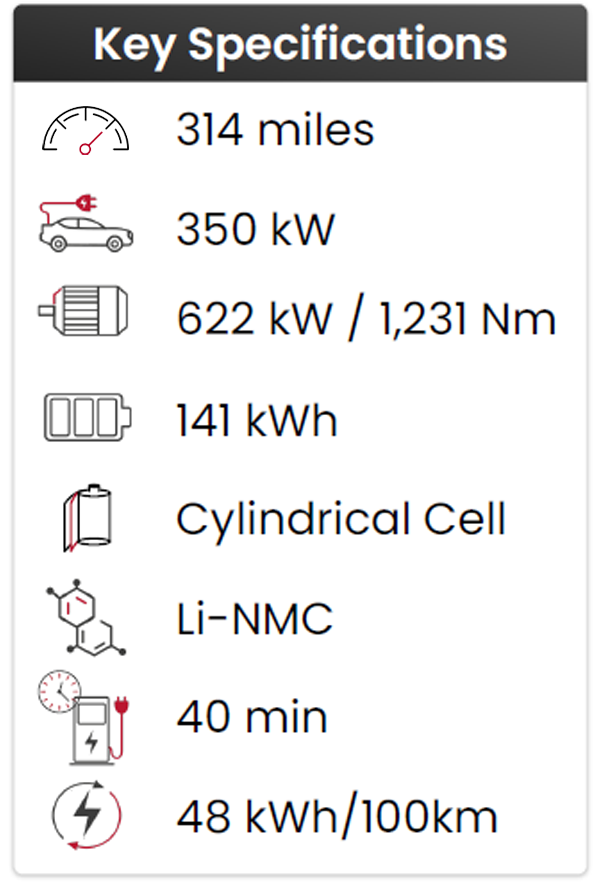

Rivian R1T 2022MY (US)

Key Features

- Rivian has developed a mass production 400 V platform, shared across all segments

- Battery capable of over 3C

- Charging from 10-80% in 40 min at 350 kW

- Front EDU is using SiC whereas rear EDU uses Si IGBT

- Rivian is developing two more versions with an SUV and another pickup truck

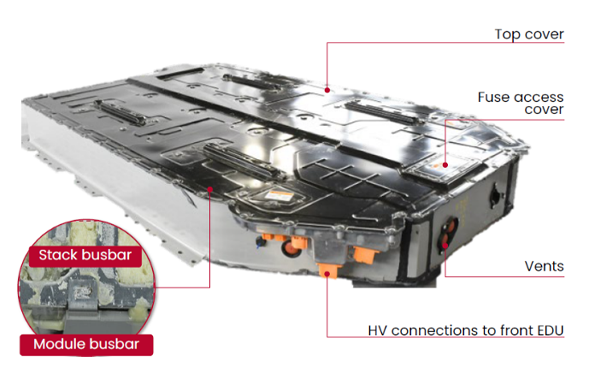

HV Battery

- 141 kwh lithium-ion NMC battery pack

- Cylindrical cells supplied by Samsung

- 9 battery modules with 18 cell stacks

- 7,776 cylindrical cells in total (3.6 V nominal)

- Energy density: Approx. 176 Wh/kg

- Liquid-cooled cell modules with hoses connected to the cold plate

- Multi-piece Aluminum extrusions welded together to form the battery housing

- Composite skid plate with copper inserts for grounding

- BDU and PDU integrated within the battery pack housing

Front and Rear EDU (Electric Drive Unit)

- Electric Drive Unit (EDU) consists of a total of four motors, with two each mounted at the front and rear.

- Front EDU: 345 kW / 409 Nm, Rear EDU: 367 kW / 637 Nm

Benchmarking Report Overview

The following reports are available:

- M1.1 – Level-1 Benchmark:

Level-1 benchmark delivers a first vehicle overview and comparison of key performance indicators within FEV scatter bands. - M2.1 – Energy Consumption

Investigate in detail vehicle energy consumption on legislative cycles installing a comprehensive sensor instrumentation. - M2.2 – Control Strategy

Capture detailed measurement data during driving cycle and critical mission tests and analyze vehicle control strategy. - M2.3 – Drivetrain Efficiency

Map out drive train efficiency numbers during steady state operating over speed and torque range at different SOC levels. - M2.4 – Charging Performance

Equip an air-conditioned chassis Dyn. with a high-power DC charger to test the charging performance under different temperature conditions. - M2.5 – Thermal Management

Analyze the energy consumption and control strategies for thermal management that impact efficiency, driving range and comfort. - M3.11 – Design Benchmark HV Battery

- M3.21 – Cost Benchmark HV Battery (sold as a set with M3.11 – Design Benchmark HV Battery)

For further details including content and price, please contact:

MarkLines Co., Ltd., Consulting Services Department

Person in charge: Mr. Usuba

TEL:(03) 4241-3906

FAX:(03) 4241-3900

e-mail:benchmarkdata@marklines.com

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India