Search Results by Category

AI Navigator

AI NavigatorAll information related to {{ key_word }}.

AI Navigation will guide you. Click here for information about {{ key_word }}.

3

3

5

5

3

3

1

1

4

4

1

1

3

3

3

3

3

3

2

2

1 - 20 of 44 results

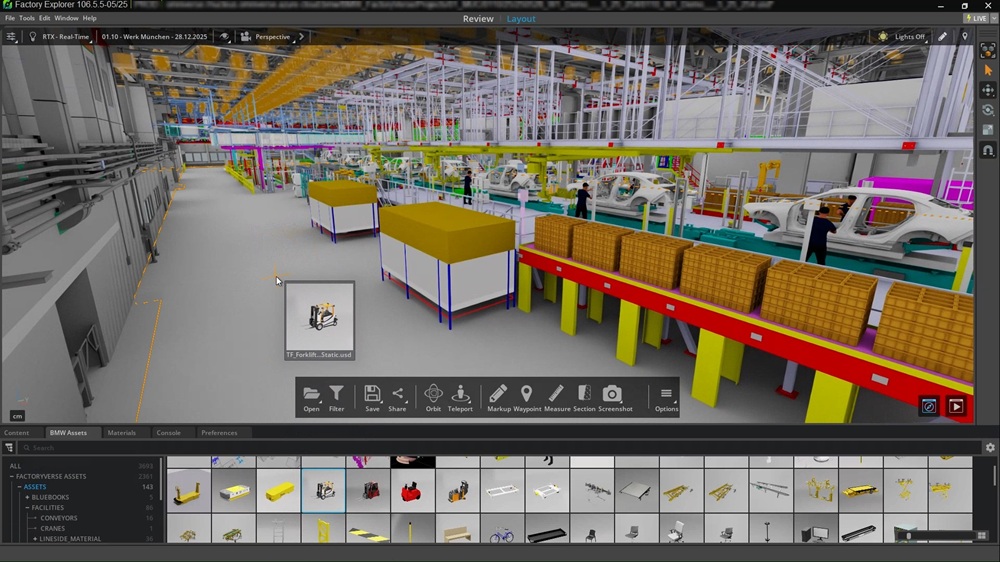

BMW expands Virtual Factory for smarter production planning

. What used to take weeks in real plants can now be tested virtually in days. From now until 2027, over 40 new or updated models will be added to global production—first virtually, then in real life. This shift is expected to cut planning costs by up to 30%. The Virtual Factory is part of BMW’s iFACTORY strategy. It combines building, logistics, equipment, and vehicle data with 3D simulations of human tasks to create digital versions of every...

News Updated at: 2025/06/12

BMW Manufacturing Co., Spartanburg Plant[USA]

ters. This reduces natural gas consumption by about 2,700 MWh. On June 21, the BMW Group announced that it will have a digital scan of every one of its vehicle plants worldwide by early 2023. Virtual planning is a core element of digitalization within the strategic vision of BMW production: the BMW iFACTORY. The aim is to make planning and simulation of all processes and the entire production system 100% virtual. This reduces planning effort and ...

OEM Plants Updated at: 2025/06/11

BMW Manufacturing Hungary Kft., Debrecen Gyar plant[Hungary]

BMW Manufacturing Hungary Kft., Debrecen Gyar plant BMW: EV iX3 (Neue Klasse PF) (2025-planning), EV iX4 (2026-planning); Battery cells (Gen6), Battery modules (Gen6) (2025-planning); BMW's Hungary assembly & battery plant, iFactory, production start is postponed from 2023 to 2025 - The strategic vision of the global production network is the BMW iFACTORY focuses on three key topic areas: LEAN, which stands for efficiency, precision and extreme f...

OEM Plants Updated at: 2025/04/28

BMW Brilliance Automotive Limited (BBA), Tiexi Plant [China]

by about 700 MWh and electricity consumption by about 700 MWh. On June 21, the BMW Group announced that it will have a digital scan of every one of its vehicle plants worldwide by early 2023. Virtual planning is a core element of digitalization within the strategic vision of BMW production: the BMW iFACTORY. The aim is to make planning and simulation of all processes and the entire production system 100% virtual. This reduces planning effort and ...

OEM Plants Updated at: 2025/04/01

BMW AG, Regensburg Plant[Germany]

BMW AG, Regensburg Plant 1 Series 3-door, 1 Series 5-door, 2 Series Gran Tourer (2015-), 3 Series M3 Coupe (-2013), 4 Series Convertible (2013-2020) , Z4 (2009-2016), X1, X2 (2018-), X1 PHV (2020-), X2 PHV (2020-), EV iX1 (2022-), EV iX2 (2024-), iX2 PHV (2024-), X2 MHV (2024-), Neue Klasse (after 2025-planning); Battery module (2022-); Passenger car assembly plant, iFactory - Investment announcement for 2023: EUR 350 million in vehicle producti...

OEM Plants Updated at: 2025/03/31

BMW China Automotive Trading Ltd.(Formerly BMW Group Posh China Area) [China]

aked eye through AI algorithms to ensure a flawless surface. IT engineers will continuously train and optimize the system using the platform to improve efficiency and accuracy. On February 20, the BMW i3 eDrive40L battery electric vehicle (BEV) rolled off the production line at the Lydia Plant (BMW iFACTORY) in Shenyang, Liaoning. As a high-end model of the BMW i3, the new vehicle boasts stronger performance and a longer range, with a maximum pow...

OEM Plants Updated at: 2025/03/26

BMW Motoren GmbH, Steyr Plant[Austria]

uce next-gen electric drives alongside combustion engines. The InnoLab serves as a digital skills hub, where around 200 diverse projects are underway, ranging from simple data visualizations to complex AI solutions across multiple production lines. These scalable digital solutions, aligned with BMW iFACTORY principles, prioritize flexibility, processes, and integrability. Employee training is a focal point in BMW Group's transformation, featuring...

OEM Plants Updated at: 2025/03/07

BMW Brilliance Automotive Limited (BBA)[China]

le expansion of power battery production. The project will be invested by BMW Brilliance with some CNY 10 billion in total. Located in the Sino-German (Shenyang) High-end Equipment Manufacturing Industrial Park of the Shenyang Economic and Technological Development Zone, the project follows the BMW iFACTORY production strategy and focuses on digitalization and sustainability. The project will significantly increase BMW’s local production capaci...

OEM Plants Updated at: 2025/02/21

BMW TechWorks Romania[Romania]

developers by year-end, with plans to eventually employ over 1,000. Key focus areas include Connected Procurement, which involves developing advanced networked IT systems to optimize complex supply chain. Another is the Digital Shopfloor, aimed at creating modern production IT solutions for BMW’s iFactory. Additionally, the company is focusing on the Direct Sales Model, where it is working on building central IT components to support BMW and MI...

OEM Plants Updated at: 2025/01/14

BMW Brilliance Automotive Ltd. Lydia Plant (formerly Tiexi New Plant (Lydia Project))[China]

BMW Brilliance Automotive Ltd. Lydia Plant (formerly Tiexi New Plant (Lydia Project)) EV i3 (2022-), EV iX3 (2023-), SUV X3 (2025-); BMW Brilliance's Third Plant(Shenyang City, Liaoning Province ), iFactory, started production in May 2022 - The strategic vision of the global production network is the BMW iFACTORY focuses on three key topic areas: LEAN, which stands for efficiency, precision and extreme flexibility; GREEN, for sustainability, reso...

OEM Plants Updated at: 2025/01/10

BMW (UK), Oxford Plant[UK]

at BMW Group Plant Hams Hall in North Warwickshire. These parts come together at MINI Plant Oxford where body shell production, paint, and final assembly take place. On November 25, BMW announced that it has been expanding its tested automated vehicle driving in factories since 2022 as part of the iFACTORY initiative. Currently operational in Dingolfing, it is now being extended to Leipzig, with plans to expand to additional locations. The pilot...

OEM Plants Updated at: 2024/12/10

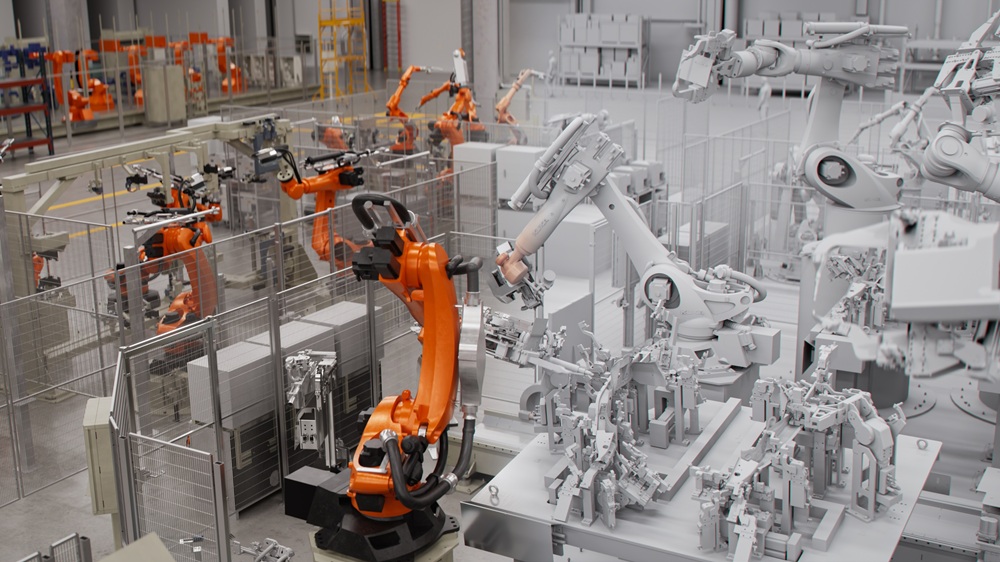

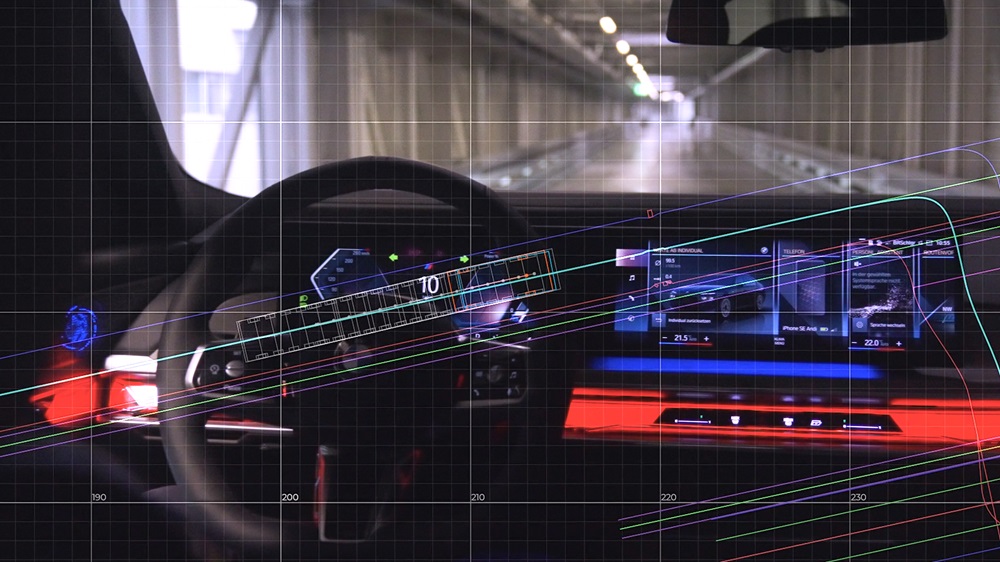

BMW expands Automated Driving in Factory Environment (AFW) project across key production plants

BMW expands Automated Driving in Factory Environment (AFW) project across key production plants On November 25, BMW announced that it has been expanding its tested automated vehicle driving in factories since 2022 as part of the iFACTORY initiative. Currently operational in Dingolfing, it is now being extended to Leipzig, with plans to expand to additional locations. The pilot project known as “Automated Driving in Factory Environment (AFW)” ...

News Updated at: 2024/11/25

BMW Brilliance Automotive Limited, Powertrain Plant[China]

le expansion of power battery production. The project will be invested by BMW Brilliance with some CNY 10 billion in total. Located in the Sino-German (Shenyang) High-end Equipment Manufacturing Industrial Park of the Shenyang Economic and Technological Development Zone, the project follows the BMW iFACTORY production strategy and focuses on digitalization and sustainability. The project will significantly increase BMW’s local production capaci...

OEM Plants Updated at: 2024/11/21

BMW AG, Dingolfing Plant[Germany]

ring and BMW M models. In 2023, the plant achieved record volumes, manufacturing approximately 292,000 BMWs, with 30% being fully electric models. Employee numbers slightly increased to over 18,500. Dingolfing is undergoing a comprehensive transformation into e-mobility and a smart factory, the BMW iFactory. The competence center for electric drive production played a significant role, producing over 560,000 electric motors and around 400,000 hig...

OEM Plants Updated at: 2024/11/05

BMW AG, Leipzig Plant[Germany]

to produce two brands, making up to 500 MINI and 800 BMW vehicles daily. This expansion has secured jobs and created around 900 new vehicle production roles in 2024. On November 25, BMW announced that it has been expanding its tested automated vehicle driving in factories since 2022 as part of the iFACTORY initiative. Currently operational in Dingolfing, it is now being extended to Leipzig, with plans to expand to additional locations. The pilot...

OEM Plants Updated at: 2024/11/02

BMW AG, Munich Plant[Germany]

; Internal Combustion Engines (-Stopped production in 2023) - 3 cylinder - 6 cylinder engines, V8 - V12 engines, V8 Twin turbo engine for BMW M5,M6,X5, X6, 7 series, M850i xDrive Coupe, - V12 engines for BMW 760Li and Rolls-Royce Phantom and Ghost (-2022); Passenger car and engine assembly plant, iFactory - Number of Employees: approx. 7,800 (as of 2023) - Investment: EUR 650 million - The strategic vision of the global production network is th...

OEM Plants Updated at: 2024/11/02

BMW Regensburg plant transforms logistics with automation and digitalization

BMW Regensburg plant transforms logistics with automation and digitalization On October 29, BMW announced that its Regensburg plant is enhancing its logistics through digitalization and automation as part of the BMW iFACTORY initiative. A new vehicle rolls off the assembly line every 57 seconds, with up to 1,400 BMW X1 and X2 models shipped daily. To support this complex production, components must be delivered “just in time” and “just in s...

News Updated at: 2024/10/29

Analysis Report: Lithium-Ion Battery (Japan, Europe, North America and Korea)

0GWh, vehicles Debrecen Made in China 2026 - Cylindrical 4695, Shenyang City, Liaoning Province BMW Brilliance Automotive Ltd. AESC U.S. South Carolina Plant, U.S. 2026 - Cylindrical 4695, plant 30GWh, vehicles Spartanburg EVE Energy Debrecen Plant, Hungary 2026 - 4695 cylindrical type, for Ifactory, plant 20GWh SVOLT Made in China 2027 - Prismatic cells Mercedes-Benz Finished product CATL Arnstadt Plant, Germany 2022 - German product...

Market & Tech Reports Updated at: 2024/10/18

BMW Rosslyn plant, South Africa ends third-generation X3 production, prepares for next-gen plug-in hybrid

over 50 global markets, with 96% of units exported. With a capacity of 76,000 units and additional investments, the plant can adjust production to meet demand. In 2023, BMW invested ZAR 4.2 billion to prepare Rosslyn for next-generation BMW X3 plug-in hybrid (PHEV) production, aligning with BMW’s iFACTORY plan for efficient and sustainable manufacturing. Starting October 2024, the Rosslyn plant will produce the fourth-generation BMW X3, includi...

News Updated at: 2024/09/06

BMW Debrecen plant progresses with first fossil fuel-free paint shop commissioned

g the first technology commissioned. The facility will be BMW's first entirely fossil fuel-free paint shop, using innovative systems like power-to-heat, Heat Grid, and eRTO. The plant will begin pre-series production of the Neue Klasse by year-end, serving as a model for future BMW plants under the iFACTORY principles. The Debrecen paint shop, covering 33,000 square meters, is designed to paint 30 vehicle bodies per hour, with potential for futur...

News Updated at: 2024/08/27

AI Navigator

AI Navigator

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India