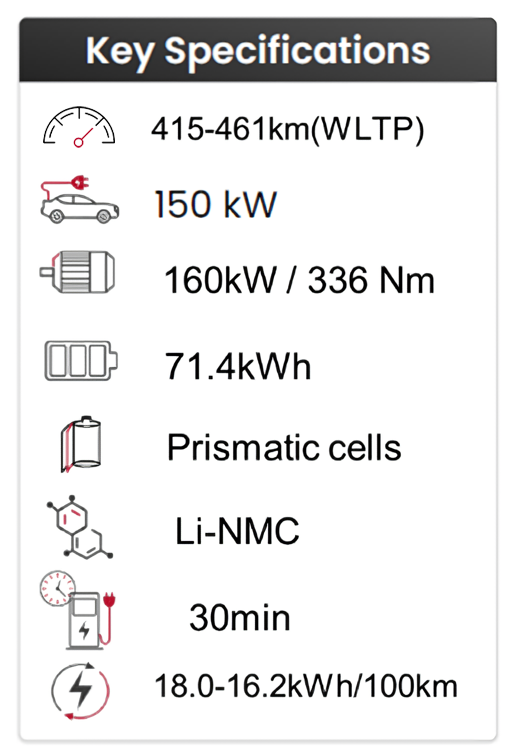

Toyota bZ4X 2022MY (EU)

Key Features

- The bZ4X is Toyota’s first battery electric vehicle based on the e-TNGA platform which was jointly developed with Subaru.

- Depending on the market and powertrain type, different battery pack variants are installed.

- 71.4 kWh* (assumed supplier: Prime Planet Energy & Solutions)

- 72.8 kWh (assumed supplier: CATL)

- The electric drive units (e-motor, inverter & gearbox) for the vehicle are developed and produced by BluE Nexus, a joint venture by AISIN and DENSO.

- Front-wheel drive: 1 x 150 kW

- All-wheel drive: 2 x 80 kW*

- On-board charger, 12 V DC/DC converter and other HV functions are combined in an electricity supply unit provided by DENSO.

*: Covered in the FEV benchmarking program

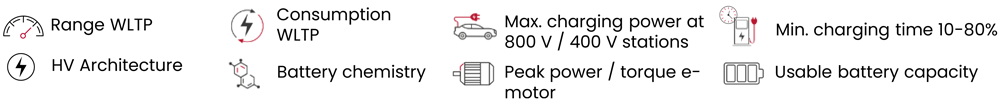

HV Battery

- Assumed cell supplier is Prime Planet Energy & Solutions (PPES), a joint venture between Panasonic and Toyota.

- In total 96 prismatic cells are equally distributed among 4 battery modules and connected in series to deliver the nominal voltage level of 355 volts.

- The battery cells are liquid cooled (water-glycol mixture) using a separate cooling plate.

- Main housing components are made of steel sheet metal (main housing & cover) and aluminum (extruded side profiles & underbody protection plate).

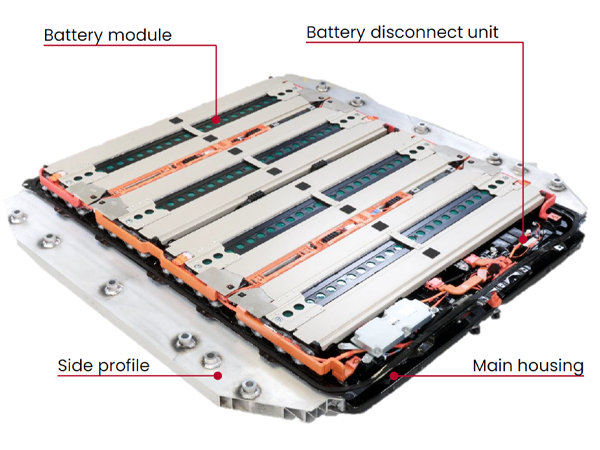

Front & Rear EDU (Electric Drive Unit)

- The electric drive units (EDUs) were developed by BluE Nexus, a joint venture of Aisin and Denso.

- Each EDU includes:

- Integrated inverter using Denso semiconductors

- Oil-cooled PMSM motor with hairpin windings

- 1-speed reducer gearbox

- To realize economies of scale, several identical parts are used for front and rear EDU.

- A park lock is included in the front EDU, park lock gear and intermediate gear are realized as one component.

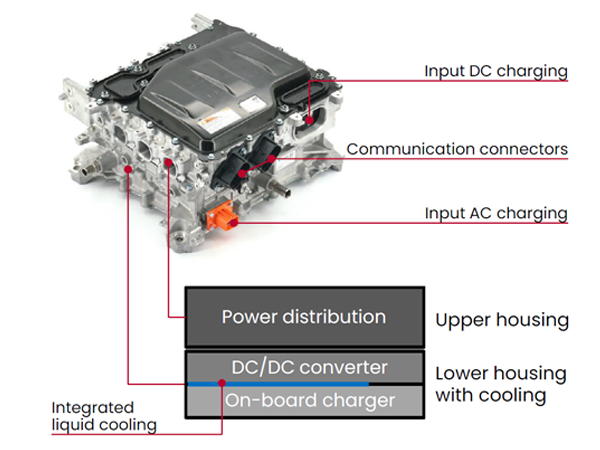

Electricity Supply Unit (ESU)

- The Toyota bZ4X is equipped with an Electricity Supply Unit (ESU) provided by Denso that combines several power electronics functions:

- Power distribution to the electric drive units, HV battery, cabin heater and A/C compressor

- 12 V DC/DC converter

- On-board charger

- Two cast housings are used to integrate the functions:

Power distribution in the upper housing, DC/DC converter & on-board charger in the lower housing - Liquid cooling (water glycol mixture) is only applied to the components located in the lower housing.

Benchmarking Report Overview

The following reports are available:

- M1.1 – Level-1 Benchmark

Level-1 benchmark delivers a first vehicle overview and comparison of key performance indicators within FEV scatter bands. - M2.1 – Energy Consumption

Investigate in detail vehicle energy consumption on legislative cycles installing a comprehensive sensor instrumentation. - M2.2 – Control Strategy

Capture detailed measurement data during driving cycle and critical mission tests and analyze vehicle control strategy. - M2.4 – Charging Performance

Equip an air-conditioned chassis Dyn. with a high-power DC charger to test the charging performance under different temperature conditions. - M3.11 – Design Benchmark HV Battery

- M3.12 – Design Benchmark EDU (e-Axle)

- M3.13 – Design Benchmark Electronics (OBC & DCDC)

- M3.21 – Cost Benchmark HV Battery (sold as a set with M3.11 – Design Benchmark HV Battery)

For further details including content and price, please contact:

MarkLines Co., Ltd., Consulting Services Department

Person in charge: Mr. Usuba

TEL:(03) 4241-3906

FAX:(03) 4241-3900

e-mail:benchmarkdata@marklines.com

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India