Beki-Shield BU11/7000 (Metal fiber roving of conductive plastic filler)

-Countermeasure to electromagnetic ray and static electricity of plastic material -Number 1 global market share of Metal fiber roving

-Countermeasure to electromagnetic ray and static electricity of plastic material -Number 1 global market share of Metal fiber roving

Beki-Shield GR75 (Metal fiber master batch of conductive plastic filler)

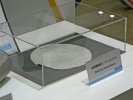

Beki-Shield (Metal Fiber Mixed Polycarbonate Plate Sample)

Gasoline Particulate Filter - Beki-Pole

-Proto type

-Proto type

Metal Fiber Heater Element (1)

Metal Fiber Heater Element (2)

Sample plate of metal fiber-concluding plastic

Molded sample of metal fiber-concluding plastic (reference exhibit)

DPF (reference exhibit)

Various applications of deformed wire for automobile

Various applications of spring steel wire for automobile

Beki-shield BU

Beki-shield GR

Zinc aluminum alloy plated wires :Bezinal(R)

--Zinc alloy wire materials include 5% aluminum

<Characteristics compared with conventional zinc plated steel wires>

-Excellent corrosion resistance

-Corrosion resistance is maintained at welding spots:

Even at temperatures exceeding 1,000 degrees Celsius. corrosion resistance attribute in the area affected by welding heat is maintained, because the steel, zinc and aluminum surface is kept intact.

-Protection of the cutting surface is improved: Sufficient sacrificial corrosion resistance function is certified.

-Molding and fabrication are improved: The product can withstand big bending due to ductility of the steel, zinc and aluminum surface.

-There is no plating peel-off even the product is heated up to 350 degrees Celsius.

<Applications for automobiles>

-Wiper blades, wiper springs, flat wiper arms and so on.

Polymer coated zinc aluminum alloy plated wires : Bezalplast(R)

-Bezalplast(R) steel wires are composed of three layers; PET (Ultra thin Polyethylene terephthalate), Bezinal (R) (High corrosion resistant zinc and aluminum alloy) and steel.

<Features>

-High corrosion resistance :Even in case of trouble with the PET coating, Bezinal (R) protects wires and contain progress of corrosion.

-Expenses and time of treatment (anti-corrosion or coloring processes), which may be required following wire processing can be reduced.

-The PET coating reduces noise and contains friction.

AI Navigator

AI Navigator

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India