Archives of Past Exhibits:TPR

Tokyo Motor Show 2015

2015 JSAE Automotive Engineering Exposition

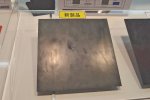

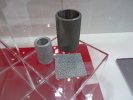

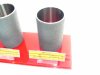

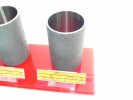

Cylinder liners

-Cast cylinder liners are widely used on Toyota vehicles and also adopted by Volkswagen.

-Cast cylinder liners are widely used on Toyota vehicles and also adopted by Volkswagen.

2014 JSAE Automotive Engineering Exposition

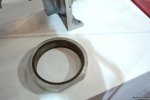

-The Company's global market share of cylinder liner is approximately 30%. -Spiny outer surface of the cylinder liner offers high adhesion properties to aluminum products. -The Company has cut down on the height of the projections to 0.5mm from the previous products’ 0.7mm in order to reduce wall thickness, while increasing the number of spines to improve heat conductivity. -Cast cylinder liners are widely used on Toyota vehicles and also adopted by Volkswagen.

-The Company's global market share of cylinder liner is approximately 30%. -Spiny outer surface of the cylinder liner offers high adhesion properties to aluminum products. -The Company has cut down on the height of the projections to 0.5mm from the previous products’ 0.7mm in order to reduce wall thickness, while increasing the number of spines to improve heat conductivity. -Cast cylinder liners are widely used on Toyota vehicles and also adopted by Volkswagen.

Tokyo Motor Show 2013

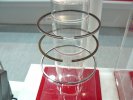

-Used on Mitsubishi Motors’ 3B20 660cc engine -Manufactured at Nagano Plant -New spacer design improves oil lubrication and prevents deposits

-Used on Mitsubishi Motors’ 3B20 660cc engine -Manufactured at Nagano Plant -New spacer design improves oil lubrication and prevents deposits

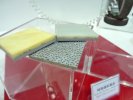

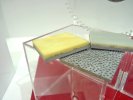

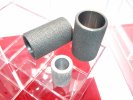

Cylinder liner - New ALH150 (Spiny outer surface)

-Centrifugal casting method creates spiny outer surface with mushroom-shaped projections. Achieves high adhesion properties with aluminum, excellent heat-transfer performances and weight savings -Height of the surface projections are reduced than existing AL13 cylinder liners to increase heat-transfer efficiency

-Centrifugal casting method creates spiny outer surface with mushroom-shaped projections. Achieves high adhesion properties with aluminum, excellent heat-transfer performances and weight savings -Height of the surface projections are reduced than existing AL13 cylinder liners to increase heat-transfer efficiency

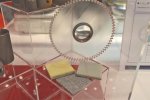

-Centrifugal casting method to create special spiny surface is applied to the inner side of the brake drum: 35 percent reduction in weight

-Centrifugal casting method to create special spiny surface is applied to the inner side of the brake drum: 35 percent reduction in weight

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India