Search Results by Category

AI Navigator

AI NavigatorAll information related to {{ key_word }}.

AI Navigation will guide you. Click here for information about {{ key_word }}.

4

4

1

1

3

3

7

7

1

1

2

2

2

2

2

2

4

4

1

1

1 - 20 of 55 results

Honda Development & Manufacturing of America, LLC (HDMA), Anna Engine Plant[USA]

ld the IPU case that will contain the EV battery module and serve as the main frame structure for the floor of Honda and Acura EVs. AEP is preparing to install six, 6,000-ton high-pressure die cast machines that will mega cast the IPU case in two pieces that will be welded together seamlessly using Friction Stir Welding. In 2023, AEP transferred production of engine components for two different generations of engines to the Alabama Auto Plant (AA...

OEM Plants Updated at: 2025/12/17

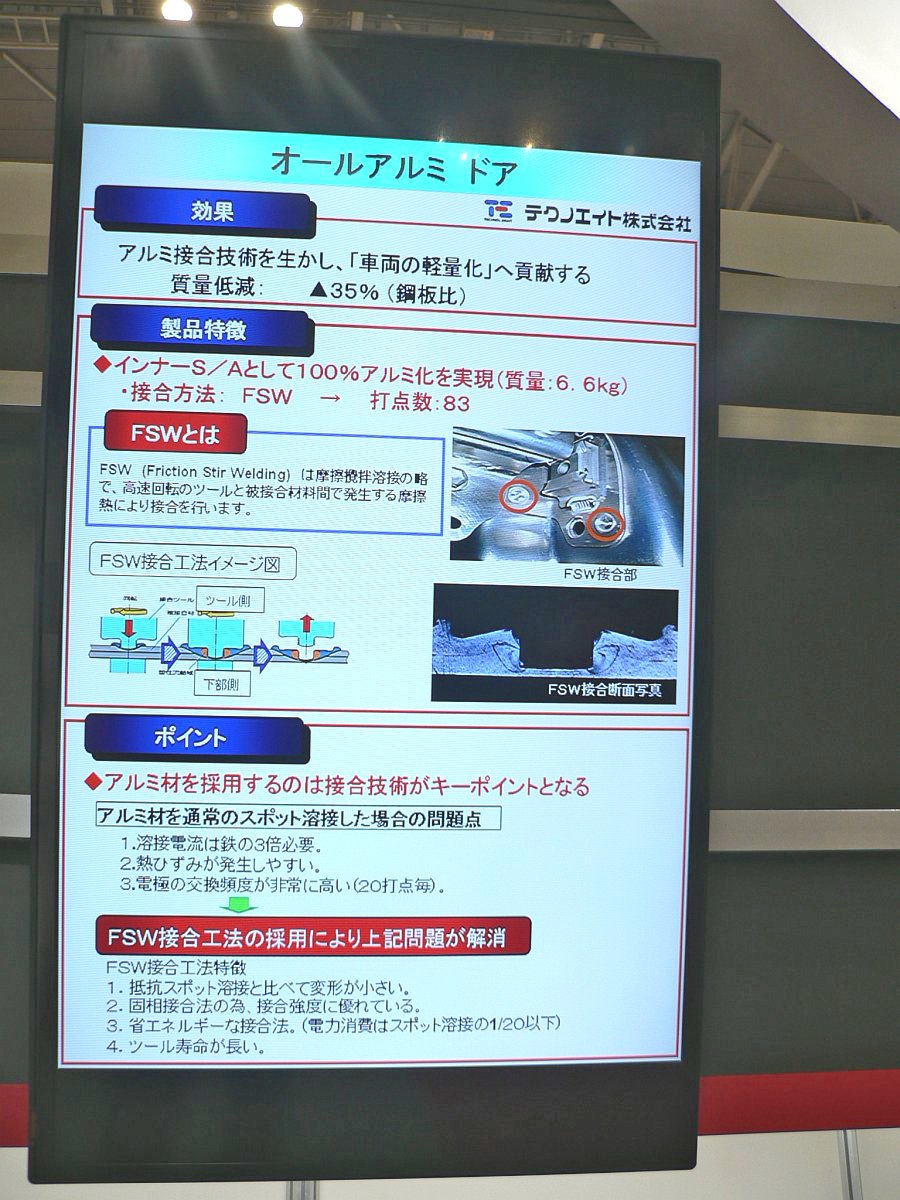

Technol Eight Co., Ltd.

e company received the award in recognition of its efforts to ensure a stable supply of spare parts, to propose the integration and reduction of part types, and to dispose of unneeded dies. (From a press release dated March 3, 2022) 2014 JSAE Automotive Engineering Exposition Aluminium door made by friction stir welding Installed vehicle: Lexus "LFA" Toyota Lexus Mitsubishi Subaru Mazda Suzuki Daihatsu Allion Alphard Alphard Hybrid Aqua Auris Cam...

Major Suppliers Updated at: 2025/12/03

Taiho Kogyo Co., Ltd

ivity copper parts with additive filler High heat radiation surface coating High heat radiation coating Pressure plate for fuel cells Stack assy End plate Using laser welding to join thin stainless steel sheets Using laser welding to join copper and titanium Plasma bonding copper and aluminum Using friction stir welding (FSW) to join copper and aluminum Motor Oil control valve Battery pack Using roll welding (solid phase) to join copper and alumi...

Major Suppliers Updated at: 2025/11/27

L-H Battery Company, Inc., Ohio Plant (tentative name)[USA]

ld the IPU case that will contain the EV battery module and serve as the main frame structure for the floor of Honda and Acura EVs. AEP is preparing to install six, 6,000-ton high-pressure die cast machines that will mega cast the IPU case in two pieces that will be welded together seamlessly using Friction Stir Welding. In 2023, AEP transferred production of engine components for two different generations of engines to the Alabama Auto Plant (AA...

OEM Plants Updated at: 2025/11/20

Honda Development & Manufacturing of America, LLC (HDMA), East Liberty Auto Plant[USA]

ld the IPU case that will contain the EV battery module and serve as the main frame structure for the floor of Honda and Acura EVs. AEP is preparing to install six, 6,000-ton high-pressure die cast machines that will mega cast the IPU case in two pieces that will be welded together seamlessly using Friction Stir Welding. In 2023, AEP transferred production of engine components for two different generations of engines to the Alabama Auto Plant (AA...

OEM Plants Updated at: 2025/10/10

Honda Development & Manufacturing of America, LLC (HDMA), Marysville Auto Plant[USA]

nnounced it will mark the 40th anniversary of the Anna Engine Plant. AEP is one of three production facilities in Ohio that are advancing the concept of flexible motors on the same production lines. AEP has added three new processes to produce the aluminum EV battery case, including: megacasting, friction stir welding (FSW) and Minimum Quantity Lubrication (MQL) machining. When EV production begins in 2026, the EV battery case megacast at AEP w...

OEM Plants Updated at: 2025/10/04

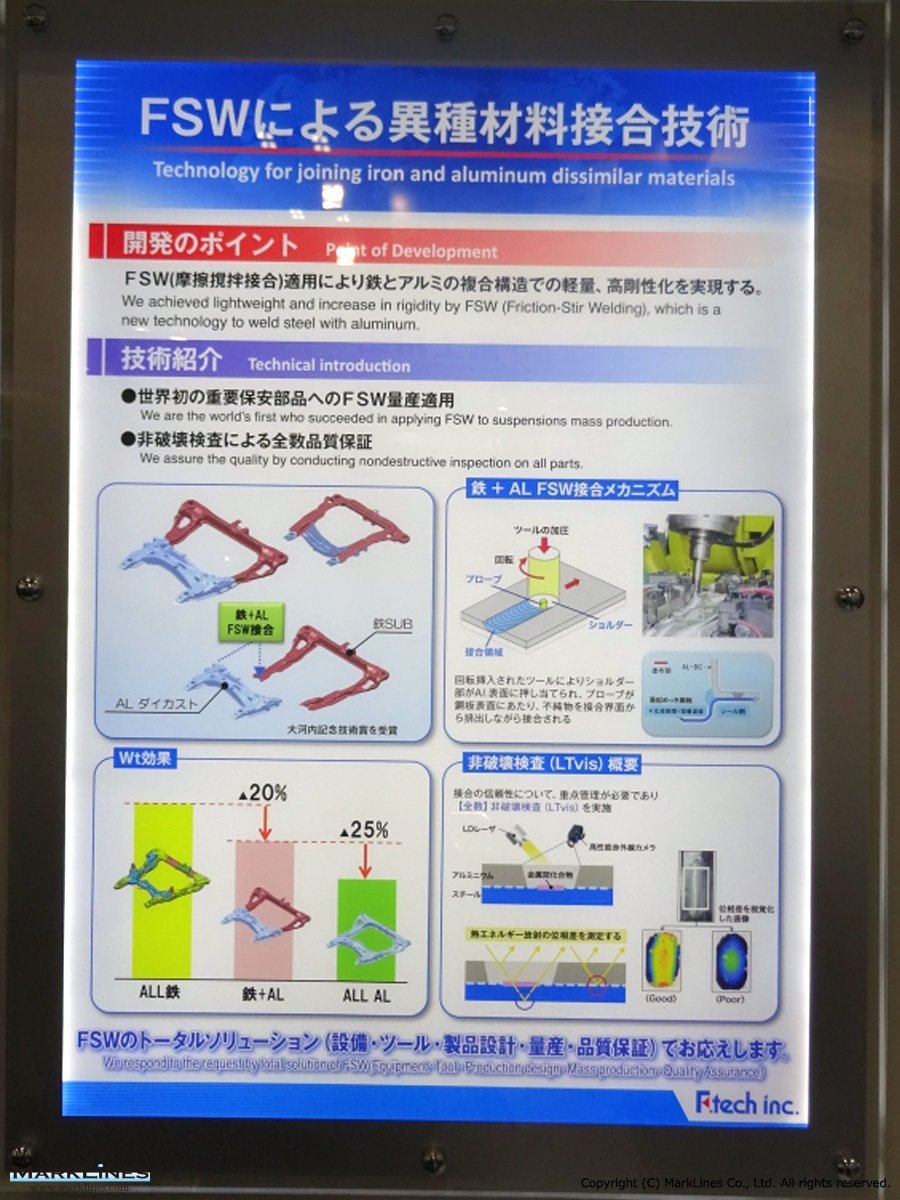

F-TECH Inc.

ficiency. (From an article in the Nikkan Jidosha Shimbun on January 28, 2019) F-Tech Inc. (F-Tech) announced that it will showcase at “Automotive Engineering Exposition 2019”. In addition to chassis components, the company will exhibit the world’s first mass production of front subframe using FSW (Friction Stir Welding) method for joining iron and aluminum, as well as forming press technology, light weight pedal, and light weight axle beam....

Major Suppliers Updated at: 2025/10/01

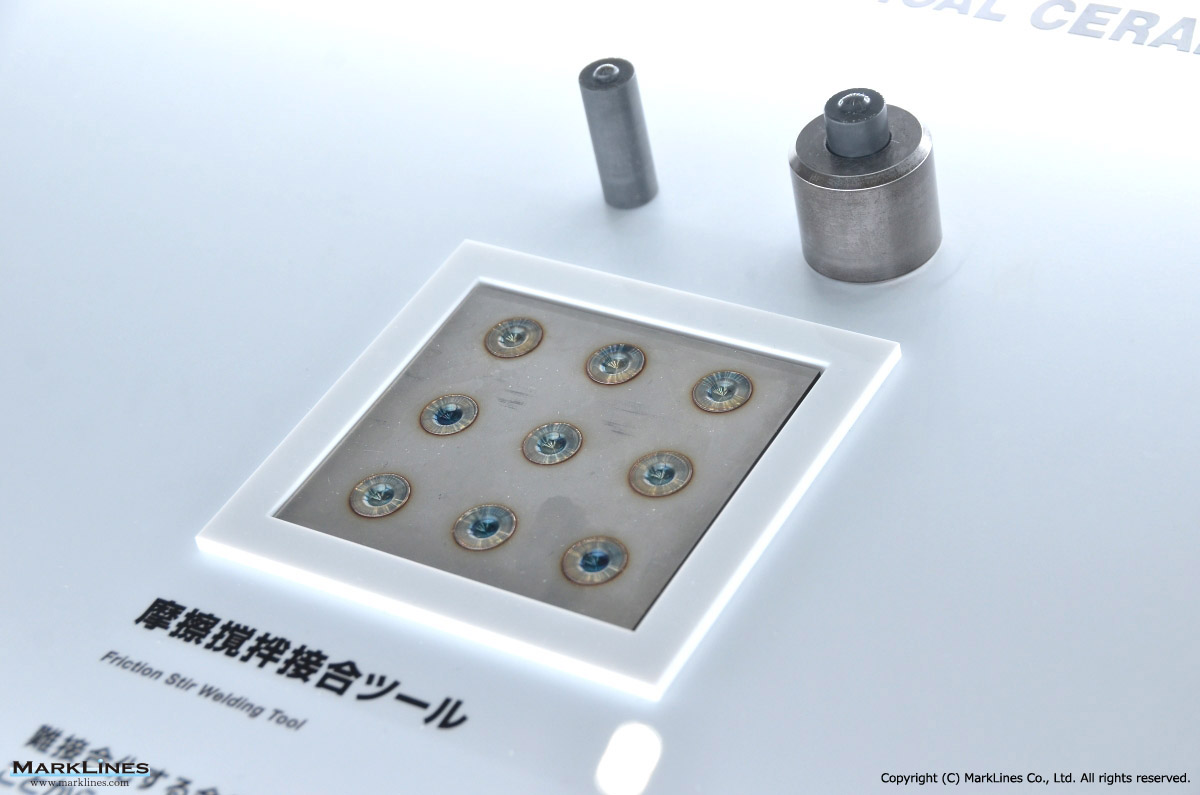

Niterra Co., Ltd. (Formerly NGK Spark Plug Co., Ltd.)

ZFAS-U3、XCU-UA、ZFAS-U2-SM ZFAS-N2.1 (NOx sensor) ERAS-KN (Non-Resonant type Knock Sensor) M10 High Performance Spark Plugs and Super Long Reach Plug OZAS-S4 (Zirconia Exhaust Gas Oxygen Sensor) All solid state battery LTCC substrate for high frequency application. Hydrogen leak detection sensor Friction stir welding tool Packages and substrates for automotive electronic devicess ZFAS-U3 (Universal A/F heated exhaust gas oxygen sensor) ZFAS-U2...

Major Suppliers Updated at: 2025/09/02

Kalyani Group

compressor development for commercial vehicles. Development of different grades ADI Cast iron for various products. Development of Spiral Bevel Gears and Laser Welded Differential. Design and Development of High Mobility Reconnaissance Vehicles. Development of Multispeed Parallel Axis e-Driveline Friction stir welding process introduced in product improvement in EV for DC-DC converter cold plate. -The company develops its products and solution...

Major Suppliers Updated at: 2025/09/01

Honda Development & Manufacturing of America, LLC (HDMA), Ohio Transmission Plant[USA]

nnounced it will mark the 40th anniversary of the Anna Engine Plant. AEP is one of three production facilities in Ohio that are advancing the concept of flexible motors on the same production lines. AEP has added three new processes to produce the aluminum EV battery case, including: megacasting, friction stir welding (FSW) and Minimum Quantity Lubrication (MQL) machining. When EV production begins in 2026, the EV battery case megacast at AEP w...

OEM Plants Updated at: 2025/08/12

Norsk Hydro ASA

the global Innovation & Technology (I&T) unit of Extruded Solutions, which includes the product application lab in Finspang and an automotive-focused research and development lab outside Detroit, in Troy, Michigan. The application lab in Finspang carries out robotic welding, hot metal gas forming, friction stir welding, thermal testing and the testing of components, such as crash testing of automotive systems. Eight employees have been trained t...

Major Suppliers Updated at: 2025/07/24

Honda prepares for EV, ICE production on flexible lines at Anna Engine Plant

t Honda auto engine plant in the world. As part of the Honda EV Hub, AEP is one of three production facilities in Ohio that are advancing the concept of flexible motors on the same production lines. AEP has added three new processes to produce the aluminum EV battery case, including: megacasting, friction stir welding (FSW) and Minimum Quantity Lubrication (MQL) machining. When EV production begins in 2026, the EV battery case megacast at AEP w...

News Updated at: 2025/07/22

KUKA, Germany receives order for 12 friction welding cells from major US automaker

KUKA, Germany receives order for 12 friction welding cells from major US automaker On July 9, KUKA announced that it has secured a follow-up order for 12 additional friction welding cells to support the production expansion of a major automotive manufacturer in the U.S. The delivered cells will be installed and commissioned in phases by August 2025. The FSW (friction stir welding) cells, equipped with KUKA KR FORTEC robots and clamping devices s...

News Updated at: 2025/07/10

Valmet Automotive Inc., Uusikaupunki Plant[Finland]

will continue to work at the Uusikaupunki plant. On March 30, KUKA AG announced that it is providing robots for process handling for the sustainable production of battery systems for electric vehicles in Uusikaupunki, Western Finland, for automotive supplier Valmet Automotive. It is also installing friction stir welding systems and equipment for end-of-line testing in the assembly line. In the plant, resource-saving processes and programming opti...

OEM Plants Updated at: 2025/06/06

Mobile World Congress 2025 (2) ITS, SDV solutions

f the NXP Trimension™ NCJ29D6 chipset, which supports secure ranging and short-range radar, enabling applications such as digital key, Child Presence Detection (CPD), kick-sensing for trunk access, and intrusion detection. The setup featured the R&S SMW200A vector signal generator and the R&S FSW26 signal and spectrum analyzer, which together can generate moving UWB radar targets at variable distances of up to a few meters. This enables p...

Market & Tech Reports Updated at: 2025/04/03

Haguro Engineering Co., Ltd.

Haguro Engineering Co., Ltd. Japan Assembly Various machining Welding Friction stir welding ...

Search Suppliers Updated at: 2025/03/25

Automotive World 2025: Metal Processing Technologies

Automotive World 2025: Metal Processing Technologies Door rings, hot stamping equipment, FSW monitors, Mg housings, and more Summary Weight reduction: Integrated body frame components, door rings, multi-material frames Weight reduction: Hot stamping line for European car frame Weight reduction: Aluminum FSW joint real-time monitoring Weight reduction: Magnesium alloy for display housing, etc. EV parts: Forging equipment for EV hollow motor shaft ...

Market & Tech Reports Updated at: 2025/02/04

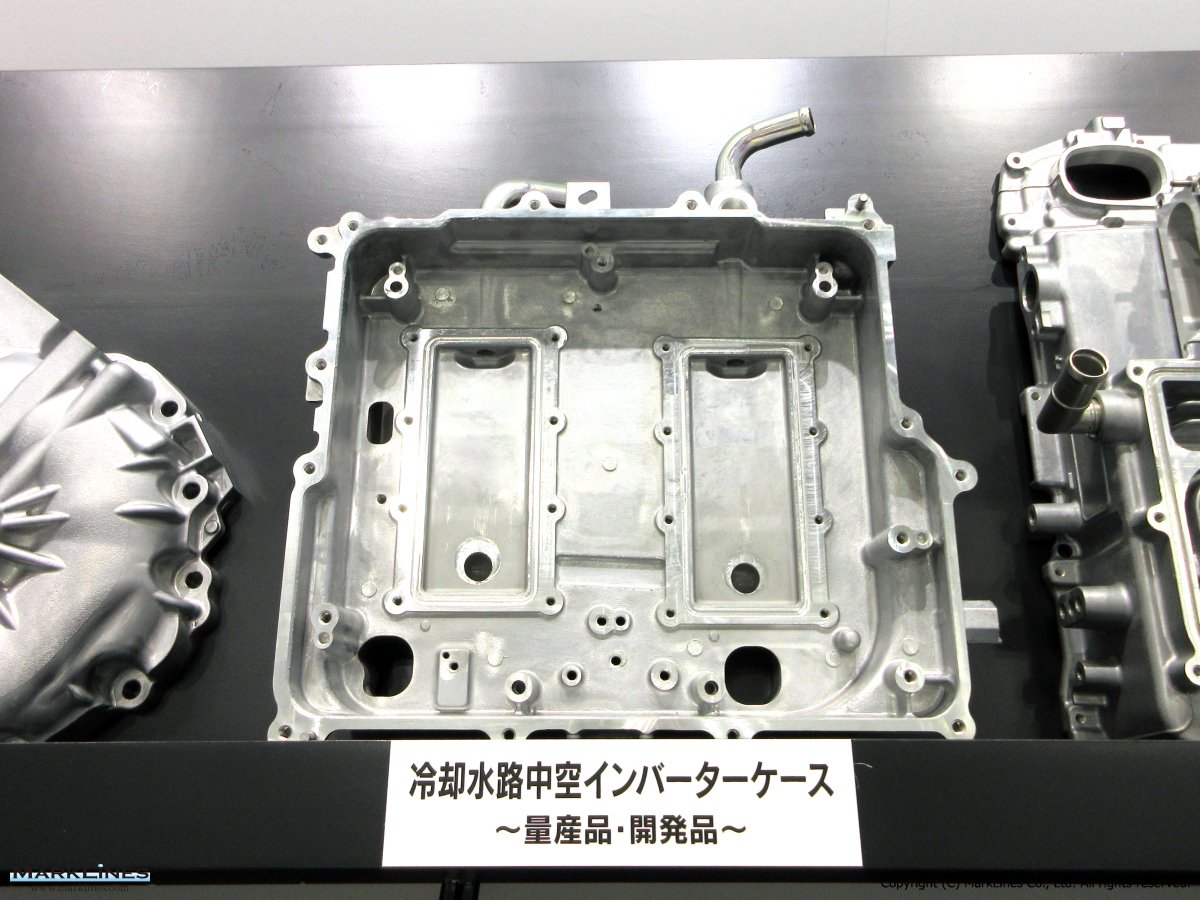

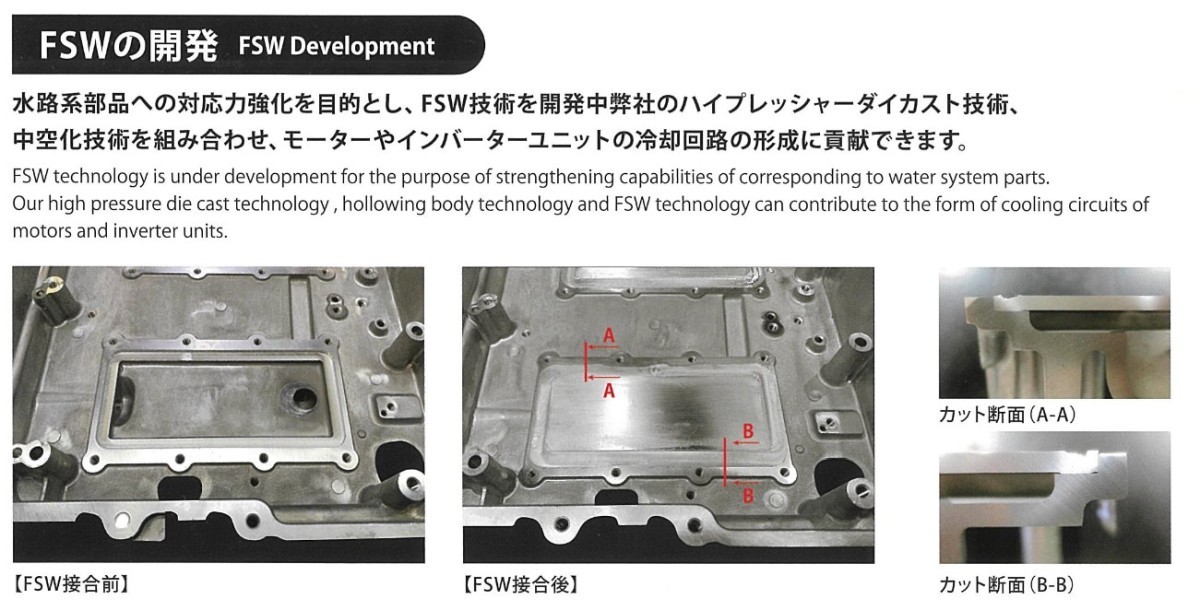

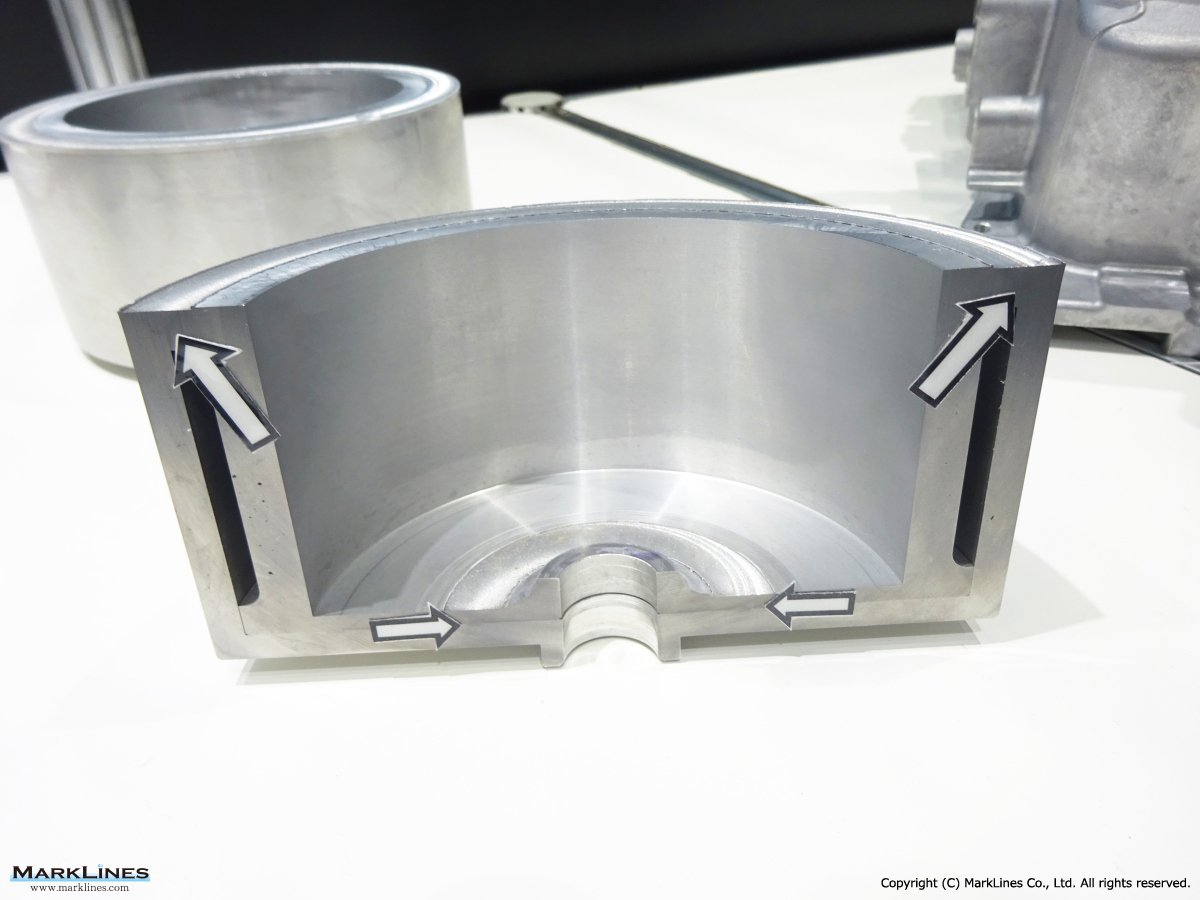

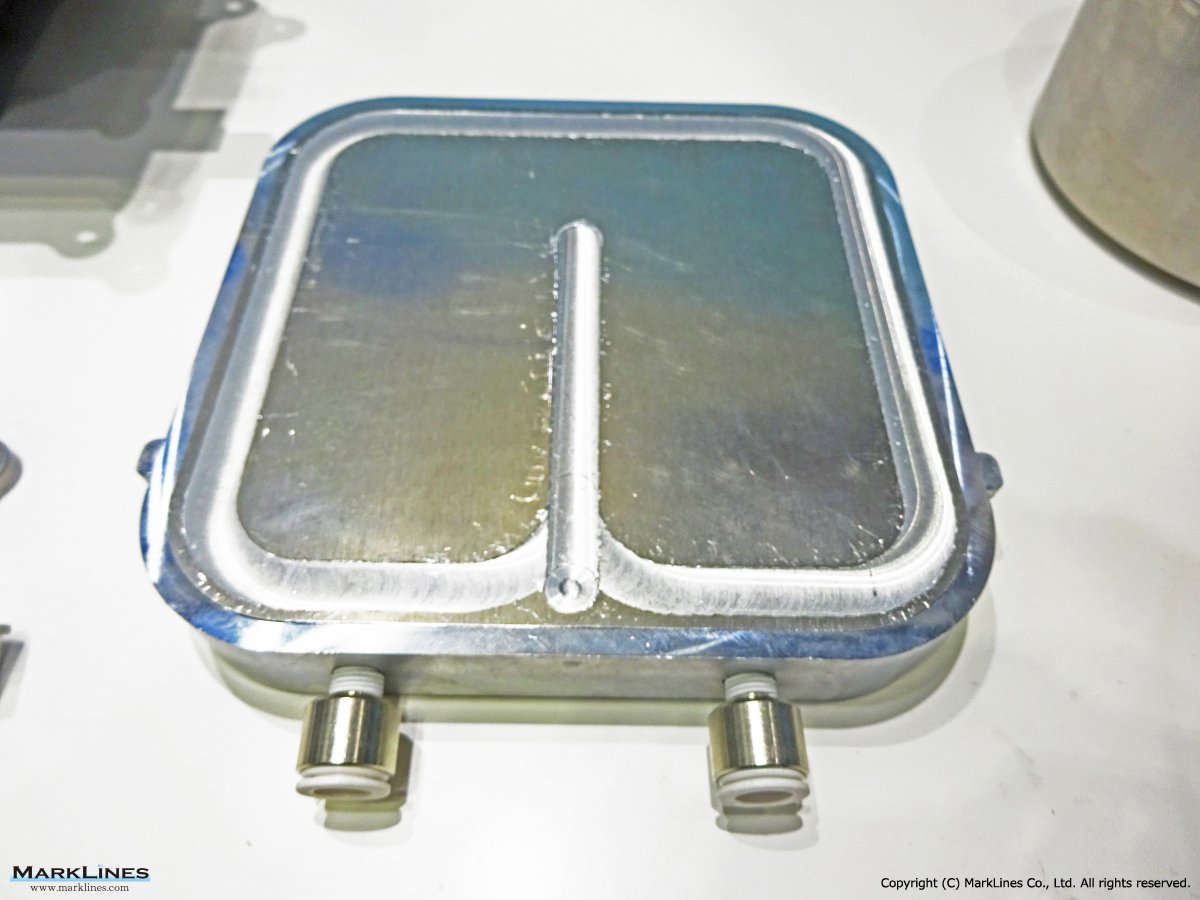

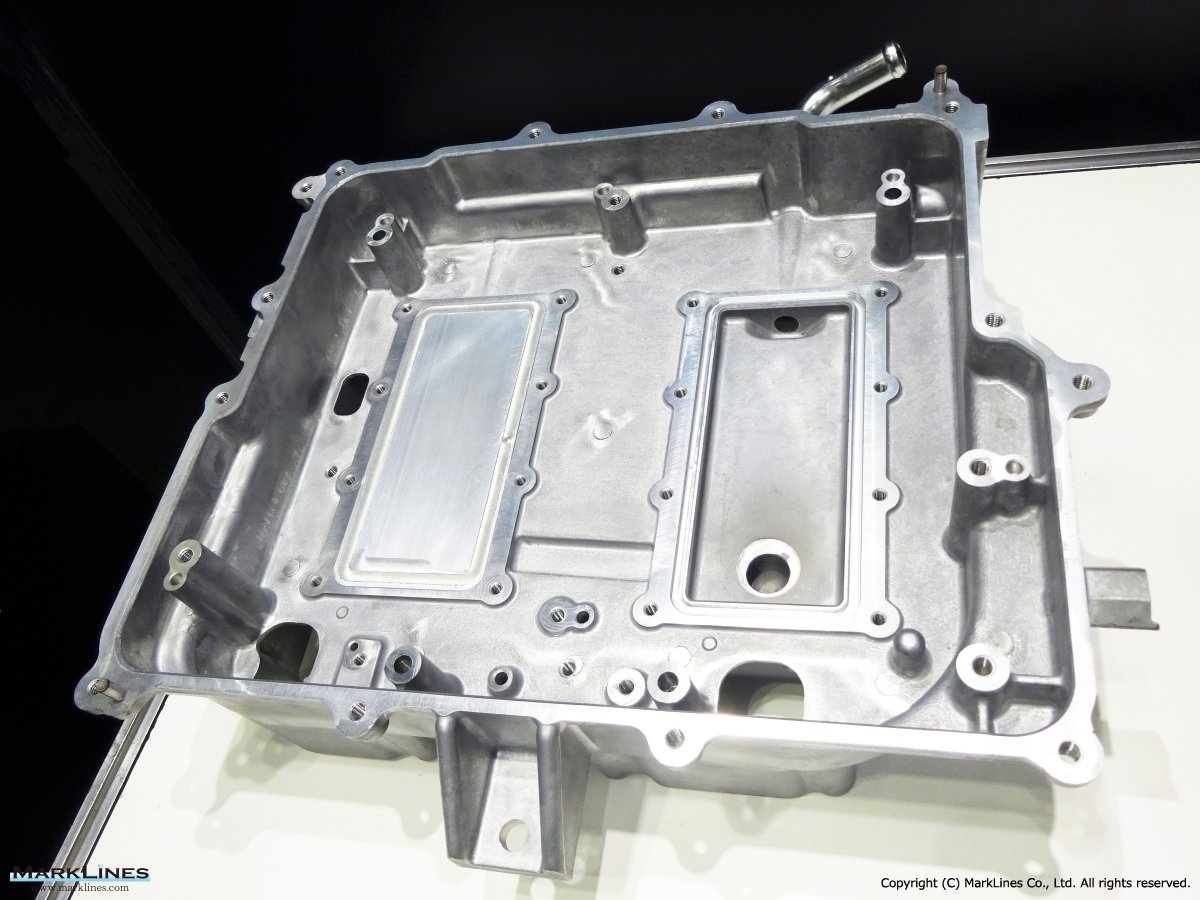

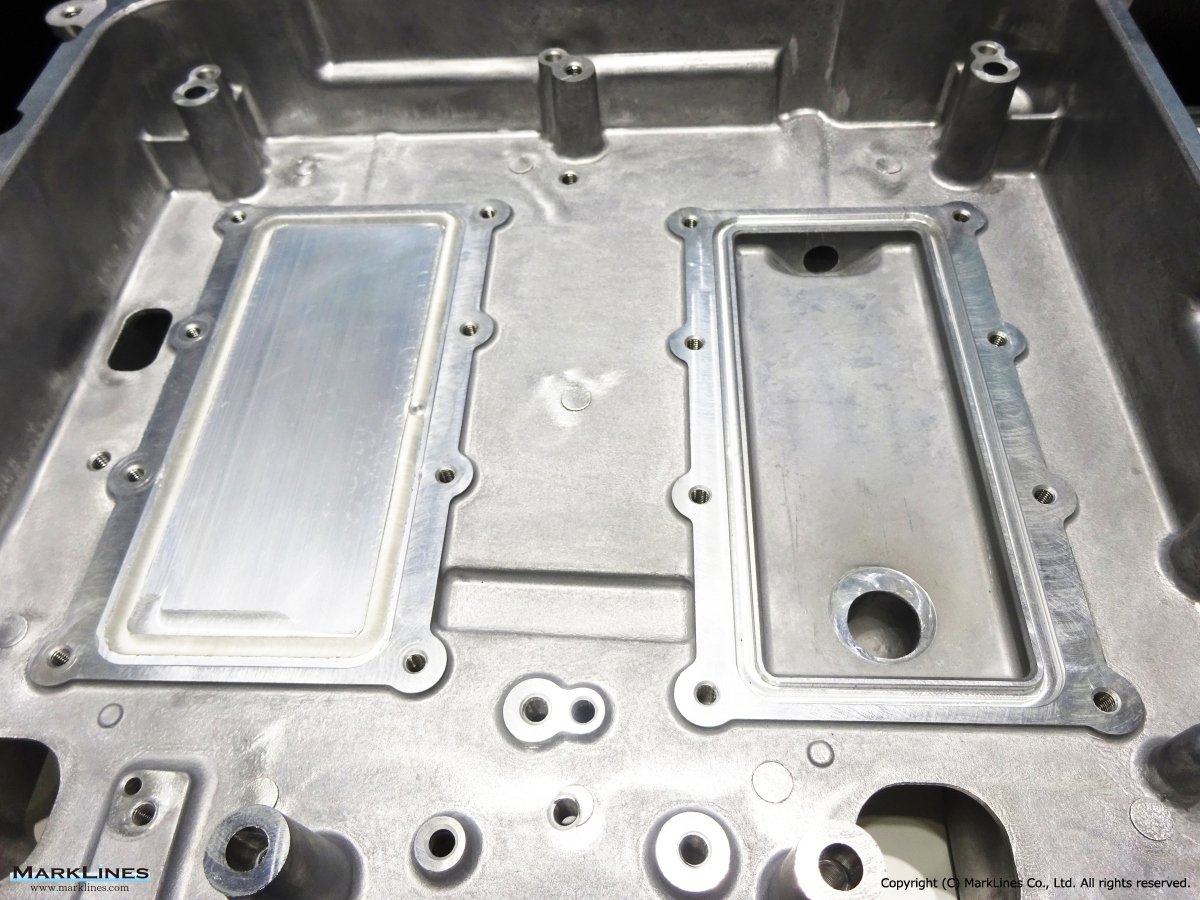

2024 Japan Die Casting Congress & Exposition: Gigacast

2024 Japan Die Casting Congress & Exposition: Gigacast Thin-walled and high-strength die casting, multiple materials, FSW bonding, etc. Summary Gigacasting Thin wall and high strength aluminum die casting The 2024 Japan Die Casting Congress & Exposition (Dates: November 14 (Thu.) to 16 (Sat.), 2024; Venue: Pacifico Yokohama convention center) was organized by the Japan Die Casting Association. The purpose of the event is to contribute to the d...

Market & Tech Reports Updated at: 2024/12/03

Alteams Poland Sp. z.o.o.

Alteams Poland Sp. z.o.o. Poland -Group: Alteams Group Aluminum casting Aluminum machining Various machining Welding Assembly FSW (Friction Stir Welding) ISO14001 IATF16949 (Formerly ISO/TS16949) ISO9001...

Search Suppliers Updated at: 2024/11/08

Xusheng Mexico S. de R.L. de C.V.

Xusheng Mexico S. de R.L. de C.V. Mexico -Shareholder(s): Ningbo Xusheng Group Co., Ltd. Heat treatment Drive motor housing Other electric powertrain system parts Welding Assembly Various machining Chassis / Frame Hot forging Other battery related parts Battery case Transmission case Various forging Aluminum extrusion processing Aluminum die casting Steering knuckle Various die casting FSW Friction Stir Welding ...

Search Suppliers Updated at: 2024/11/01

AI Navigator

AI Navigator

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India