Sort by :

1 - 20 of 46 results

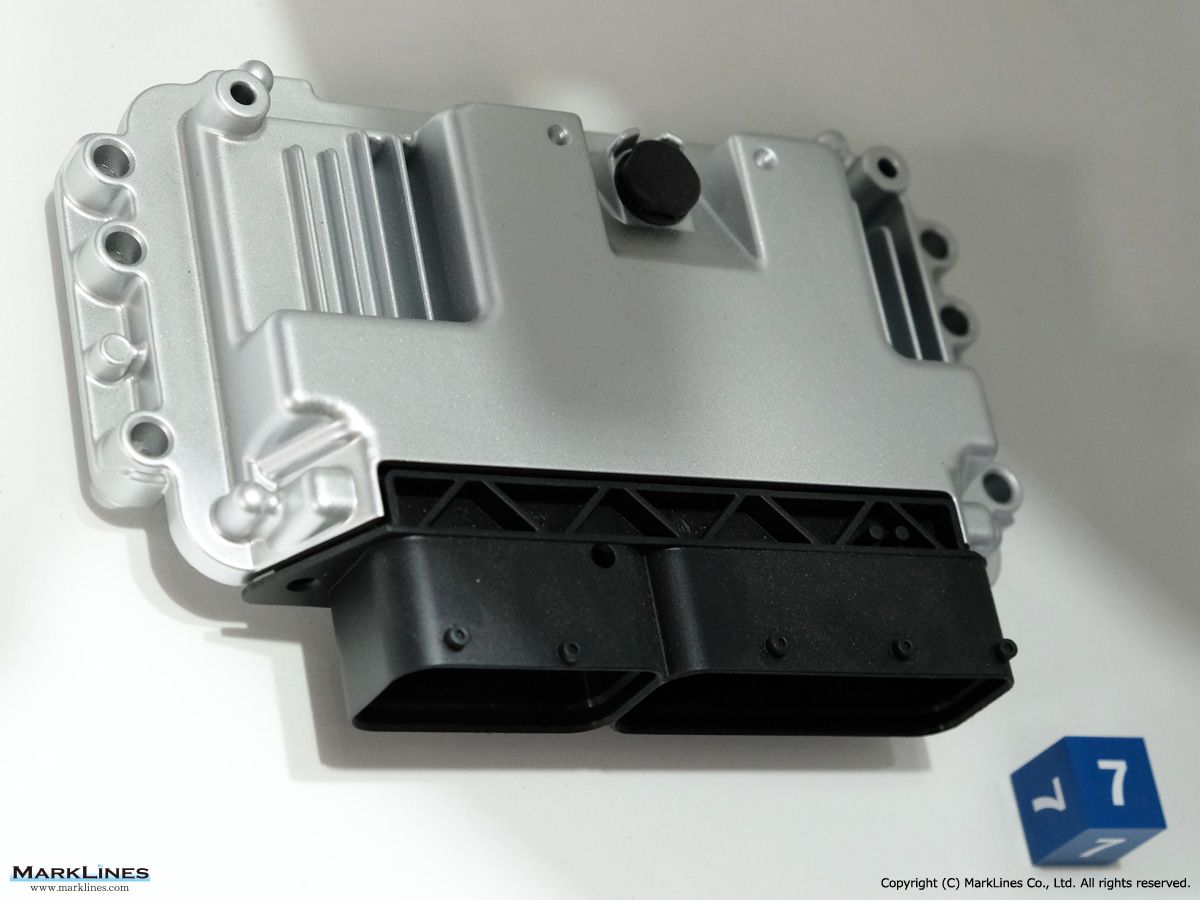

7

7

1

1

2

2

2

2

1

1

1

1

1

1

1

1

1

1

5

5

2

2

1

1

1

1

8

8

5

5

5

5

4

4

3

3

2

2

5

5

AI Navigator

AI Navigator

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India