Archives of Past Exhibits:NTN

Tokyo Motor Show 2015

Auto tensioner with the Variable damper mechanism for ISG-Equipped engine / Resin pulley

Auto tentioner: -Under development -Automatically adjusts the tension of accessory belts to suit ISG-Equipped engine's conditions. Resin pulley: -Series production

Auto tentioner: -Under development -Automatically adjusts the tension of accessory belts to suit ISG-Equipped engine's conditions. Resin pulley: -Series production

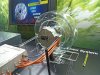

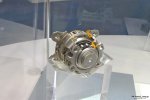

Two motor on-board drive system

-To provide the optimum torque to each wheel independently according to traveling conditions

-To provide the optimum torque to each wheel independently according to traveling conditions

Electric ball screw actuator unit for spool valve drive -World premier-

-Axial force: More than 35N -Electric actuator unit for the spool valve drive system of CVT/AT.

-Axial force: More than 35N -Electric actuator unit for the spool valve drive system of CVT/AT.

Linear type electric actuator

-Max. axial force: 2,000N (Design example) -Gear shifting mechanism of transmission for AMT, CVT etc.

-Max. axial force: 2,000N (Design example) -Gear shifting mechanism of transmission for AMT, CVT etc.

Ball screw drive module for electric hydraulic brake (GEAR BOX)

-Max. load capacity: 14kN -Electric hydraulic brake system Installed vehicle: Honda "Fit"

-Max. load capacity: 14kN -Electric hydraulic brake system Installed vehicle: Honda "Fit"

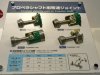

Advanced driveshaft module -World premier-

-"Press Connect Spline Hub Joint" on the tire side, with CVJ standardized and commonized for each required torque range and a hub bearing welded using the press connect method for a lighter weight and higher performance. -The diff side features "EBW Driveshaft" that connects standardized and communized CVJ by required torque range and individually designed stem section with a high level of precision using electron beam welding.

-"Press Connect Spline Hub Joint" on the tire side, with CVJ standardized and commonized for each required torque range and a hub bearing welded using the press connect method for a lighter weight and higher performance. -The diff side features "EBW Driveshaft" that connects standardized and communized CVJ by required torque range and individually designed stem section with a high level of precision using electron beam welding.

2015 JSAE Automotive Engineering Exposition

Mechanical clutch unit for next generation steering

-Connect mechanically in case steer-by-wire is in breakdown Installed vehicle: Nissan "Skyline"

-Connect mechanically in case steer-by-wire is in breakdown Installed vehicle: Nissan "Skyline"

Mechanical clutch unit for next generation steering (Demonstration)

-Connect mechanically in case steer-by-wire is in breakdown

-Connect mechanically in case steer-by-wire is in breakdownBall screw drive module for electric hydraulic brake

-Motor rotation conversion efficiency using ball screw: 80% -8% efficiency increase of regenerative braking system Installed vehicle: Honda "Fit EV", "Fit Hybrid", "Accord Hybrid"

-Motor rotation conversion efficiency using ball screw: 80% -8% efficiency increase of regenerative braking system Installed vehicle: Honda "Fit EV", "Fit Hybrid", "Accord Hybrid"

Low section high strength press pulley

-Pulley boss ratio O.D/I.D.: less than 1.4 -Pulley material thickness: more than 3.0mm -Load-resistance: more than twice

-Pulley boss ratio O.D/I.D.: less than 1.4 -Pulley material thickness: more than 3.0mm -Load-resistance: more than twice

Shanghai International Automobile Industry Exhibition 2015

2014 JSAE Automotive Engineering Exposition in NAGOYA

China Auto Parts And Service Show 2014

2014 JSAE Automotive Engineering Exposition

Mechanical Clutch Unit for Next Generation Steering

-Back up function of Steer-by-wire. -World first exhibit Installed vehicle: Nissan "Skyline"

-Back up function of Steer-by-wire. -World first exhibit Installed vehicle: Nissan "Skyline"

Ball Screw Drive Module for Electric Hydraulic Brake

Installed vehicle: Honda "Fit EV", "Fit Hybrid", "Accord Hybrid" *The regenerative braking system is made by Nissin Kogyo

Installed vehicle: Honda "Fit EV", "Fit Hybrid", "Accord Hybrid" *The regenerative braking system is made by Nissin Kogyo

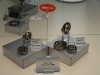

Compact Shudderless Pillow Journal Tripod Joint (EPTJ)

-Highest level of NVH performance in the world. (NVH = Noise, Vibration, Harshness)

-Highest level of NVH performance in the world. (NVH = Noise, Vibration, Harshness)

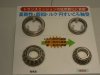

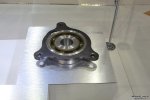

Super Low Friction Hub Bearing

-Bearing friction is 33% reduced. -Minute damping in surface and special low friction grease are applied.

-Bearing friction is 33% reduced. -Minute damping in surface and special low friction grease are applied.

Electromechanical Brake System with Parking Brake

-Fuel saving by regenerative brake. -Parking brake function available. -Under development

-Fuel saving by regenerative brake. -Parking brake function available. -Under development

High Speed Deep Groove Ball Bearing for Motor and Reducer of EV/HEV (Grease lubrication type)

-Reference Exhibit

-Reference Exhibit

2014 Auto China - Beijing International Automotive Exhibition

Tokyo Motor Show 2013

2013 JSAE Automotive Engineering Exposition

Shanghai International Automobile Industry Exhibition 2013

JSAE 2012

| By-wire system concept | In-wheel motor | ||

|

|

||

| image |  |

||

| Inverter for in-wheel motor | Electric brake and multiaxial load sensor | ||

|

|

||

| image | |||

| Steering reaction force actuator (steer by wire) | Wheel-turning actuator and controller | ||

|

|

||

| image | image image |

||

| One motor type EV drive system | Inverter for one motor type EV drive system | ||

|

|

||

| Electromechanical brake system for front wheel | Electromechanical brake system for rear wheel with parking function | ||

|

|

||

| image |  |

image |  |

| Axle bearings - Global production bases | Low friction hub bearing | ||

|

|

||

|

|

||

| Hub bearing for severe environment | Hub bearing for severe environment / Improvement of sealing performance | ||

|

|

||

| image |  |

image |  |

| Lightweight GEN3 hub bearing | Next generation high efficiency fixed type CVJ "CFJ" | ||

|

|

||

| image image image image |

|

image image |

|

| "E-series" Constant velocity joint for automobiles | Value series VUJ | ||

|

|

||

| image image image image image |

|

image image |

|

| Sensor integrated corner module for EV | Press cut spline hub joint | ||

|

|

|

|

| image |   |

image image |

|

| Linear type electric actuator | Linear type electric actuator | ||

|

|

||

| image image |

|

image image |

|

| Ball screw | Rotational type electric actuator | ||

|

|

||

| image image |

image |  |

|

| Motor and roller reducer | High speed and low torque deep groove ball bearing | ||

|

|

||

| image image image image |

|

||

| Low torque sealed deep groove ball bearing for EV motor | Low torque deep groove ball bearing (without seal) | ||

|

|

||

| image image image image |

|

image image image |

|

| Self-formed seal low torque deep groove ball bearing | High thrust load deep groove ball bearing (Developed) | ||

|

|

||

| image | image image |

|

|

| Taper roller bearing (Conventional) | Applied to the differential | ||

|

|

||

| image image |

|||

| High thrust load deep groove ball bearing | High thrust load deep groove ball bearing (Developed) | ||

|

|

||

|

image image |

||

| Deep groove ball bearing (Conventional) | |||

|

|||

2012 Beijing International Automotive Exhibition

| Hub bearing for severe environment | Sensor integrated hub bearing | ||

|

|

||

| Image | Image | ||

|

|

||

| Lightweight GEN3 hub bearings | |||

|

|

||

| Image | Image | ||

|

Image | ||

| Press cut spline hub joint | Constant velocity steering joint | ||

|

|

||

| Image | Image | ||

|

|

||

| Value series CVJ | Constant velocity joint | ||

|

|

||

| Image | Image | ||

|

|

||

| Bearings for transmission | Clutch for seat lifter | ||

|

|

||

| Image | Image | ||

|

|||

| Needle roller bearings for rocker arm in engine | Clutch for seat lifter | ||

|

|

||

| Image | Image | ||

|

|

||

| Linear type electric actuator | High speed and low torque deep groove ball bearing | ||

|

|

||

| Image | Image | ||

|

|

||

| Needle roller bearings for camshaft | In-wheel motor system | ||

|

|

||

| Image | Image | ||

|

In-wheel motor system for electric commuters |

||

Tokyo Motor Show 2011

| Low Friction Chain Lever & Guide | High Thrust Load Deep Groove Ball Bearing | ||

|

|

|

|

| image | |||

| One Motor Type Electric Vehicle Drive System | Steering System for Steer-by-Wire | ||

|

|

|

|

| image image image image |

|||

| In-Wheel Motor System | Electromechanical Brake System | ||

|

|

|

|

| image | image | ||

| Constant Velocity Joint/Hub Bearing | Constant Velocity Joint for Propeller Shaft | ||

|

|

|

|

| image | |||

| Linear type electric actuator | Linear type electric actuator | ||

|

|

|

|

| image | image | ||

| Low Torque Sealed Deep Groove Ball Bearing for EV Motor | High-Speed Low-Torque Deep Groove Ball Bearing for EV and HEV | ||

|

|

|

|

| Lightweight GEN3 Hub Bearing | Sensor Integrated Corner Module for EV | ||

|

|

|

|

| image | |||

| Hub bearing for severe environment | |||

|

|

||

JSAE 2011

| In-wheel Motor System for Electric Commuters | In-wheel Motoer System | ||

|

|

|

|

| Image | Image | ||

| One Motor Type Electric Vehicle Drive System | Sensor integrated Corner Module for EV | ||

|

|

|

|

| Image | |||

| Image | |||

| Image | |||

| On-board Drive System | Electromechanical Brake Actuator System | ||

|

|

|

|

| Image | Image | ||

| Test Vehicle for On-board Drive System | Steering System for Steer-by-wire | ||

|

|

|

|

| Image | Image | ||

| Hub bearing for severe environment | Super Light Weight GEN3 Hub Bearing for K-cars | ||

|

|

|

|

| Image | Image | ||

| Image | |||

| Axle Bearing Global Production | Phenol Resin Pulley Unit | ||

|

|

|

|

| Short-type Auto Tensioner for Accessory Belt Drive | Self-mount Type Chain Tensioner | ||

|

|

|

|

| Image | Image | ||

| Image | Image | ||

| Image | |||

| Low Torque Deep Groove Ball Bearing(without Seal) | High-rigidity and Super Low Torque Tapered Roller Bearing | ||

|

|

|

|

| Image | |||

| Image | |||

| Low Section Thrust Needle Roller Bearings in Radial Direction & Races for Eccentric | Linear Type Electric Actuator | ||

|

|

|

|

| Image | |||

| Image | |||

| Low Torque Deep Croove Ball Bearing(with Seal) | Low Torque Sealed Deep Groove Ball Bearing for EV Motor | ||

|

|

|

|

| Image | Image | ||

| EPTJ Compact Shudderless Pillow Journal Tripod Joint | "E-series" Constant Velocity Joint for Automobiles | ||

|

|

|

|

| Value series VUJ | CSJ(Constant Velocity Steering Joint) | ||

|

|

|

|

| Image | |||

| Low-torque Roller Lifter Unit | Needle Roller Bearings for Rocker Arm in Engine | ||

|

|

|

|

| Low Friction Split type Needle Roller Bearings for Automotive Engine | Planetary Gear Unit | ||

|

|

|

|

| Image | |||

| Ceramic Ball Bearing for EV Motor | Planetary Reduction & Differential Module for Electric Vehicle | ||

|

|

|

|

JSAE 2010

| V-series hub joint | |||

|---|---|---|---|

| V-series hub joint | V-series hub joint | ||

|

|

||

| Image Image Image |

Image Image Image |

||

| V-series hub joint assembly (non-separable type) |

|||

|---|---|---|---|

|

|||

| Image Image |

|||

| V-series angular unit | Super light weight | ||

|---|---|---|---|

|

|

||

| Image Image Image Image Image |

Image Image (Conventional type) Image (Improved type) |

||

| Wide-range high-resolution small sensor integrated hub bearing |

Optimized hub bearing for weight savings | ||

|---|---|---|---|

|

|

||

| Image Image Image |

Image Image (Conventional type) Image (Conventional type) Image (Improved type) Image (Improved type) |

||

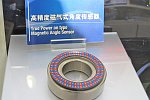

| True power on type magnetic angle sensor (Reference exhibit) |

Multiaxis load sensor integrated hub bearing |

||

|---|---|---|---|

|

|

||

| Image Image Image |

Image Image Image |

||

| High capacity tapered roller bearing | CSJ (Constant velocity steering joint) | ||

|---|---|---|---|

|

|

||

| Image Image (Conventional type) Image (Conventional type) Image (Improved type) Image (Improved type) Image Image |

Image Image Image |

||

| Light weight and high efficiency drive shaft for FR vehicle |

High efficiency undercut free joint | ||

|---|---|---|---|

|

|

||

| Image Image |

Image Image |

||

| Constant velocity joint for propeller shaft | Value series VUJ (Under development) | ||

|---|---|---|---|

|

|

||

| Image Image (FEBJ Fixed type) Image (FEBJ Fixed type) Image (HEDJ Plunging type) Image (HEDJ Plunging type) Image (HETJ Plunging type) Image (HETJ Plunging type) Image (HLJ Plunging type) Image (HLJ Plunging type) |

Image Image |

||

| High efficiency ELJ for propeller shaft | Phenol resin pulley unit | ||

|---|---|---|---|

|

|

||

| Image (Improved type) Image (Conventional type) |

Image Image Image Image |

||

| Short-type auto tensioner for accessory belt drive | |||

|---|---|---|---|

|

|||

| Image Image Image |

Image Image (Conventional type) Image (Improved type) |

||

| Self-mount type chain tensioner | |||

|---|---|---|---|

| Self-mount type saw-tooth screw chain tensioner | Self-mount type ring chain tensioner | ||

|

|

||

| Image | Image | ||

| High-rigidity and super low torque tapered roller bearing |

Needle roller bearings for rocker arm in engine |

||

|---|---|---|---|

|

|

||

| Image Image (Conventional type) Image (Improved type) Image |

Image Image (Conventional type) Image (Improved type) Image (Improved type) Image (Improved type) |

||

| Minimized cross section drawn cup needle roller bearings | Low-torque thrust needle roller bearings | ||

|---|---|---|---|

|

|

||

| Image Image (Conventional type) Image (Improved type) Image |

Image Image (Conventional type) Image (Improved type) |

||

| Low friction split type needle roller bearings for automotive engine | |||

|---|---|---|---|

| Split type drawn cup needle roller bearings for camshaft |

Split type needle roller bearings for camshaft |

||

|

|

||

| Image Image (Improved type) |

Image Image (Conventional type) Image (Improved type) |

||

| Planetary gear unit | Low-torque roller lifter unit | ||

|---|---|---|---|

|

|

||

| Image Image (Conventional type) Image (Improved type) Image (Planetary gear bearing) Image (Planetary gear bearing) Image (Planetary gear bearing) |

Image Image |

||

| Low torque deep groove ball bearing (with seal) | Low torque deep groove ball bearing (without seal) | ||

|---|---|---|---|

|

|

||

| Image Image (Conventional type) Image (Improved type) |

Image Image Image |

Image Image Image |

|

| Intelligent in-wheel (Reference exhibit) | |||

|---|---|---|---|

|

|||

| Image Image Image |

|||

JSAE 2008

| <Low Friction Zone> | |||

| Super Low Torque Tapered Roller Bearing | High Efficiency Compact Cross Groove Joint | ||

|

While maintaining long life and rigidity, the size, weight and rotating torque have been substantially reduced. |  |

Downsizing the diameter of balls and increasing their number from 6 to 10 have resulted in reduction in size and weight, as well as high performance. |

| Image | Image | ||

| Hub Bearing Integrated High Sealed up and Low Friction Seal | Ballscrew Unit for Continuously Variable Valve System | ||

|

Optimized structure, shape and rubber materials in the same seal space have doubled sealing performance and reduced friction by 15%. |  |

The ballscrew unit has achieved lower consumption of electricity and higher responsiveness in the Continuously Variable Valve System. |

| Image | Image1 | ||

| Image2 | |||

| Low Friction Split type Needle Roller Bearings for Automotive Engine | Minimized Cross Section Drawn Cup Needle Roller Bearings | ||

|

Low friction due to shifting from slide bearings to roller bearings can improve fuel efficiency by 3%. |  |

Rotating torque can be reduced by 50% compared with sliding bearings. |

| Image (for Crankshaft) | Image | ||

| Image (for Camshaft) | |||

| <Smaller size, lighter weight Zone > | |||

| FA Deep Groove Ball Bearing | Super-high Capacity Tapered Roller Bearing | ||

|

Fine Austenite Strengthening (FA) treatment on a standard axis bearing has expanded longevity. |  |

World's highest capacity and rigidity |

| Image | Image | ||

| Planetary Gear Assembly | Triple-unit 2mm Cross Section Thrust Needle Roller Bearings | ||

|

Responding to higher speed and more compact transmissions |  |

|

| Image (Parts) | Image | ||

| Image | |||

| FA-treated Bearings for Rocker Arm in Engine | Constant Velocity Steering Joint | ||

|

Application of technology for long life has reduced weight in valves and expanded their product life.. |  |

The joint provides smooth steering without shudder in 360-degree operational angles. |

| Image | Image | ||

|

Image |

|||

| Coupled Ball Undercut-free Joint | EPTJ Compact Shudderless Pillow Journal Tripod Joint | ||

|

|

|

Light-weight, compact low vibration constant velocity joint with the world's highest level of NVH |

| Image | Image | ||

| Light weight Hub Bearing for saving | Super Light Weight GEN3 Hub Bearing for Light Weight Vehicle | ||

|

|

|

Hub bearing for mini vehicles of a 1.0 kg mass |

| Image1 (Left: conventional type/Right: new type) | Image1 (Left: conventional type/Right: new type) | ||

| Image2 | Image2 | ||

| High-temperature Resin Pulley Unit for Accessory Belt Drive | |||

|

Light weight and longevity have been achieved. | ||

| Image | |||

| <Hub Joint Zone> | |||

| V-series Hub Joint<Non-separable type> | Value series VBJ | ||

|

Hub bearing and CVJ integrated |  |

High cost performance, light weight and compact fixed type constant velocity joint with the maximum operating angle of 47 degrees |

| Image | Image (Left: conventional BJ / Center: Conventional outer wheel stem type VBJ / Right: Outer wheel press cut tyep VBJ) | ||

| Image (ASSY) |

|||

| Value series VDJ | V-series Hub Joint<Separable type> | ||

|

High cost performance, light weight and compact sliding ball-type constant velocity joint |  |

Hub bearing and constant velocity joint integrated |

| Image (Left: conventional DOJ / Right: new VDJ) | Image | ||

| Value series VTJ | |||

|

|

||

| Image (Left: conventional TJ / Right: new VTJ) | |||

| Intelligent Axle Unit | Next Generation of Load Sensing Hub Bearing | ||

|

Responding quickly to generate driving and braking power by the motor |  |

|

| Image | Image | ||

| Hub Bearing with the Load Sensor | |||

|

|||

| Image | |||

JSAE 2007

| Coupled ball Undercut-free Joint | |||

|

-New compact fixed-type constant velocity joint. -Max. operating angle 50 degrees. -The smallest size in the world. -Contributes to weight reduction and greater flexibility in drive train designing |

Image | Targeted at small and mini vehicles |

| Tapered Roller Hub Bearing for Semifloating Suspension | |||

|

-The world's first mass production model for semifloating suspensions. -Featuring light weight, easy mounting and reliability. |

Image | -For axle bearings of compact trucks and commercial vehicles. -Installed on Daimler Sprinter. |

| High-speed Thrust Needle Roller Bearings | |||

|

-The highest speed in the world -1.5 million dmn -Rise in temperature reduced by 35% -1.3 times more sturdy than conventional bearings |

Image | Used for hybrid systems and automatic transmissions |

| GEN3 Hub Bearing with Active ABS Sensor | |||

|

-Embedding active ABS sensor -Mounting workload reduced -Reliability improved |

Image | -Installed on Suzuki SX-4 -Used for axle bearings |

JSAE 2006

["Reference Model"]

In-Wheel Type Integrated Motor Axle Unit

Hub bearings, deceleration gears and a motor are integrated to reduce the axial size, which is designed for electric and hybrid vehicles.

Performance

Unit mass: 20 kg

Rated output: 20 kW

Decelerator efficiency: Max. 94%

Motor revolution: Max. 15,000 rpm equivalent to vehicle speed of 150 km/h

Features and structure

-Adoption of cycloid deceleration mechanism provides for a high deceleration ratio and a reduced axial size.

-Adoption of an axial gap-type motor reduces the axial size.

-Use of rollers at the connecting point and adoption of counterweight improve efficiency of decelerators and rotation allowance.

New Type CVT (Monoring CVT)

A high performance CVT, which was designed by the company's own technology, has attracted a keen attention since its debut at the 2005 Tokyo Motor Show.

Features and performance

-New mechanism in place of belt CVTs. It features simple structure and deceleration mechanism. Transmission efficiency is high in the range of constant use.

Technology for development

-A tooth ring is used instead of a metallic belt.

-It has a simple structure, and adjusts pushing pressure passively depending on load.

(Improvement in efficiency and life)

High Capability Tapered Roller Hub Bearing

-The number of roller bearings can be increased from 23 to 25 by sliding a roller retainer outward without changing a bore size.

-Calculated life is made longer by 20% and bearing rigidity is improved by 7%.

Current /New development

Tokyo Motor Show 2005

New type of one-way clutch with stator

- The sprag support structure by garter spring reduced the trailing torque by one fifth (vs.

the Company's product). The drawn-cup structure reduced number of part items from

5 to 3.

- Applicable for torque converter 1WC and transmission converter 1WC.

Mechanical lash adjuster

- Comparing to the conventional hydraulic type (HVA), shortening of height to shaft direction

by one half was achieved. Thus, this contributed to a compact design of engine.

- A splash lubrication of engine oil doesn't require any hydraulic supply compulsorily, nor

hydraulic supply circuit.

- No case of aeration and rare occurrence of valve lift loss when starting ignition under low

temperature.

New type CVT (Monoring CVT)

- CVT composed with toothed ring, V-pulley and output gear. Independent-teethed ring is

used as a torque transfer media.

- Comparing to other, this type requires less parts items and does not require any outer

control device.

Hub bearing with sensor for ABS and detection of rotational direction

- Built-in active ABS sensor with detection function of rotational direction. Improvement of

reliability due to the reduced assembly process and sealed sensor.

- Sensor with detection function of rotational direction: Able to detect vehicle's direction

(forward/backward)

- Active Sensor: Able to detect the wheel motion at the minimum level

- Free air-gap adjustment

- Applicable for drive-shaft wheel bearing

In-Wheel type integrated motor axle unit

- Compact and light weight unit realized by the combination of hub bearing, cycloid reduction gears and axial gap type motor.

- Adaptation of counter weight improved the efficiency of reduction gear and permissible

rotation.

- The counter weight reduced vibration caused by the imbalance of inertia force during high

speed driving.

- Applicable for electric and hybrid vehicles.

Minimize cross section thrust needle roller bearings

- The improvement of roller retainer made the world thinnest cross section of 1.0mm (half

than conventional one).

- Rigidity became three times as hard as the conventional retainer. And weight became less

by 25 %.

- Applicable for automatic transmission, CVT and air compressor.

Micro HL tapered roller bearing

- Under sever condition that would not form oil film, the durability became five time longer as the conventional one.

- Applicable for transmission and differential for vehicles.

High capacity tapered roller bearing

- Ultra long life and high stiffness were realized by the design of roller bearing with roller

retainer.

- Applicable for transmission and differential gear for passenger cars.

High angle low vibration PTJ

- Maximum operating angle at 30 degree. Available to install in SUV.

Compact low vibration EPTJ

- Reduced outer ring and outside diameter by 4 % and weight by 8 %. (vs. conventional

products)

Low idling vibration constant velocity joint

- Reduction of idling vibration by 20 %.

GEN4 hub joint (for rear drive axle)

- Integrated hub-bearing and constant velocity joint

- Detachable structure of out board joint and drive-shaft

- Cut weight by 420 g and upgraded rigidity by 22 % (vs. the Company's GEN3 type mounted

in L-class minivan)

- Preload adjustment free

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India