Search Results by Category

AI Navigator

AI NavigatorAll information related to {{ key_word }}.

AI Navigation will guide you. Click here for information about {{ key_word }}.

1

1

2

2

1

1

2

2

2

2

2

2

2

2

1

1

1

1

2

2

1 - 20 of 33 results

Resonac Holdings Corporation (Formerly Showa Denko K. K.)

ng concept Laminated cooler Battery cooling device Showa Denko Battery Cell Materials Aluminium laminate film SPALF Anode Binder POLYSOL LB Series Additive material for electrode VGCF-H Ready-to-fit power module solution Benefits: - high reliability - long life - low electric resistance - weight & cost reduction -Water-cooled type heat dissipation solution based on aluminium technologies. Applications: Power semiconductor cooler for EV, EV batte...

Search Suppliers Updated at: 2025/08/04

SHW AG

from SHW are designed for 12V to 48V on-board systems and consist of a hydraulic component (the pump), an electric motor and a control unit and associated software, which can be connected with other control units in the powertrain via a CAN or LIN bus interface. Modular design concept allowing the reduction of the total amount of electric water pumps in BEVs/PHEVs [Technical data] Motor-Type: dry-run brushless DC electric motor, Control: Integra...

Search Suppliers Updated at: 2025/06/30

Hikari Seiko Co., Ltd.

without power loss. (photo courtesy of Hikari Seiko Co., Ltd.) Spider parts for small universal joints used in steering shaft joints (photo courtesy of Hikari Seiko Co., Ltd.) Various parts that comprise the engine, also said to be the heart of the vehicle. Excellent in terms durability and weight reduction. (photo courtesy of Hikari Seiko Co., Ltd.) Automatic transmission parts that are required to be of high-precision to achieve smooth shifti...

Search Suppliers Updated at: 2025/05/19

BYD Electronic (International) Co., Ltd.

-house production of all processes from design/simulation, mold design to mass production. -Dual chamber stiffness adjustment valve: adjusts the stiffness of the air spring through changing the volume of the air chamber of the air spring. -Pressure-retaining valve: convenient connection method, low cost, light weight, and long life characteristics. -Friction-resistant and high-temperature resistant materials, characterized by high sensitivity an...

Search Suppliers Updated at: 2025/02/20

Dai Nippon Printing Co., Ltd.

teriors, considering interiors other than coatings as well as interior decorations for next-generation mobility, using the Company's printing technology cultivated over many years. The Company can propose the most suitable interior surface design from several variations in consideration of design, cost, and performance. The Company achieves futuristic seamless design by integrating high quality decoration and optical capability for display/switc...

Search Suppliers Updated at: 2025/02/20

Kolon Glotech, Inc.

ermeability -Thermal resistance -Impact strength at low temperature -Material: PP + LGF (long glass fiber) Features: -Low shrinkage -Lightweight -Material of composite part: PA6 + GF60 woven fabric -Material of injection part: PA66 +SGF (short glass fiber) Features: -Steel replacement -Parts number reduction (8ea-->5ea) -28% lighter -Material: Para-Aramid (pulp) + others -Process: press Features: -Highly fibrillated -Asbestos replacement -Eco-fri...

Search Suppliers Updated at: 2025/02/19

Mitsubishi Chemical Corporation

Engineering Exposition 2019 SAE-China Congress & Exhibition JEC World 2022 JEC World 2023 The Battery Show North America 2023 Epoxy Firm(development) Lithium-ion battery pack material Plastic Optical Fiber Wavelength selective polycarbonate Insulations for HV, EV Motors Metal Appearance Part Weight Reduction of Automobile Parts by Prepreg Comression Molding (PCM) Technology Weight reduction of automobile parts by Shield Molding Compound (SMC) Lig...

Search Suppliers Updated at: 2025/02/13

Asahi Kasei Corp.

passenger battery electric concept vehicle highlighting technology developed by the Company's subsidiaries including lithium-ion battery separators, lead-acid battery separators, in-vehicle sensors to detect carbon dioxide in the cabin or alcohol on a driver's breath, plastics for increased weight reduction, artificial leather and suede for increased comfort, and electromagnetic noise suppression sheets. - MEF is a material for weight and noise...

Search Suppliers Updated at: 2025/02/12

Yura Tech Co., Ltd.

nical relay. Improved system performance with faster response. Can reduce size and weight of system. High-performance, high-precision drive motor rotation angle sensor that integrates e-Resolver and Shaft Grounding Ring (2 in 1 design). High-speed and high precision, compact and lightweight, system cost reduction, robust electromagnetic wave design, ISO26262 functional safety standard compliant. Scheduled to be installed in Hyundai vehicles in 20...

Search Suppliers Updated at: 2025/02/12

Marui Industrial Co., Ltd.

powder is deposited on it. Emblems created without plating or painting The molding color alone can produce color and luster that is comparable to painting or plating. Two-tone molding can also be used to create complex coloring. No surface treatment, plating, or painting is required, which leads to cost and CO2 reduction. In addition to various plating samples, emblems such as those for the Honda Civic Type R and Toyota Alphard were on display. E...

Search Suppliers Updated at: 2025/02/12

LEONHARD KURZ Stiftung & Co. KG

ooden floor console panel Shy Tech steering wheel controls Functional dashboard design Overhead light console with GoBo projection Smart Crystal Steering Wheel Advanced lighting design Wallbox design concept Smart 3D interior control panel concept Lightweight door trim and shy tech IP panel concept Cost-effective plastic display panel Smart Crystal Steering Wheel Front panel concept Advanced front End Design Rim insert with holographic Carbon Des...

Search Suppliers Updated at: 2025/02/05

L&L Products Inc.

technology that combines high engineered heat-activated structural adhesive material with a thermoplastic carrier for lightweight and strong structural applications. -Developed in partnership with BASF, used in the 2022 Toyota Tundra. -It is a CCS (Continuous Composite System) and provides weigh reduction and cost reductions by 20%. The overmolded pultrusion increases impact, strength and rigidity of the back from by 60%, as the pultrusion can...

Search Suppliers Updated at: 2025/02/05

LANXESS AG

ponents and battery covers. -The battery tray is based on polyamide 6 and is also produced via hybrid molding using Tepex dynalite 102-RG600 and the highly reinforced compound Durethan BKV60H2.0EF. -Material: TEPEX semipreg -Roving glass weaving Advantages: -Mass production due to short cycle time -Cost-cutting integration of functions -Weight reduction up to 5kg compared to steel -Thin-wall technique: significant thickness reduction compared to ...

Search Suppliers Updated at: 2024/07/22

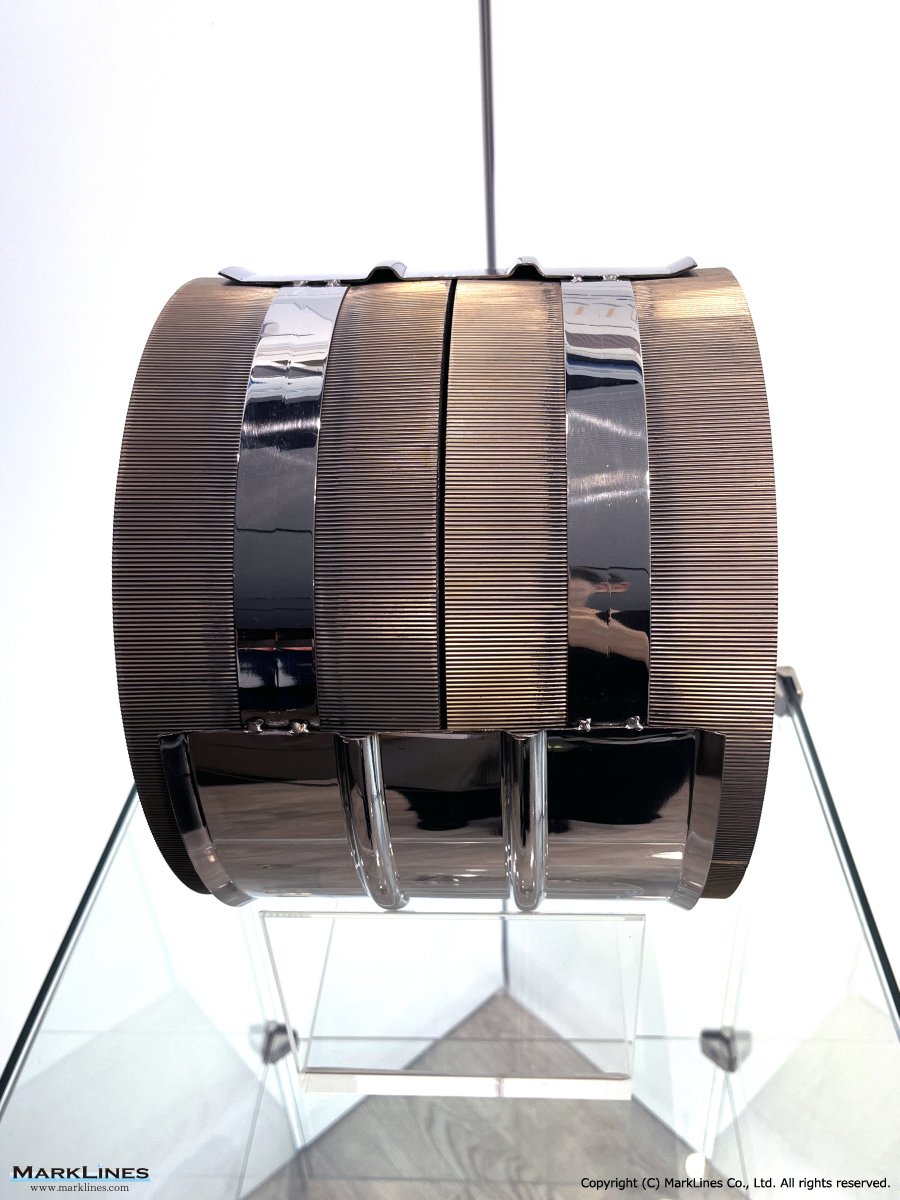

Kanemitsu Corporation

is possible to increase or decrease the thickness in different areas of the product and strain hardening makes it possible, even with thin shapes, to satisfy the necessary functions and reduce the weight. In addition, this process is characterized by the elimination of machining processes to reduce costs and creation of surface gloss to improve the roughness of the product surface. -Press forming technology that increases or decreases the thickne...

Search Suppliers Updated at: 2024/05/31

Fuji Electronics Industry Co., Ltd.

casing on the cam tops and bottoms, preventing cracking during grinding caused by uneven casing. (photo courtesy of Fuji Electronics Industry Co., Ltd.) Our original coil and machine designs achieve low runout of long workpieces such as ball screws and linear guide rails and contribute to workload reduction in grinding. (photo courtesy of Fuji Electronics Industry Co., Ltd.) Uneven heating and quenching can cause cracking during gear hardening....

Search Suppliers Updated at: 2024/04/05

Minamida Co., Ltd.

ng shaft construction method conversion Cold forged hollow shaft Bolt material conversion Deformed nut, hydraulic parts and tie rods construction method conversion Large nut construction method conversion CVT shaft and flange collar process conversion Hollow bolt to reduce weight High precision and cost reduction by conversion of manufacturing method (extrusion ⇒ cold forging) Cost reduction by conversion of construction method (vertical press ...

Search Suppliers Updated at: 2024/01/18

IO Industry Co., Ltd.

e same time in the same mold and complete the assembly in the mold. By controlling the gate layout and molding conditions, there is no need to adjust the operating force in the subsequent process. It is possible to integrate different colors and integrate different materials in the molding process. Cost: 55% reduction. The thin-walled folded plate and even arrangement of the cross ribs at the apex provide rigidity equivalent to or greater than th...

Search Suppliers Updated at: 2024/01/16

Victrex plc.

Engine peripherals made with PEEK VICTREX PEEK Gear Solutions VICTREX PEEK Electrical Insulation for E-Motors VICTREX PEEK High Speed Bearing Cage VICTREX PEEK Slide Bushing for Electric Water Pump VICTREX PEEK for Powertrain and Brake Applications -PEEK film for electrical insulation enables both cost-effective and high output motors. >>>Product information -Contributing to weight and NVH reductions with the use of polymers for powertrain gears...

Search Suppliers Updated at: 2023/08/10

Matec Co., Ltd.

anufacturing process: Hot forging → Cutting Right - Material: Carbon steel SC,Manufacturing process: Cold forging Hot forging of stainless steel as shown above as well as hot and cold forging of iron is possible. After forging, the Company can also perform cutting operations. -The Company offers cost reduction by cold forging net shape processing and can handle both parts formers and presses. In addition to forging rough materials, the Company...

Search Suppliers Updated at: 2023/04/20

Ezaki Industrial Co., Ltd.

ents of the adopted model. Bending accuracy is required for proper flow and to avoid oil accumulation. Utilizing the company’s pipe welding and processing technologies, production of products of various shapes are possible in combination with sheet metal stamping and deep drawing. In some cases, cost reduction can be achieved by changing from cast products to press-welded products. ISO14001 ISO9001 IATF16949 (Formerly ISO/TS16949)...

Search Suppliers Updated at: 2022/08/18

AI Navigator

AI Navigator

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India