Archives of Past Exhibits:F.C.C.

Shanghai International Automobile Industry Exhibition 2015

2014 JSAE Automotive Engineering Exposition

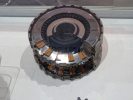

Front-Transverse 9 Speed Planetary Transmission Clutch for ZF (1)

Installed Vehicle: Jeep "Cherokee" (Year 2014 model)

Installed Vehicle: Jeep "Cherokee" (Year 2014 model)

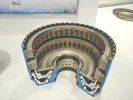

Front-Transverse 6 Speed Planetary Transmission Clutch for Ford

Installed Engine: Ford 4 cylinders in Line "Eco Boost" engine Installed Vehicle: Ford "Explorer"

Installed Engine: Ford 4 cylinders in Line "Eco Boost" engine Installed Vehicle: Ford "Explorer"

2013 JSAE Automotive Engineering Exposition

2012 JSAE Automotive Engineering Exposition

JSAE 2011

| AT clutch for high torque planetary gear type transmission |

AT clutch for planetary gear type transmission | ||

|

|

Installed vehicle : Ford Explorer |

|

| Image | Image | ||

| Dry twin disk clutch |

Wet multi disk - Triple clutch with low hold |

||

|

|

Installed vehicles : Honda Elysion Honda Legend Honda Acura TSX |

|

| Image | Image | ||

| Differential system clutch - with cam function |

|||

|

Installed vehicles : Honda CR-V Honda Odyssey |

||

| Image | |||

| Multi plate lock-up clutch |

Lock-up clutch |

||

|

Installed vehicle : Honda Acura MDX |

|

Installed vehicles : Honda Elysion Honda Accord Honda CR-V Honda Fit |

| Image | Image | ||

| Image | Image | ||

| Wet multi disk clutch with assist & slipper system |

Racing slipper clutch |

||

|

|

||

| Image | Image | ||

| Image | |||

| Electrical resistance welding |

Limited slip differential for ATV "FCCTRAC(R)" |

||

|

|

||

| Image | Image | ||

| Drive plate |

|||

| -Drive plate (FSD) |

-Drive plate (FAS) | ||

|

Installed vehicles : Honda Fit Honda Insight Honda CR-Z |

|

Installed vehicles : Honda Accord Honda CR-V Honda Civic |

| Image | Image | ||

JSAE 2010

| Multi plate lock-up clutch | Differential system clutch with cam function |

|---|---|

|

|

| image | image |

| Dry twin disk clutch | Wet multi disk-double clutch |

|---|---|

|

|

| image | image |

| AT clutch for planetary gear type transmission |

Drive plate |

|---|---|

|

|

| image | image |

| Advanced friction material for lock-up clutch | Paper ceramic material | |

|---|---|---|

|

|

|

| image | image |

JSAE 2009

| Catalyst Paper (under development) Aimed at commercialization by the end of fiscal 2010 |

|||

|

Multi-pore structure produced by wet-type paper pressing process Ceramic material embedded in paper by application of paper pressing technology |

Image Image Image |

|

| CVT Clutch Following products are actual products installed in Honda Insight except drum integrated with HUB |

|||

|

Image Image (CVT starter clutch1) Image (CVT starter clutch2) Image (CVT forward clutch) Image (Drive plates / Driven plates for CVT) Image (Drum integrated with HUB) |

||

| Differential system clutch - with cam function | AT clutch for planetary gear type transmission | ||

|

Image1 Image2 Installed in Honda CR-V |

|

Image1 Image2 Installed in Ford Explorer |

| Wet multi disk - Double clutch | |||

|

Image1 Image2 Installed in Honda Accord |

||

| Drive plate for AT/CVT/DIFF | Wet multi disk - Single clutch | ||

| Image1 Image2 |

|||

| Dry single disk clutch | Lock-up clutch - with long torsional spring | ||

|

Image1 Image2 |

|

Image1 Image2 |

JSAE 2008

| <Highlights> |

|

|

What do you want us to see ? |

|

|

(2) AT Mission Clutch Pack (Image1) (Image2) (Image3) - Installed in Acura MDX |

SAE World Congress 2006

FCC Indiana, the Company's subsidiary in the U.S. for production, exhibited at the SAE 2006 World Congress.

Clutch for Ford Explorer, 6-speed AT mode: Whole ![]() / Enlarged

/ Enlarged ![]()

-Its production started in spring 2005.

-It will be installed on Expedition and other models in the future.

Aluminum pistons are adopted.

-Planetary type.

-GROB forming to reduce housing size.

Overview of FCC Indiana

Since established in 1988, FCC Indiana has manufactured more than 3.5 million AT clutch assemblies and torque converter lock-up clutches. Its sales exceed 178 million dollars and main customers are Honda Transmission Manufacturing of America, Honda Engine Plant, Saturn Corporation and Ford.

Tokyo Motor Show 2005

AT clutch for planetary gear type transmission

- Mass production started in May 2005 in FCC (Adams), LLC. in USA. and the scale

volume supply to FORD Motor started in 2005.

- Low cost and better productivity thanks to the press molding technology and roll forming.

CVT starter clutch - Hybrid engine -

- The display introduced the new friction material with good judder behavior, high endurance

for continuous slip and temperature features. Achieved the light weight thanks to the thin

clutch guide.

- Technical Information -

Clutch Housing

"One Time Press"(Thick Steel Machining Process)

Feature: This method requires only one die and it can contribute to reduce initial investment (the investment for die) in large amount.

"Saving of production process"(Thin Steel Machining Process)

Features : Adopting thin-plate made clutch made it possible to reduce weight, and change of production method allows cost reduction. Elimination of the cutting process realizes the unmanned production line and contributes to the mass production.

| Category | Clutch Housing | Features | |||

| precision | Cost | ||||

| small lot production | mass production | ||||

| Plasticity Process | Press | One time Press | ◎ | ○ | ○ |

| saving technology for production process | ◎ | △ | ◎ | ||

Segment System

-The "segment method" is the Company's original method that has improved clutch

production. The material yield is greatly improved from the punched type by adhering

tape-type friction material to the disk core plate, thereby increasing speed and eliminating

wastes. This method is also effective in improving the press and die cast accuracy, reducing

machining processes, and leading to great reductions in delivery schedules and costs.

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India