Metalart Corporation

Company Profile

Business Overview

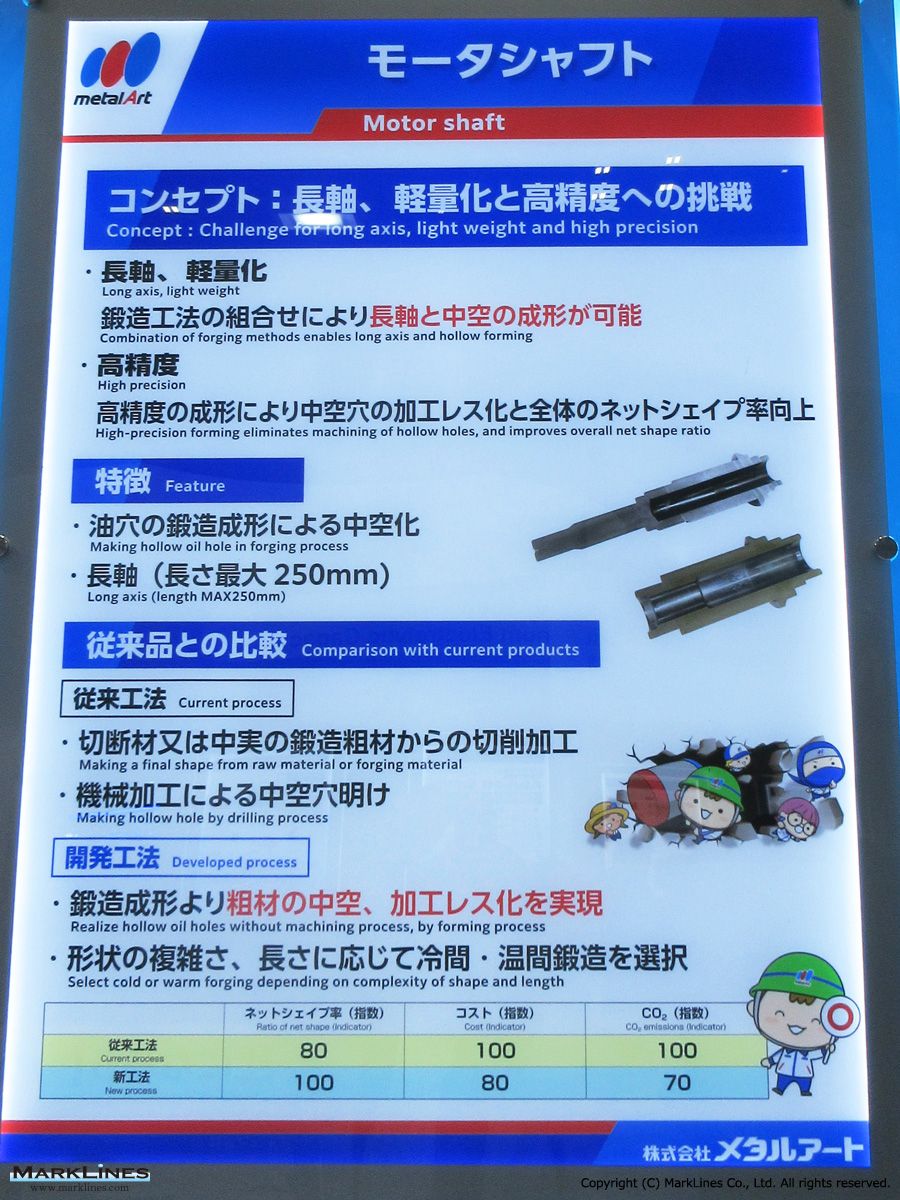

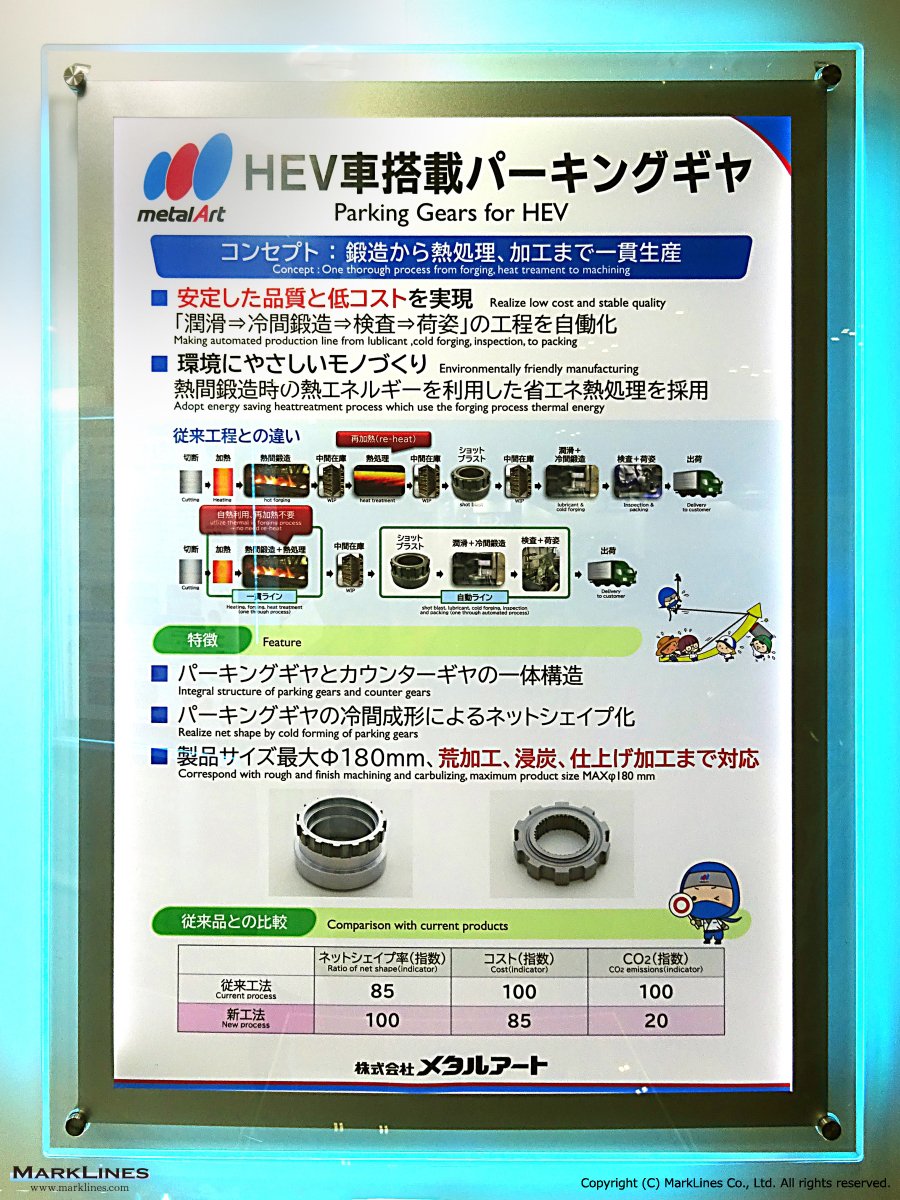

-Mainly manufactures and sells automotive components (crankshafts, connecting rods, etc.) and precision forgings for construction machinery.

-Integrated production from die design, forging (hot and cold) to machining and assembly.

-The Company's largest customer is Daihatsu, which accounted for 29.4% of the Company's sales for fiscal year ended Mar. 31, 2024.

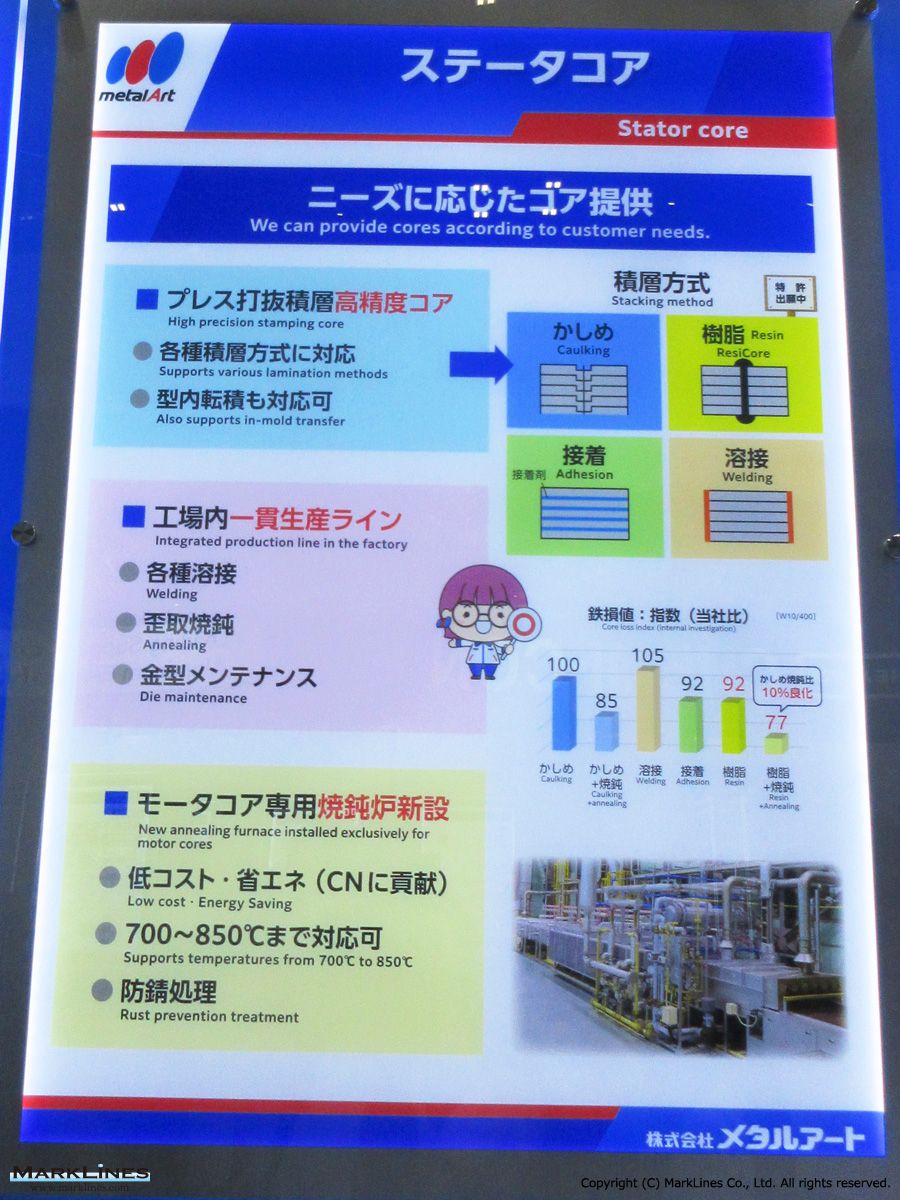

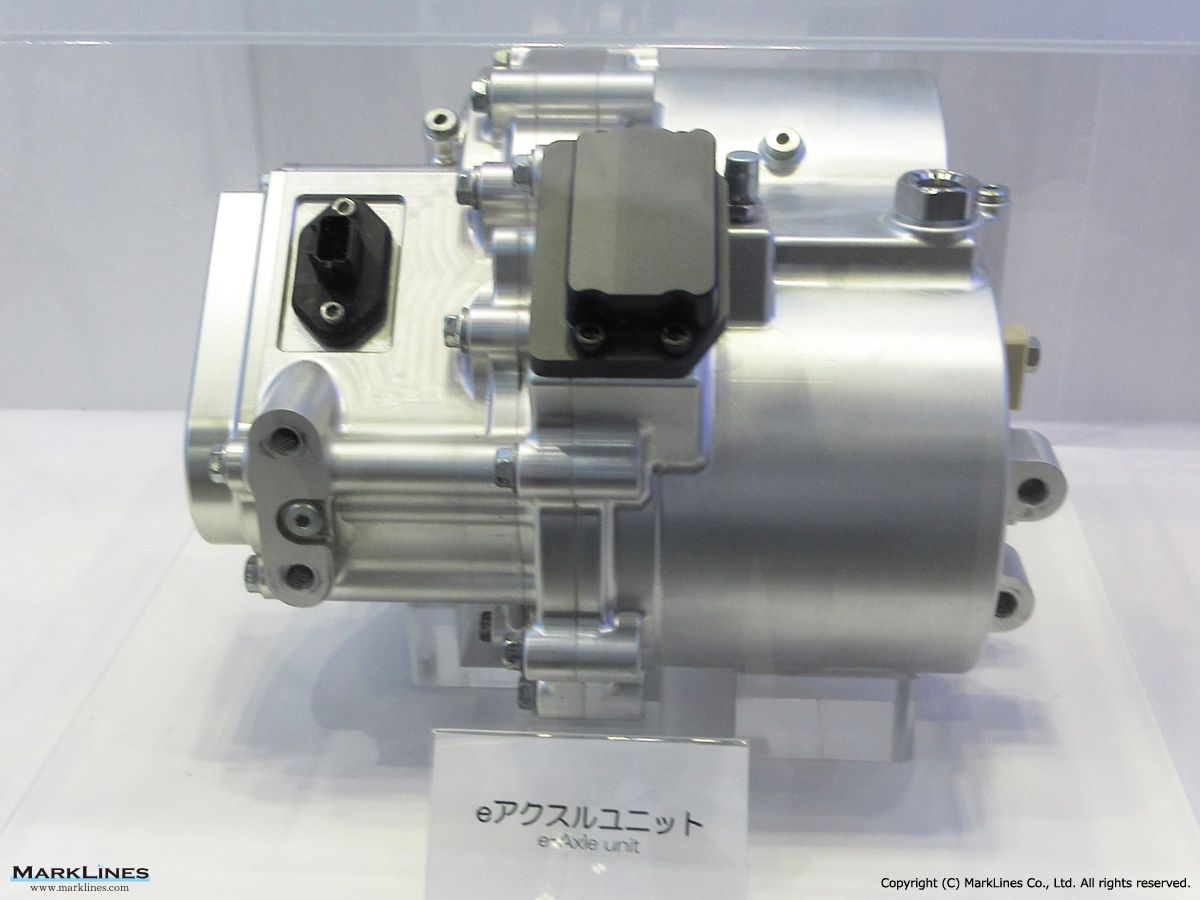

-Announced in May 2022 that is will launch business operations in an area new to the Company, the motor business, in line with the current trend in electrification.

Financial Highlights

-Business results for the fiscal year that ended in March 2025 are provided below:

Consolidated sales: JPY 43,954 million (2.4% year-on-year decrease)

Operating profit: JPY 2,995 million (2.5% year-on-year increase)

Ordinary profit: JPY 3,253million (2.2% year-on-year increase)

Current net profit attributable to the parent company: JPY 1,998 (5.7% year-on-year decrease).

Shareholders

| -Listed on the Standard Market of the Tokyo Stock Exchange. | (As of Mar. 31, 2025) |

| Name or Company Name | Investment ratio (%) |

| Daihatsu Motor Co., Ltd. | 35.73 |

| Gohsyu Corporation | 4.42 |

| Individual shareholder | 3.91 |

| The Shiga Bank,Ltd. | 3.45 |

| RE FUND 107-CLIENT AC (Standing proxy: Citibank, N.A., Tokyo Branch) | 2.50 |

| Resona Bank, Limited. | 2.07 |

| Employee stock holdings | 1.69 |

| Custody Bank of Japan, Ltd. (Trust Account) | 1.67 |

| Mitsubishi UFJ Morgan Stanley Securities Co., Ltd. | 1.38 |

| Ueda Yagi Tanshi Co., Ltd. | 1.31 |

| Total | 58.13 |

Products

Engine parts

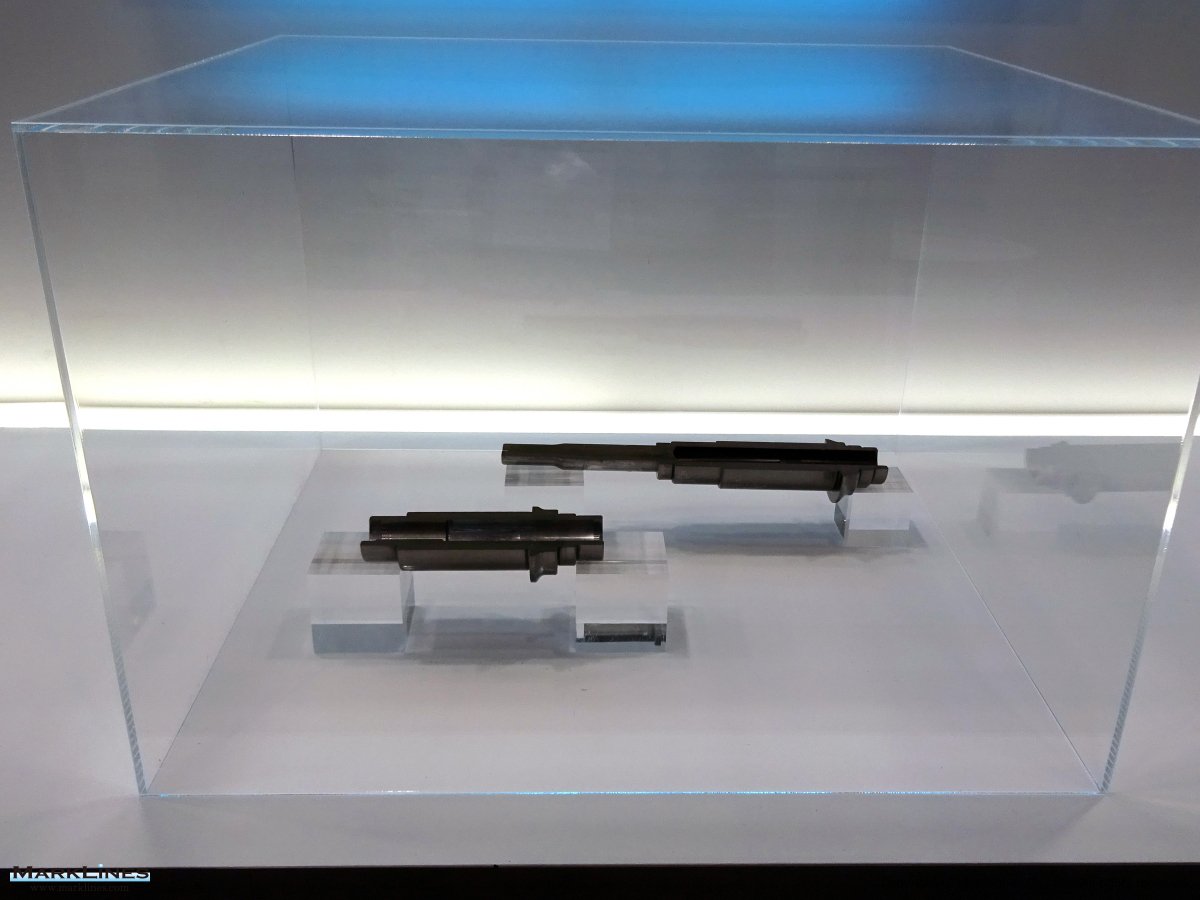

-Crank shafts

-Connecting rods

Precision forged gears

Continuously Variable Transmission parts

Manual Transmission gears

Automatic Transmission parts

Truck links

Suspension Components

History

| May, 1933 | Goto Tankosho was established as a limited partnership. |

| Aug. 1943 | The Company was incorporated. |

| Apr. 1958 | The Fukumachi Plant was established at 1-9 Higashi-Fukumachi, Nishi-Yodogawa-ku, Osaka. |

| Nov. 1962 | Listed on the Second Section of the Osaka Stock Exchange. |

| June, 1964 | Established the Shiga Plant at 1350 Noji-machi, Kusatsu City, Shiga Pref. |

| June, 1965 | Recruited executives from Nissho (currently Nissho Iwai) to improve management. |

| Sep. 1967 | Integrated three plants in Nozato, Fuku-machi, Shiga were into two plants, in Osaka and Shiga. |

| Dec. 1967 | Established Omi Seiko Inc. (currently a consolidated subsidiary) |

| July, 1970 | Moved headquarters to 1 Okawa-cho, Higashi-ku, Osaka. Moved headquarters office to its current location. The Shiga plant was renamed as Headquarters Plant. |

| Apr. 1972 | The Osaka Plant was integrated into the Headquarters Plant. Established an integrated production system. |

| July, 1975 | Headquarters moved to its current location, 1350 Noji-cho, Kusatsu City, Shiga Pref. |

| May, 1981 | Established San Emu Industry Inc. (currently a consolidated subsidiary). |

| Dec. 1987 | Established a 2000t automated forging stamping plant. |

| Oct. 1991 | Renamed as Metalart Corporation. |

| July, 1992 | Corporate name of Omi Seiko Inc. was changed to Metaltech Corporation. |

| July, 1992 | Corporate name of San Emu Industry Inc. was changed to Metalmac Corporation. |

| Mar. 1993 | Established Metal Forge Corporation (currently a consolidated subsidiary). |

| Apr. 1998 | Metaltecs Corporation took over Metalmacs Corporation. |

| May, 2002 | Set up a cold forging line. |

| Aug. 2005 | Metaltecs Corporation established a link line at the Baba plant. |

| Feb. 2006 | Established the Baba plant, moving a precision forging line and installing an integrated production line for heat and surface treatment. |

| Mar. 2008 | Metal Tex established its Mizuguchi Plant. A new production line for processing CVT components was built. |

| Jan. 2013 | Metal Tex established its Kyushu Plant. A new production line for machine processing was built. |

| May 2013 | Established PT. Metalart Astra Indonesia in Indonesia. (This company is currently a consolidated subsidiary.) |

| February 2015 | Operation of PT.METALART ASTRA INDONESIA started. |

| Apr. 2018 | METALART CORPORATION marged with METALTEX CORPORATION. |

| Apr. 2022 | Moved from the Second Section of the Tokyo Stock Exchange to the Standard Market. |

| Nov. 2023 | Established a new motor core factory within the Minakuchi Plant. |

| Apr. 2025 | Metal Art Corporation absorbed Metal Forge Corporation. |

Supplemental Information 1

>>>Business report for FY ended Mar. 31, 2008

>>>Business report for FY ended Mar. 31, 2009

>>>Business report for FY ended Mar. 31, 2010

>>>Business report for FY ended Mar. 31, 2011

>>>Business report for FY ended Mar. 31, 2012

>>>Business report for FY ended Mar. 31, 2013

>>>Business report for FY ended Mar. 31, 2014

>>>Business report for FY ended Mar. 31, 2015

>>>Financial Forecast for the Next Fiscal Year (Sales, Operating Income etc.)

Note: A figure in brackets ( ) indicates a loss

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India