Toyota MIRAI 2 2021MY (EU)

| Specification | |

|---|---|

| Fuel Cell Type | Polymer electrolyte |

| Number of cells | 330 |

| Max output (kW/DIN hp) | 128/174 |

| Power density (kW/l) | 5.4 |

| Fuel tank capacity (kg) | 5.6 |

| Volume (litre) | 142.2 |

| HV Battery Type | Lithium-ion |

| Nominal voltage (V) | 310.8 |

| E-Motor Type | PMSM |

| Max. power (kW/DIN hp) | 134/182 |

| Max. torque (Nm) | 300 |

Key Features

- The MIRAI 2 is developed based on Toyota's modular GA-L platform.

- The new platform allows the addition of a third hydrogen fuel tank, extending the driving range by 30% to approximately 650 km.

- The fuel cell system has been completely redesigned, significantly reducing the size and weight of key components.

- By mounting a fully redesigned fuel cell electric powertrain on the GA-L vehicle platform, the MIRAI 2 achieves an ideal 50:50 chassis balance.

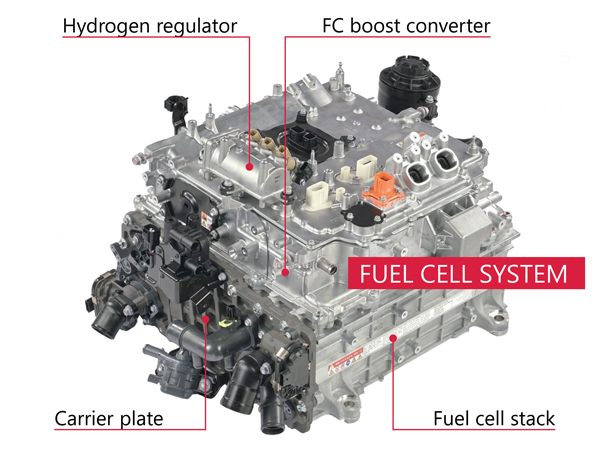

Fuel Cell System Integration

- Main components of the MIRAI 2 fuel cell system are installed at front compartment of the vehicle above the front axle.

- The fuel cell stack and the FC boost DC/DC converter are stacked on top of each other

- The FC boost converter contains:

- DC/DC converter to boost FC voltage to 650V

- Other power electronics components like inverter stages of e.g. coolant pumps

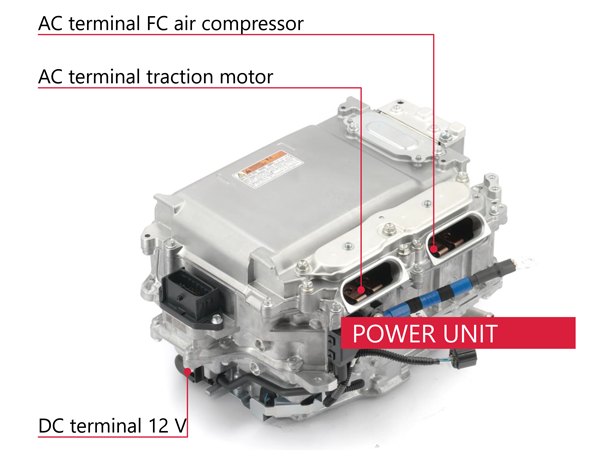

Power Unit

- Different power electronics functions are integrated within one power unit in a highly integrated approach.

- DC/DC converter HV to 12 V board net

- DC/DC converter for HV battery

- Inverter traction motor

- Inverter fuel cell air compressor

- Denso power card modules enable double-sided cooling for semiconductors.

- The multipiece housing consists of cast and sheet metal components.

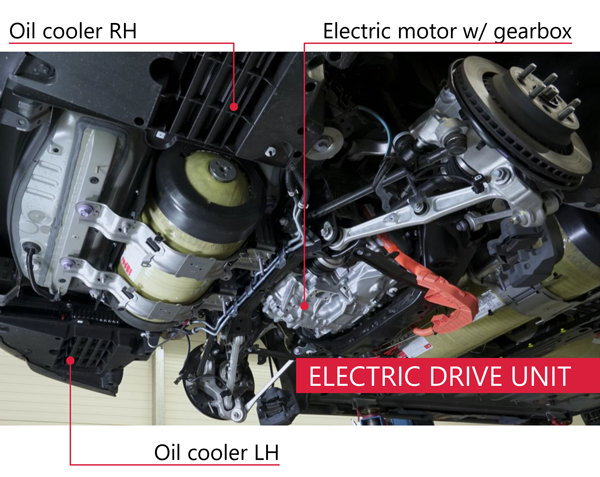

Electric Drive Unit (EDU)

- MIRAI 2 is driven by an electric motor at the rear axle with maximum power of 134 kW.

- The electric drive unit (EDU) including electric motor and 1-speed gearbox is cooled using a separate oil circuit consisting of:

- Electrical oil pump mounted to the EDU

- Two oil coolers mounted behind rear wheel housings using air as cooling medium

- Lubrication of gearbox is realized with internal mechanical oil pump.

- Park lock system is integrated into gearbox.

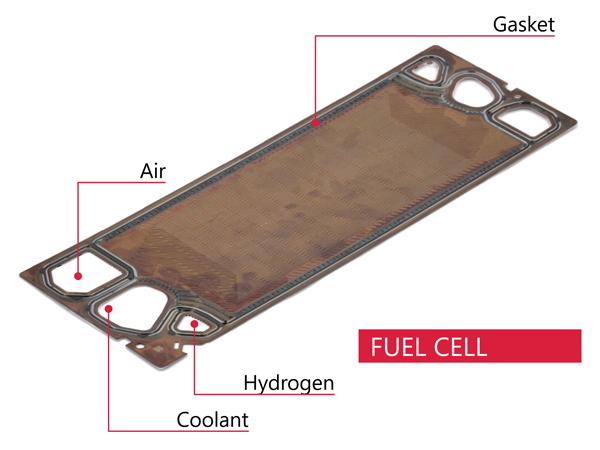

Fuel cell

- Proton-exchange membrane fuel cell is used for MIRAI 2.

- Different media are supplied through cutouts.

- 330 cells are connected in series, which is 40 cells less compared to MIRAI 1.

- One fuel cell consists of different subcomponents.

- Semi-bipolar plates (Cathode + Anode side)

- Rubber gasket between cells

- Subgasket between bipolar plates

- Gas diffusion layer + Microporous layer

- Membrane electrode assembly

Benchmarking Report Overview

The following reports are available:

- M1.1 – Level-1 Benchmark

Level-1 benchmark delivers a first vehicle overview and comparison of key performance indicators within FEV scatter bands. - M2 - Operations & Consumption

Detailed investigation of the Hybrid operation strategy & Energy management - M3 – Fuel Cell System Evaluation

Comprehensive insights into system performance, efficiency and fuel cell operation strategy - M4 – Fuel Cell System Teardown, Design & Cost BMK

- M5 - Electric Powertrain Component Teardown, Design & Cost BMK

- M6 - Acoustics & NVH

- M7 - Powertrain Thermal Management

- M8 - Compressor Analysis & Mapping

Compressor benchmarking of aerodynamics, acoustics and electronics - M9 - Fuel Cell Stack Investigation

Fuel Cell stack mapping and efficiency investigations

For further details including content and price, please contact:

MarkLines Co., Ltd., Consulting Services Department

Person in charge: Mr. Usuba

TEL:(03) 4241-3906

FAX:(03) 4241-3900

e-mail:benchmarkdata@marklines.com

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India