Archives of Past Exhibits:Taiho Kogyo

Tokyo Motor Show 2015

2015 JSAE Automotive Engineering Exposition

Installed vehicle: Toyota "Lexus LS600h", "Lexus GS450h", "Camry Hybrid", "Crown Hybrid"

Installed vehicle: Toyota "Lexus LS600h", "Lexus GS450h", "Camry Hybrid", "Crown Hybrid"

Installed vehicle: Toyota "Prius" Honda "N-BOX" Mitsubishi "Mirage (Thailand)" Suzuki "Wagon R"

Installed vehicle: Toyota "Prius" Honda "N-BOX" Mitsubishi "Mirage (Thailand)" Suzuki "Wagon R"

Installed vehicle: GM "Cadillac CTS" Toyota "Camry", "Lexus IS-F", "Vitz/Yaris"

Installed vehicle: GM "Cadillac CTS" Toyota "Camry", "Lexus IS-F", "Vitz/Yaris"

Installed vehicle: Toyota "Lexus LS", "86" Nissan "Note" Porsche "Cayenne" -The Company's market share of transmission bushing for Japanese car manufacturer in 2014 is 55 percent. (According to the Company)

Installed vehicle: Toyota "Lexus LS", "86" Nissan "Note" Porsche "Cayenne" -The Company's market share of transmission bushing for Japanese car manufacturer in 2014 is 55 percent. (According to the Company)

2014 JSAE Automotive Engineering Exposition in NAGOYA

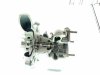

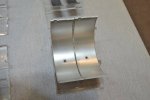

Transmission bearings

-The Company's market share of transmission bushing for Japanese OEMs reaches 50%.

-The Company's market share of transmission bushing for Japanese OEMs reaches 50%.

2014 JSAE Automotive Engineering Exposition

Installed vehicle: Toyota "Lexus LS600h", "Lexus GS450h", "Camry Hybrid", "Crown Hybrid"

Installed vehicle: Toyota "Lexus LS600h", "Lexus GS450h", "Camry Hybrid", "Crown Hybrid"

2013 Tokyo Motor Show

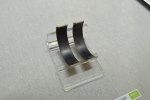

| Main bearing with eccentric oil groove | Engine bearing with bismuth coating | ||

|

Installed vehicle: Toyota "Prius" Honda "N BOX" Mitsubishi "Mirage" Suzuki "Wagon R" |

|

Installed vehicle: Toyota "86" Subaru "BRZ" |

|

|

||

| Con-rod bearing designed excreting foreign particles | Copper alloy engine bearing with overlay | ||

|

Installed vehicle: Toyota "Lexus IS-F", "Camry", "Vitz; Yaris" GM "Cadillac CTS" |

|

|

|

|||

| Engine bearing with RA coating | Aluminum alloy engine bearing | ||

|

|

||

| Engine bearing with next-generation resin coating | Engine bearing with new resin coating | ||

|

|

||

| image |  |

image |  |

| Engine bearing with RA coating | Thrust washer with resin coating for engine | ||

|

Installed vehicle: Toyota "Lexus LS600h", "Lexus GS450h", "Crown Hybrid", "Camry Hybrid" |

|

|

| image image image image image image |

image |  |

|

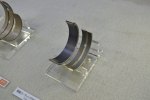

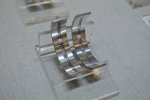

| Copper alloy bearing | New aluminum alloy bearing | ||

|

Installed vehicle: Toyota "Lexus LS", "86" Nissan "Note" Porsche "Cayenne" -The Company's Market share of transmission bushing for Japanese car manufacturer is 55 percent. |

|

|

| image |  |

|

|

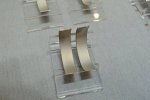

| Copper alloy bearing | PTFE composite bearing | ||

|

|

||

| image image |

image image image |

||

| Tapered land thrust washer with resin coating for transmission | |||

|

|||

| image | |||

| Pb-free Cu-alloy bearing for turbo charger | Thrust bearing for turbo-charger (Steel with surface treatment) | ||

|

|

|

|

|

|||

| Thrust bearing for turbo-charger (Brass materials) | Journal bearing for turbo-charger | ||

|

|

||

| New low friction swash plate for compressor | New weight saving shoe | ||

|

|

|

|

|

|||

| New carbon bearing for scroll type compressor | |||

|

|

||

| Vacuum pump | DC brush-less motor drive vacuum pump | ||

|

Installed vehicle: Toyota "Noah", "Voxy" |

|

|

| image |  |

|

|

| DC brush-less motor drive EGR valve for commercial vehicle | DC brush motor drive exhaust throttle valve for passenger car | ||

|

Installed vehicle: Hino "Profia" |

|

|

| image |  |

image |  |

2013 JSAE

| Engine bearing with RA coating (RA530/SA250) | Engine bearing with new resin coating | ||

|

Installed Vehicle: Toyota "Lexus LS600h","Lexus GS450h", "Crown HYBRID", "Camry HYBRID" -Expanding RA coating adoption for HYBRID, for downsizing and for idling stop |

|

-Con-rod and Main bearing for engine -Under development |

| image image |   |

|

|

| Engine bearing with next-generation resin coating |

Thrust washer with resin coating for engine | ||

|

-Under development |  |

-Under development |

|

|

||

| Tapered land thrust washer with resin coating for transmission |

Con-rod bearing and main bearing for crankshaft | ||

|

-Under development |  |

|

|

|

||

| Main bearing with eccentric oil groove | Pb-free Cu-alloy Bearing for Turbo charger (CZ-X) |

||

|

Installed Vehicle: Toyota "Prius" Mitsubishi "Mirage" Suzuki "Wagon R" Honda "N BOX" |

|

-Under development |

|

|

||

| New weight saving shoe and new low friction swash plate for compressor |

New aluminum alloy bushings (SA156) | ||

|

|

-Under development | |

| image |  |

|

|

| New carbon bushing (CB600) for scroll type compressor |

Mechanical vacuum pump | ||

|

-Under development |  |

Installed Vehicle: Toyota "NOAH", "VOXY" |

|

|||

| Electric vacuum pump for HV/EV | Electric exhaust control valve | ||

|

-Under development |  |

-Under development |

|

|

||

| Pulp mold resin product-Balance shaft gear | Pulp mold resin product -Low friction material/Heat insulator material |

||

|

Installed Vehicle: Toyota "Crown HYBRID" (SOP after Jan. 2013) |

|

|

|

|

||

2012 JSAE

| The Taiho Group's Network expand at World Wide | Advanced Coating Material | ||

|

|

|

Installed vehicle: Honda "N-BOX" |

| image | |||

| New carbon bushings for scroll compressor, CB-X | New low cost resin coating bearing for low fuel consumption | ||

|

|

|

|

| EGR Valve | Vacuum pump | ||

|

|

|

|

| image | image | ||

| Sheet in-between cylinder head gaskets | |||

|

|

||

| image | |||

2011 Tokyo Motor Show

| Exhaust manifold gaskets | Gasket, turbo to exhaust manifold | ||

|

|

BN coating addition type Grommet type |

|

| image | image |  |

|

| Gasket, turbo to exhaust manifold | EGR cooler gasket | ||

|

Grommet type |  |

Bead type |

| Cylinder head gasket | Carbon composite bushings (Non-lubrication) | ||

|

|

|

|

| PTFE composite bushings (Boundary-lubrication) | Aluminum alloy bushings & Copper alloy bushings (Fluid lubrication) | ||

|

|

||

| Copper alloy bushings (Mix lubrication) | Bushing and washer for automatic transmission | ||

|

|

|

|

| Engine bearings for reduction of demand oil amount | Engine bearings designed for excreting foreign particles | ||

|

|

|

|

| Engine bearings for reduction of friction | Engine bearings for high unit load & high sliding velocity | ||

|

|

||

| Engine bearings for radical reduction wear volume & reduction of starting torque | Electric vacuum pump for full support | ||

|

|

|

|

| Electric vacuum pump for assist | Vacuum pump for midget car | ||

|

|

||

| Vacuum pump for midsize car | Vacuum pump for full-sized car | ||

|

|

||

| Cutting model of turbocharger | Compressor housing | ||

|

|

|

|

| Seal plate | Bearing housing | ||

|

|

||

| Journal bearings & thrust collar & thrust bearings | EGR valve | ||

|

|

Drive:DC brush motor Valve type:Poppet type |

|

|

|||

| EGR valve | EGR valve | ||

|

Drive:DC brush-less motor Valve type:Butterfly type |

|

Drive:Torque motor Valve type:Butterfly type |

| Exhaust reduction valve | |||

|

Drive:Torque motor Valve type:Butterfly type |

||

| image | |||

2011 JSAE Automotive Engineering Exposition

| <Vacuum pumps> |

|||

|---|---|---|---|

| Low driving torque vacuum pumps |

|

||

| -Vacuum pump for full-size car |

-Vacuum pump for midsize car | ||

|

|

||

| Image | Image | ||

| -Vacuum pump for midget car | |||

|

|||

| Image | |||

| Electric vacuum pumps |  |

||

| |

|||

| -Electric vacuum pump for assist |

-Electric vacuum pump for full support |

||

|

|

||

| Image | Image | ||

| <Exhaust system components> |

|||

|---|---|---|---|

| |

|||

| Exhaust system components corresponding to exhaust emission regulations |  |

||

| Exhaust system valves for various diesel engines |

|

||

| |

|||

| -EGR valve |

-EGR valve | ||

|

|

||

| Image | Image | ||

| -EGR valve | -Exhaust reduction valve |

||

|

|

||

| Image | Image | ||

| |

|||

| -High airtight valve shut off structure |

|||

|

|||

| Image | |||

| |

|||

| Bearings for turbochargers |

|

||

| -Cutting model of turbocharger |

-Journal bearings, Thrust bearings |

||

|

|

||

| Image | Image | ||

| |

|||

| -Actuator for turbocharger |

-Seal plate for turbocharger |

||

|

|

||

| Image | Image | ||

| <Structural parts> |

|||

|---|---|---|---|

| |

|||

| Machining-free die-casting products |

Thin-walled die-casting products |

||

| -ABS cover |

-EMPS cover |

||

|

|

|

|

| Image | Image | ||

| Resin products saving weight & cost |

|

||

| -Thermostat assembly |

-Inlet water |

||

|

|

||

| Image | Image | ||

| <Engine bearings and bushings> |

|||

|---|---|---|---|

| |

|||

| World-leading "Development of engine bearings" |  |

||

| Lead-free bushing demonstrates high performance with various products (Examples of the application) |

|

||

| |

|||

| -Engine bearings for idling stop & hybrid vehicles |

-Engine bearings for high unit load & high sliding velocity |

||

|

|

|

|

| Image | Image | ||

| -Low friction engine bearings | -Engine bearings for reduction of demand oil amount |

||

|

|

|

|

| Image | Image | ||

| -Engine bearings designed for excreting foreign particles |

-Engine bearings with good & moderate price |

||

|

|

|

|

| Image | Image | ||

| Bushings |

|||

| -Mix lubrication |

-Fluid lubrication | ||

|

|

||

| Image | Image | ||

| -Boundary-lubrication | -Non-lubrication | ||

|

|

||

| Image | Image | ||

| <Metal gaskets> |

|||

|---|---|---|---|

| -Cylinder head gaskets |

-Exhaust manifold gaskets |

||

|

|

|

|

| Image | Image | ||

| -Gaskets for turbochargers |

|||

|

|

||

| Image | |||

JSAE 2010

| EGR valve | Exhaust reduction valve | ||

|---|---|---|---|

|

|

|

|

| image | image | image | |

| Vacuum pump | Microgrooved bearings | ||

|---|---|---|---|

|

|

|

|

| image | image | image | |

| Engine bearings with eccentric oil groove |

High performance bismuth overlay | ||

|---|---|---|---|

|

|

|

|

| image | image | image | |

| Lineup of lead-free engine bearing materials | Lineup of lead-free bushing materials | ||

|---|---|---|---|

|

|

|

|

| image | image | image | |

| Bushing and washer for automatic transmission | Thrust washer for differential | ||

|---|---|---|---|

|

|

|

|

| image | image | ||

| High wear resistance engine bearings | |

|---|---|

|

|

| image | |

JSAE 2009

| Engine Bearings |  |

||

| Low Friction Solid Lubrication Coating(RA) | Microgrooved Bearings | ||

|

|

||

| Image | Image | ||

| Engine Bearings with Eccentric Groove | High Wear Resistance RA/HS, RA/SA | ||

|

|

||

| Image | Image | ||

| Lead-free Bearings | |||

|

|

||

| Image | |||

| Lead-free Bushings | |||

|

|

Image 1 Image 2 Image 3 |

Image 4 Image 5 Image 6 |

| Exhaust System Components |  |

||

| Exhaust Reduction Valve for Diesel Particulate Filter (DPF) Recycling, Standard (Newly Developed Product) |

|||

|

Image : Standard Image : Pressure Adjustment |

||

| Bypass Valve for Two-stage Turbochargers (Newly Developed Product) |

|||

|

Image | ||

| Drive by DC Motor, Butterfly Type, EGR Valve for Passenger Car (Newly Developed Product) |

|||

|

|

Image Image : Line Contact (Cutting Model) |

|

| Vacuum Pump | |||

| Low Torque, Vacuum Pump | |||

|

|

Image 1 Image 2 |

|

| Aluminum Die-Casting Products |  |

||

| Camshaft Housing | ABS Actuator Housing | ||

|

Image |  |

Image |

| Oil Control Valve Sleeves for Variable Valve Timing Systems |

Automatic Transmission Valve Body | ||

|

Image |  |

Image |

| Metal Gaskets | |||

| Cylinder-head Gaskets | |||

|

|

Image 1 Image 2 Image 3 |

|

| Exhaust Manifold Gaskets | Gasket for Turbochargers | ||

|

|

|

|

| Image | Image | ||

Tokyo Motor Show 2005

The Company's exhibit focused mainly on various themes such as environmental solutions, reduced usage of materials, lower fuel consumption and less pollution.

-The Company is engaged in reducing substances that harm the environment; as examples, it developed lead-free aluminum and copper alloys. In its activities in the areas of engine bearings and bushes, it created a diversified product mix that meets regulations on lead.

-Metal Gaskets:

The Company turned Nippon Gasket Co., Ltd. in a wholly owned subsidiary in January 2005 to enhance its competitive edge in developing and producing metal gaskets.

-Exhaust Parts:

EGR valves designed for large-sized diesel engines reduced NOX emissions. By replacing a poppet value with a butterfly value, the Company was able to comply with the New Long-term Emission Regulation.

-High-Performance Engine Bearings:

By studying tribology and applying the knowledge gained to these engine bearings, the Company was able to lower fuel consumption. These eccentric-groove engine bearings reduce not only oil consumption but also the load on the oil pump as well, thus improving fuel consumption. The micro groove bearing, coupled with the use of lead-free bearing material, is fully capable of demonstrating its true worth.

-The Company is engaged in reducing substances that harm the environment; as examples, it developed lead-free aluminum and copper alloys. In its activities in the areas of engine bearings and bushes, it created a diversified product mix that meets regulations on lead.

-Metal Gaskets:

The Company turned Nippon Gasket Co., Ltd. in a wholly owned subsidiary in January 2005 to enhance its competitive edge in developing and producing metal gaskets.

-Exhaust Parts:

EGR valves designed for large-sized diesel engines reduced NOX emissions. By replacing a poppet value with a butterfly value, the Company was able to comply with the New Long-term Emission Regulation.

-High-Performance Engine Bearings:

By studying tribology and applying the knowledge gained to these engine bearings, the Company was able to lower fuel consumption. These eccentric-groove engine bearings reduce not only oil consumption but also the load on the oil pump as well, thus improving fuel consumption. The micro groove bearing, coupled with the use of lead-free bearing material, is fully capable of demonstrating its true worth.

Tokyo Motor Show 2004

The company and Nippon Gasket Co., Ltd. jointly exhibited the following products

- Cylinder head gaskets

- Exhaust manifold gaskets

- Air switching valve gaskets

- Turbine outlet elbow gaskets

- Turbo exhaust manifold gaskets

Proprietary Technologies

Engine bearings

- Engine bearings produced by the company's integrated production system, from raw materials to finished products, as well as based on its half-century tribology research. Taiho Kogyo became a pioneer in developing and commercializing lead-free engine bearings, which are gaining special attention as next-generation bearings.

Special Bearings

The company's special bearings for swash-plate type compressors - one of the main types of compressors used in car air conditioners - are recognized as a global standard due to their high performance.

EGR Valves/Actuators

The company utilizes applied tribology technology and advanced industrial engineering technology to manufacture EGR valves and turbocharger actuators, which are required to operate accurately even under severe conditions.

Aluminum Die-Castings

Although the development and commercialization of various kinds of high-precision, high-tensile, and complex shape aluminum die-castings have been regarded as difficult to achieve, the company successfully materialized.

Balance Weights

The company was quickly able to market environmentally friendly lead-free balance weights by utilizing plastic forming technology and surface treatment technology.

Metal Gaskets

The company, which has drawn upon a new product concept, developed world's first single-layered metal head gaskets for aluminum cylinder heads.

Bush Washers

The company offers various types of bush washers that utilize different kinds of materials formed in different shapes. In the same manner as regards to engine bearings, the company manufactures a wide variety of lead-free bushes.

Electrical and electronic components

The company manufactures coil core assemblies that are the driving part of solenoid valves for automatic transmission. The assemblies are compact and light units using an advanced technology on plastic forming and also a core technology employing slide bearings.

- Cylinder head gaskets

- Exhaust manifold gaskets

- Air switching valve gaskets

- Turbine outlet elbow gaskets

- Turbo exhaust manifold gaskets

Proprietary Technologies

Engine bearings

- Engine bearings produced by the company's integrated production system, from raw materials to finished products, as well as based on its half-century tribology research. Taiho Kogyo became a pioneer in developing and commercializing lead-free engine bearings, which are gaining special attention as next-generation bearings.

Special Bearings

The company's special bearings for swash-plate type compressors - one of the main types of compressors used in car air conditioners - are recognized as a global standard due to their high performance.

EGR Valves/Actuators

The company utilizes applied tribology technology and advanced industrial engineering technology to manufacture EGR valves and turbocharger actuators, which are required to operate accurately even under severe conditions.

Aluminum Die-Castings

Although the development and commercialization of various kinds of high-precision, high-tensile, and complex shape aluminum die-castings have been regarded as difficult to achieve, the company successfully materialized.

Balance Weights

The company was quickly able to market environmentally friendly lead-free balance weights by utilizing plastic forming technology and surface treatment technology.

Metal Gaskets

The company, which has drawn upon a new product concept, developed world's first single-layered metal head gaskets for aluminum cylinder heads.

Bush Washers

The company offers various types of bush washers that utilize different kinds of materials formed in different shapes. In the same manner as regards to engine bearings, the company manufactures a wide variety of lead-free bushes.

Electrical and electronic components

The company manufactures coil core assemblies that are the driving part of solenoid valves for automatic transmission. The assemblies are compact and light units using an advanced technology on plastic forming and also a core technology employing slide bearings.

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India