Search Results by Category

AI Navigator

AI NavigatorAll information related to {{ key_word }}.

AI Navigation will guide you. Click here for information about {{ key_word }}.

1

1

2

2

3

3

2

2

3

3

3

3

5

5

5

5

1

1

4

4

1 - 20 of 71 results

Analysis Report: EV/HV Drive Motor (Chinese Market)

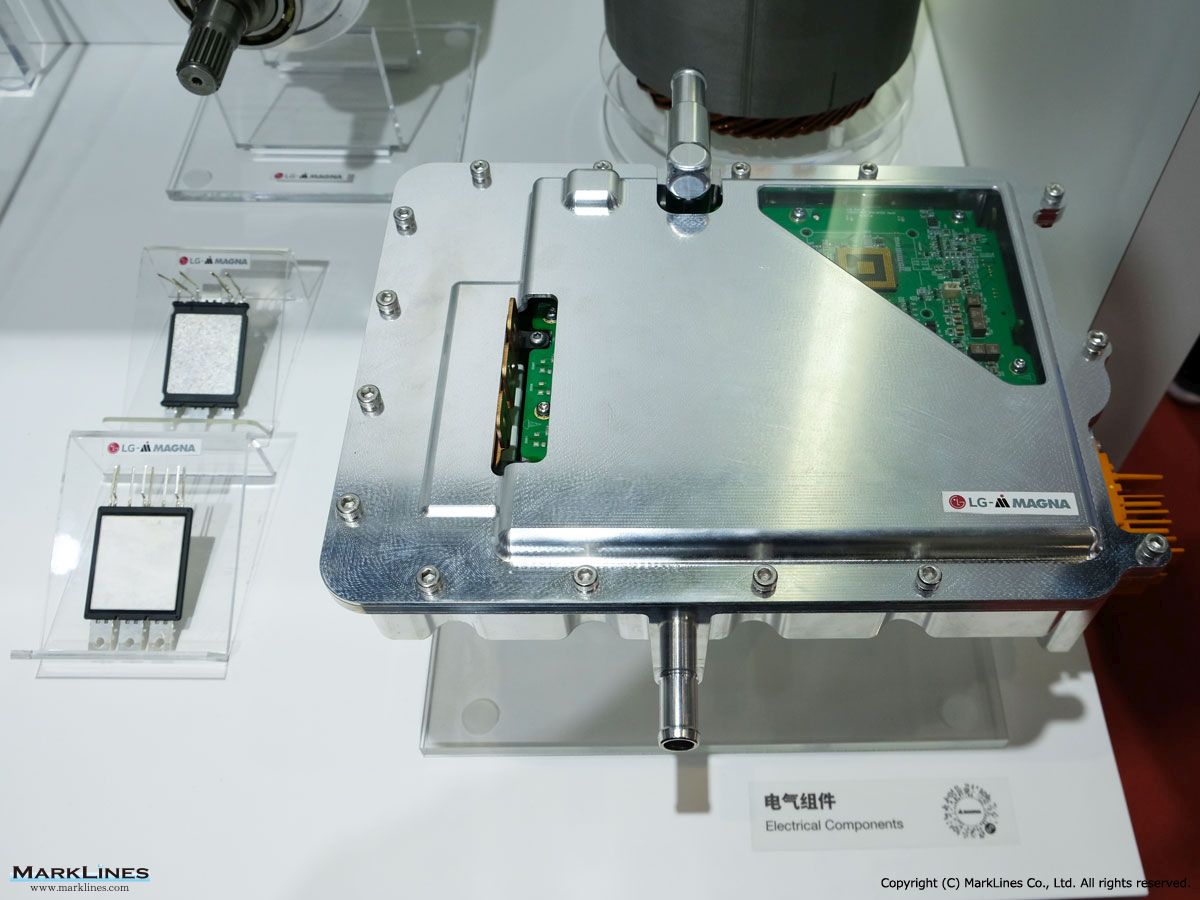

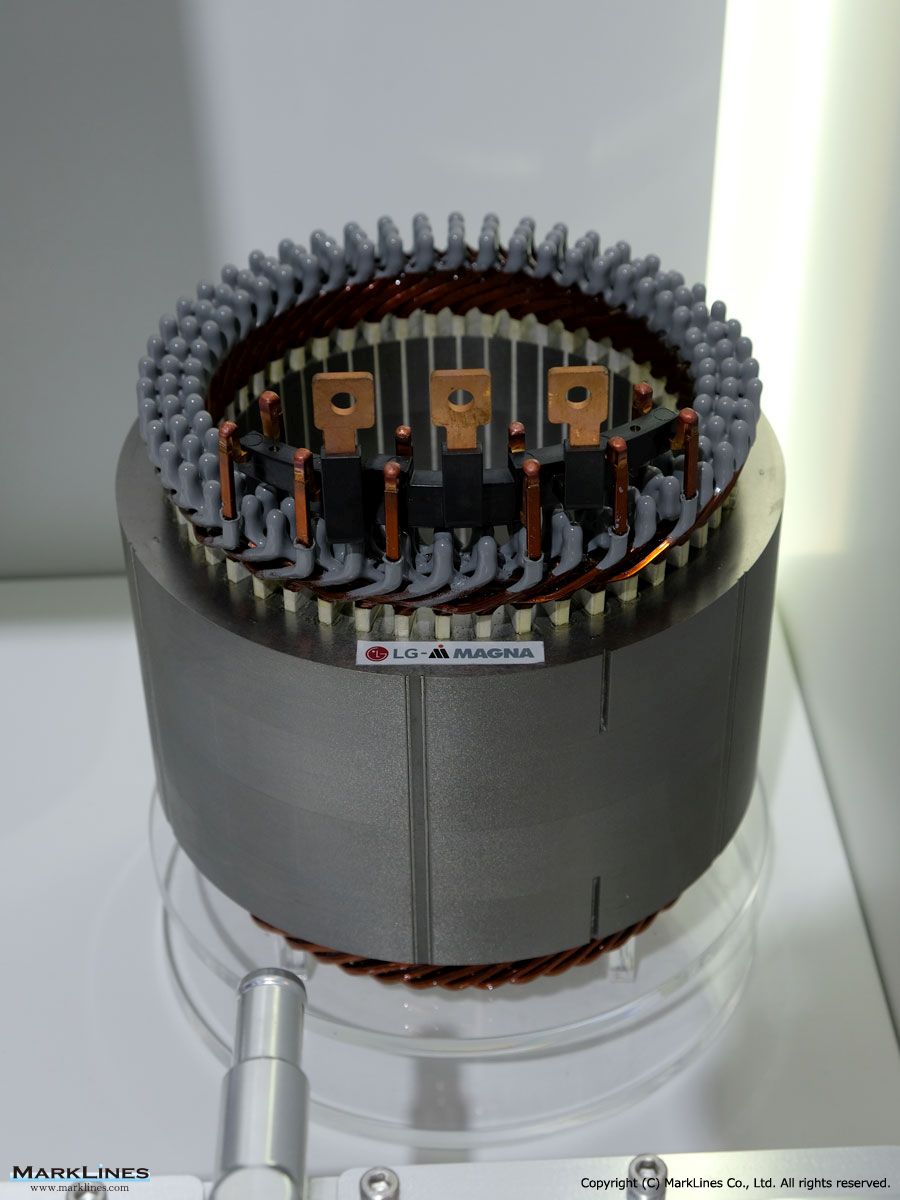

ave been progressively introduced into the heat dissipation and design structure of the motor to improve local heat exchange efficiency and temperature control stability. This has helped to increase the overall system density and power output. (2) Light-weight structures and higher power density: Hairpin windings dominate the market. With their obvious advantages in terms of power density and thermal characteristics, hairpin-wound motors are no...

Market & Tech Reports Updated at: 2025/12/11

Analysis Report: EV/HV Drive Motor (European Market)

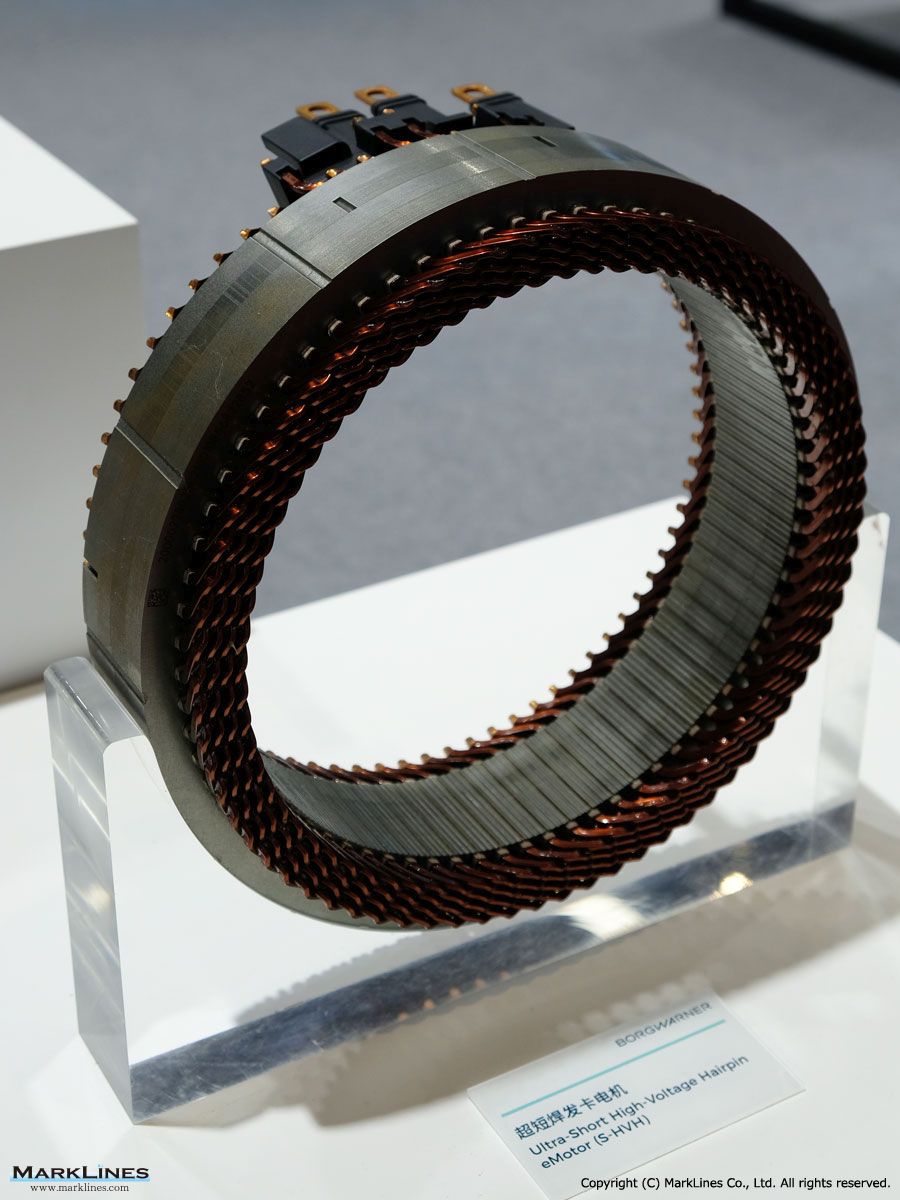

mplex shaped core gives rise to portions which are difficult to wind, such cores are often divided into pieces. Conversely, there is a structure in which a series of windings are made by inserting a large number of rectangular cross-section (improved space efficiency by winding with no gaps), short hairpin-shaped coil wires into the stator, welding the protruding sides in pairs then covering; such configuration started to be widely used in Toyota...

Market & Tech Reports Updated at: 2025/12/09

34th Aachen Colloquium Sustainable Mobility

ble Mobility, organized by © Aachener Kolloquium Fahrzeug- und Motorentechnik GbR, Slide: Copyright © ZF Group) The stator diameters range from 210 to 245 mm, with power classes from 130 to 550 kW and torque from 200 to 1,000 Nm. All machines are oil-cooled and use a six- or eight-layer PRI hairpin winding design, with ongoing optimization of active length and winding heads. For the secondary drive, ZF recommends the induction motor, fe...

Market & Tech Reports Updated at: 2025/12/02

Analysis Report: EV/HV Drive Motors (Japanese Market)

t, assist-driven motors. In recent years, the inserter-type distributed winding using round wire (enameled wire with a round cross section) has been decreasing, and distributed winding using "SC winding," in which flat rectangular wire (enameled wire with a rectangular cross section) is inserted as hairpin-shaped segments into the stator slots, formed, and welded to form a wave-wound coil, has become more common. Flat wire, as opposed to round wi...

Market & Tech Reports Updated at: 2025/11/04

Automotive World Autumn 2025: Chinese electric vehicles teardown exhibit

ependently. The electric powertrain is not an in-wheel motor type, but a motor, inverter, and reduction gear for each of the four wheels, grouped together in the front e-Axle and rear e-Axle. The four drive motors are 8-pole embedded magnet synchronous motors (IPMSM) with flat-wire wave wound hairpin type (SC) windings, each with maximum output of 220kW and maximum torque of 320Nm. BYD Yangwang U8 motor related parts display Stator R...

Market & Tech Reports Updated at: 2025/10/14

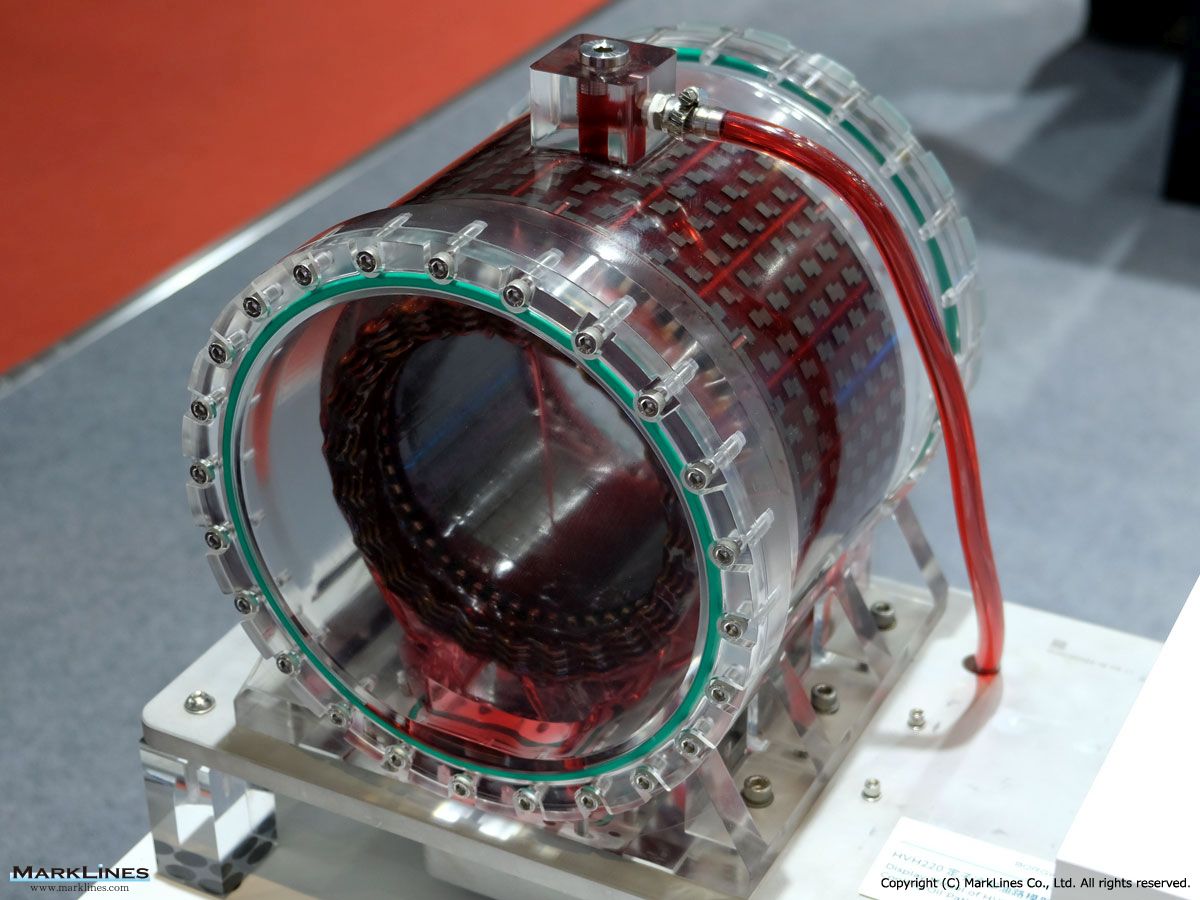

Vienna Motor Symposium 2025 (3) Reaching zero carbon mobility emission

rranged cooling channel features a geometrically simple design and is significantly easier to manufacture compared to conventional radially arranged cooling jackets in electric machines. The winding production eliminates the need for basket making, bending, and separating, which are necessary in hairpin manufacturing. The complex process of assembling the complete winding in the stator lamination stack is also omitted. Prototyping and testing ...

Market & Tech Reports Updated at: 2025/07/17

JSAE 2025 in Yokohama: e-Axles, Motors, xEVs

The electric powertrain does not use in-wheel motors, but rather has a motor, inverter, and reducer for each of the four wheels, which are combined and installed in the front e-Axle and rear e-Axle. The four drive motors are 8-pole IPMSM (Interior Permanent Magnet Synchronous Machine) motor with hairpin-type (SC winding) flat-wire wave windings, with a maximum output of 220kW and a maximum torque of 320Nm. In addition, MarkLines Co., Ltd. h...

Market & Tech Reports Updated at: 2025/06/16

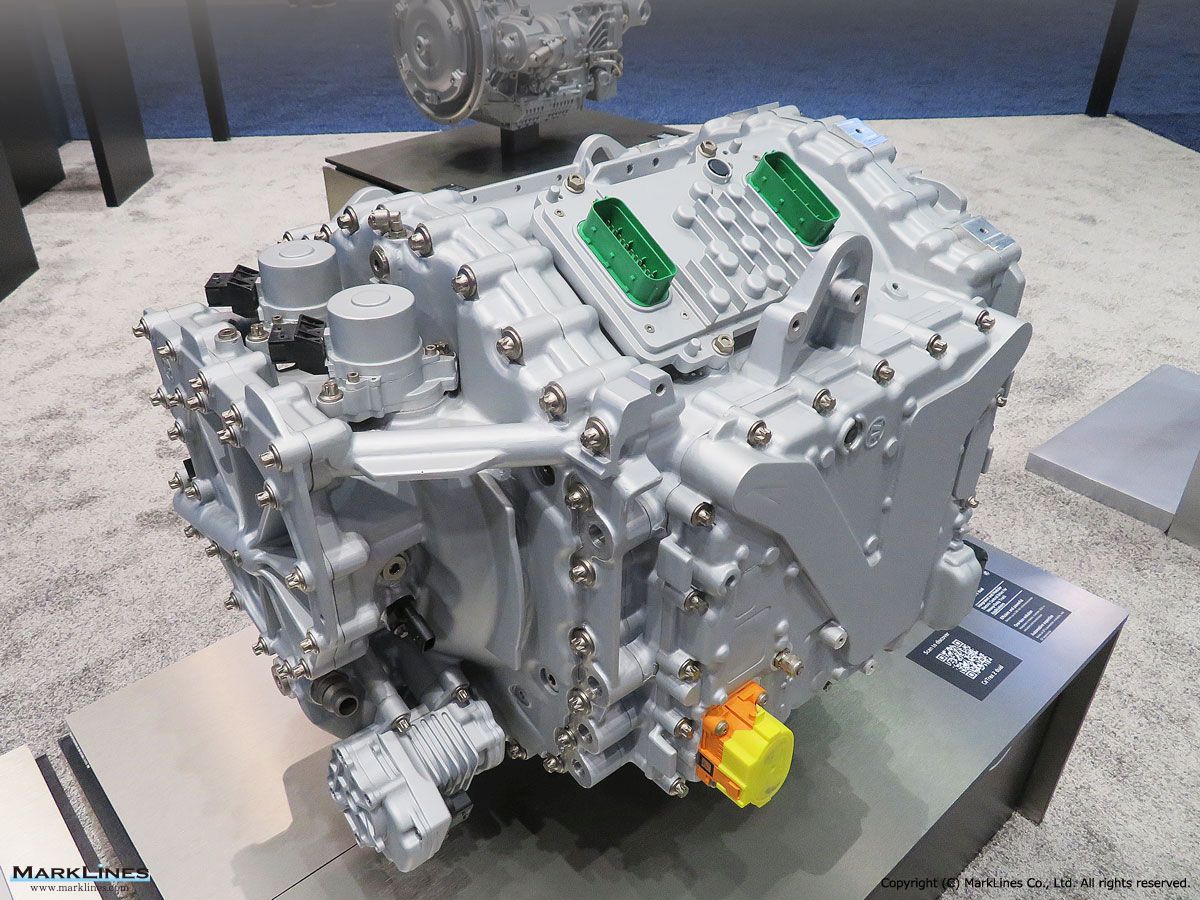

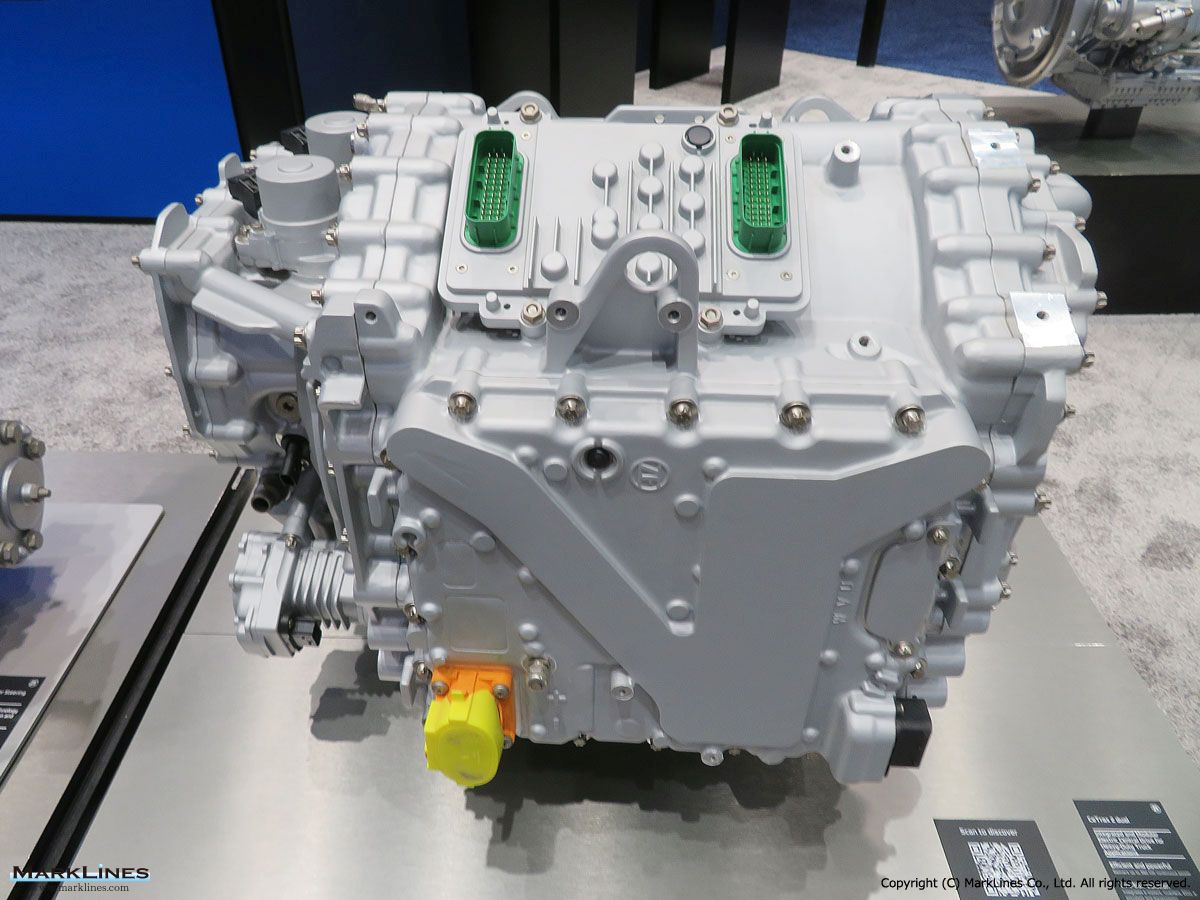

ACT Expo 2025: Electric and hybrid commercial vehicles

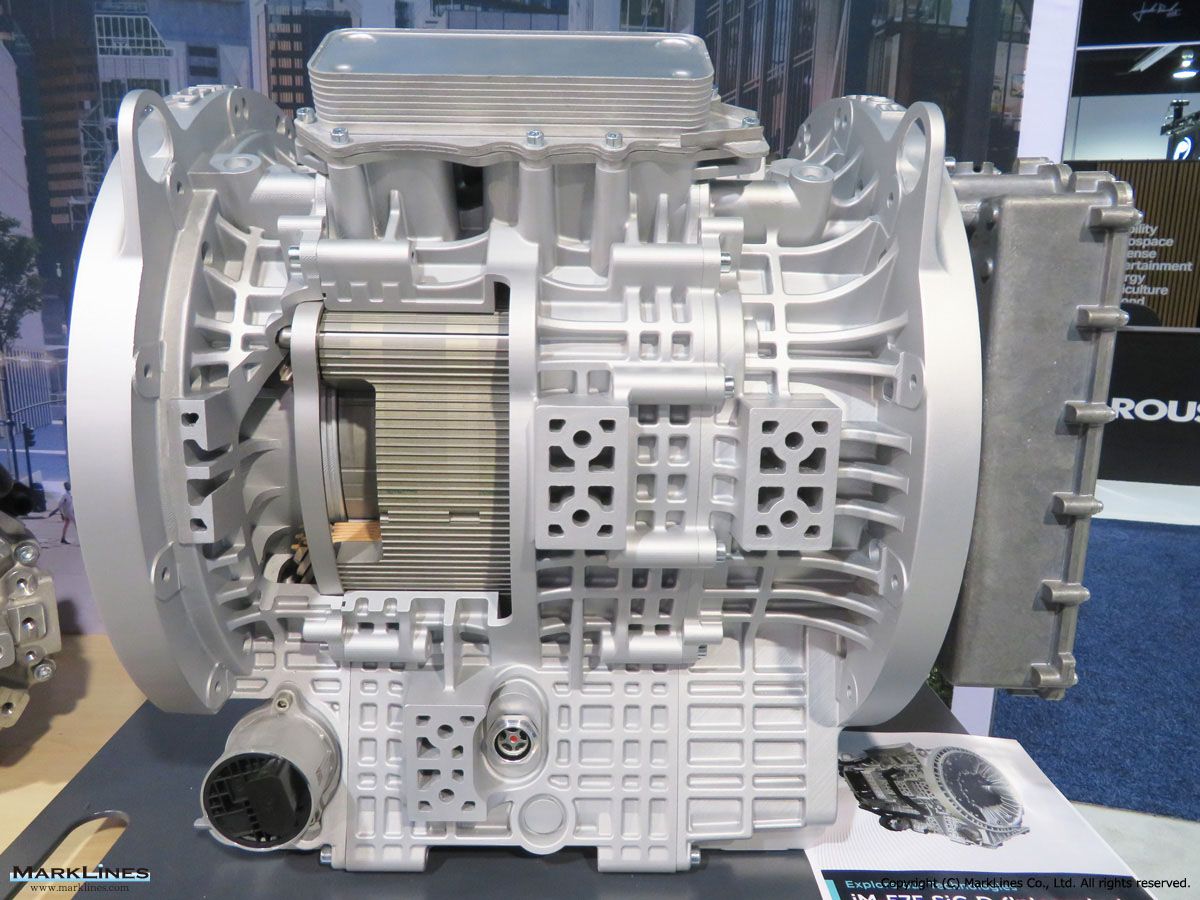

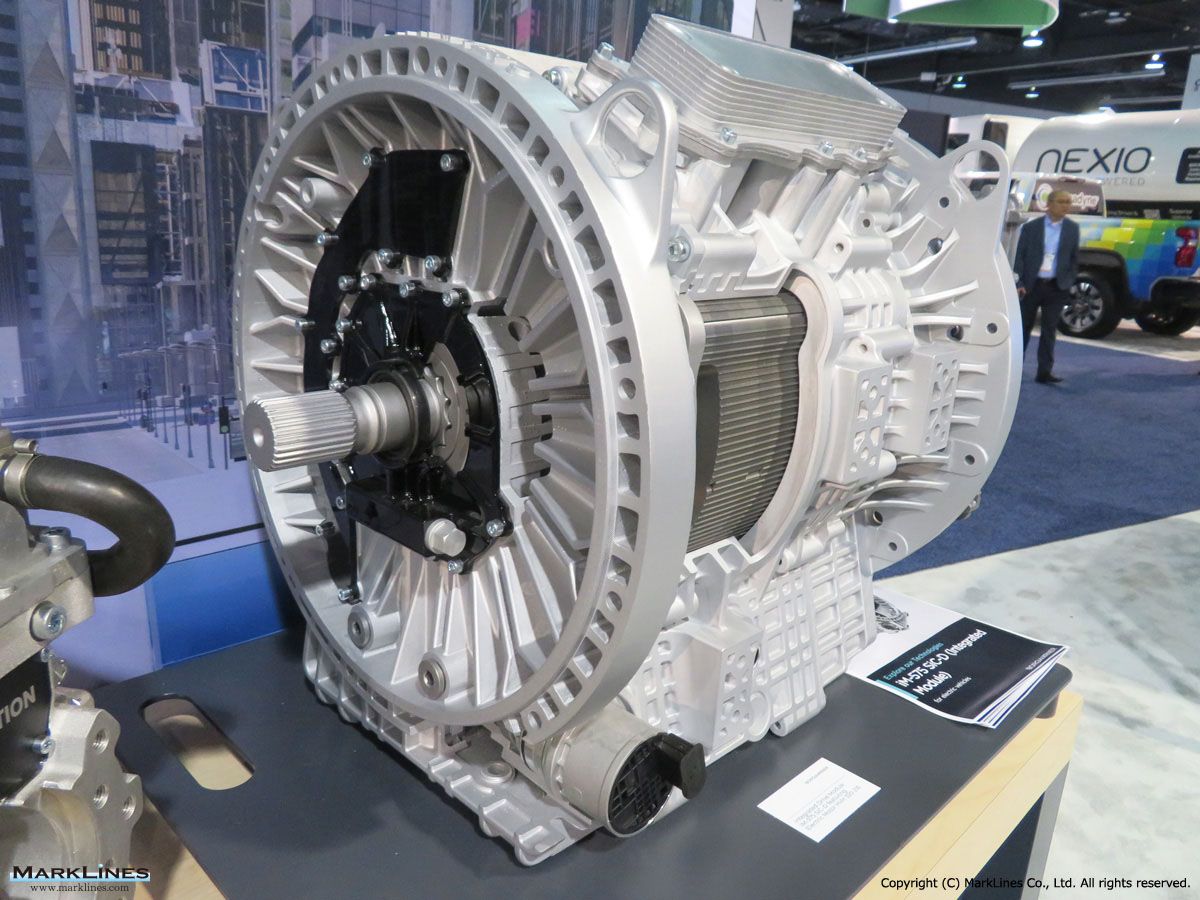

BorgWarner iM-575 SiC-D integrated drive module Beyond its 9 AKM and LFP battery systems, BorgWarner's exhibit at ACT Expo 2025 highlighted the iM-575 SiC-D integrated drive module developed with its Cascadia Motion subsidiary. The iM-575 combines BorgWarner's HVH320-216 high-voltage hairpin motor with Cascadia Motion's CM350 inverter which features a Viper silicon carbide power module. The drive module provides a peak torque of 1,...

Market & Tech Reports Updated at: 2025/06/06

Automotive World 2025: e-Axle, Motors

an finished motors. Core stamping and lamination can be performed with electromagnetic steel sheets of 0.2mm to 6.5mm, and the lineup also includes CFRP rotors that are reinforced by covering the rotor surface with CFRP, which uses carbon fiber. Core and CFRP rotorCFRP rotor display panel Hairpin-wound stator Hairpin-wound stator display panel Motor drive unit Motor drive unit display panel Fukuta Electric has abundant...

Market & Tech Reports Updated at: 2025/02/27

Tesla Cybertruck Teardown: Electric Powertrain

alent to 0.738 lb/ft.) It uses a permanent magnet (PM) synchronous motor (with locking differential) at the front and two induction motors (with torque vectoring control) at the rear. The stators for the Cyberbeast's front and rear motors have been changed from the conventional wire-wound type to a hairpin type, a first for Tesla. Previous Tesla vehicles have used inverters with electronic boards shaped like the borders of the United States, b...

Market & Tech Reports Updated at: 2024/11/13

Smart Energy Week Autumn: Electrification Technologies

d area in question, detecting the effects of the generated heat and thermal diffusion using an infrared array sensor, and inspecting for internal defects such as voids and cracks in addition to surface defects. The laser welding monitor LWM (Laser Welding Monitor), which may be useful when welding hairpin-type motor windings (SC windings) with a laser, monitors, evaluates, and records each laser weld, ensuring 100% traceability during production...

Market & Tech Reports Updated at: 2024/10/29

Korea Next Gen Mobility Technology Expo 2024

., Ltd. Korens EM: Stator assembly for EV drive motor, rotor assembly for EV drive motor Stator assembly display panel Rotor assembly display panel Korens EM Co., Ltd. had a panel showing its stator and rotor assemblies for EV drive motors. Most of the stator assemblies use a hairpin stator (SC winding) with a maximum output of 33kW to 205kW, and the company has mass production experience of over 50,000 units. Rotors are...

Market & Tech Reports Updated at: 2024/10/10

Analysis Report: EV/HV Drive Motor (European Market)

mplex shaped core gives rise to portions which are difficult to wind, such cores are often divided into pieces. Conversely, there is a structure in which a series of windings are made by inserting a large number of rectangular cross-section (improved space efficiency by winding with no gaps), short hairpin-shaped coil wires into the stator, welding the protruding sides in pairs then covering; such configuration started to be widely used in Toyota...

Market & Tech Reports Updated at: 2024/09/05

TECHNO-FRONTIER 2024: Electric Vehicle Technologies

r). Display panel for drive unit VREMT nameplate on front inverter The rear unit's motor is an interior permanent magnet synchronous motor (IPMSM) with a maximum output of 310kW, peak torque of 440Nm, and maximum rotational speed of 18,000 rpm. The stator uses flat wire SC windings (hairpin type), and the rotor is skewed in six steps to prevent vibration. Rear motorRotorStatorResolver, terminal block Rear inverterPower modu...

Market & Tech Reports Updated at: 2024/08/27

Analysis Report: EV/HV Drive Motors (Japanese Market)

t, assist-driven motors. In recent years, the inserter-type distributed winding using round wire (enameled wire with a round cross section) has been decreasing, and distributed winding using "SC winding," in which flat rectangular wire (enameled wire with a rectangular cross section) is inserted as hairpin-shaped segments into the stator slots, formed, and welded to form a wave-wound coil, has become more common. Flat wire, as opposed to round wi...

Market & Tech Reports Updated at: 2024/08/22

BYD's e-Platform 3.0 Evo

otor and new generation silicon carbide (SiC) power module The motor of the electric drive system uses 0.25mm ultra-thin silicon steel sheets. The high-speed low-leakage magnetic rotor structure and dual-split (V-shaped) magnet design are optimized. Motor slot full rate reaches 92%. It also uses hairpin flat wire coil technology. The motor rotation speed is 23,000 rpm. As of May 2024, this is the highest rotation speed in the world for a mass-...

Market & Tech Reports Updated at: 2024/07/16

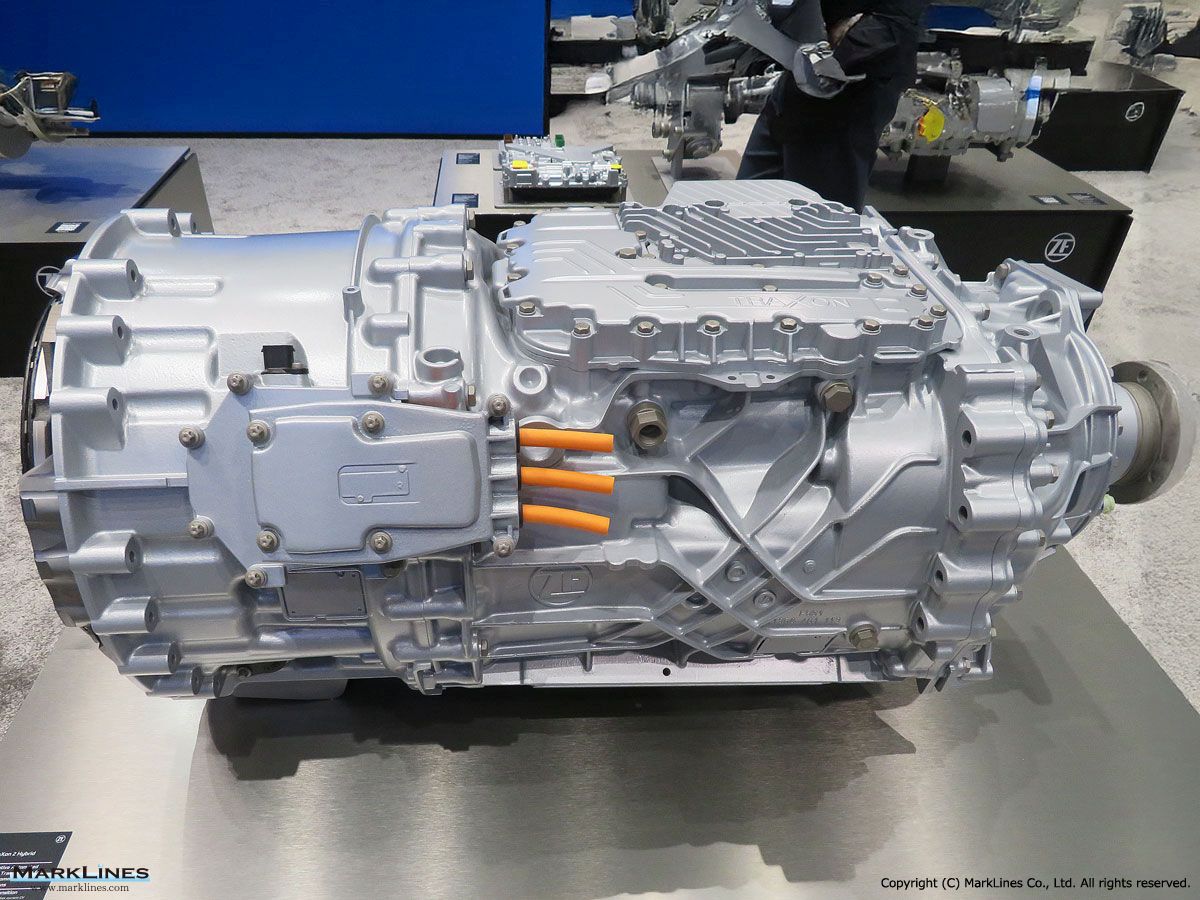

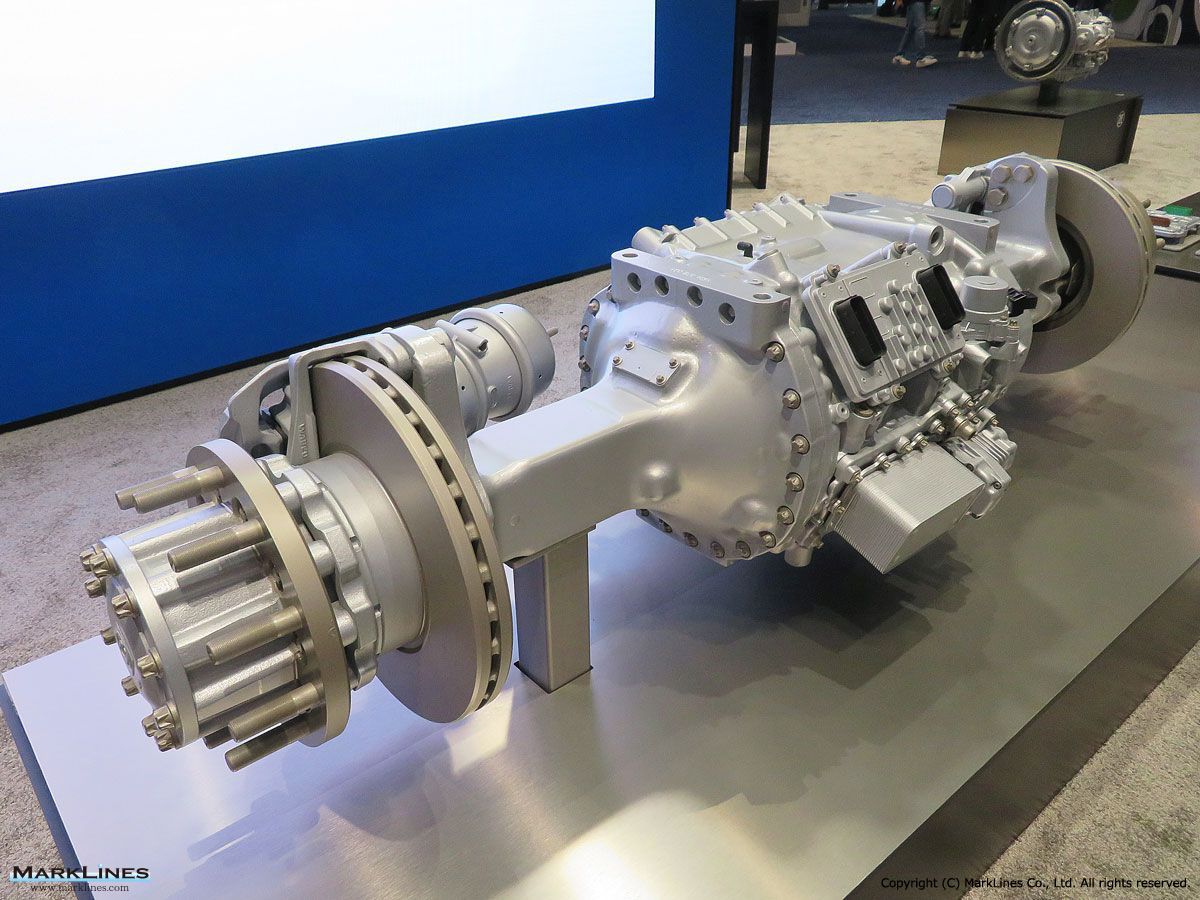

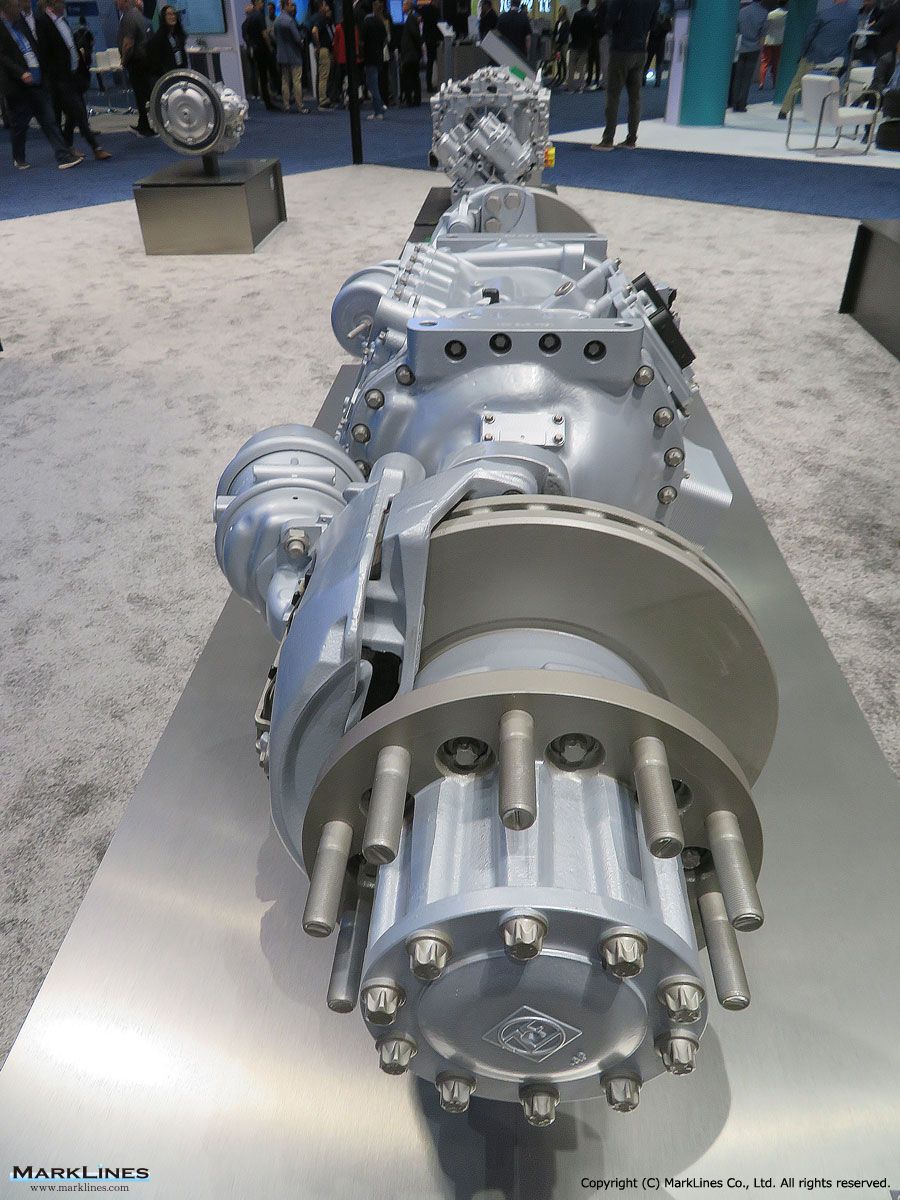

ACT Expo 2024 (2) Electric Powertrains for Commercial Vehicles

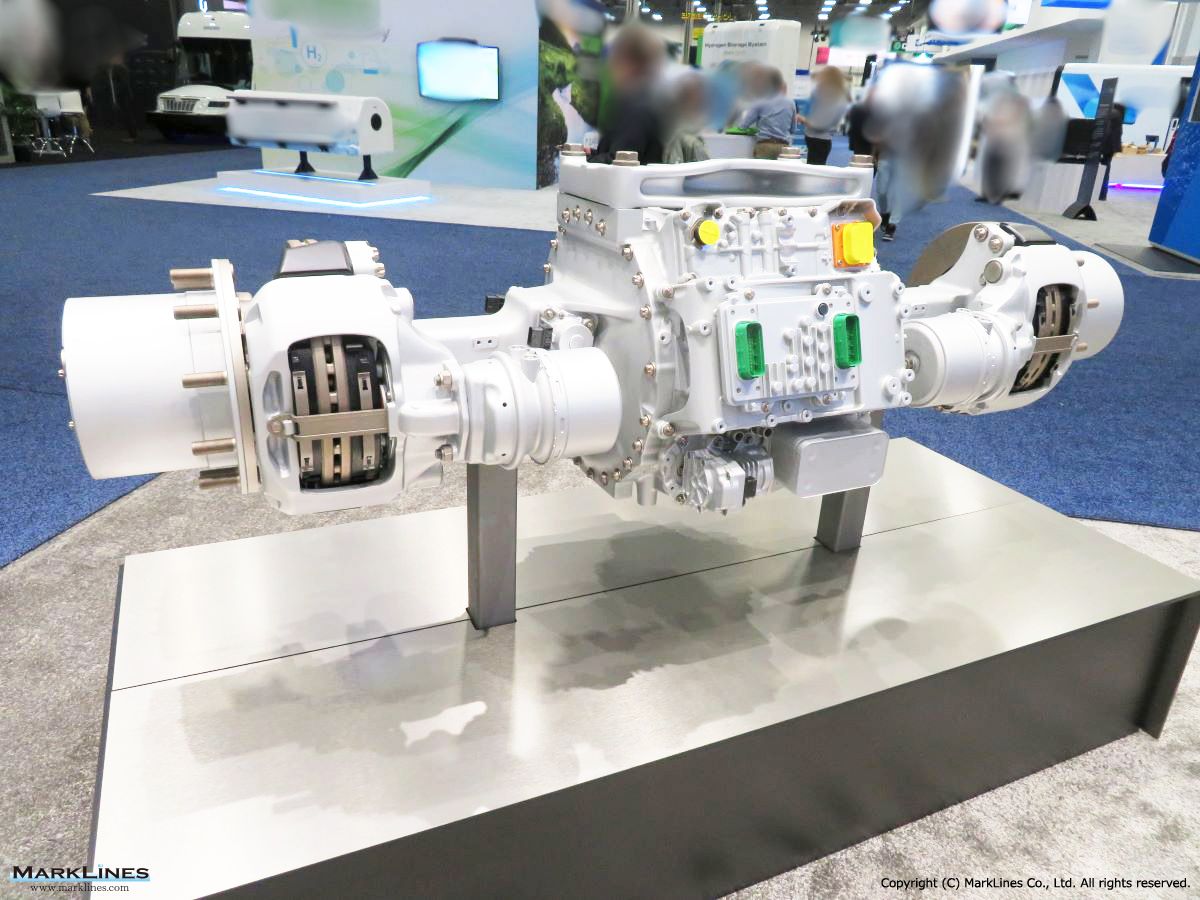

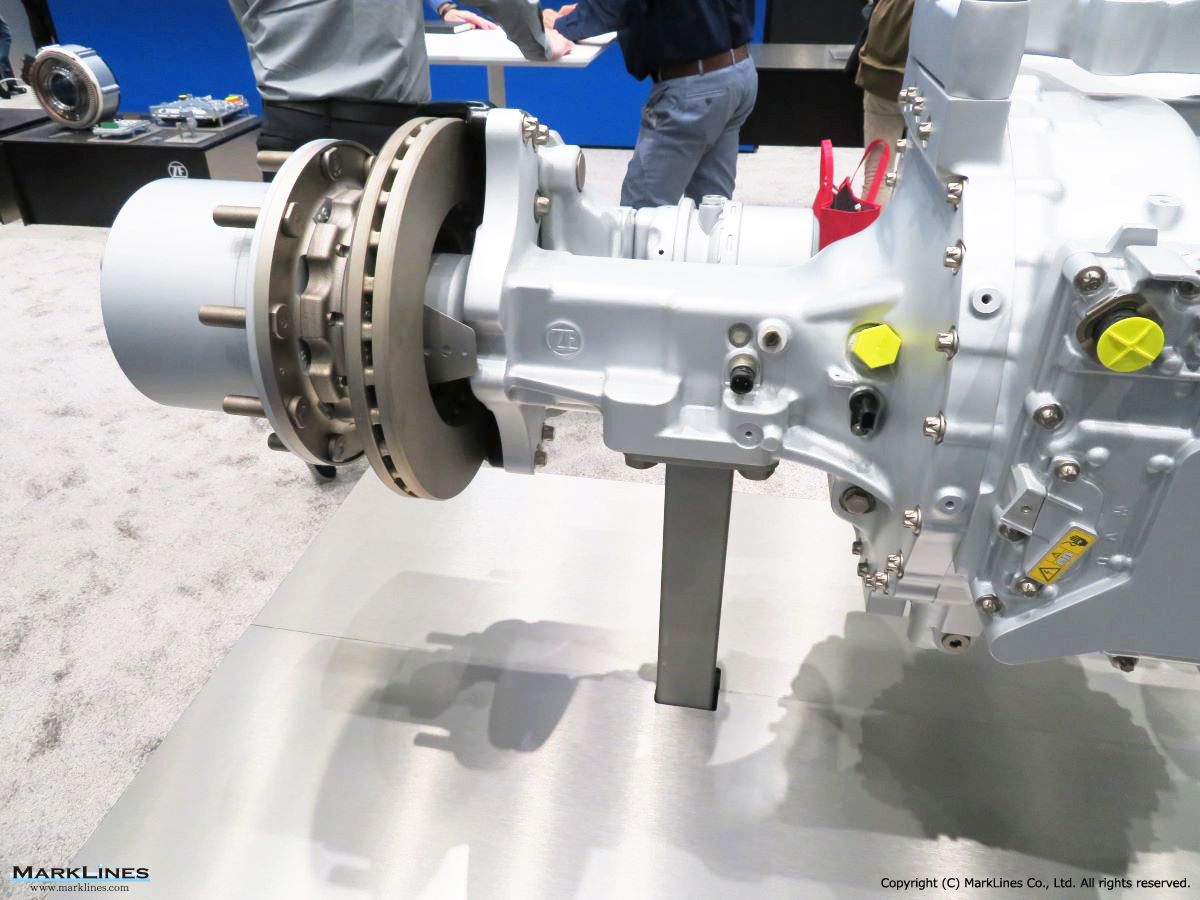

peak power of 738 hp, and peak torque of 3,689 lb-ft. Accelera Gen 4.5 14Xe eAxle with ELFA 3 v3.2 inverter Accelera 1CS2022 traction motor with two ELFA 3 v3.0 inverters ZF highlighted the AxTrax 2 e-axle which debuted at ACT Expo 2023. AxTrax 2 is a modular system which integrates a hairpin electric motor, silicon carbide inverter, ECU, electric actuator and three-speed transmission. The AxTrax2 produces 282 hp of continuous power...

Market & Tech Reports Updated at: 2024/07/05

Vienna Motor Symposium 2024 (3) Rise of SDVs, Electric Powertrains

or, with a small outer diameter of 150 mm and an active length of 175 mm, has a peak performance of 250 kW and a rotational speed of 155 m per second. It has a total active mass of less than 20 kg and uses standard magnets, that are optimized in terms of weight and efficiency. The stator features a hairpin winding with a copper fill factor of 60%. Specifications and cooling principle of the e-motor (45th International Vienna Motor Symposiu...

Market & Tech Reports Updated at: 2024/07/03

JSAE 2024 in Yokohama: Electric Powertrains

Since the 1-motor hybrid transmission is a 1M2C (1 motor, 2 clutch) system, it does not have the power split mechanism used in THS, and the clutch is located inside the motor. Although the motor's axial dimension is limited, the motor is not a concentrated winding type, but uses a segment coil (hairpin) type distributed winding motor similar to those used in the 5th generation Prius and BZ4X. The starting clutch is large, capable of withst...

Market & Tech Reports Updated at: 2024/06/12

WCX 2024 (2) Improved vehicle sustainability and industry perspectives

but with a closed design. The laminate offset is not a sequential step design and only has two positions. The keeper plate for the permanent magnet motor is not as large, exposing the magnet tops and laminate for what Sandy Munro speculated was cooling purposes. Finally, the motor stators use a new hairpin design which can be wound using one machine instead of multiple. The Cybertruck is the first Tesla model to use a 48-V low-voltage system inst...

Market & Tech Reports Updated at: 2024/05/21

AI Navigator

AI Navigator

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India