-range radar sensors, and multi-function cameras in the Advanced Driver Assistance Systems business unit

- Increased production capacity for fully integrated transmission control systems at facility in Sibiu, Romania within the Transmission business unit

- Global expansion of production capacity for gasoline high-pressure injectors and gasoline high-pressure pumps in the Engine Systems business unit.

- Increased production capacity for gasoline turbochargers at locations in China and North America

- Increased development of 48-Volt Eco Drive projects in China, Germany and North America for the Hybrid Electric Vehicle business unit

- Increased production capacity for central displays in Germany and North America

- Increased production capacity of passenger tires in Eastern Europe, China and North America

- Increased production capacity of commercial vehicle tires in North America

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India