"Bearing" technology satisfying the needs of customers

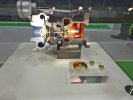

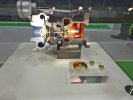

Turbo charger bearing -Journal bearing / Thrust bearing

Transmission bush (DDK05)

-PTFE polymer bearing for non-lubrication condition

-PTFE polymer bearing for non-lubrication condition

Transmission bush (A66T)

-Wear resistance aluminum alloy

-Wear resistance aluminum alloy

Fuel injection pump bush

Bearings for sliding door -Roller bearing / Door stopper

Shock absorber bush

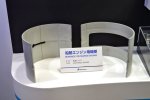

Engine bearing

-World share number 1. (Number 2 is Federal Mogul .)

-World share number 1. (Number 2 is Federal Mogul .)

Engine bearing -New surface treatment for low friction (DMS1)

-New treatment of dispersing MOS2 (solid lubricant) on the bearing surface.

-New treatment of dispersing MOS2 (solid lubricant) on the bearing surface.

Engine bearing -New surface treatment for wear resistance (DLA02)

-New treatment with solid lubricant dispersed on the resin layer of bearing surface.

-New treatment with solid lubricant dispersed on the resin layer of bearing surface.

New surface treatment for low friction: DMS1

-New treatment of dispersing MoS2 (solid lubricant) on the bearing surface. -No resin used. -Application: Engine

-New treatment of dispersing MoS2 (solid lubricant) on the bearing surface. -No resin used. -Application: Engine

New surface treatment for wear resistance: DLA02

-New treatment with solid lubricant dispersed on the resin layer of bearing surface. -Application: Engine

-New treatment with solid lubricant dispersed on the resin layer of bearing surface. -Application: Engine

High strength material: A46X

-Application: Engine

-Application: Engine

Daido Eco Crescent

-Decrease oil leakage -Application: Engine

-Decrease oil leakage -Application: Engine

Daido Eco Lug

-Application: Engine

-Application: Engine

Daido Eco Cleaner

-Improve robustness against foreign matter contamination.

-Improve robustness against foreign matter contamination.

R & P (Ramp and Pad)

-Thrust washer improving load capacity and reduce friction

-Thrust washer improving load capacity and reduce friction

Corrosion and wear resistance copper alloy: YZ6X

-Application: Journal bearing for Turbocharger

-Application: Journal bearing for Turbocharger

Bushing (Aluminum / Copper)

Copper solid bushing

High strength PEEK polymer bearing: DTK57

-Application: Fuel injection pump

-Application: Fuel injection pump

PTFE polymer bearing for non-lubrication condition: DDK05

-Application: Bushing for air conditioner compressor, Support bearing for steering rack, Bushing for throttle body, Bushing for wiper arm link, Bushing for door hinge, AT, CVT

-Application: Bushing for air conditioner compressor, Support bearing for steering rack, Bushing for throttle body, Bushing for wiper arm link, Bushing for door hinge, AT, CVT

PTFE polymer bearing for boundary lubrication condition: DDK02

-Application: Bushing for hydraulic pump of power steering, Bushing for air conditioner compressor, AT, CVT, Shock absorber

-Application: Bushing for hydraulic pump of power steering, Bushing for air conditioner compressor, AT, CVT, Shock absorber

Polyamide resin with fibrous reinforcement polymer: DHA03

-Application: Roller bearing for sliding door

-Application: Roller bearing for sliding door

Heat resistance and low friction PPS polymer: DTP11

-Application: Tip seal

-Application: Tip seal

Oil-impregnated bearings of own proprietary lubrication characteristics: DBB01

Pre-lubricating bearing: DBX01

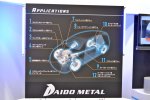

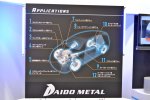

Bearing applications

- Various types of bearings made from different materials are placed optimally in accordance with the characteristics of each materials

- Various types of bearings made from different materials are placed optimally in accordance with the characteristics of each materials

Engine Cut Model

- Current bearings are used in BMW 3 series and 1 series engines

- Current bearings are used in BMW 3 series and 1 series engines

Bearings for Marine Engines

Bearings and Bushes for Automobile Engines

Improvement of Bearing Robustness: Daido Eco Cleaner & Decrease Oil Leakage: Daido Eco Lug

High Strength Material: A09H & Superior Wear Resistance Material: A67T

High Strength PEEK Polymer Bearing: DTK57 & Superior Wear and Seizure Resistance Material: BX1

New Surface Treatment for Wear Resistance: DLA02 & New Surface Treatment for Low Friction at Steady Speed: DMS1

PTFE polymer bearing for boundary lubrication condition

High strength PEEK polymer bearing

PTFE polymer bearing for non-lubrication condition

Wear resistance copper alloy

Wear resistance Al alloy

Heat resistance and low friction PPS polymer

Seizure resistance and wear resistance copper alloy

Nylon resin with fibrous reinforcement polymer

Bearings for automotive engines

Rack and pinion steering bushes

Superior wear resistance bearings

Low friction bearings

Aluminum alloy half bearings

Bearings for low fuel consumption

Pb free aluminum alloy bearings

Lead free copper alloy bearings

Throttle Body bushes

Shock absorber bushes

Rack-support

Scroll compressor

Starter bushes

AT

Thrust bearing for Turbo charger

Power steering pump

Floating bearing for Turbo charger

Fuel injection pump

-New treatment of dispersing MoS2 (solid lubricant) on the bearing surface. -No resin used. -Application: Engine

-New treatment of dispersing MoS2 (solid lubricant) on the bearing surface. -No resin used. -Application: Engine

-New treatment with solid lubricant dispersed on the resin layer of bearing surface. -Application: Engine

-New treatment with solid lubricant dispersed on the resin layer of bearing surface. -Application: Engine

-Application: Bushing for air conditioner compressor, Support bearing for steering rack, Bushing for throttle body, Bushing for wiper arm link, Bushing for door hinge, AT, CVT

-Application: Bushing for air conditioner compressor, Support bearing for steering rack, Bushing for throttle body, Bushing for wiper arm link, Bushing for door hinge, AT, CVT

-Application: Bushing for hydraulic pump of power steering, Bushing for air conditioner compressor, AT, CVT, Shock absorber

-Application: Bushing for hydraulic pump of power steering, Bushing for air conditioner compressor, AT, CVT, Shock absorber

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India