Continental AG Business Report FY ended Dec. 2019

Financial Overview |

(in million EUR) |

| FY ended Dec. 31, 2019 | FY ended Dec. 31, 2018 | Rate of change (%) |

Factors | |

| Overall | ||||

| Sales | 44,478.4 | 44,404.4 | 0.2 | 1) |

| EBITDA | 4,977.2 | 6,235.7 | (20.2) | - |

| Chassis & Safety | ||||

| Sales | 9,381.6 | 9,588.0 | (2.2) | 2) |

| EBITDA | 1,145.3 | 1,213.3 | (5.6) | - |

| Powertrain | ||||

| Sales | 7,802.3 | 7,741.0 | 0.8 | 3) |

| EBITDA | 192.5 | 574.6 | (66.5) | - |

| Interior | ||||

| Sales | 9,595.5 | 9,707.2 | (1.2) | 4) |

| EBITDA | 582.4 | 1,389.2 | (58.1) | - |

| Tires | ||||

| Sales | 11,728.0 | 11,352.2 | 3.3 | 5) |

| EBITDA | 2,497.7 | 2,495.2 | 0.1 | - |

| ContiTech | ||||

| Sales | 6,401.5 | 6,344.7 | 0.9 | 6) |

| EBITDA | 670.5 | 701.4 | (4.4) | - |

Factors

1) Net Sales

-The Company’s net sales for the fiscal year ended December 31, 2019 increased by 0.2% over the previous year to EUR 44,478.4 million. Excluding changes in the Company’s scope of consolidation or currency exchange effects, sales decreased by 2.6% from the previous year. A slight increase in sales from the Company’s Rubber Group was almost entirely offset by the decline in sales of the Automotive Group. Changes in the Company’s scope of consolidation as well as currency exchange effects also increased sales.

2) Chassis & Safety sales

-The Chassis & Safety division had sales of EUR 9,381.6 million in the fiscal year ended December 31, 2019, a decrease of 2.2% from the previous year. Excluding changes in consolidation scope and exchange rate effects, the division’s sales declined by 4.2% compared to the previous year. The decrease in sales was driven by significantly decreased sales volumes of electronic brake systems, brake boosters and conventional brake calipers. Increased sales of brake calipers with integrated electric parking brakes slightly offset the previous losses. In the Passive Safety & Sensorics business unit, sales volumes of air-bag control unit decreased, while volumes of advanced driver assistance systems increased significantly.

3) Powertrain sales

-Sales for the Company’s Powertrain division increased by 0.8% to EUR 7,802.3 million during the fiscal year ended December 31, 2019. Ignoring changes in consolidation scope and exchange rate effects, the division’s sales decreased by 2.5% compared to the previous year. In the Engine & Drivetrain Systems business unit, sales volumes of engine control units and turbochargers increased, while sales volumes of pumps remained level and sales volumes of injectors and transmission control units declined. Sales of power electronics and 48-volt drive systems in the Hybrid Electric Vehicle business unit increased, while power stabilization products and battery system sales decreased. In the Powertrain Components business unit, exhaust gas sensors and SCR system sales increased while fuel delivery modules, mechatronic sensors for combustion engines and catalytic converter sales all decreased.

4) Interior sales

-In the fiscal year ended December 31, 2019, the Interior division had sales of EUR 9,595.5 million, a decreased of 1.2% from the previous year. Excluding the effects of consolidation scope changes and currency translation, sales in the division decreased by 2.5%. Sales volumes in the Body & Security business unit increased slightly over the previous year due to the integration of the Intelligent Antenna Systems business area. Similarly, sales in the Infotainment & Connectivity business unit grew substantially due to increases in the connectivity business. Sales volumes in the Commercial Vehicles & Aftermarket business unit declined despite growth in the commercial vehicles business due to a slight restructuring of the aftermarket and replacement parts business. Sales of the Instrumentation & Driver HMI business unit declined due to weakness in the Chinese market.

5) Tires sales

-The Company’s Tire division’s sales in the fiscal year ended December 31, 2019 were EUR 11,728.0 million, an increase of 3.3% from the previous year. Before changes in consolidation scope and currency translation effects, the division’s sales decreased by 0.2%. Sales volumes for passenger and light truck tires declined by 5% in the original equipment business and remained approximately level for the replacement tire business. In the commercial vehicle tire business, sales declined slightly during the fiscal year.

6) ContiTech sales

-Sales for the ContiTech division increased by 0.9% over the previous year to total EUR 6,401.5 million in the fiscal year ended December 31, 2019. Excluding changes in consolidation scope and currency exchange rate effects, sales in the division decreased by 3.4% from the previous year. Sales related to the automotive market declined compared to the previous year while industrial business sales increased slightly over the previous year.

Acquisitions

Acquisition of Cooper Standard's Anti-Vibration Systems business (listed in chronological order)

-The Company has received unconditional approval from all relevant antitrust authorities for the acquisition of the Anti-Vibration Systems business of Cooper Standard. The Company will close the acquisition of Cooper Standard’s Anti-Vibration Systems business as planned in the first half of the year. The acquisition of the business was agreed on November 1, 2018. Cooper Standard’s Anti-Vibration Systems has five production sites, R&D facilities in Canada, France, India and the U.S. and has a workforce of approximately 1,000 employees. The business brings extensive expertise in vibration control technology and sound insulation and will enhance the Company’s capabilities in these fields. The unit develops global anti-vibration solutions that mitigate noise, vibration and harshness in vehicles and thus improve suspension comfort and handling. (From a press release on March 5, 2019)

-Cooper Standard announced that it has completed the divestiture of its anti-vibration systems (AVS) business to the Company. The total sale price of the transaction was USD 265.5 million, subject to certain adjustments. The divested AVS business has approximately 1,000 employees and offers a comprehensive portfolio of anti-vibration systems, technologies and products to automotive OEMs that mitigate vehicle noise, vibration and harshness, and enhance ride comfort and handling. (From a press release on April 1, 2019)

Other acquisitions

-The Company announced that it acquired a minority stake in Israeli start-up company Cartica AI. Cartica AI develops software in the field of artificial intelligence. The solutions from Cartica AI are designed to accelerate machine learning in the field of object recognition. The Company’s aim is to make the Cartica AI software available to the entire automotive industry and thus promote the rapid implementation of AI technologies for safe mobility in the future. (From a press release on September 4, 2019)

-The Company announced the successful completion of the acquisition of Kathrein Automotive GmbH after antitrust authorities officially cleared the transaction. Incorporating the automotive division of Rosenheim-based antenna and satellite technology manufacturer Kathrein is a move that will give the Company an important key segment to add to its wealth of expertise. Intelligent vehicle antennas are the starting point for future-proof connectivity concepts in the vehicle interior and beyond. The Company is incorporating all Kathrein Automotive employees and all eight locations in Brazil, China, Germany, Mexico, Portugal and the U.S. The two parties have agreed not to disclose the purchase price. (From a press release on February 4, 2019)

Restructuring

Discontinuation of hydraulic businesses (listed in chronological order)

-As part of the Company’s Transformation 2019 - 2029 structural program, it will shed 20,000 of more than 244,000 jobs over 10 years. This will reduce gross costs by EUR 500 million annually starting in 2023 when 15,000 jobs will have been ended. The Instrumentation & Driver HMI business unit will gradually withdraw from mass production in Babenhausen, Germany, by the end of 2025. In Roding, Germany, where 540 people are employed, the production and development of high-pressure pumps for gasoline and diesel engines will be discontinued in 2024. In Limbach-Oberfrohna, Germany, where 1,230 people are employed, the injectors business for diesel engines will be discontinued in 2028. In Pisa, Italy, where 940 people are employed, production of injectors for gasoline engines will be discontinued some time between 2023 and 2028. The Company will close its location in Newport News, Virginia, U.S. in 2024, where 740 people manufacture injectors for gasoline engines, as well as the location in Henderson, North Carolina, U.S., where 650 employees produce hydraulic brake systems. The Company will end truck tire production in Petaling Jaya, Malaysia, where it currently has 270 employees, by the end of 2019. The Company will concentrate on assisted and automated driving, connected driving, and integrated software-based system solutions, as well as its tire business, in which it invested more than EUR 1 billion in the last seven years to expand production capacity. (From a press release on September 25, 2019)

-The Company’s supervisory board approved the structural adjustments at the locations in Roding, Germany; Limbach-Oberfrohna, Germany; Newport News, U.S.; and Pisa, Italy. With its approval, the Supervisory Board supports the decision of the Executive Board to discontinue the business in hydraulic components for gasoline and diesel engines in the coming years. Roding will stop production and development of high-pressure pumps for gasoline and diesel engines in 2024, resulting in the closure of the location. Approximately 520 jobs will be affected. Newport News will also close in 2024, affecting 720 employees. The Newport News location produces injectors for gasoline engines. The Company will discontinue the Pisa location which produces injectors for gasoline engines between 2023 to 2028. Approximately 750 jobs will be affected from the Pisa closing. Finally, talks will be held with the local works council in Rubi, Spain about the future prospects of the location. The Company currently employs around 760 people in Rubi, producing mainly analog displays and controls. (From a press release on November 20, 2019)

Spin-off of Powertrain division (now known as Vitesco Technologies) (listed in chronological order)

-The Company announced that its powertrain business will trade on the market under the name Vitesco Technologies in the future. It will develop, sell and produce systems and solutions for conventional and electrified drives for automotive manufacturers worldwide. The Company’s preparations for a potential partial IPO in the second half of 2019 are on schedule. The name combines two key elements of the business: Vitesco stands for speed and agility, and establishes a direct reference to the Company’s attractive product and service portfolio for the mobility and automotive sector. The word “Technologies” underscores the commitment as a provider of innovative and pioneering technologies, systems and services. (From a press release on March 7, 2019)

-The Company announced that its powertrain business has become the first part of the Company to complete its realignment, with the management team fully in place since April 1, 2019. It now operates as an independent business that will trade under the name of “Vitesco Technologies”. The introduction of this new name is planned for the second half of 2019. The new company has three business areas, each of which is economically independent. Aiming to strengthen their portfolio and boost their performance, the former Engine Systems and Transmission units have been merged to create a new Engine & Drivetrain Systems (E&DS) business area. The former Sensors & Actuators and Fuel & Exhaust Management units have also been merged to form the new Powertrain Components (PTC) business area. As a strategic growth area, there are no changes to the Hybrid & Electric Vehicle (HEV) business area, which encompasses all the main components for drivetrain electrification in hybrid and electric vehicles. (From a press release on April 30, 2019)

-The Company announced that its executive board has decided to consider the possibility of a spin-off of the Powertrain division and subsequent stock exchange listing. The spin-off will be named Vitesco Technologies. This review will be conducted in parallel with the Company’s ongoing preparations for a potential partial IPO of the division. In addition to examining the technical and legal requirements, the review of this option also includes the possibility of a complete spin-off. The executive board and supervisory board will reach a decision regarding the actual implementation after the review has been completed. Powertrain employment guarantee would continue to apply through 2023 in the event of any change to the company. (From a press release on September 2, 2019)

-The Company announced that, effective immediately, its former powertrain division will now operate under the name Vitesco Technologies. Vitesco Technologies, which has been operating independently since January 2019, is now rolling out its new brand identity at its approximately 50 locations worldwide. Vitesco Technologies is headquartered at Siemensstrasse in Regensburg, Germany. Vitesco Technologies’ portfolio includes innovative and efficient technologies for 48-volt electrification, electric engines, as well as performance electronics for hybrid engines and battery-powered vehicles. The competencies developed over decades will continue to be part of its core business in electronics, sensors, and actuators. (From a press release on October 1, 2019)

-The Company announced that its board has decided to fully spin off its powertrain business Vitesco Technologies (formerly the Powertrain division) with a subsequent listing. With the spin-off, the Company is taking the offensive and tackling the accelerating trend toward powertrain electrification. It is also reacting to the presently unpredictable conditions for a potential partial IPO in 2020. Therefore, it will no longer pursue the preparation of a potential partial IPO of its powertrain operations, which had originally been considered. Subject to the approval of the Company’s Supervisory Board, the spin-off of Vitesco Technologies shall be submitted for decision by the Annual Shareholders’ Meeting on April 30, 2020. The spin-off could occur as early as 2020. (From a press release on October 22, 2019)

Other restructuring activities

-Faurecia announced that it has signed a MoU to acquire the remaining 50% of its SAS joint venture from the Company. This project would expand Faurecia’s systems integration offer to cover all interior modules as well as Faurecia’s new product lines such as displays, electronics, sensors and thermal management. Established in 1996, the joint venture has become a key player in complex interior module assembly and logistics. Sales in 2019 are expected to reach EUR 700 million. Faurecia would acquire the 50% share of the joint venture for EUR 225 million. Closing is expected to occur in early 2020. (From a press release on October 14, 2019)

Joint Ventures

-The Company, Michelin and Smag announced the creation of a joint venture specializing in the development and deployment of Rubberway, a technological solution for mapping sustainability practices in the supply chain of natural rubber. The joint venture is expected to begin business before the end of 2019. Rubberway is a technological solution that maps and assesses practices and risks regarding environmental issues, social affairs, and Corporate Social Responsibility governance throughout the natural rubber industry, from rubber-processing plants downstream to plantations upstream. Rubberway will provide tire manufacturers with the collected data and enable them to identify and improve sustainability in the natural rubber chain. In this joint venture, Michelin is bringing the rights of use and exploitation, as well as its user experience of the solution. The Company’s investment in the joint venture aims to open the path to wider use of the application by other tire-makers and car-parts manufacturers. Smag is sharing all of its technological and sector-specific expertise in digital solutions for agriculture. (From a press release on September 12, 2019)

Business Partnership

-Elektrobit (EB), a Company subsidiary, announced that it has signed a strategic partnership with Baidu in which EB will provide automotive infrastructure software for the Apollo Computing Unit (ACU), Baidu’s advanced in-vehicle computing platform for autonomous driving. EB is providing its EB tresos automotive basic software products to the Baidu ACU-Advanced Automated Valet Parking project. EB’s industry-leading software will allow car manufacturers and suppliers using ACU to expedite the market introduction of safe systems for Automated Valet Parking. The ACU, an autonomous driving in-vehicle computing platform for mass production, is one Baidu Apollo’s most important products, and is being developed with 156 industry partners including Chinese automakers. EB is also working with Baidu Apollo in other areas and has published a joint whitepaper on reliable and safe maps for automated driving. (From a press release on August 7, 2019)

Recent Developments

-The Company and Pyrolyx announced that they have entered into a five-year recovered carbon black (rCB) supply agreement for the Company’s tire manufacturing facilities worldwide. This joint development commitment aims to lay the foundation for using rCB in various tire segments during tire production. Pyrolyx expects to absorb over 3,000,000 end-of-life tires and reduce CO2 emissions by more than 25,000 tons annually in each plant compared to use of traditional carbon black production. The supply agreement will support Pyrolyx’s growth with additional manufacturing facilities in North America and Eastern Europe, and specifically details sales over the next five years rising to 10,000 tons per year. (From a press release on November 11, 2019)

-The Company held the topping-out ceremony for its new corporate headquarters on Hans-Bockler-Allee in Hanover. The new headquarters will be ready for occupancy in time for the Company‘s 150th anniversary in 2021. In the first stage of development, the eight interconnected buildings will house 1,250 employees, with scope for subsequent expansion to 1,600 workstations. The new corporate headquarters were designed by Munich-based architecture firm Henn. The central design concept is a bridge system that connects the buildings of the new headquarters. The work environment will be based on an open-space design throughout, featuring state-of-the-art technical equipment. The Company has set up a test space, called the Workspace Lab, on the plant premises at its current headquarters. It simulates the spatial concept, complete with all planned furnishings. (From a press release on November 6, 2019)

-The Company has submitted a plan of action to the Lower Saxony Ministry for the Environment, Energy, Construction and Climate Protection with which the Company intends to immediately reduce the lead content in some of its electronic components to legally prescribed maximum quantities in accordance with the End of Life Vehicles Directive. In the action plan, the Company analyzes the situation together with its customers on an individual basis and defines the necessary conversion steps. The changeover will not jeopardize the launch of new vehicle models. The Company has now undertaken to design all components in the future in accordance with the limit values of the End of Life Vehicles Directive. The End of Life Vehicles Directive (Directive 2000/53/EC of the European Parliament and of the European Council of September 18, 2000 on end-of-life vehicles) regulates the disposal and recycling of motor vehicles within the European Union. (From a press release on August 9, 2019)

-The Company is now focusing more rapidly and systematically on its strengths and is targeting the future of electric mobility. Combustion-only components are set to offer only selective growth opportunities in the future, which have prompted the Company’s powertrain division to reduce investment in the hydraulic components business such as injectors and pumps for gasoline and diesel engines. As such, while existing orders will be fulfilled, new orders will play an increasingly marginal role. In the medium term, the Company will make transportation for the masses even cleaner by offering comprehensive support for mild- and full-hybrid solutions. The next generation of technology for long-term, CO2-free mobility is already being developed in its laboratories and workshops. This includes e-drives and technologies for CO2-neutral, hydrogen-based fuels, fuel cells and synthetic fuels. The Company will make more targeted investments in electrified and all-electric technologies, and increasingly shift internal resources in this direction. The Company will not consider potentially entering into the production of solid-state battery cells in the future. Until now, the Company was open regarding a potential investment in the field. (From a press release on August 7, 2019)

-The Company announced that trucks equipped with the its eHorizon sensor system have saved over one billion liters of diesel and nearly three million tons of CO2 since 2012. The static eHorizon delivers information about the condition of the route ahead to ECUs, based on highly precise topographical route data from the location cloud developer HERE Technologies and GPS signal information. The ECUs then automatically adapt the vehicle’s driving style and speed. The next generation of the electronic horizon, the dynamic eHorizon, offers an additional savings potential of up to two percent compared to its predecessor. In this expansion stage, the digital map material is updated in close to real time through networking with the cloud, providing accurate and current data on traffic situations. Thus, driving behavior can be adapted to various scenarios at an early stage, increasing safety. In this fashion, the dynamic eHorizon becomes an important basis for automated driving. The Company is currently testing the dynamic eHorizon in various predevelopment projects specifically for commercial vehicles. (From a press release on June 6, 2019)

-The Company has laid the foundation stone for its new headquarters in Hanover. The new headquarters will contain enough space for 1,250 employees, with reserve space available to increase capacity to 1,600 employees in the future. The work environment in the new headquarters will be characterized by an open-space design throughout, featuring state-of-the-art technical equipment. Construction of the basic structure for the new, global headquarters began in March 2019, and the first few basement walls are already in place. Completion of the basic structure will be celebrated at a topping-out ceremony scheduled for between late 2019 and early 2020, while final completion of the entire building is scheduled to coincide with the Company’s 150th anniversary in 2021. (From a press release on May 8, 2019)

-The Company announced that it is supporting the German Inclusion Act (Teilhabechancengesetz) and will begin a joint pilot project with the Federal Employment Agency at the end of January. The Company plans to recruit those who have been unemployed long-term at its locations in Hanover, Ingolstadt and Regensburg. The new employees are to be engaged primarily in traditional training activities in production and receive targeted support over the first few years. Two of the joint initiatives with the Federal Employment Agency are the WeGebAU project and the Fit for Industry 4.0 initiative at the Company’s site in Regensburg. The WeGebAU support program enables employees to train as mechatronics specialists certified by the Chamber of Industry and Commerce. (From a press release on January 21, 2019)

Contracts

-The Company’s tires will be factory-fitted to the Volkswagen ID.3 electric vehicle. Volkswagen has granted approvals for summer and winter tires for 18- and 19-inch rims. The EcoContact 6 summer tire and the WinterContact TS 850 P winter specialist have both been adapted to suit the specific requirements of the ID.3. The ID.3 will run on tires with low rolling resistance, thus saving energy to deliver the maximum possible range between charges. Both the summer and winter tires also feature ContiSeal technology. ContiSeal automatically and reliably closes punctures with a diameter of up to five millimeters in the tire tread, thereby protecting against approximately 90% of all punctures. (From a press release on November 14, 2019)

-The Company has developed an in-car application server (ICAS1) for Volkswagen that will be used for its upcoming family of ID electric vehicles. In the future, two or three servers will be used on a single vehicle depending on the model and its features to provide the necessary computing power. (From a press release on November 1, 2019)

-Vitesco Technologies, the Company’s former powertrain division, announced it has signed agreements with Groupe PSA and Hyundai to supply the first fully integrated electric axle drive system for various volume-production models. Production of the new electric drive system at Vitesco Technologies’ plant in Tianjin, China, has already started. Groupe PSA will use it for its e-CMP modular electric platform, which compact battery electric vehicle models such as the Peugeot e-208 and Opel Corsa-e will be built on. Hyundai has made Vitesco Technologies the supplier of choice in China through its joint venture Beijing Hyundai for the Encino compact SUV and the Lafesta sedan. In addition, other vehicle manufacturers have chosen Vitesco Technologies to supply drive systems for battery electric cars that are planned to launch over the next 12 months. The innovative electric axle drive system will also power German start-up Sono Motors’ Sion battery electric vehicle. The Sion has a maximum output of 150 kW and maximum torque of 310 Nm. (From a press release on October 9, 2019)

-EvoBus is equipping its entire fleet of buses with a lightweight air spring featuring an integrated plastic roller piston, developed by the Company. These innovative roller pistons ensure outstanding ride comfort thanks to maximum utilization of the inner air volume and their special design. Instead of steel or aluminum, plastic components made from polyamide are used. This helps to reduce weight without compromising ride comfort. It also generates weight savings of between 2 and 2.6 kilograms in each air spring module. Lightweight air springs can reduce the weight of a two-axle urban bus by up to 15 kilograms. The solution is also helping the EvoBus meet the requirements of the EU’s Euro 6 emissions standard, which makes provisions for substantial reductions in pollutant levels for trucks and buses. The extra weight added by increasingly complex exhaust gas aftertreatment systems can be effectively offset thanks to lightweight components. (From a press release on September 30, 2019)

-The Company’s Continental Tire Japan Co., Ltd. announced that its ContiSportContact 5 high-performance tire has been adopted as original equipment for the Mercedes-Benz GLE. ContiSportContact 5 has adopted the Company’s original BlackChili Compound for the tread areas to achieve increased fuel efficiency by reducing rolling resistance and high maneuverability on wet roads and during emergencies. To improve safety, the performance of the ContiSportContact 5 was also synchronized with the control of in-vehicle electronic devices such as electronic stability program systems. (From an article in the Nikkan Jidosha Shimbun on August 31, 2019)

-On August 21, the Company’s subsidiary Continental Tire Japan Co., Ltd. announced that its PremiumContact 6 sporty comfort tire has been adopted as original equipment for the BMW X7. The tire features self supporting runflat (SSR) technology to allow a car to run on a flat tire with no pneumatic pressure for a certain distance. The tire’s sidewall has BMW’s approved marking. PremiumContact 6 was developed to offer comfort, safety, and improved fuel efficiency. The Company’s latest compound technology enables the tire’s excellent abrasion resistance. (From an article in the Nikkan Jidosha Shimbun on August 23, 2019)

-Elektrobit (EB), a Company subsidiary, announced it provided the software design, development and integration services for Weltmeister (WM) Motor’s first electric vehicle, the WM EX5, a compact sports utility vehicle. EB was brought in specifically for the design and development of basic software for ECUs associated with the new vehicle’s communication systems supporting diagnostics and AUTOSAR network management. EB also supplied vehicle software products to support over-the-air updates. EB also worked with various Tier 1 suppliers involved in the project, creating documentation, user manuals and training materials to ensure all teams were aligned. WM Motor is using EB tresos, which enables industry-leading implementation of AUTOSAR- and OSEK/VDX-compliant basic software for automotive ECUs. It also enables customization of basic software to meet WM Motor’s specific requirements. (From a press release on August 20, 2019)

-The Company’s subsidiary, Continental Tire Japan Co., Ltd., announced that its PremiumContact 6 sporty comfort tire and SportContact 6 supersports tire equipped with noise reduction technology have been adopted as original equipment for the Audi Q8. PremiumContact 6 was developed to offer comfort, accurate steering response, and safety. SportContact 6 has adopted the Company’s original BlackChili compound technology that ensures optimal contact between the tire and the road surface, and realizes nanoscale grip performance. (From an article in the Nikkan Jidosha Shimbun on July 20, 2019)

-The Company announced that the production of its highly integrated electric axle drives will begin at its plant in Tianjin, China, in the third quarter of 2019 for electric vehicle models from several Chinese and European manufacturers. The axle will combine the electric motor, power electronics and reduction gear in a single housing. The new axle drive now weighs less than 80 kilograms. The Company offers the highly integrated axle drive in two performance levels, with 120 kW or 150 kW. With an output of up to 150 kW and a maximum torque of up to 310 Nm, the new electric axle drive is roughly equivalent to a conventional two-liter turbo-diesel engine. The electric motor and power electronics of the new system are liquid-cooled. Beyond the new electric models, the new technology is also suitable for small European models like the Sion electric vehicle from German start-up Sono Motors. (From a press release on July 10, 2019)

-The Company is helping deliver the FCA US LLC eTorque mild-hybrid technology to the all-new Jeep Wrangler. The Company’s industry-first, liquid-cooled 48-volt Eco Drive supports the eTorque system. It marks the technology’s first application in the SUV segment and with a North American vehicle manufacturer. The Company’s compact 48-volt Eco Drive with integrated power electronics contributes to the benefits eTorque technology offers, including better fuel economy, improved auto-start response, overall start-stop functionality and reduced noise levels. Eco Drive provides up to 88.5 lb-ft (120 Nm) of torque delivered to the crank via the engine’s front-end accessory drive. This enables auto-starts in less than 0.5 sec. The 31.5-lb (14.3-kg) Jeep version also helps maximize regenerative braking and offers an impressive 4.1 kW/L in power density. Further, the technology helps deliver torque to the wheels more than twice as fast as a conventional 12-volt starter can accommodate. (From a press release on January 16, 2019)

Outlook

-The Company will be shaping the mobility ecosystem in three fields of technology in the next 20 years: alternative drive systems, autonomous driving, and interconnectivity and data management with the cloud. Cars currently require more than 100 million lines of software code for their functions. The amount of software required for future functions will increase tenfold. The Company’s need for software developers is accordingly high. By the end of 2022, the number of software and IT experts will be increased from 19,000 to 25,000. The Company will focus a significant part of its R&D activities in the new Automotive group sector, which will specialize in vehicle electronics. The aim is to reduce development times and be able to respond more flexibly and directly to customer demands. (From a press release on April 26, 2019)

R&D Expenditure by Divisions |

(in million EUR) |

| FY ended Dec. 31, 2019 | FY ended Dec. 31, 2018 | FY ended Dec. 31, 2017 | |

| Chassis & Safety | 1,048.7 | 1,023.2 | 913.8 |

| Powertrain | 664.1 | 672.6 | 699.0 |

| Interior | 1,189.2 | 1,064.7 | 1,062.7 |

| Tires | 299.4 | 299.4 | 289.8 |

| ContiTech | 162.8 | 149.1 | 138.4 |

| Total | 3,364.2 | 3,209.0 | 3,103.7 |

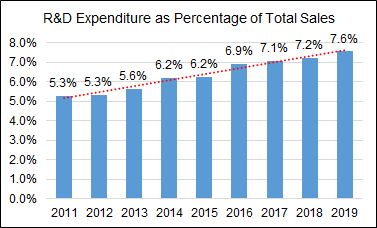

-The Company aims to invest between 7% and 8% of its sales in research and development every year.

-The Company aims to invest between 7% and 8% of its sales in research and development every year.

-The Company has steadily increased the amount invested into research and development as a percentage of its total sales every year due to its increased focus on business areas such as electric mobility, automated driving, connectivity, digitalization and urbanization.

R&D Structure

-The Company has approximately 49,000 engineers working on new trends and technologies. Just under a third of those engineers have a background in software. The Company wants to increase its workforce of software and IT experts from its current figure of 19,000 employees to 25,000 by the end of 2022. (From a press release on March 7, 2019)

R&D Facilities

-In the fiscal year ended December 31, 2019, the Company had 88 locations that were used for research and development.

-The Company inaugurated a new production module and a new building dedicated to R&D activities with a total investment of EUR 32 million in Sibiu, Romania. The R&D facility features three levels, a floor area of over 4,600 square meters and a total area of over 12,000 square meters. The new facility is capable of employing 1,100 people. With the inauguration of the two buildings, Sibiu has 6 production modules and 3 buildings for research and development. (From a press release on December 6, 2019)

-The Company announced that it is investing in expanding its operations in Sibiu, Romania. The investment will include a facility dedicated towards R&D activities, planned to open on December 6, 2019. The R&D facility is built on 3 levels, with a floor area of over 4,600 square meters and a total area of over 12,000 square meters. The ground floor of the new building will host laboratories that will be used by employees and students of Lucian Blaga University. The facility will also host technical spaces, classrooms, and offices. The new facility can hold up to 1,100 people. (From a press release on October 15, 2019)

-The Chemnitz University of Technology announced that the Company is expanding its fuel cell technology sector in strategic cooperation with the Chemnitz University of Technology Professorship of Advanced Powertrains (ALF) with the dedication of a newly established fuel cell laboratory. The new fuel cell materials laboratory features a test bench which accommodates permanent testing of powertrain performance up to 150 kW, which can be converted up to 300 kW in the future. In order to test the performance of the fuel cell under different conditions, the new test bench is able to simulate changing environmental conditions and workloads. One of the first two Company projects in the fuel cell laboratory is dedicated to the development of new bipolar plates, a central component of the fuel cell stack. The plates disperse gases and dissipate the current generated by their reaction. (From a Chemnitz University press release on July 17, 2019)

-The Company has begun to expand its existing office building in Iasi, Romania. The building is designed for up to 1,700 employees, and includes a full test and validation area for products developed within the Company. The planned investment for the expansion will be EUR 27 million. When complete, the building will have a total built area of over 21,000 square meters. The expansion is expected to be completed by March 2020. Engineers in Iasi are involved in the development of automotive technologies, such as glazing and hatch control units, navigation and multimedia applications, petrol and diesel engine control units, and inverters used on hybrid and electric vehicles. The center is also developing the world's first vacuumless "one box design" braking system, which enhances braking efficiency. Other focus areas include designing and building functionalities for autonomous vehicles. (From a press release on June 14, 2019)

-The Company opened the Company-wide competence center for 3D printing at its electronics plant in Karben. The state-of-the-art 8,000-square-meter manufacturing facility enables the precise and efficient production of small quantities of components for internal and external customers. In addition to additive manufacturing, the following technologies are in use: high-performance CNC machines, injection molding and laser welding systems, and state-of-the-art electronics manufacturing for printed circuit board assembly. The Company combines the entire process chain, from design and production, to reworking, testing and validation, and environmental testing all under one roof. In a process involving selective melting of metal powder, a three-dimensional structure is built, layer by layer. Further technologies that involve using plastic include: Selective Laser Sintering (SLS), which uses various plastics such as PA, PP or polystyrene; Stereolithography (SLA); Digital Light Printing (DLP) and Fused Deposition Modelling (FDM). (From a press release on May 22, 2019)

-Osram Continental GmbH, a joint venture between the Company and Osram, and a global provider of automotive intelligent lighting solutions, celebrated the opening of its new location in Guadalajara, Mexico. The 2,100-square-meter facility will initially employ 65 people and will serve as a R&D center to support companies in the Americas region. Since Osram Continental started operations in July 2018, the company has played an innovative role in the automotive lighting industry. (Mexico-Now article on April 15, 2019)

-On March 6, 2019, the Company announced the start of operations of its R&D center in Chongqing, China. The Company invested CNY 280 million in the construction of this new development center with a floor area of 15,000 square meters in first phase of development. The lab will focus on the development of car body and powertrain products, automotive electronics solutions, in particular, regarding the development and testing of smart keys, car body controllers, and transmission controllers. By the end of 2020, the center is expected to create 400 new jobs. This is the Company’s 18th development center in China. (From a press release on March 6, 2019)

-The Hungarian Investment Promotion Agency informed that the Company has chosen Hungary to build its newest R&D center for the development of self-driving vehicles. Integrated into the global network of the business branch for ADAS, the center will be involved in the examination, development and testing of options for the analysis and improvement of AI-based deep machine learning. The new unit will employ 100 software and hardware experts and will shape the future of partly or entirely self-driving technologies based on real-time software applications of critical safety. It studies application and integration of technologies, substantially reducing the period between the stages of development preparation and product planning. The new solutions can be readily built into specially equipped test vehicles to enable experts to obtain experience under real conditions. (From HIPA press release on February 21, 2019)

R&D Activities

-The Company announced that it will be demonstrating the mobility of the future using a Robo-Taxi CUbE (Continental Urban Mobility Experience) with the French company EasyMile. The two companies have set up a demonstration track for a driverless Robo-Taxi. The Robo-Taxi CUbE is a Company development platform for driverless vehicles technologies based on the EZ10 shuttle and driverless software from EasyMile. The technology is ready for series production and is already in use worldwide in several pilot projects in countries such as the U.S., Japan, China, Singapore and Germany. The CUbE is equipped with laser sensors, cameras and radar sensors. Proven products from high-volume passenger car production are intelligently integrated and modified, making them suitable for new mobility offerings. The CUbE helps to reduce the risk of accidents, relieve parking shortages and reduce noise pollution through its electric powertrain. (From a press release on September 12, 2019)

-The Company has conducted tests of the CO2 savings potential of the MK C1 electrohydraulic brake system in a plug-in hybrid. TUV confirmed in a certified test that MK C1 reduces the amount of CO2 emitted under the WLTP (Worldwide Harmonized Light Vehicle Test Procedure) by approximately 5 g/km on average compared to a conventional hydraulic hybrid brake system. At the end of 2020, the Company will begin production of the MK C1 in Shanghai for a Chinese customer. The brake pedal in the MK C1 is usually completely decoupled from pressure generation, giving a uniform pedal feel. The full use can be made of recuperation phases, thus reducing CO2 emissions. The measurements were taken on a dynamometer test in accordance with the WLTP, the globally valid measurement procedure for determining exhaust emissions and fuel and electricity consumption of motor vehicles, and were supervised by TUV experts. (From a press release on April 16, 2019)

-The Company has completed intensive trialing and testing with Deutsche Telekom, Fraunhofer ESK, MHP and Nokia on the A9 motorway digital test track in Germany under the Car2MEC project. Car2MEC was funded by the Bavarian Ministry for Economic Affairs. The goal of the project was to gain insights into the value of Multi-access Edge Computing (MEC) for connected driving in regards to technology, network architecture and economic considerations. The project partners tested a number of different use cases on the A9 motorway, including emergency warnings, end of jam warnings, variable speed limit assistants and HD maps. In the future, MEC will be a very important communication technology for the connected vehicle. The Company is currently working on a vehicle architecture that takes MEC into account. (From a press release on March 21, 2019)

Technological Alliance

-Immersion Corporation announced that it has signed an agreement with the Company. The agreement grants the Company access to Immersion’s advanced haptic technologies for its automotive interfaces. Immersion and the Company initially signed a license agreement in 2014, providing the Company with access to Immersion’s patented haptic technology for use in in-vehicle touchscreens and touch pads. (From a press release on November 20, 2019)

-Hamburg signed a partnership agreement with the Company for the future development of urban mobility at the ITS (Intelligent Transport Systems) World Congress in Singapore. The partners plan to implement joint ITS projects to improve the safety of vulnerable road users and use parking spaces more efficiently. One of the planned projects aims to improve road safety by using a collision warning system to protect particularly vulnerable road users. Using mobile edge computing, a cloud-based calculation of potential collisions with road users, such as cyclists, pedestrians and e-scooter users, is to be carried out at black-spot crossings in Hamburg, which will wirelessly send warning messages in dangerous situations. The partnership also aims to improve the efficiency of managing available parking facilities. Various solutions, such as sensor-based, in-vehicle detection of available parking spaces, navigation to the nearest parking space or paying for parking spaces both on and off the street, will be examined and implemented if feasible. (From a press release on October 22, 2019)

-The Company has entered into a collaborative evaluation partnership with 3M to assess the infrastructure-to-vehicle (I2V) interface between infrastructure-related objects and technologies and vehicle-related technologies. The short-term goal is to help increase road safety while continuing to work toward automated driving solutions. The Company and 3M will collaboratively evaluate the I2V interface in the following ways: localization and correction services using clear environmental landmarks for locating a vehicle on a high-definition map; identification and classification of objects in urban roadway environments such as urban cross-walks, signalized intersections and other stationary and moving objects to improve safety; improved awareness of objects in and around work zones and work zone statuses; and enhanced object detection using sensor fusion detectable infrastructure-related objects. (From a press release on October 15, 2019)

-The Company’s subsidiary, Elektrobit (EB), signed a long-term collaboration agreement with MBition, a fully owned subsidiary of Daimler AG to open a new software lab in Berlin, Germany. MBition selected EB as a key partner to design and implement the software platform for the next generation of Mercedes-Benz telematics systems. Drivers will benefit from enhanced and latest state of the art user experience features developed by MBition. EB’s new office is located at Franklinstrasse, close to the Technical University of Berlin. EB’s focus is the development of automotive-grade software platforms for high-performance computing systems, bringing the next generation of automated and connected cars to the road. (From a press release on September 30, 2019)

-The Company and Knorr-Bremse are taking another step in their development partnership towards highly automated commercial vehicles. Initial test runs and demonstrations of automated platooning by three trucks from different makers to customers have already been conducted at testing grounds. The showcase includes platoon formation, platoon driving, use of the emergency braking function, exiting of the platoon by individual vehicles and safely splitting up the entire platoon. The Company is responsible for the sensors including cameras, radar and lidar systems. Knorr-Bremse is contributing its expertise in the specific requirements placed on commercial vehicle dynamics. For both companies, the experience gained during development of the platooning demonstrator forms the basis for addressing further highway pilot applications. (From a press release on July 16, 2019)

-The Company’s technology for driverless vehicles will be in production for the first time in French company EasyMile’s EZ10 autonomous shuttle. The central development platform for this work is the Contiental Urban Mobility Experience (CUbE), a small driverless shuttle based on the EZ10 platform. With the aid of CUbE, the Company has developed a production-ready radar system especially for driverless vehicles. The vehicle can generate a 360-degree image of its surroundings by combining the data from different sensors. The radar sensor detects the vehicle’s environment within a radius of up to 200 meters. The vehicle is equipped with a total of seven radar sensors, as well as laser sensors and cameras. The Company, EasyMile, Oakland University, and the City of Auburn Hills in Michigan are set to implement the pilot deployment of an autonomous shuttle thanks to a grant from Michigan’s PlanetM mobility initiative. The initiative supports companies testing future mobility technologies. The pilot will begin in late August and last up to six months. (From a press release on July 9, 2019)

-Elektrobit, a Company subsidiary, and Synopsys announced a collaboration to accelerate automotive electronic systems development using virtual environments. The two companies are collaborating to bring together Synopsys Virtualizer Development Kits (VDKs), Elektrobit operating systems, development and test tools, and complementary expertise to enable pre-silicon and pre-Electronic Control Unit (ECU) hardware availability and software development. The combined solution, already in process of being deployed at leading automotive companies, accelerates system testing cycles and enables automotive tier 1 and OEM companies to transition from physical to virtual system testing. (From a press release on May 13, 2019)

-T-Systems and Argus Cyber Security, an independent Company subsidiary, will work together on automotive cyber defense. In March, T-Systems announced that it is planning a Security Operations Center specializing in vehicles (Automotive SOC). The collaboration with Argus will serve to enhance cyber security development. The Israeli automotive cyber security specialist has a highly developed Information and Event Management System (SIEM) for cars as well as in-vehicle solutions. OEMs and fleet operators use SIEM to identify anomalies for connected vehicles. (From a press release on April 4, 2019)

-Singapore telecommunication company Singtel and the Company’s subsidiary, Argus Cyber Security, a leader in automotive cyber security from Israel, have signed a Memorandum of Understanding (MoU) to collaborate on several initiatives to strengthen the cyber security capabilities for Singapore’s transportation sector, facilitating the introduction of connected cars and technologies such as autonomous vehicles. Under the MoU, both parties will launch a suite of solutions which includes Argus’ in-vehicle solutions and technologies, and its stand-alone cyber security backend platform. Both companies will also conduct cyber security R&D at the Singtel Cyber Security Institute to help defend autonomous vehicles against cyber threats. The partnership announcement is timely as the introduction of autonomous vehicles in Singapore is one of the initiatives of the government’s Smart Nation plan. (From a press release on January 28, 2019)

-Through collaboration with the German based start-up company Automotive Artificial Intelligence (AAI), the Company has enhanced its approach for virtual development of its ADAS and automated driving functions. Virtual development is already an integral part in today’s product development. The Company is responding by developing a highly scalable, highly modular development and testing environment that meets the new requirements. AAI has the competence to create virtual environments based on HD-maps and AI-driven road users, while aiming to accomodate the increasingly broader scope of validation in automated driving. The simulation tools developed within the collaboration will be made available to the entire automotive industry. (From a press release on January 9, 2019)

Product Development

Holistic solution for human-machine interaction

-The Company is developing a holistic solution for human-machine interaction specifically designed for autonomous vehicles. This solution was developed in the CUbE, the Company’s development platform for driverless technologies. At CES 2020, it will demonstrate seamless human-machine cooperation within and outside the CUbE using complementary audio and visual interfaces. Users can book a shuttle and reserve a seat through a smartphone application. As users wait, the shuttle’s location can be tracked through the application. Inside, passengers can view complete travel information, local service availability and vehicle notifications aggregated in the form of a dynamic timeline on a large display. Also, audio cues complement visual elements, notifying passengers about their ride status and trip events with ambient sound synchronized to the vehicle’s movement. It will also respond and communicate with pedestrians that are detected in the shuttle’s path. The vehicle’s sensors will register the pedestrian’s presence and validate this through an external audio-visual interface. (From a press release on December 12, 2019)

Contact Sensor System (CoSSy)

-The Company will present a new modular and scalable contact sensor to detect scratches and damages at CES 2020. The miniaturized Contact Sensor System (CoSSy) uses sensors to pick up sound signals from low-speed impacts. If a low-speed impact is detected, based on the sound signals picked up by CoSSy, the car can be brought to an immediate emergency stop. The scalable CoSSy solution will typically include two to twelve sensors installed at specific locations on the vehicle. The sensors deliver their signals to a central processing system which can be a dedicated electronic control unit (ECU) or integrated into an existing ECU such as the airbag control unit. In the future, CoSSy could be used for other applications, for example by providing an additional signal path to gauge road conditions. The sound of water hitting the vehicle structure from below can be used to determine the potential for hydroplaning. Through the Doppler effect, CoSSy can also detect the direction of approaching emergency vehicles. The sensor signal could also be used to trigger specific cameras to take a photo of the vehicle’s surroundings or to make other drivers aware of collisions by sounding an alarm or sending information to an associated smartphone. (From a press release on December 10, 2019)

Dedicated Hybrid Transmission (DHT) technology

-Vitesco Technologies presented an extremely cost-effective and compact hybrid transmission solution with integrated electric machines, designed for use in applications such as Plug-in Hybrid Electric Vehicles (PHEVs) at the CTI Symposium. The solution involves unorthodox thinking regarding powertrain design with a concept that reassigns some functions previously performed by the transmission. The basic aim of Dedicated Hybrid Transmission (DHT) technology for cost-effective PHEVs is to enable the design of compact automatic transmissions with an integrated high-voltage electric motor on the output side of the transmission. A DHT with Vitesco technology has only four mechanical gears and no mechanical synchromesh systems, auxiliary hydraulics or start clutch. Moving off 1st and 2nd gear and reversing are handled by the electric drive motor, while synchronization is performed by a starter-alternator that also provides fast and smooth starting of the internal combustion engine. The DHT for cost-effective PHEVs is designed for speeds of up to 120 km/h in all-electric mode, and speeds of up to 160 km/h in hybrid mode. (From a press release on December 9, 2019)

Complete system bundle of cameras and sensors

-The Company is bundling sensors like cameras and surround view systems, which were previously separately deployed, to form a complete system. Several satellite cameras provide high-precision image data that is processed and evaluated by a central control unit. Computer vision systems include intelligent front cameras that can detect, recognize and evaluate traffic signs, traffic lights, lanes or obstacles. The driver then receives the appropriate acoustic, visual or haptic information or warnings. With the help of the new optical information, a vehicle can be maneuvered precisely and in a controlled manner. The transparent hood is an extension of what experts call human vision systems, which are based on camera displays and support the driver. If all four satellite cameras, which permanently record the surroundings of the car, are connected to a central control unit that can evaluate the image information and trigger the corresponding functions, not only is automated parking even safer, but remote or valet parking functions can also be implemented. Satellite cameras with an image resolution of 1.3 megapixels are currently being installed on cars, and a new generation of cameras with a resolution of 2.5 megapixels and excellent night vision performance are about to go into production. (From a press release on December 3, 2019)

ICAS1 in-car application server

-On November 12, the Company developed an in-car application server (ICAS1) for Volkswagen, which will be used for its upcoming ID electric vehicles based on the modular electric drive matrix MEB developed by Volkswagen. The new server concept is a central element for the conversion to a service-oriented electronics architecture in the highly connected ID models. ICAS1 includes a host of vehicle connectivity features such as the ability to install new functions and safety updates via a wireless connection. The conceptual framework for the server is a high-performance computer platform developed by the Company in cooperation with Elektrobit. The middleware also supports connectivity via Gigabit Automotive Ethernet, which provides the necessary data throughput for applications. The ICAS1 covers previous gateway functions as well as comprehensive functions from the body control domain. It also coordinates over-the-air updates and controls charging management for the battery. Depending on the specific vehicle model and its features, two or three servers will be used in the future to provide the computing power for the entire vehicle. Since the beginning of the development, The Company designed the ICAS1 for the increased service life requirements in electric vehicles. (From a press release on November 12, 2019)

ContiConnect tire monitoring management service for autonomous driving

-The Company will start offering its ContiConnect tire monitoring management service for autonomous driving. The service automatically adjusts air pressure with sensors installed in tires, and provides notification of wear. It reduces the burden on the maintenance for autonomous driving when vehicles and tires are not directly controlled. The Company will start proposing the ContiConnect for applications such as robo-taxis. Tires are constantly monitored with sensors. When a decrease in air pressure is detected, air is automatically injected by using centrifugal force, while tread wear is managed with electrical resistance. Data is collected and sent to an ECU on vehicles via wireless communication, and is displayed on instrument panels. The Company will consider a system to share data with external devices to utilize it for operational fleet management. (From an article in the Nikkan Jidosha Shimbun on October 31, 2019)

Technologies showcased at ITS World Congress Singapore

-The Company participated in the ITS World Congress Singapore and showcased services for smart cities such as car-sharing, connected services, city transport, and traffic and fleet management solutions, the services with high interconnectivity. Also, the Company demonstrated Corriere LM, a last-mile delivery robot, for the first time at the show. The Continental Urban Mobility Experience (CUbE) acts as a platform to enable the robot to perform last-mile delivery services. Corriere LM can also be used as a fully autonomous driving vehicle to deliver parcels directly from a sender to a receiver without any use of delivery cars. The Company also focused on driver safety and wellbeing at the exhibition with solutions for anti-collision, driver fatigue monitoring, blind-spot detection, and driver health monitoring. (From a release on Wednesday, October 30, 2019)

EB Assist Test Lab cloud-based validation tool for ADAS

-Elektrobit announced a cloud-based tool, the EB Assist Test Lab, for end-to-end validation of ADAS and autonomous systems. Available on Microsoft’s Azure cloud platform, the tool provides distributed teams with a single solution to more easily manage petabytes of driving-scene data generated in real and simulated test drives during the validation and verification process. It also enables easier collaboration to ultimately bring features into production more quickly. EB Assist Test Lab covers the entire testing cycle, from data collection to data analysis, and includes optimized processes for collaboration, integration with third-party tools and services, data processing and management. In collaboration with cloud partners such as Microsoft and data center providers like Equinix, EB Assist Test Lab is infinitely scalable and able to handle the vast and growing amounts of data generated by today’s increasingly complex systems equipped with radar, lidar and high-resolution cameras. (From a press release on October 16, 2019)

Integrated Interior Platform (IIP) concept shown at IAA 2019

-The Company will present the latest version of its Integrated Interior Platform (IIP) at IAA 2019. The IIP exhibit will feature displays connected across the entire width of the cockpit under a glass surface, highlighting the number of functions that fully connected vehicles must be able to simultaneously operate. The Company uses virtualization solutions for the IIP architecture that allow several operating systems with various security requirements to be operated simultaneously on a single computer. The IIP is capable of controlling multiple displays in the cockpit. Around 20 teams across four locations in Europe and Asia are participating in the development of the IIP software. (From a press release on September 5, 2019)

Connectivity, HMI and audio technologies shown at IAA 2019

-The Company will bring a demonstrator at IAA 2019 that shows how connected systems, solutions and services can holistically determine the user experience of tomorrow and make mobility safe, intelligent and stress-free. To make connected mobility a tangible experience, the Company has combined its expertise in human-machine interaction and connectivity and integrated a wide range of technologies from both areas in the demonstrator. It allows the Company to further advance human-machine interaction for future mobility scenarios by extending or retracting a display spanning the width of the cockpit according to driving mode. Company developers have integrated the Ac2ated Sound audio solution into the demonstrator. The speakerless technology uses existing surfaces in the vehicle as sound boxes. Thanks to eHorizon, the vehicle always has up-to-date map data and is warned of possible dangers via its connection to intelligent intersections. At the same time, wireless software updates ensure that vehicle electronics and software are always up to date and as secure as possible. (From a press release on August 29, 2019)

Connected Parking demonstrator highlighting data sharing applications at IAA 2019

-The Company announced that it will use the example of Connected Parking at IAA 2019 to demonstrate how the future will see drivers benefit from the transfer of data collected by their vehicles in road traffic. The data transfer service is based on the blockchain-based data-monetization platform. The platform was developed as part of a strategic partnership between the Company and Hewlett Packard Enterprise and is based on Crossbar.io technology. Connected Parking is based on the Company’s “On-Street Parking” service, which enables stress-free parking along the road. The driver will use an app to register for the “Earn as you ride” program of his car manufacturer. On the subsequent journey, the vehicle’s sensors detect free and occupied parking spaces along the road - and also vehicles that are parking into or moving out from a parking space. The vehicle systems send this data to the automobile manufacturer. At the end of the journey, the driver receives a message that coins have been credited to their virtual wallet for sharing data. The decentralized platform approach based on blockchain technology ensures transparency, security and efficiency. (From a press release on August 27, 2019)

Technologies shown at IAA 2019

-At IAA 2019, the Company will showcase technologies for the safe, clean and connected mobility of the future. These technologies include an electric axle drive which will go into production in Europe and China later in 2019. The compact axle drive weighs less than 80 kg and consists of an electric motor, transmission and inverter. By being packaged together, the three components reduce weight by 20 kg. Another production-ready highlight is a new short-range radar which assists car drivers when turning and protects cyclists and pedestrians by detecting other road users and obstacles with extremely high precision. Another technology presented is an autonomous driving robo-taxi in collaboration with EasyMile that is available for test drives for IAA visitors. A technology display will showcase tires that can communicate information, enabling robo-taxis to perform tire maintenance themselves. (From press release on August 22, 2019)

Vision system combining outward-facing camera and inward-facing infrared camera

-The Company has developed a combined camera system comprising an inward-looking infrared camera and an outward-looking camera for the safe transfer of driving controls in automated driving. The Company will start series production of this system in 2021. The Road AND Driver camera is located behind the windshield of the vehicle, above the rear-view mirror. The lens is aimed at the road ahead and provides data for ADAS systems. The interior camera detects the position of the driver, the direction of his or her gaze, and the location of his or her hands, all of which are necessary as a prerequisite to bring cars with autonomous driving functions to the road. In addition, with the aid of the Occupant Safety Monitor software, the interior camera can be used to adapt passive safety systems such as seatbelts and airbags. The consumer protection organization Euro NCAP has included the topics of driver monitoring and baby or child monitoring systems in closed vehicles in its agenda to enhance road safety and contribute to vision Zero. (From a press release on August 13, 2019)

System of networked technologies to judge upcoming road conditions and take precautionary measures against risks

-The Company has developed a function that enables cars to take pre-emptive action against potential driving risks. To achieve a new level of safety on the way to Vision Zero, the vision of accident-free driving, the Company is now networking several well-established technologies. The Road Condition Observer uses systems already present such as ESC and cameras, to continuously transmit friction coefficient data in near-real time to the cloud, where information on the friction coefficients of other vehicles as well as weather data are also collected. eHorizon processes the cloud data collected from the entire vehicle fleet with the aid of artificial intelligence and other technologies. This information from eHorizon is fundamental to PreviewESC, which adapts the vehicle’s speed to current road situations. In addition to PreviewESC, new functions will be possible in future with the aid of eHorizon. The eHorizon is a building block of V2X communication and extends and supports V2V communication by providing better coverage and full functionality to enhance safety. (From a press release on July 31, 2019)

Intelligent Glass Control update

-The Company is enhancing and refining its Intelligent Glass Control technology by connecting car windows with the on-board computer. The Company is using an innovative technology that is suitable for all windows and significantly increases the potential of glass control. Intelligent Glass Control uses special films that are integrated into the glass and can change their degree of translucency through electrical control signals, which offers various benefits when it comes to thermal management and privacy. The technology can also improve adaptive camera systems and transform window screens into smart displays with a range of touchscreen elements. (From a press release on July 25, 2019)

Third-generation of power electronics

-The Company has developed the third generation of power electronics. The system’s central component is the power module, which enables currents of up to 650 amps. The new power electronics is used in an electric SUV of a European manufacturer in a configuration that processes these high currents, providing outstanding driving performance. The technological highlight of the power electronics is the sintering technology. Microchips are sintered on both sides in the power module, offering major gains in terms of service life, reliability and thermal capacity. The Powertrain division is using sintering technology for the first time in automotive electronics. The third generation delivers six times the performance of the first, while its weight has been reduced from 12 kg to 8 kg. (From a press release on July 22, 2019)

Adaptive voice-activated digital assistant

-The Company announced that it has developed an adaptive voice-activated digital assistant for driver assistance and infotainment systems. The smart voice assistant offers a number of key benefits, such as the seamless transition between various function menus. Another benefit is the system’s ability to infer meaningful connections without being restricted to standard command words and phrases. The digital assistant is also capable of learning, and optimizes a user’s profile with each interaction. The smart voice assistant is a hybrid solution comprising a cloud-based, voice-activated digital companion and in-vehicle natural voice recognition system. Another benefit is that the new assistant can coordinate with similar systems from other providers, allowing users to call up content, apps and files from work or home while in the car. (From a press release on July 18, 2019)

HD headlamp system

-OSRAM Continental, a joint venture between the Company and Osram, will present an innovative HD headlamp system at the Continental TechShow 2019. The system is based on SMARTRIX-HD technology with a high number of individually controllable pixels. It consists of EVIYOS LEDs and appropriate control electronics integrated onto a single printed circuit board. This allows the pixels - 1,024 pixels per chip – to be individually controlled by the electronics. The compact design offers advantages for the design of the headlamps and offers vehicle manufacturers far-reaching design options for the front of the vehicle. The system is also equipped with a laser auxiliary high beam with a 600-meter range. The HD headlamp system can be coupled with the sensors of other driver assistance systems. (From a press release on July 2, 2019)

48V hybrid drive system

-The Company has developed a 48-volt hybrid system that boasts features similar to those of a high-voltage electric drive. It reduces fuel consumption and CO2 emissions by approximately 20% compared to similar vehicles with combustion engines. The key component here is a new, water-cooled electric motor, the peak output of which was doubled to 30 kW versus the old motor. Electric-only driving is therefore possible at a speed range of 80 to 90 km/h. The integrated power electronics also uses a new technology that enables it to handle significantly higher currents. During recuperation, the losses in the electric drive system have been halved. The innovations of the new 48-volt high-power technology result in a level of electrical efficiency that surpasses the previous system by almost 10%. The 48-volt system requires considerably less effort in terms of insulation protection, features smaller and less expensive electrical components, and utilizes a design that can be made significantly more compact, as smaller gaps are required between the individual components than is the case with high-voltage technology. (From a press release on July 2, 2019)

Technologies showcased at IAA 2019

-The Company will be presenting numerous innovations that reflect the three major trends of the industry summit, all under the tagline of “Mobility is the Heartbeat of Life.” The Company will focus on the themes of zero accidents, zero emissions and zero stress at IAA 2019. The Company’s electric axle drive weighs less than 80 kg and includes an electric motor, transmission, power electronics, and motor control. The Company will present a production-ready radar system specifically developed for driverless vehicles. A total of seven radar sensors, each with a range of up to 200 meters, continuously monitor the vehicle environment. The Company’s connectivity experts are combining the features of fifth-generation cellular communications with technologies for short-distance radio for direct data exchange between different vehicles and the infrastructure. The Company is also working on an adaptive voice-activated digital companion that reacts to natural speech and is precisely adapted to vehicle conditions. Another system shown is a 48-volt high-power drive system with 30 kilowatts of output, enabling long-distance drives purely on electric power for the first time. Previously, this was only possible using high-voltage drive systems, but not with 48-volt technology. (From a press release on July 1, 2019)

77 GHz short-range radar

-The Company has unveiled a new short-range radar which represents the next development stage towards more precise detection of vehicle surroundings. The new radar generation operates using 77 GHz technology. It detects movement directions and speeds more precisely than 24 GHz radars. One of the new radar sensors can be positioned at each of the four corners of the vehicle body to ensure almost seamless 360-degree monitoring of the vehicle’s surroundings. This technology enables Right-Turn Assist systems for passenger cars, which makes turning significantly safer and provides welcome support for car drivers, especially in situations that sometimes occur in urban traffic. The radar will also form the basis for other advanced driver assistance systems in the future especially in relation to automated and autonomous driving. Emergency Steer Assist, for example, allows the vehicle to be steered away from collision risk areas. (From a press release on June 25, 2019

Ultra-compact high-performance HUD

-The Company announced that it has developed the first ultra-compact, high-performance head-up display (HUD) in a project spearheaded by its own development and production service provider, Continental Engineering Services. The HUD is particularly suitable for integration into cockpits with limited installation space, such as in sports cars. It allows for reliable visualization of information in the driver’s field of vision, which makes it intuitive and safe to use. By optimizing the virtual image size visible to the driver in the windshield and modifying the projection distance, the developers have succeeded in significantly reducing the space taken up by the HUD. (From a press release on June 17, 2019)

Natural 3D Lightfield Instrument Cluster

-The Company is developing an innovative cockpit solution, the Natural 3D Lightfield Instrument Cluster, in cooperation with Silicon Valley company Leia. The new system is expected to begin series production by 2022. Lightfield displays are the next generation of display medium not only allowing the comfortable perception of 3D depth, but also the rendering of highlights, sparkles and other complex light effects. Passengers in the front and back seats can also clearly see the same 3D image from their seated positions. The 3D-image produced by the Lightfield display is made up of a total of eight perspectives of the same object that subtly vary according to the point-of-view. (From a press release on June 11, 2019)

EB cadian Sync toolchain for OTA software and firmware updates

-Elektrobit (EB), a Company subsidiary, announced that it will be demonstrating EB cadian Sync, a scalable, flexible and secure toolchain for software and firmware updates over the air at CES Asia. It enables car makers to offer upgradeable vehicles that allow them to continuously improve vehicle functions and react quickly to security issues. In addition, car makers can provide updated features at any time during the vehicle’s life. (From a press release on June 11, 2019)

CAirS air suspension system solution

-The Company exhibited its all-new electric air suspension system solution at CES Asia 2019. The new air supply system, Continental Air Supply (CAirS), is an electric air suspension system for improved driving dynamics control. It is suitable for electric and autonomous vehicles due to its quiet and efficient operation. The system also enhances the stability of vehicles and is capable of controlling vehicle height efficiently to reduce energy consumption. It will meet the needs for lighter vehicles and electric vehicles in China. (From a press release on June 11, 2019)

Technologies showcased at CES Asia 2019

-The Company will exhibit solutions and key technologies for intelligent mobility at CES Asia 2019 in Shanghai. The exhibit includes a new glassless 3D instrument, an augmented reality head-up display (AR-HUD) system, and an electric vehicle built on a driverless driving technology development platform called the CUbE. The CUbE stands for Continental Urban mobility Experience and is a driverless vehicle. It will be shown in China for the first time. Also, the Company will display cameras, a roadside unit, an intelligent street light and road-to-vehicle coordination technology between pedestrians and the CUbE. These technologies will enable participants to have first-hand experience of future intersections with improved safety and efficiency. (From a press release on June 6, 2019)

Technologies showcased at Electric Vehicle Symposium