Archives of Past Exhibits:Mahle

2018 JSAE Automotive Engineering Exposition

Tokyo Motor Show 2017

IAA Frankfurt Auto Show 2017

2017 JSAE Automotive Engineering Exposition

Shanghai International Automobile Industry Exhibition 2017

ACMA Automechanika New Delhi 2017

North American International Auto Show 2017

2016 Automechanika Shanghai

2016 JSAE Automotive Engineering Exposition

Tokyo Motor Show 2015

2015 IAA Frankfurt Motor Show

2015 JSAE Automotive Engineering Exposition

Plastic lightweight cylinder head cover

-New plastic cylinder head cover offering a 20 percent reduction in product weight compared with the Company’s conventional products. -Plastic cylinder head covers feature rib-like projections on the inner side and the side surface that increase product strength. The new product uses fewer ribs and provides additional weight-saving feature.

-New plastic cylinder head cover offering a 20 percent reduction in product weight compared with the Company’s conventional products. -Plastic cylinder head covers feature rib-like projections on the inner side and the side surface that increase product strength. The new product uses fewer ribs and provides additional weight-saving feature.

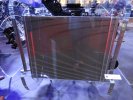

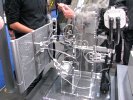

Intake manifold with water-cooled charge air cooler

-Developed jointly by the Company's filtration division and the thermal management division. -Space saving in the vehicle’s frontend -Smaller intercooler -Integrating water-cooled intercooler into the intake manifold reduces pressure loss.

-Developed jointly by the Company's filtration division and the thermal management division. -Space saving in the vehicle’s frontend -Smaller intercooler -Integrating water-cooled intercooler into the intake manifold reduces pressure loss. Air-cooled charge air cooler

Installed vehicle: Honda "Amaze" -Mainly developed and produced in India

Installed vehicle: Honda "Amaze" -Mainly developed and produced in India

Shanghai International Automobile Industry Exhibition 2015

2014 JSAE Automotive Engineering Exposition

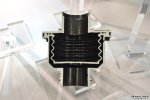

Plastic lightweight cylinder head cover

Installed vehicle: Suzuki "Hustler", "Wagon R" -New plastic cylinder head cover with wall thickness of 1.5mm, offering a 20 percent reduction in product weight compared with the Company’s conventional 2mm-thick products. (Industry’s standard wall thickness: 2.3mm-2.5mm) -Plastic cylinder head covers feature rib-like projections on the inner side and the side surface that increase product strength. The new product uses fewer ribs and provides additional weight-saving feature.

Installed vehicle: Suzuki "Hustler", "Wagon R" -New plastic cylinder head cover with wall thickness of 1.5mm, offering a 20 percent reduction in product weight compared with the Company’s conventional 2mm-thick products. (Industry’s standard wall thickness: 2.3mm-2.5mm) -Plastic cylinder head covers feature rib-like projections on the inner side and the side surface that increase product strength. The new product uses fewer ribs and provides additional weight-saving feature.

Delhi Auto Expo 2014

Tokyo Motor Show 2013

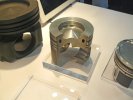

MonoGuide laser welded steel piston

-2-piece type piston by means of laser welding -Compression height is lower than that of aluminum piston -Comparing to conventional piston, the MonoGuide has a longer skirt, which remains decoupled from the piston crown. This design improves the NVH behavior and seems to be well-suited for the use in aluminum engine blocks. -Will be used in a series production passenger car diesel engine for the first time in 2014

-2-piece type piston by means of laser welding -Compression height is lower than that of aluminum piston -Comparing to conventional piston, the MonoGuide has a longer skirt, which remains decoupled from the piston crown. This design improves the NVH behavior and seems to be well-suited for the use in aluminum engine blocks. -Will be used in a series production passenger car diesel engine for the first time in 2014

sSC2 aluminum piston with elevated salt core cooling channel

-The cooling channel lowers temperatures at the piston crown and in the region of the first ring land, increasing the load capacity.

-The cooling channel lowers temperatures at the piston crown and in the region of the first ring land, increasing the load capacity.

Diesel piston with remelted bowl rim and elevated salt core cooling channel (eSC)

-Piston bowl rim is reinforced

-Piston bowl rim is reinforced

EvoTherm engine valve

-Extended hollow cavity is made by means of electrochemical machining. The valve head is cooled by the shaker effect: the hollow space is not completely filled with sodium, so that it is shaken as the valve moves; the sodium produces greater heat dissipation.

-Extended hollow cavity is made by means of electrochemical machining. The valve head is cooled by the shaker effect: the hollow space is not completely filled with sodium, so that it is shaken as the valve moves; the sodium produces greater heat dissipation.

TopTherm engine valve

-Its construction as a rigid and rotation-symmetrical surface with a large sodium-filled cavity leads to lightweight and efficient heat dissipation

-Its construction as a rigid and rotation-symmetrical surface with a large sodium-filled cavity leads to lightweight and efficient heat dissipation

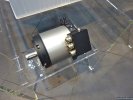

Power Cell Unit (PCU) for commercial vehicle

-Comprised of MONOTHERM steel piston, cylinder liner, machined connecting rod, piston pin and piston rings

-Comprised of MONOTHERM steel piston, cylinder liner, machined connecting rod, piston pin and piston rings

Cylinder head cover with integrated mist separation and cylinder head frame (for commercial vehicle)

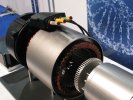

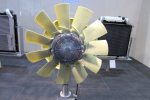

Exhaust gas turbocharger with waste gate

*Turbo chargers are manufactured by Bosch Mahle Turbo Systems, a 50-50 joint venture with Robert Bosch

*Turbo chargers are manufactured by Bosch Mahle Turbo Systems, a 50-50 joint venture with Robert Bosch

2013 IAA Frankfurt Motor Show

2013 JSAE Automotive Engineering Exposition

JSAE 2012

| Piston | Intake manifold | ||

|

|

||

| image image image |

|

image image |

|

| Sound creator | Carbon canister | ||

|

|

||

| image |  |

image |  |

| Plastic head cover | Plastic oil pan | ||

|

|

||

| image image image image |

|

image |  |

| Oil cooler / Oil warmer | Oil filter module | ||

|

|

||

| image image image image |

|

|

|

| Range extender | |||

|

|||

| image image |

|

||

Auto China 2012

| Bosch Mahle TurboSystems | |||

| Diesel turbocharger (TDI) | Variable turbine geometry(VTG) | ||

|

|

||

| Image | Image | ||

| CamInCam camshaft | Plastic intake manifold | ||

|

|

Installed vehicle: Nissan |

|

| Image | Image | ||

| Valve cover system with integrated oil drain pipe and oil mist separator |

Electrical wastegate actuators | ||

|

|

||

| Image | Image | ||

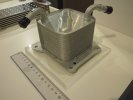

| Air intake module with integrated tumble flap system for gasoline applications |

Aluminum oil cooler for 6-speed automatic transmissions | ||

|

|

||

| Image | Image | ||

| Aluminum oil cooler for CVT |

Fuel filter | ||

|

|

||

| Image | Image | ||

| Oil pump proportional solenoid valve | Pistons | ||

|

|

||

| Image | Image | ||

| Connecting rod | Bearings | ||

|

|

||

| Image | Image | ||

Delhi Auto Expo (India) 2012

| Piston for gasoline engines | Power Cell Units for commercial vehicles | ||

|

|

||

| image | |||

| All-plastic oil pan with pick-up tube and windage tray | Map controlled pendulum-slider oil pump with plastic slider & All-plastic oil filter module with map-controlled thermostatic valve for coolant | ||

|

|

||

| Fuel filter | Carbon canister, LEV2 and PZEV | ||

|

|

||

| Air cleaner module | |||

|

|||

Tokyo Motor Show 2011

| Range extender | Piston for gasoline engines | ||

|

|

|

|

| image | |||

| Piston for diesel engines | Map controlled pendulum-slider oil pump with plastic slider | ||

|

|

|

|

| All-plastic oil pan with pick-up tube and windage tray |

Aluminum oil cooler for spin-on oil filter module | ||

|

|

||

| Aluminum oil cooler for 6-speed automatic transmission | Aluminum oil cooler for CVT automatic transmission | ||

|

|

||

| Aluminum oil cooler for truck application |

Air intake module with integrated swirl flap system for diesel applications | ||

|

|

||

| Electrical wastegate actuator | Air intake module with integrated tumble flap system for gasoline applications | ||

|

|

||

| Plastic intake manifold | Sound creator | ||

|

|

||

| Air cleaner module with cylindrical filter element (cellulose) | Valve head cover system with integrated oil drain pipe and oil mist separator (impactor) | ||

|

|

||

| Valve head cover system with integrated oil mist separation |

Urea filter unit with variable heater concept (without/electrical heater/coolant) | ||

|

|

||

| All-plastic fuel filter with preheating valve, priming pump, water level sensor, and water drain screw | Fuel filter for truck application | ||

|

|

||

| Carbon canister, LEV2 and PZEV | Bushingless connecting rods | ||

|

|

||

| Ultra light weight conrod version approx 25% less weight | Power cell units - Aluminum piston with cooled ring carrier | ||

|

|

||

| Power cell units | Piston rings | ||

|

|

||

| image image |

|||

| Piston pins | Pb-free bimetallic thrust washers with either a "flat" or an engineered ramp and pad hydrodynamic profile | ||

|

|

|

|

| image | |||

| Pb-free bimetallic bearings | Bushings | ||

|

|

||

| image | |||

Frankfurt Motor Show 2011

| Engine with Mahle components and Audi racing car | Air cleaner module with plasticized U-shape filter element(cellulose) | ||

|

|

||

| image image |

|||

| Air intake module with integrated tumble flap system for gasoline applications | Air intake module with integrated swirl flap system for diesel applications | ||

|

|

||

| All-plastic oil pan with pick-up tube and windage tray | Fuel filter module with highly efficient pressure side water separation | ||

|

|

||

| All-plastic oil filter module with map-controlled thermostatic valve for coolant | Power Cell Unit | ||

|

|

|

|

JSAE 2011

| Carbon Canister |

Sound Creator | ||

|

|

Installed vehicle : Mazda ROADSTER |

|

| Image | Image | ||

| Image | |||

| Oil Cooler |

Oil Filter Module |

||

|

|

||

| Intake Manifold | Plastic Head Cover |

||

|

|

||

| Image | Image | ||

| Image | |||

| Plastic Oil Pan |

Piston and related products | ||

|

|

||

| PCU - Power Cell Unit | EvoTec Piston - lightweight gasoline piston |

Spray-jet cooling | Salt-core cooling |

|---|---|---|---|

|

|

|

|

|

Elevated salt-core cooling |

Cooled ring carrier | Cooled ring carrier with pin bush | MONOTHERM steel piston for passenger car diesel engines |

|---|---|---|---|

|

|

|

|

| Lightweight hollow valve | CaminCam | Low Friction Camshaft(LFC) | Controlled pendulum slider oil pump |

|---|---|---|---|

|

|

|

|

JSAE 2010

| Piston | Cam shaft |

|---|---|

|

|

| image | image |

| Oil pump | Carbon canister |

|---|---|

|

|

| image | image |

| Oil cool, oil filter module | Head cover | |

|---|---|---|

|

|

|

| image | image | image |

| Intake manifold | Sound creator |

|---|---|

|

|

| image | image |

2010 Delhi Auto Expo

|

MAHLE Filter Systems India Ltd. |

|||

|---|---|---|---|

| Oil mist separator | Oil filter | ||

|

|

For Suzuki | |

| Image | Image | ||

| Oil filter module | Roll filter | ||

|---|---|---|---|

|

For Ford |

|

For Nissan |

| Image | Image | ||

| Fuel filter | Fuel filter | ||

|---|---|---|---|

|

Installed vehicles : Suzuki "Alto" Suzuki "Wagon R" |

|

Installed vehicle : Suzuki "Swift" |

| Image | Image | ||

| Air filter | Air filter | ||

|---|---|---|---|

|

Installed vehicle : GM "Chevrolet Aveo" |

|

Installed vehicle : Suzuki "Wagon R" |

| Image | Image | ||

| Air intake manifold | |||

|---|---|---|---|

|

|||

| Image | |||

|

Mahle IPL Ltd. |

|||

|---|---|---|---|

| Piston | Piston | ||

|

For Ford "DV4" engine |  |

For Fiat "1.3L SDE" (Small Diesel Engine) |

| Image | Image | ||

| Piston | Piston | ||

|---|---|---|---|

|

For Maruti Suzuki "K10B" engine |

|

For Ashok Leyland "Neptune" engine |

| Image | Image | ||

| Piston | Piston | ||

|---|---|---|---|

|

For Tata Cummins "6BT" engine |

|

For Mahindra & Mahindra "Acteon" engine |

| Image | Image | ||

| Piston | |||

|---|---|---|---|

|

For Tata 2.2L "Dicor" engine |

||

| Image | |||

2009 IAA Frankfurt Motor Show

<Downsizing>

| Mahle downsizing engine as technology demonstrator | Turbocharger for modern gasoline engine | ||

|---|---|---|---|

|

Image 1 Image 2 Image 3 |

|

Image |

|

-Reducing displacement while simultaneously adapting all the systems and components relevant to engine performance and emission behavior characteristics -Shifting frequently used engine operating points to areas of higher specific engine load, thereby reducing fuel consumption. |

-High temperature resistance using materials such as cast steel in the turbine housing or exhaust manifold module, and nickel-based superalloys for the turbine rotor. -Electrical actuators for wastegate and VTG control to optimize performance -Turbine wheel with direct inflow from the exhaust port, using CamlnCam control (additional impulse charge) |

||

| Electrical wastegate actuator | |

|---|---|

|

Image |

<Charge exchange>

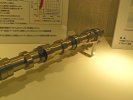

| Cylinder deactivation with switchable roller finger follower | CamlnCam camshaft for 4 cylinder engine | ||

|---|---|---|---|

|

Image |  |

Image |

|

-Exhaust camshaft + Inlet camshaft |

|||

<Frictional Loss>

| Assembled camshaft | |

|---|---|

|

|

|

-Simple replacement for the standard camshaft |

|

| Lightweight valve | All-plastic transmission oil filter module | ||

|---|---|---|---|

|

Image |  |

Image |

|

-Up to 50% lower weight compared to conventional solid shaft valve |

|||

Tokyo Motor Show 2005

<Highlights>

Lightweight Valves

・Made from sheet metal

・Scheduled to be mass-produced in 2006

Camshafts

Front: Assembled Camshaft

Center: Adjustable Camshaft installed in the Ferrari V8 engine

Back: Cast Camshaft installed in Porsche Cayenne

Pistons

For diesel engines: for EU models

For gasoline engines: Cast Pistons

Power Cells

繝サSinter-forged connecting rods are supplied by other manufacturers.

Installed in the Chevrolet Corvette.

繝サForged connecting rods, which are produced in-house, are being installed in GM's HF V6 engine.

Cylinder Liners

Aluminum: For gasoline engines

Gray Cast Iron: For diesel engines

Steel: For SUV models in the EU and Japan

Tokyo Motor Show 2004

The Company presented its new filter modules for lubricating oil and fuel. In addition to saving space, they offer an increase in efficiency and service life.

The combination of an efficient two-stage water separator and new separating media provides the KM 35 fuel filter module with reliable protection for modern diesel injection units like time controlled distributor injection, unit injectors, pump line injector systems and common rail systems - in even the smallest of spaces. The new oil filter module uses an efficient jet centrifuge in the bypass that is especially effective against dirt caused by soot.

<Fuel management systems>

While in the past the fuel systems of a commercial vehicle included a pre-filter, in some cases with a water separator and a main filter, the Company's current diesel fuel filter modules combine these and many other functions into a single module.

Function and filtration

To maximize the service life of modern commercial vehicle engines, the Company's filter systems prepare fuel optimally for the combustion process. Very precise component tolerances in modern diesel injection systems require highly separating filter media. Another trend is longer maintenance intervals. The Company also offers multi-layer filter media for operation under severe conditions, for example construction site vehicles or poor fuel quality.

The first melt-blown filter layer, consisting of extremely thin synthetic fibers, acts as a deep end filter, which is used together with an ultra fine filter made of cellulose carrier materials. These multi-layer filter elements offer a higher level of particle separation than earlier conventional cellulose materials and last at least as long.

Water separation

A two-stage water separation system was implemented in the Company's fuel filter module, the KM 35, which is use in medium to heavy commercial vehicles. It also disperses very fine and stable emulsion effectively.

The coaxial arrangement of the particle filter creates an integrated coalescence effect. A final hydrophobic separator ensures a multi-level separation process, a reliable fuel supply while protecting the engine under all operating conditions.

The standard range of the KM 35 module also includes an automatic filter drain when changing elements for prefilters and main filters as well as elements for metal free filters. Maintenance indicators are optional, as are electrical heaters, water level sensors, manual pumps, fuel coolers, bypass valves for prefilters and dirt cans for main filters.

The range of options includes both cost optimized, additional heaters and intelligent self-regulating heat modules that are activated in the filter depending on how much paraffin is present. The wide selection of additional electrical heaters is rounded out by bimetallically controlled preheater valves and thermostatic controllers with expandable wax elements.

Easy maintenance

To increase ease of maintenance when changing elements, dirt cans with automatic drain function may also be used. A new pump design ensures reliable suction of fuel even at the lowest operating temperatures when filling or venting the filter. A wide range of maintenance indicators also takes into consideration applications with alternative fuel filters such as FAME (fatty acid methylester) or biodiesel.

Advantages of the Company's fuel filter modules

-Multi-layer melt-blown filter media for the separation of extremely fine particles

-Efficient water separation in a compact design

-Service friendly maintenance possible

-Environmentally friendly metal free filter insert

-Customer specific applications

-Modular system structure

<Modern oil filtration: centrifugal force and new media>

Against a background of dramatically increased requirements for oil filters, the Company's latest development projects aims to further extend service intervals and provide optimal protection for engine components.

Longer service interval

Mixed fiber filter media consist of cellulose fibers in to which up to 30% plastic fibers are mixed. In addition to a considerable increase in dirt capacity, this also results in an improvement in resistance to aging of the oil. This makes it possible to achieve service intervals of up to 50,000 km in passenger car applications, and as much as 150,000 km for commercial vehicles.

Fully synthetic

The Company offers a fully synthetic filter element with a filter medium made from a combination of actual filter materials, polyester fibers and plastic support fabric. Embedded in plastic end disks, it is completely metal free and therefore fully able to be incinerated completely.

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India