Archives of Past Exhibits:KSPG AG (Formerly Kolbenschmidt Pierburg AG)

2015 IAA Frankfurt Motor Show

2015 JSAE Automotive Engineering Exposition

Shanghai International Automobile Industry Exhibition 2015

Delhi Auto Expo 2014

2013 IAA Frankfurt Motor Show

Shanghai International Automobile Industry Exhibition 2013

2011 IAA Frankfurt Motor Show

CIAPE 2010

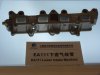

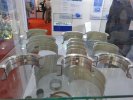

| Kolbenschmidt Pierburg Shanghai Nonferrous Components Co., Ltd. | |||

|---|---|---|---|

| Lower intake manifold | Cylinder head | ||

|

Used for VW "EA111" engine |

|

|

| Image | Image | ||

| Cylinder block | Bracket | ||

|---|---|---|---|

|

|

Used for VW "EA888" engine |

|

| Image | Image | ||

SAE World Congress 2007

<Highlights>

What do they want us to see?

-Showing diversity of products

-Emphasizing an expertise in Diesel

aluminum cylinder blocks: stays cooler, lighter weight, good dealing with emissions and issues of diesel

-Environmentally friendly products and benefits of:

1) help with emission objectives

2) fuel energy objectives

3) performance objectives

Models the products (s) shown are installed into?

-Engine blocks for BMW (V12), Porsche Boxter, Volvo IL5

>>See ""Major Supply Agreements"

Where the products shown are made (facilities)?

All over the world. For example, South Carolina, Wisconsin, South America

and Europe.

SAE World Congress 2006

<Highlights>

Following four product groups, which were focused on 2010 diesel emission regulations, were highlighted at the exhibit.

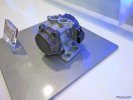

1.Diesel EGR

EGR Valve Dual Poppet ![]()

DC Motor EGR Valve ![]()

The Company is the leading supplier of EGR valves in Europe with approximately two-thirds of the market share.

Features

The unrestricted cross-section intended for high throughput exhaust rates

Increased durability and dependability of the emission control system in terms of on-board diagnosis (OBD).

The electric EGR valves will be made at its Fountain Inn, S.C., manufacturing facility in mid 2006.

2. Electric Water Pump: Image 1/ Image 2 ![]()

3. All steel piston![]()

For diesel applications, Karl Schmidt Unisia has developed the Spinteks(R) all steel, one piece piston.

Features

A finite element analysis (FEA) optimized design to reduce weight

A large, well positioned cooling gallery to reduce piston heat and ultimately reduce emissions

An optimized skirt length to improve NVH and piston secondary motion.

A one-piece forging to eliminate potential crown and skirt separation

A fully supported ring belt structure for reduced blow-by and oil consumption

A bushingless pin bore that has been optimized using FEA.

Also for hybrid vehicle, for example, Ford Escape Hybrid

This pistons will be produced at one of Karl Schmidt Unisia's facilities in North America.

4. Aluminum Technology

LOKASIL (R) technology ![]()

-Is a quasi-monolithic block structure that is used for mass production engines.

With LOKASIL, the contact surfaces of the cylinders in the engine block are enriched with silicon by aluminum infiltration of the silicon preforms

LOKASIL die casting with closed deck image 1/ image 2 ![]()

ALUSIL(R) technology ![]()

-Is an aluminum alloy with high silicon content. The alloy is cast by a low pressure die cast process creating monolithic block structure whose primary silicon is formed during solidification as small, hard gains on the most stressed surfaces of the cylinder bore.

These particles form the supporting structure for pistons and piston rings and produce a wear-resistant surface that does not require liners as additional reinforcement.

It also helps reduce weight by up to 50 percent as compared to cast iron blocks.

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India