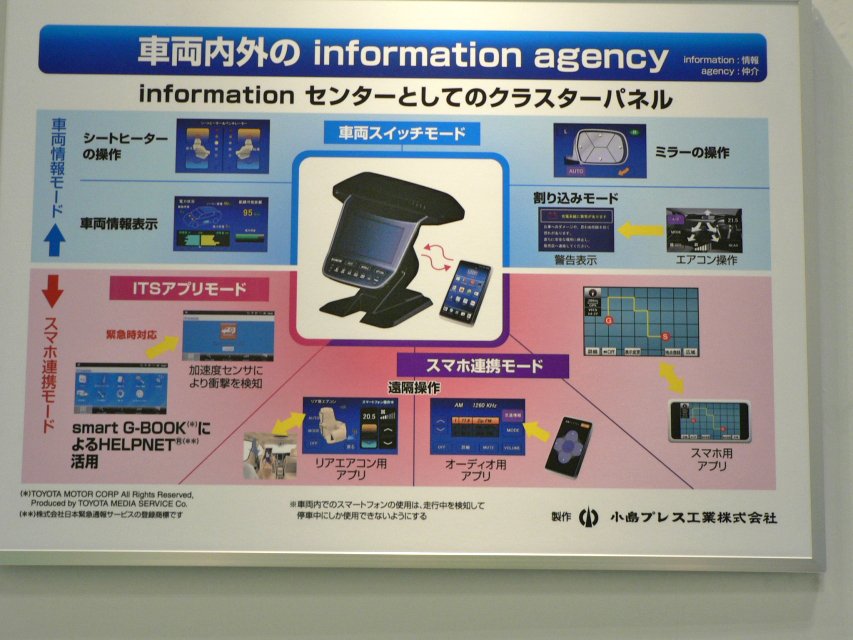

Kojima Industries Corporation

Company Profile

■URL

https://www.kojima-tns.co.jp/en/

■Address

Business Overview

-The Company manufactures interior and exterior automotive parts and is a member of the Toyota Group.

-The Company manufactures composite parts incorporating technology on electronics, plastic, and iron.

Shareholders

-Unlisted Company

Products

Interior

-Assist grips/Long assist grips

-Camera cover

-Antenna amp

-Microphone

-Overhead console

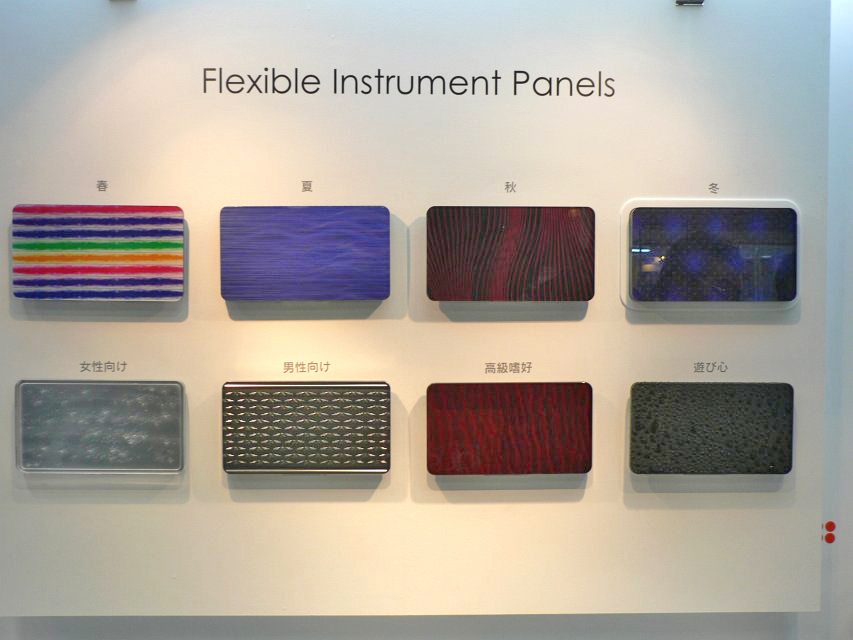

-Instrument panel ornaments

-Door pockets

-Center cluster

-Cup holders

-Box sub assembly console

-Heater control

-Upper console

-USB sockets

-Registers

-Switch bases

-Electronic inside handles

-Decorative panels

-Rear seat center Armrests

-Large Rear Seat Light Module

Zero Emission

-Oil separator

-V-ribbed pulleys

-Insulators

-Balancer

-Ring gears

-Direct clutch

-Oil strainer

-Turbo tube

-Cowl louvers

-Lower absorber

-Over fenders

-Fender liners

-Battery case

-Rocker molding

-Floor covers

-Clips and clamp

-Battery trays

-Exhaust and drainage pipes for FCVs

-End plate

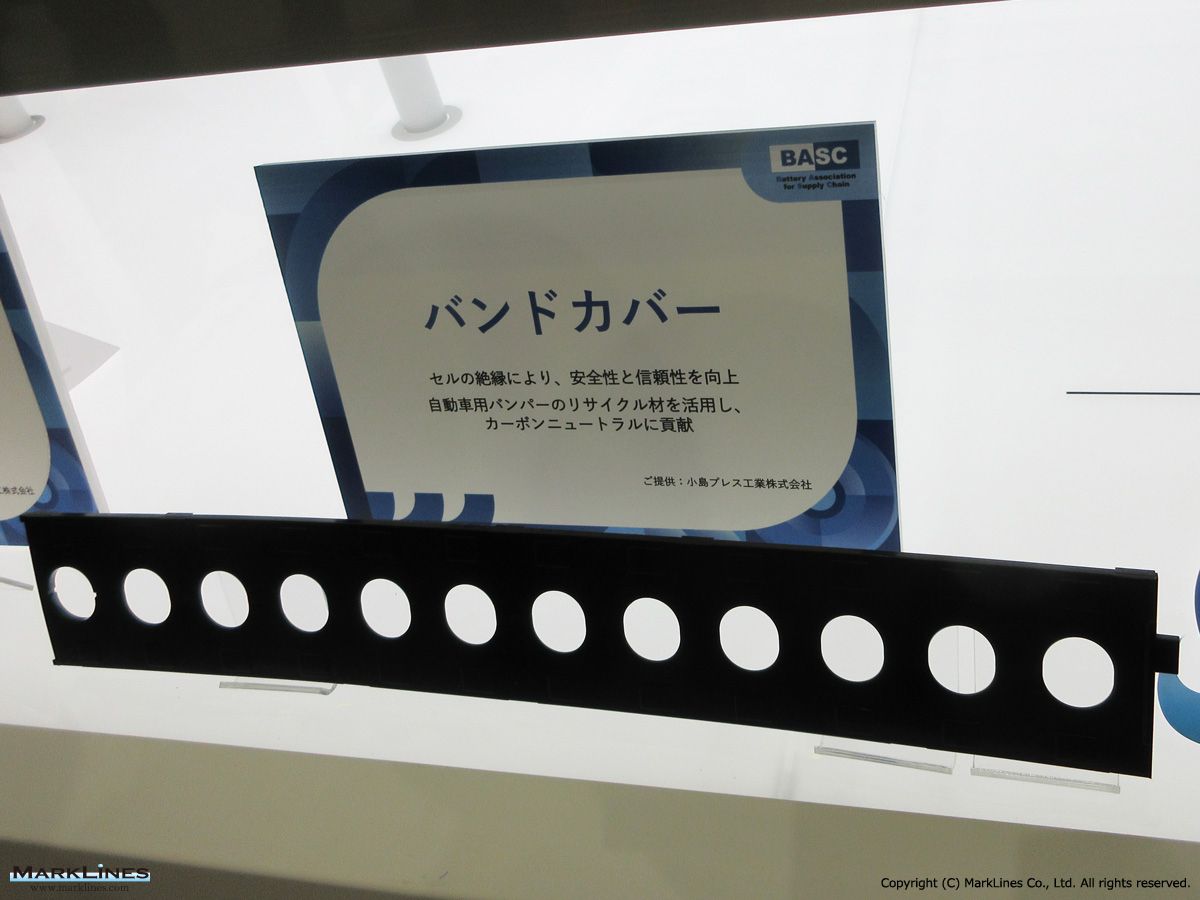

-Cell separator

-Smoke exhaust cover

-Collision prevention part (intermediate mount)

-Water-cooling cooler

-Car covers

-Air guides

History

| Jan. 1950 | Established with the capital of 500 thousand yen. |

| Jan. 1959 | Renamed as Kojima Press Industry Co., Ltd. |

| July, 1968 | Set up Takaoka plant in Sumiyoshi-cho, Toyota-city. |

| Jan. 1978 | Established Fujioka Research Center in Fujioka-cho, Nishikamo-gun, Aichi Pref. |

| May, 1990 | Established Eiwa Research Institute. |

| Dec. 1997 | Set up Moriso Plant in Miyoshi-cho, Nishikamo-gun, Aichi Pref. |

| May, 1999 | Established Kojima Research Institute. |

| Dec. 2002 | Completed the construction of Kurozasa R&D Technical Center. (Miyoshi-cho, Nishikamo-gun, Aichi Pref.) |

| Jan. 2007 | Started operations of "Production preparation center"at the headquarters. |

| Jan. 2014 | Acquired 76% shares in Iwate Kasai (currently called Tohoku KAT) from Kasai Kogyo, making Iwate Kasai the Company's subsidiary. |

| Mar. 2016 | Completed the Komaba Plant, which is a hub supplying parts throughout the Company. |

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India