Archives of Past Exhibits:Calsonic Kansei

Tokyo Motor Show 2017

2017 JSAE Automotive Engineering Exposition

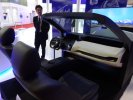

Shanghai International Automobile Industry Exhibition 2017

2016 Shanghai International Auto Parts and Service Exhibition

2016 JSAE Automotive Engineering Exposition

2015 JSAE Automotive Engineering Exposition

Shanghai International Automobile Industry Exhibition 2015

China Auto Parts And Service Show 2014

2014 JSAE Automotive Engineering Exposition

JSAE 2013

| Instrument clusters | Instrument clusters | ||

|

Installed vehicle: Nissan "Fairlady Z" |

|

Installed vehicle: Nissan "GT-R" |

| image |  |

image | |

| Instrument clusters | Instrument clusters | ||

|

Installed vehicle: Nissan "Cima", "Fuga" Infiniti "M37/M56" |

|

Installed vehicle: Nissan "Patrol" Infiniti "QX56" |

| image | image | ||

| Instrument clusters | Instrument clusters | ||

|

Installed vehicle: Nissan "Sylphy" (Country of production: China, Thailand, Mexico) |

|

Installed vehicle: Nissan "NV350 Caravan" |

| image | image | ||

| Instrument clusters | Instrument clusters | ||

|

Installed vehicle: Nissan "Latio", "Sunny", "Almera", "Versa" (Country of production: China and Mexico) |

|

Installed vehicle: Nissan "March/Micra" (Country of production: Mexico) |

| image | image | ||

| Instrument panels | Instrument panels | ||

|

Installed vehicle: Nissan "Sylphy" |

|

Installed vehicle: Nissan"Fuga" |

| image |   |

|

|

| Instrument panels | Inverter | ||

|

Installed vehicle: Nissan "Note" |

|

Installed vehicle: Nissan "Leaf" |

|

image image |

|

|

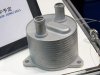

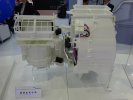

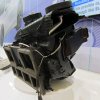

| Battery Controller | Compact Battery Cooler | ||

|

Installed vehicle: Nissan "Leaf" |

|

-Under development |

| image image |  |

image |  |

| Hot-water sheathed heater for high voltage | High performance EGR cooler for Petrol engine | ||

image |

-Under development |  |

-Under mass production readiness |

|

|

||

| High performance mixing device for urea SCR system | Super Heat Resistant Exhaust Manifold | ||

|

-Under development |  |

-Resistance to heat of 1050℃/resistance to oxidization -Under development |

| image image |  |

image |  |

| Brushless Motor for HVAC & Battery Cooling | Small Fixed Displacement Compressor | ||

|

|

|

Installed vehicle: Suzuki "Palette" (CR06) |

| image image image |

image image image |

|

|

| Rotary Compressor | Comfortable air-conditioning unit of tri-zone | ||

|

|

|

|

| image | |||

FISITA 2012 World Automotive Congress (Beijing)

| GTR Front end module | Single layer integrated cooling module | ||

|---|---|---|---|

|

|

||

| Image | Image | ||

|

|||

| Compressor | Compressor | ||

|---|---|---|---|

|

|

||

| Image | Image | ||

|

|

||

| Spinning muffler | Muffler (rear) | ||

|---|---|---|---|

|

|

Installed vehicle: Nissan "Teana" |

|

| Image | Image | ||

|

|||

| Muffler (front) | Injection skin | ||

|---|---|---|---|

|

Installed vehicle: Nissan "Teana" |

|

|

| Image | Image | ||

|

|||

China Auto Parts and Service 2012 Show 2012

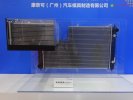

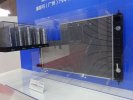

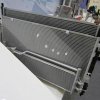

| Engine cooling module | 12NMFC type condense | ||

|

Installed vehicle: Dongfeng Nissan Leaf |

|

|

| Image | Image | ||

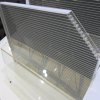

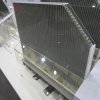

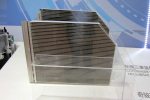

| Water cooling type EGR-cooler | Charge air cooler | ||

|

|

||

| Image | Image | ||

| Front end module | Lightweight cockpit module | ||

|

Installed vehicle: Dongfeng Nissan X-rail |

|

Installed vehicle: Nissan Teana |

| Image | Image | ||

| Air conditioner | Air conditioner | ||

|---|---|---|---|

|

Installed vehicle: Dongfeng Nissan Teana |

|

Installed vehicle: Dongfeng Nissan Sunny |

| Image | Image | ||

| Instrument panel assembly | |

|---|---|

|

Installed vehicle: Nissan new Sylphy |

| Image | |

| 40D evaporator | Slide door | ||

|---|---|---|---|

|

|

||

| Image | Image |

| Compressor | Heat core | ||

|---|---|---|---|

|

Installed vehicle: Dongfeng Nissan Sunny |

|

Installed vehicle: Dongfeng Nissan Sunny |

| Image | Image | ||

| Lithium battery control Leaf | Brushless motor | ||

|---|---|---|---|

|

Installed vehicle: Nissan Leaf |

|

Installed vehicle: Dongfeng Nissan Teana |

| Image | Image | ||

| Integrated controller | Integrated controller | ||

|---|---|---|---|

|

Installed vehicle: Nissan Fuga |

|

Installed vehicle: Nissan Sunny |

| Image | Image | ||

| Exhaust system | Two gate stage valve | ||

|

Installed vehicle: Dongfeng Nissan Teana |

|

|

| Image | Image | ||

JSAE 2012

| Triple Display Analog Meter | Advanced HMI Concept | ||

|

|

|

|

| Battery Thermal Control Unit | Exhaust Heat Recovery Device | ||

|

|

|

|

| Integrated Cooling Module | Activity for climate control system of future eco-car | ||

|

|

|

|

| Injection Skin | Comfortable air-conditioning unit of tri-zone | ||

|

|

|

|

| image | |||

| Small Fixed Displacement Compressor | Built-In Oil Cooler & Warmer | ||

|

|

|

|

| Radiator | High performance EGR cooler for Petrol engine | ||

|

|

|

|

| image image |

|||

| Highly Efficient Fan Blade | |||

|

|

||

2012 Beijing International Automotive Exhibition

| Brushless motor | Body control module | ||

|

Installed vehicle: Dongfeng Nissan Teana |

|

Installed vehicle: Dongfeng Nissan Sunny |

| Image | Image | ||

| Meter | Meter | ||

|

Installed vehicle: Dongfeng Nissan Sunny |

|

Installed vehicle: Dongfeng Nissan TIIDA |

| Image | Image | Image | |

| Cockpit module and console | Cockpit module | ||

|

Installed vehicle: Dongfeng Nissan Teana |

|

Installed vehicle: Dongfeng Nissan Sunny |

| Image | Image | ||

| Exhaust system | Rear air conditioner | ||

|

Installed vehicle: Dongfeng Nissan Teana Sylphy |

|

Installed vehicle: Nissan Elgrand |

| Image | Image | ||

| Compressor | Compressor | ||

|

Installed vehicle: Nissan Renault Megane |

|

Installed vehicle: Dongfeng Nissan Sunny |

| Image | Image | ||

| Evaporator | Heat core | ||

|

|

Installed vehicle: Dongfeng Nissan Sunny |

|

| Image | Image | ||

| Slide door | Radiator | ||

|

|

||

| Image | Image | ||

| Condenser | Radiator for EV | ||

|

|

||

| Image | Image | ||

| Charge-air cooler | Front-end module | ||

|

|

Installed vehicle: X-Trail |

|

| Image | Image | ||

2012 Delhi Auto Expo (India)

| Radiator 16 Core | Switch | ||

|

|

Installed Vehicles: Nissan "JUKE" |

|

| imageimage | |||

| Lightweight Exhaust Manifold | Console | ||

|

|

Installed Vehicles: Nissan "JUKE" |

|

| Keyless Entry & Push Button Start | |||

|

|||

JSAE 2011

| Low reflection hard Instrument panel | Small siza and high performance HVAC | ||

|

Installed vehicle : Nissan MARCH |

|

Installed vehicle : Nissan JUKE (Europe) |

|

Image |  |

|

| Image | |||

| High-function Air Filter | White meter | ||

|

Under development |  |

Installed vehicle : Nissan TIIDA |

|

|

||

| Basic meter | Variable displacement compressor | ||

|

Installed vehicle : Nissan MARCH(for Mexico) |

|

Installed vehicle : Nissan SKYLINE Infiniti EX35, FX35 and others |

|

|

||

| Variable displacement compressor | Variable displacement compressor | ||

|

Installed vehicle : Suzuki ESCUDO, KIZASHI |

|

Installed vehicle : Nissan SYLPHY, TIIDA |

|

|

||

| Fixed displacement compressor | Fixed displacement compressor | ||

|

Installed vehicle : Suzuki MR Wagon, Pallet |

|

Installed vehicle : Nissan MARCH, JUKE |

|

|

||

| Fixed displacement compressor | Valve for controlling exhaust | ||

|

Installed vehicle : Renault/Samsung SM3 |

|

Mass production |

|

Image |  |

|

| Exhaust heat recovery device | SLIM(Single Layer Integrated cooling Module) | ||

|

Under development |  |

Under development |

| Image |  |

Image |  |

| Built-In Oil Cooler & Warmer | Electric Power Unit Cooling Module | ||

|

Mass production in preparation |  |

Mass production |

| Image |  |

Image |  |

| EV Inverter | Battery Controller | ||

|

Mass production |  |

Mass production |

| Image |  |

Image |  |

| Image | |||

| Image | |||

| Double variable display meter | 3D Meter | ||

|

|

|

|

| Image | |||

| Variable display switch | |||

|

Installed vehicle : Nissan JUKE |

||

| Image |  |

||

2011 AUTO Shanghai

| Air condition switch | Air condition switch | ||

|---|---|---|---|

|

Installed in the Nissan FUGA |  |

Installed in the Nissan JUKE |

| Image | Image | ||

| Meter | Meter | ||

|---|---|---|---|

|

Installed in the Donfeng Nissan TEANA |  |

Installed in the Zhengzhou Nissan NV200 |

| Image | Image | ||

| Cockpit module | Front end module | ||

|---|---|---|---|

|

Installed in the Donfeng Nissan Sunny |  |

Installed in the Nissan X-Trail |

| Image | Image | ||

JSAE 2010

| New soft feeling instrument panel | PCB harness | ||

|---|---|---|---|

|

|

|

|

| Image Image |

Installed in the Nissan Fuga | Image Image Image Image |

|

| Small and light HVAC | Module HVAC | ||

|---|---|---|---|

|

|

|

|

| Image Image Image Image |

Image Image Image |

Installed in the Renault Fluence | |

| Dual air cond + cool box | |||

|---|---|---|---|

|

|

||

| Image (FR HVAC) Image (FR HVAC) Image (FR HVAC) Image (FR HVAC) |

Image (RR HVAC) Image (RR HVAC) Image (Cool box) Image (Cool box) |

||

| Installed in the Nissan Patrol | |||

| Variable displacement compressor | Fixed displacement compressor | ||

|---|---|---|---|

|

|

|

|

| Image Image Image |

Image Image Image Image |

Image Image Image |

|

| Slim-type radiator | Slim-type condenser | ||

|---|---|---|---|

|

|

|

|

| Image Image |

Image Image |

||

| Built-in oil cooler & warmer (Φ85) | |||

|---|---|---|---|

|

|

||

| Image | |||

| Multi functional cluster meter | High visibility cluster meter (High intensity type) |

||

|---|---|---|---|

|

|

|

|

| Image | Installed in the Nissan NV200 | Image | Installed in the Nissan Fuga |

| Power saving & dehumidification heat pump system | |||

|---|---|---|---|

|

|||

| Image Image (Evaporator) Image (Inner condenser) Image (PTC heater) Image (Electric driven compressor) |

Image (3 way valve) Image (3 way valve) Image (Accumulator) Image (Solenoid valve) Image (Check valve) |

||

JSAE 2008

| Cockpit module for Nissan Murano | |||

|

Image | ||

| Lightweight exhaust manifold | |||

|

|

||

| Image | |||

| Perforated Metal substrate (On display for reference) | Spun converter | ||

|

|

|

|

| Image | Image 1 Image 2 |

||

| EGR Cooler | Built-in Oil Cooler & Warmer Series | ||

|

|

|

|

| Image 1 Image 2 |

Image | ||

| HVAC | |||

|

|

||

| Image | |||

| Compressor Line up |  |

||

| Variable Displacement Compressor | Fixed Displacement Compressor | ||

|

|

||

| Image | Image | ||

| An electric driven compressor for Hybrid vehicles and electric vehicles | |||

|

|

||

| Image | |||

| Thermal Energy Management (On display for reference |

|

||

| INST PAD with Negative Vacuum Forming skin | |||

|

|

||

| Image 1 Image 2 |

|||

| High visibility meter (High intensity type) |

High visibility meter | ||

|

|

|

|

| Image | Image | ||

| BCM(Body Control Module) | Airbag Control Unit | ||

|

|

|

|

| Image | Image | ||

JSAE 2007

| Skyline Cockpit-Module | Skyline Front-End-Module | ||

|

Aim: -Increase layout efficiency and design flexibility -Reduce weight -Improve quality due to fewer parts -Increase sharing among E-segment models |

|

|

| Image | Image | ||

Eco-friendly technologies: Improved recycling and dismantling performance of all-aluminum unified condenser and radiator. Improved purification performance of emissions by metal substrate |

|||

| New Structure metal substrate | |||

|

|

Image (Foil) Image (Corrugation) Under development |

|

| New Motor Fan | |||

|

|

Image Image |

Installed on Skyline in Japan, and Altima in North America |

| Unification of Condenser & Radiator | |||

|

|

Image | -Aluminum radiator tank -Unitized forming of fins made possible. -Installed on Nissan Skyline |

| LINK structure | |||

|

|

Image | -Installed on Nissan Sylphy, and also adopted by BMW |

| Condensed information display in the meter to improve visibility for safety when switching from head-up display | |||

| ALTIMA Meter | |||

|

|

Image | |

|

Development of head Up Display |

Airbag Control Unit | ||

|

|

-Accounting for70 to 80% share in Nissan's airbag products | |

JSAE 2006

<Highlights>

Exhibits included front end modules, cockpit modules, and their components.

Cold catalyst filter ![]()

The filters achieved a high level of performance in terms of their deodorization features through the application of catalyst technology. The recommended period for replacement has been extended to two years from one year. >>Technical Information

Dual air conditioning mounted in Nissan's new Serena

-Integrated, compact and high-performance HVAC system: The company integrated the blower, heater and cooler to make the unit more compact

-Adopted dual air conditioning ![]() system

system

-This system is based on dual piping for air conditioning and on a heater for the rear: The Company was able to reduce the number of pipes to two from four, the standard number in conventional systems, and thus create more room. The Company plans to further reduce the size of this HVAC unit, setting a target of 30% for the next model which will launch between 2008 and 2010.

Tokyo Motor Show 2005

<Σ12 Cockpit Module Concept>

The Company exhibited a concept model, which is designed to improve interior comfort and facilitate the ease in operating switches and display systems. The following technologies, which the Company developed, were installed.

Reflection-Type LCD Meter

Scanning HUD >>Technical Information

Dichromatic Indication Technology: Dichromatic technology enables two different characters to be displayed in the same display area through the use of two luminescence sources. (Audio Climate)>>Technical Information

-Next Generation Motor Assisted Shift for Automatic Transmission >>Technical Information

<MODULE>

The Company exhibited their concept model, installing a front end module, a cockpit module, (being installed in the Nissan Fuga), an exhaust system, and a compressor.

*The Company's the front end module is designed to reduce the number of component parts by 50% and reduce weight by 20%.

<HEAT EXCHANGER>

Condenser, Radiator

Unification of Condenser & Radiator >>Technical Information

Inter Cooler >>Technical Information

<Room and Air Conditioning>

HVAC Unit (Installed in Nissan FUGA) >>Technical Information

Dual A/C (Installed in Nissan SERENA) >>Technical Information

-Adoption of Double layers piping system

Automatic Air conditioner >>Technical Information

Cold Catalytic Filter >>Technical Information

<Compressor>

Fixed Compressor (being supplied to Suzuki, Daihatsu, Subaru, Mazda, Nissan and Isuzu) >>Technical Information

Variable Compressor (being supplied to Renault, BMW, GM-Holden, Nissan, VW, Honda, Opel, Nissan Diesel) >>Technical Information

<Environment>

The Company displayed a Co2 Air-Conditioning System, EGR Cooler, Dual Spun Converter. >>Technical Information

<Electronics , Instrument>

Motor Assist Automatic Transmission (Installed in Nissan LAFESTA and SERENA) >>Technical Information

High-Value Added Multifunctional Meter >>Technical Information

Body Control Module (BCM) >>Technical Information

Occupant Detection System (ODS) >>Technical Information

*This products is designed for the US market.

New Airbag Unit >>Technical Information

Airbag Control Unit

Tokyo Motor Show 2004

<Features>

1. Lightweight and thin instrument panel with the use of small HVAC unit.

2. New operating and display system using next generation control devices.

3. The cockpit has been laid out into the driver's area and comfort area that follows the driver to drive at will and passengers to relax in comfort.

<Driver's Area>

It has become possible to input all driving functions directly. The driver is able to concentrate on driving stress-free as the cockpit layout has been designed so that all driving operations are within natural reach of the hands, thus contributing to the enhancement of safety of safety for people in the vehicle.

Steering Module

-Switch design is used where the switches are laid out in the order of the functions most frequently used during a drive.

-Steering angle has been markedly reduced, allowing the driver to operate the car with the minimum of turning angle.

-The incorporation of trigger-type accelerator in the steering wheel allows the driver to control acceleration with the index and middle fingers of both hands, while the traditional method of applying the brakes is done by the right foot.

-Combination switch functions have been arranged on the handle surface.

Vertical Meter

-The driver's downward field of vision has been reduced with the use of remote and large-scale indicator.

-The visible area for the meter has been expanded by lowering the handle.

-Night vision is also displayed in the meter.

Electronically Controlled A/T Shifter

-The shifter generates optimum handling torque based on ergonomics.

<Comfort Area>

-Functional switches that are infrequently used during driving and those that can be operated by the passengers have been placed in the instrument center and the console section. This feature provides comfortable driving to both the driver and passengers.

Centralized Switch Panel

-Centralized control switches are adopted in the center panel designed to allow the driver finger-tip control of air conditioner and audio system.

Pointing Device

-A new centralized control switch (pointing device) has been incorporated in the console section which uses a sensor to detect an approaching hand and allowing the driver to place his hand and easily operate the air conditioner, auto system and navigation system.

-This device enables driving without forcing the driver to alter his posture.

-The pointing device is made in symmetrical design so that systems can be operated by the driver as well as the passengers.

Agent Function for Aiding Drive

-The Company has incorporated a system that acts like the driver's secretary who gives the driver appropriate advice with the use of voice synthesizing technology and artificial intelligence.

CPM Core Module

<Features and Aims>

The Company is continuously studying the most efficient layout for the steering member, HVAC unit, and the AC duct which the Company considers to be the core module. Specifically, for Nissan's Fuga, the Company uses a magnesium die-cast steering member that benefited in allowing the following:

Light weight: 25% less weight then the normally used steel steering member.

Space efficient: AC duct can be included within the member.

Less number of parts (integrated die-cast molding)

CO2 Air-Conditioning

<Aims>

Natural Gas

-Natural (not artificial)

-No toxicity and Non-flammable

Reproduced Material

-Reuse of CO2 discharged by the factory

Prevent Global Warming

-Very Small Global Warming Potential 1/1300 of that of HFC 134a

Auxiliary Heating

-The refrigerant is suitable for heat pump cycle

<Feature>

-Operating pressure is about 7 times the current refrigerant

-Special cycle exceeding the critical point

-Thermal properties that lowers efficiency in hot conditions

All-in-one, Compact & Light Weight HVAC Module

<Aims>

1. Compact HVAC module for CPM space utility

2. High performance & Ultra-light

3. Common use (Sedan - MPV & R/H/ L/H)

<Development Sample>

High performance & Low-Noise Compact 3-D Scroll & Fan

High performance Thin & Compact Evaporator

Slide Type Air / Mix Door Cartridge

Compact Distribution Door Module

High performance Thin & Compact Heater Core

Externally controlled Compressor

-Externally controlled compressor provides lower fuel consumption compared with a fixed capacity compressor.

-Capacity is varied by the electrical signal of external control system.

<Aims>

Light weight (-20% with Plastic Pulley)

Saves electric power consumption (-75%: from 40W to 10W)

Vane Rotary Compressors

-Vane Rotary Type compressor uses engine power directly without converting rotation energy to piston movement, which makes the Vane Rotary Compressor high performance.

-By adopting the simple structure and design, vane rotary compressor achieves less parts, small size and light weight.

Body Control Module

<Features>

-Reduction of wire harness by using CAN communication - The wire harness between the cabin and the engine room has been eliminated

-More value-added by adopting in combination switch signal

-Combined lamp and hazard functions

-Combined head lamp control functions

-Combined wiper & window washer control functions

Smart keyless Entry System

<Features and Aims of Development>

1. Enhances the convenience of user.

2. High reliable electric wave communication based on its experiences with radio type keyless and immobilizers.

3. A built-in antenna within the CPM expanded the choice of the door handle design and material.

<Function>

A remote controller is only have to be carried. The lock/unlock of the door and having the engine started can be done without having to take out the remote control from your pocket, bag, etc.

Instrument Cluster Module with Display

<Features and Aims of Development>

1. Advanced Design with

-Meter Module (display ventilator and switch)

-Low reflective cluster cover that rid away with the hood

2. Display visibility improved with a display that can be titled to face the driver

<Specifications>

-4 Rings 4 Gauges Fine Vision Instrument Cluster

-Illuminator color: Orange (Light source: LED <Gauges and Pointers>)

-Display: 8 inches Wide

ETC (Electronic Toll Collection system) unit

<Aims>

The Electronic Toll Collection (ETC) system was introduced from April 2001 with the aim to reduce exhaust gases by allowing vehicles to pass tollgates without stopping and thereby relieving highway traffic congestion. Its application is spreading rapidly. To respond to this trend, the Company has developed and commercialized an onboard unit for the ETC system.

<Features>

The ETC onboard unit is a built-in type with its antenna installed on the back side of the instrument panel and separated from the ETC main body.

Front-End Module

1. Cost reduction by parts integration (Target: -10%)

2. Reduction of assembly process by reducing number of parts (Target: -50%) (Other advantages: Assembly time reduction by eliminating complex process)

3. Weight reduction by resin radiator core support (Target: -20%)

<Features>

1. Parts of the front-end periphery, especially the R.C.S. (Radiator Core Support) are integrated in a rational way to help reduce the number of parts, weight, and cost. It also facilitates assembly and disassembly.

2. Total thermal management of cooling system including optimal airflow around the front-end.

Cooling System for Heavy Duty Trucks

<Aims>

Development of high performance radiators and inter-coolers to enable to comply with future emission regulations.

<Features>

Radiator

High performance down flow core developed for increased combustion heat and heavier vehicles.

Inter-cooler

High performance core developed for increased engine power and improved fuel efficiency for turbo diesel vehicles.

EGR Cooler

Exhausted gas recirculation (EGR) systems and the common rail system applies high pressure fuel injection unit, which has been used to comply with exhaust gas regulations for diesel engine vehicles (to reduce NOx, PM). Since the regulations are becoming even severer, the development of the technologies to reduce the emission has been accelerated. The EGR cooler systems, one of these technologies, lower the combustion temperatures which help reduce NOx efficiently.

<Features>

1. High performance and low gas resistance

2. High aging performance

3. High corrosion resistance

(Patent applied: 27 in Japan, USA and EUR)

Retains the filter by using across-the-surface MAT

Simple holding of catalyst and filter only by MAT instead of SUS mesh.

Lowered the loss from airflow resistance.

The MAT has the heat retention effect to alleviate the drop in temperature surrounding the catalyst filter

There' re less number of parts and easier to assemble.

<Features>

-High performance

-Heat retention

-Cost down

Oval Spun Converter

<Aims>

Light weight

Cost down

1. Heat shroud was eliminated through applying across-the-surface MAT support (The MAT works as a heat shroud and keeps the case's surface temperature down)

2. Parts and weight can be reduced by changing method of construction.

3. Cost is reduced by the reduction of number of parts.

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India