Archives of Past Exhibits:NHK Spring

Tokyo Motor Show 2017

2017 JSAE Automotive Engineering Exposition

Thin type suspension seat

* Models that equip this component: Isuzu Elf (E.U. model), vehicles for Japan are expected to use these seats in the future as well. * The seat has a structure with dampers and wings, and the large suspension structure had its size and weight reduced through the use of urethane. As a result, the seat can be installed in small trucks. It also reduces costs as they have fewer components. * The seat received an award from the Monodzukuri Nippon Conference in 2016.

* Models that equip this component: Isuzu Elf (E.U. model), vehicles for Japan are expected to use these seats in the future as well. * The seat has a structure with dampers and wings, and the large suspension structure had its size and weight reduced through the use of urethane. As a result, the seat can be installed in small trucks. It also reduces costs as they have fewer components. * The seat received an award from the Monodzukuri Nippon Conference in 2016.

CEATEC JAPAN 2016

Special forming polyurethane products

-Water proof of airtight seal in the field of automobile, electronics and household appliance.

-Water proof of airtight seal in the field of automobile, electronics and household appliance.

2016 JSAE Automotive Engineering Exposition

Tokyo Motor Show 2015

Ceatec Japan 2015

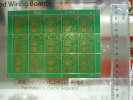

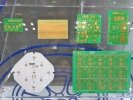

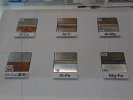

High thermal conductive Metal based printed wiring boards

Applications: -High power device for HEV/EV -High luminosity LED

Applications: -High power device for HEV/EV -High luminosity LED

2015 JSAE Automotive Engineering Exposition

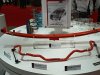

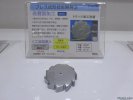

jE Coil Spring

-Installed: Mazda model -Achieve further weight reduction and durability by equalized stress design with variable coil radius. -"jE" means "j" shaped side view and Egg-shaped circle. -Able to produce with existing facilities.

-Installed: Mazda model -Achieve further weight reduction and durability by equalized stress design with variable coil radius. -"jE" means "j" shaped side view and Egg-shaped circle. -Able to produce with existing facilities.

Coil Spring

-FSD coil spring has stress equalization design. Hollow coil spring uses high strength tubular material. Both coil springs are under development.

-FSD coil spring has stress equalization design. Hollow coil spring uses high strength tubular material. Both coil springs are under development.

Ceatec Japan 2014

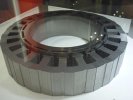

Stamped and stacked metal core for EV/HV motor

-The Company has capability from stamping die design and fabrication to complete motor core mass production. There are two mass production plants for motor core. (USA and Japan) -Started delivering to one EV/HV manufacturer.

-The Company has capability from stamping die design and fabrication to complete motor core mass production. There are two mass production plants for motor core. (USA and Japan) -Started delivering to one EV/HV manufacturer.

Friction stir welding

-Applying Aluminum and Iron bonding to automotive parts is under consideration.

-Applying Aluminum and Iron bonding to automotive parts is under consideration.

2014 JSAE Automotive Engineering Exposition

Tokyo Motor Show 2013

Ceatec Japan 2013

2012 JSAE Automotive Engineering Exposition

Tokyo Motor Show 2011

JSAE 2011

| Stabilizer | Fully Stressed Design Coil Spring | ||

|

|

||

| Image | |||

| Plastic Stabilizer Link | Accumulator | ||

|

|

||

| Image | Image | ||

| Totsubane | Pressure Unit for Stacked Device | ||

|

|

|

|

| Metal-Base Printed Wiring Board | Light Weight Seat Frame | ||

|

|

|

|

| Image | Image | Image | |

| Image | Image | ||

| Ceramic Spring | Direct under type flat lighting technology using the High Luminance LED | ||

|

|

|

|

JSAE 2010

| The seats for the FUGA | Light weight seat frame | ||

|---|---|---|---|

|

|

||

| Image Image |

Image Image Image |

||

| Totsubane | |||

|---|---|---|---|

|

|

||

| Image Image Image Image |

|||

| Contact spring | |||

|---|---|---|---|

| Electric contact spring | Spring contactor | ||

|

Image Image Image Image |

|

Image Image Image Image |

| Pressure unit for stacked device | |||

|---|---|---|---|

|

Image Image Image |

||

| Aluminum-base printed wiring board |  |

||

|---|---|---|---|

| -Aluminum P.W.B. for automotive parts- | |||

| Aluminum P.W.B. for electric motor pump inverter |

Aluminum P.W.B. for electric power steering |

||

|

Image |  |

Image |

| -Aluminum P.W.B. for LED- | |||

|---|---|---|---|

| Aluminum printed wiring boards for LED light |

|||

|

Image Image Image |

||

| Machinable ceramics/ Joining technologies | |||

|---|---|---|---|

|

Image |   |

|

| Micro-slits | Micro-holes | ||

|

Image Image(Type-S) Image(Type-H) |

|

Image Image(Type-S) Image(Type-H) |

| Grooves & holes | Ceramic chips | ||

|---|---|---|---|

|

Image Image(Type-S) Image(Type-H) |

|

Image Image(Type-S) Image(Type-H) |

| Joining to metals (by brazing) | |||

|---|---|---|---|

|

Image | ||

| Tubular stabilizer bar | Tubular torsion bar (Reference exhibit) | ||

|---|---|---|---|

|

|

|

|

| Image Image Image |

Image Image Image |

||

| Fully stress design coil spring (Reference exhibit) |

Tubular coil spring (Reference exhibit) | ||

|---|---|---|---|

|

|

|

|

| Image Image(Wire for FSD coil spring) Image(Wire for FSD coil spring) |

Image | ||

2009 TOKYO Motor Show

| Seat | Active headrest mechanism | ||

|---|---|---|---|

|

Installed vehicle : Nissan "Fuga" |

|

|

| Image | Image | ||

| Seat for premium sport SUV | Seat for high-end 4WD sport car | ||

|---|---|---|---|

|

Installed vehicle : Nissan "Murano" |

|

Installed vehicle : Subaru "WRX" |

| Image | Image | ||

| Seat for compact comfort car | Seat for mini-sized vehicle | ||

|---|---|---|---|

|

Installed vehicle : Nissan "Cube" |

|

Installed vehicle : Suzuki "Wagon R" |

| Image | Image | ||

| Seat for heavy duty truck | |||

|---|---|---|---|

|

|||

| Image | |||

| Leaf spring (above) Tubular stabilizer bar (below) |

Mono leaf spring (above) Tubular torsion bar (below) |

||

|---|---|---|---|

|

|

||

| Image | Image | ||

| Image: Leaf spring | |||

| Image: Tubular stabilizer bar | |||

| Image: Stabilizer link made by aluminum | |||

| Image: Stabilizer link made by steel | |||

| Tubular coil spring | Coil spring | ||

|---|---|---|---|

|

|

||

| Image | Image | ||

JSAE 2009

| Active Headrest Mechanism | AVEC Foam | ||

|

Image |

|||

| Tubular Torsion Bar (reference exhibit) |

Mini Block Coil Spring | ||

|

|||

| Image | Image | ||

| Image | |||

| Tubular Stabilizer Bar | Valve Spring | ||

|

|

|

Image Image (History of valve spring) Image (Current) |

| Image | |||

| Image | |||

| Frictionless Coned Disc Spring | High-Accuracy Disk Springs | ||

Image |

|||

| Aluminum Base Printed Wiring Boards | |||

Image |

Image (Aluminum P.W.B for Electric Motor Pump Inverter/Electric Power Steering) Image (Aluminum P.W.B for Automotive Parts) Image (Aluminum P.W.B for LED Head-up Display) |

||

JSAE 2008

JSAE 2006

< Exhibition Highlights >

Left (Anti-Clockwise) Wound Coil Spring

By adopting the coil springs which are wound in the reverse direction for the front McPherson Strut Suspension, the improvement over the symmetry of the RH & LH geometry could be realized, and it results in high freedom in designing /packaging and vehicle stability.

>>>Technical Information1 , Technical Information2

Bellows Flexible Heat Exchanger

Heat Exchanger Using Metal Bellows >>>Technical Information

Spring Actuator with Energy Absorption (E.A.) function

Actuator for operating pedestrians and passengers protection device

>>>Technical Information

Left (Anti-Clockwise) Wound Coil Spring

By adopting the coil springs which are wound in the reverse direction for the front McPherson Strut Suspension, the improvement over the symmetry of the RH & LH geometry could be realized, and it results in high freedom in designing /packaging and vehicle stability.

>>>Technical Information1 , Technical Information2

Bellows Flexible Heat Exchanger

Heat Exchanger Using Metal Bellows >>>Technical Information

| Features | ||

| - | Possible to be directly attached to various shapes due to high flexibility and expandability | |

| - | High heat transferability compared with conventional heat exchanger using pipes. Possible to achieve high heat exchange rate in small area. | |

| - | Simple structure compared with conventional fluid heat exchanger. | |

| Applications | ||

| - | CPU Cooler >>>Image | |

| - | Heat Spreader for Motor and Generator | |

| - | Cooler for Thermal-Electro Transducer | |

Spring Actuator with Energy Absorption (E.A.) function

Actuator for operating pedestrians and passengers protection device

>>>Technical Information

| Features | ||

| - | Quick pop-out using accumulated spring energy | |

| - | Impact reduction to pedestrians or passengers by E.A. function | |

| - | Reversible on collision avoidance | |

| Applications | ||

| - | Pedestrian protection device >>> Head protection device , Leg protection device | |

| - | Passenger protection device >>> Pop-out E.A. device , Pop-out Roll-bar | |

Tokyo Motor Show 2005

- The Company exhibited several seats of passenger cars which visitors can sit and experience comfort in seat and these functions.

<Automotive Seats>

- Driver's seat for Impreza <<< Features

This seat shape fits the body by using a trim cover bonding method.

- Driver's seat for Legacy (Export specification) <<< Features

- Passenger's seat for Fuga <<< Features

Blowing warm/cold air from inside of the seat makes passenger comfortable.

- Armrest Adjuster <<< Features

Spring clutch function is adapted.

- Hinge unit for Console boxes <<< Features

High torque is exerted in a small space, and it allows arbitrary angle adjustment.

<Suspension springs>

- Thick Wall Tubular Stabilizer Bars <<< Features

This stabilizer bar uses electric resistance welded tube of high wall thickness ratio (ratio of wall/outer diameter : 18 - 30 %), and has the equivalent durability to solid material and is 20 % or more lighter than solid material.

- Accumulator <<< Features

Metal bellows seal initial gas so as to realize maintenance free solution.

<Automotive Seats>

- Driver's seat for Impreza <<< Features

This seat shape fits the body by using a trim cover bonding method.

- Driver's seat for Legacy (Export specification) <<< Features

- Passenger's seat for Fuga <<< Features

Blowing warm/cold air from inside of the seat makes passenger comfortable.

- Armrest Adjuster <<< Features

Spring clutch function is adapted.

- Hinge unit for Console boxes <<< Features

High torque is exerted in a small space, and it allows arbitrary angle adjustment.

<Suspension springs>

- Thick Wall Tubular Stabilizer Bars <<< Features

This stabilizer bar uses electric resistance welded tube of high wall thickness ratio (ratio of wall/outer diameter : 18 - 30 %), and has the equivalent durability to solid material and is 20 % or more lighter than solid material.

- Accumulator <<< Features

Metal bellows seal initial gas so as to realize maintenance free solution.

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India