Search Results by Category

AI Navigator

AI NavigatorAll information related to {{ key_word }}.

AI Navigation will guide you. Click here for information about {{ key_word }}.

3

3

4

4

11

11

1

1

1

1

1

1

1

1

1

1

3

3

3

3

1 - 20 of 169 results

SEAT S.A., Martorell Plant[Spain]

00 new solar panels to triple energy capacity in production facilities SEAT's Martorell plant production increase by 20.9% Y-on-Y in 2023 SEAT S.A. announces plans for future electric and hybrid models SEAT shows construction progress of Martorell battery plant SEAT S.A. starts using electric paint drying oven in Martorell in 2023 SEAT S.A. reveals details about e-House department in Martorell plant for EV electronics Cupra begins production of F...

OEM Plants Updated at: 2025/12/18

BMW AG, Regensburg Plant[Germany]

transfer heat instead of relying on gas. This system allows flexible energy use and can run on electricity or gas, making it easier to switch to renewable power even when the local grid can’t yet meet high energy demands. During the New Year production break, BMW replaced one gas-powered top coat drying line with an electric thermal oil system and a new eRTO exhaust air unit. Instead of directly heating air, the new setup uses electric heaters ...

OEM Plants Updated at: 2025/12/18

PowerCo begins Unified battery cell production at Salzgitter Gigafactory, Germany

in Salzgitter, with a new test facility under construction which is set to open in early 2026. The Salzgitter Gigafactory sets new benchmarks for low-carbon dioxide battery cell production. It runs entirely on renewable energy from wind and solar. For the first time, the energy-intensive clean and drying rooms will also be operated with green electricity. In the industry, fossil fuels are typically used for this purpose. Based on VW Group press ...

News Updated at: 2025/12/17

Chongqing Changan Automobile Co., Ltd.[China]

, Changan Auto issued the "Changan Auto 2022 Social Responsibility Report". It is mentioned in the report that the company's Yubei plant has launched a special campaign to control the disorganized emissions of volatile organic compounds (VOCs). The plant installed 1 set of TNV treatment system for drying exhaust gas, 2 sets of “ozone oxidation + chemical oxidation + plant liquid spraying” treatment system for wastewater station exhaust gas,...

OEM Plants Updated at: 2025/12/17

Mazda Motor, Hiroshima Plant[Japan]

then the second and third colors, which have a narrower coating area, are painted on a newly installed dedicated line. The paint spray gun on the dedicated line can spray paint in a concentrated area, reducing paint loss by about 45% compared to the conventional coating line. Additionally, for the drying process, Mazda has adopted newly developed paints that harden at a low temperature of approximately 80°C instead of having to be heated to 140...

OEM Plants Updated at: 2025/12/16

Kojima Industries Corporation

(Uchihamakasei), a subsidiary of Kojima Industries Corporation (Toyota City, Aichi Prefecture). The new in-mold coating technology combines resin molding and surface coating into a single integrated process. The new technology will eliminate the need for coating application booths and post-coating drying ovens, which have been needed for conventional coating methods, and help to reduce CO₂ emissions by 60%. The two companies will share this ne...

Major Suppliers Updated at: 2025/12/16

SAIC-GM-Wuling Automobile Co., Ltd. (SGMW) [China]

ogy and Saike Ruipu, two subsidiaries of SAIC Motor, began production as well. On March 30, SAIC released the 2023 SAIC MOTOR CORPORATION LIMITED ESG & Sustainability Report. According to the report, to reduce the amount of waste generated, the SGMW painting workshop added paint slag dewatering and drying equipment. This equipment allows the paint slag to be transferred from the scraping tank to the dewatering and drying equipment, helping reduce...

OEM Plants Updated at: 2025/12/11

Japan Mobility Show 2025: Hydrogen, Batteries

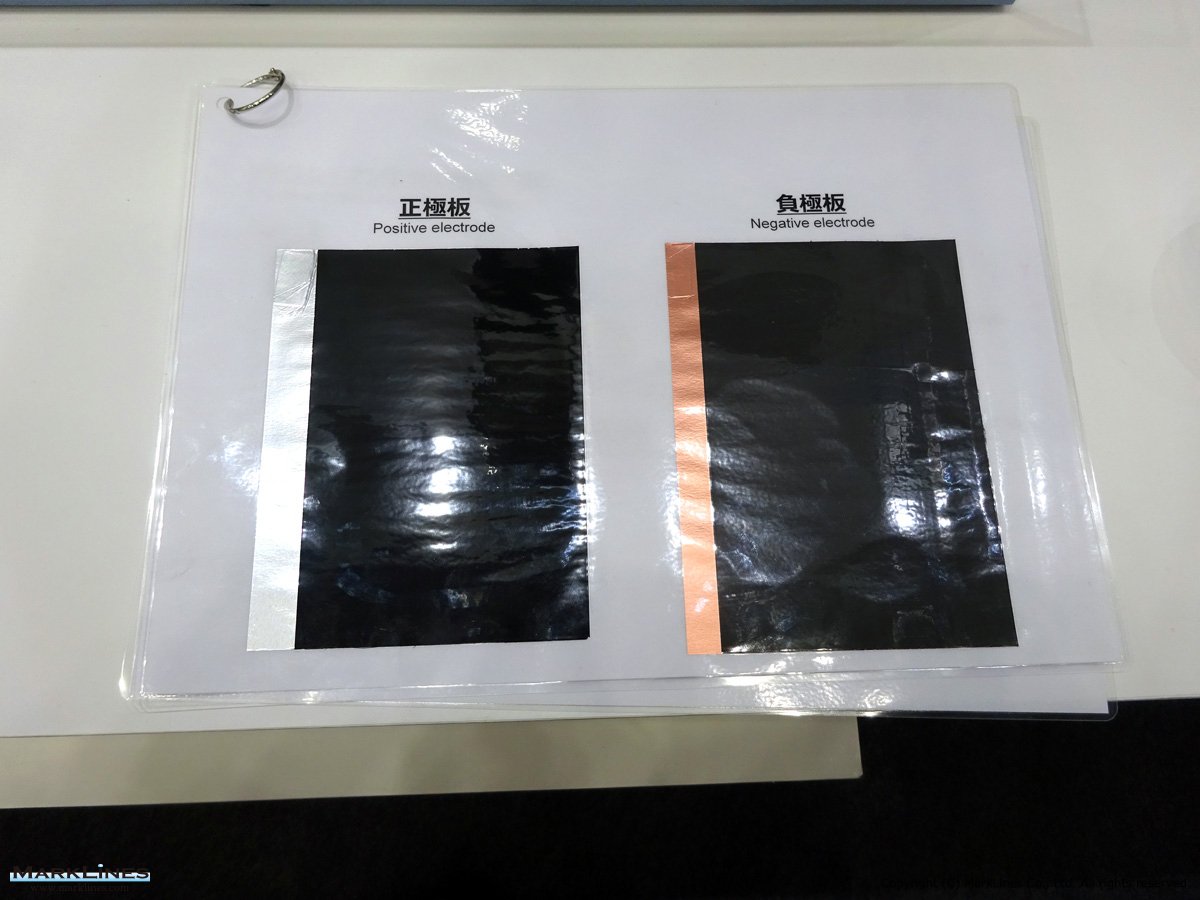

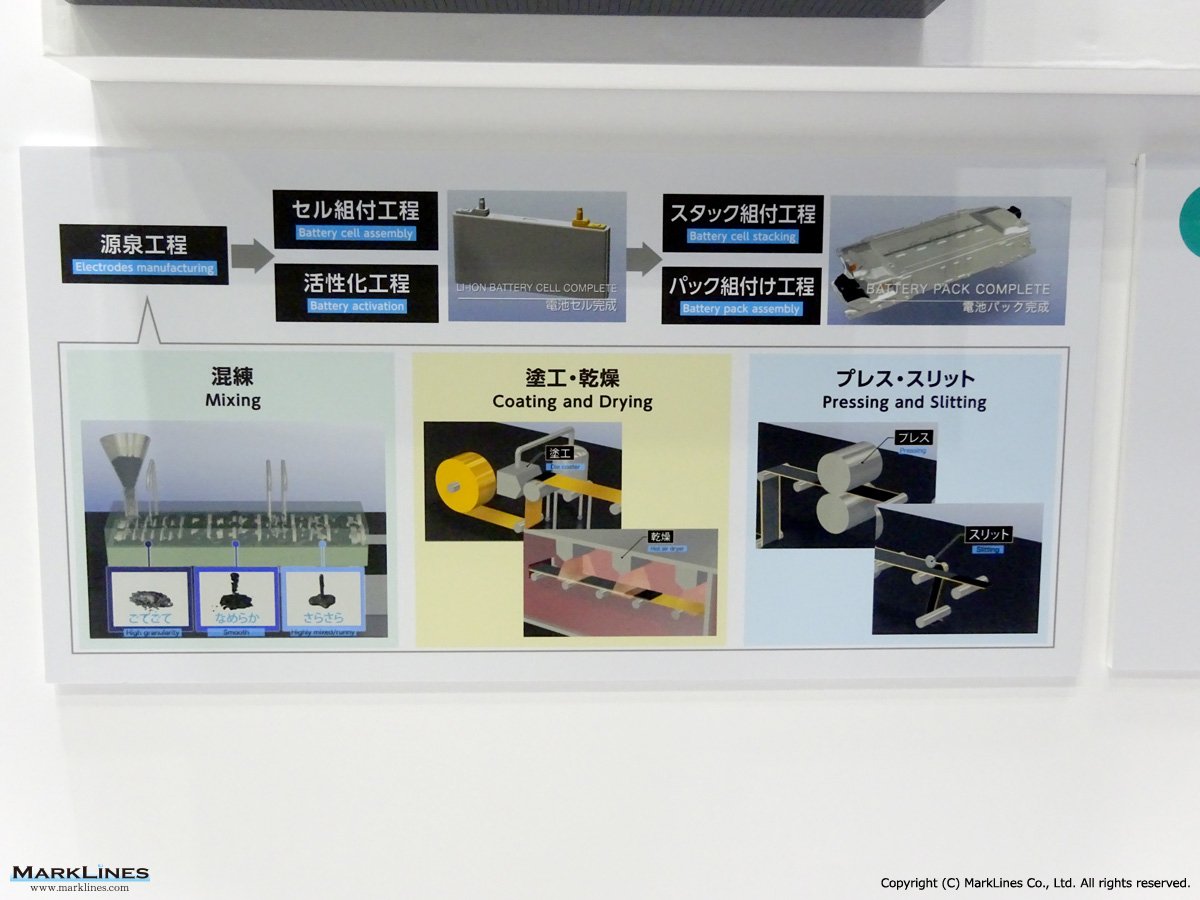

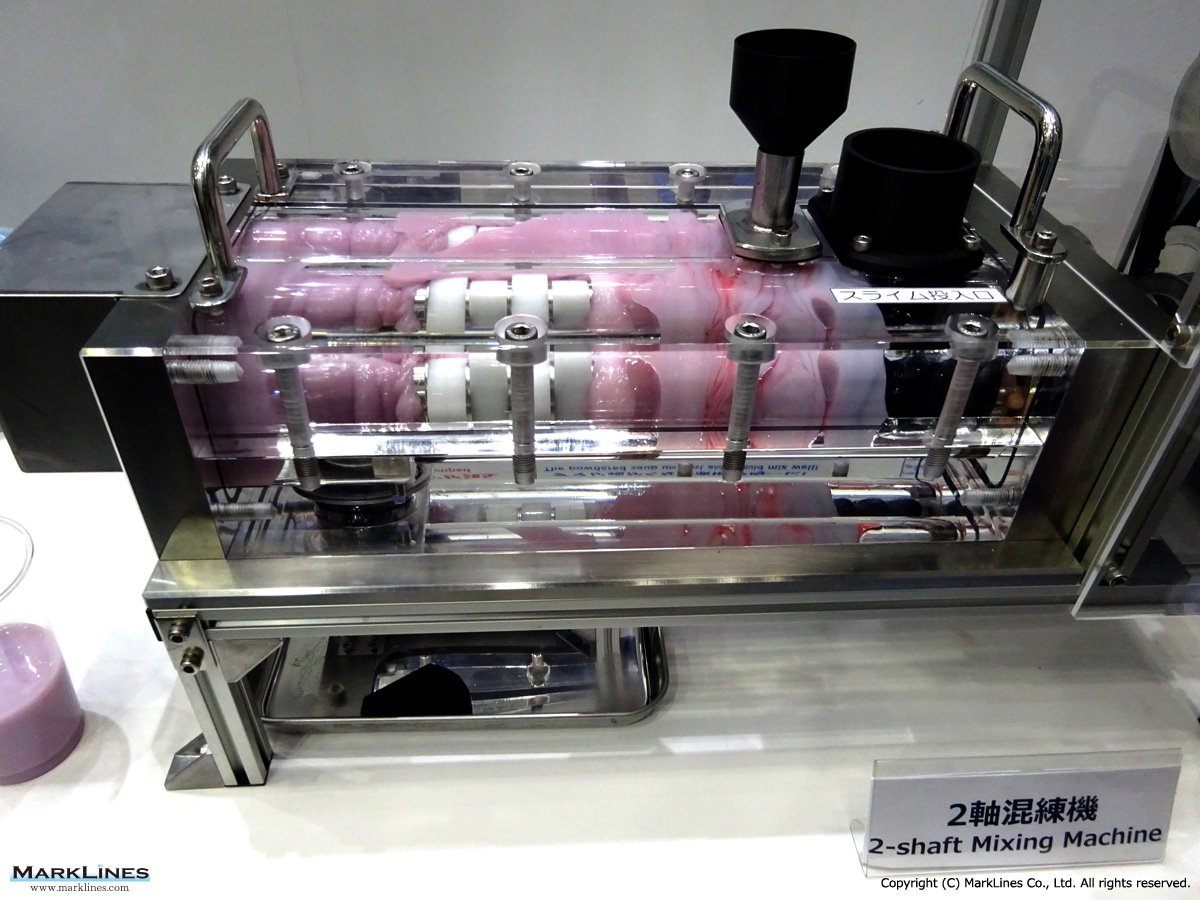

tphone battery. Display comparing battery capacity of various electric vehicles Of the six co-exhibitors, JTEKT Corporation (JTEKT) was in charge of the battery production equipment, and displayed 1/30 scale miniature models of the equipment for each process, including mixing, coating/drying, and pressing/slitting, and used panels to introduce efforts to improve productivity and reduce CO2 emissions. They also demonstrated how to mi...

Market & Tech Reports Updated at: 2025/12/11

Audi AG, Audi Sport GmbH, Böllinger Höfe Plant[Germany]

atures fully automated systems for priming all Audi models produced in Neckarsulm and nearby Böllinger Höfe. Audi has introduced modern methods for corrosion protection, including an improved cathodic dip painting (CDP) process that reduces space and prevents air bubbles. A more energy-efficient drying process and a new thin-film method have replaced the older phosphating process, making the system more efficient. On March 24, Audi announced t...

OEM Plants Updated at: 2025/12/09

Audi AG, Audi Sport GmbH, Neckarsulm Plant[Germany]

rsulm factory. Audi has optimized processes and introduced eco-friendly methods for the A5 launch. The models feature a new wet-on-wet painting process, replacing the traditional filler, and use sustainable water-based paints. Advanced corrosion prevention methods and an energy-efficient transverse drying process have also been implemented, better suited for future electric and hybrid vehicles. A new paint separation process captures paint mist w...

OEM Plants Updated at: 2025/12/09

Dongfeng Nissan Passenger Vehicle Company (DFN)[China]

o planning, guarantee and emergency systems to empower the whole supply chain system with strong anti-risk capability to maintain its production rhythm even in the case of emergencies. On May 19, Dongfeng Motor Group released its 2021 ESG Report. The report introduces Dongfeng Nissan's painting and drying room indirect burner waste heat recovery project. The high-temperature exhaust heat of the indirect burner is recovered through the heat pipe h...

OEM Plants Updated at: 2025/12/09

Chuo Spring Co., Ltd.

cle assembly plants. (From an article in the Nikkan Jidosha Shimbun on March 7, 2025) Chuo Spring Co., Ltd. (Chuo Spring) announced that an accident occurred at its Fujioka Plant's No. 4 building, in which a part of the equipment exploded. The accident occurred at around 12:15 pm on October 16. The drying furnace and part of the building were damaged, but the cause is under investigation. According to multiple media reports, Toyota has suspended ...

Major Suppliers Updated at: 2025/12/03

Renault ElectriCity, Maubeuge Plant (formerly Maubeuge Construction Automobile (MCA))[France]

lutionary two-tone painting technology that enhances precision, efficiency, and sustainability, for the production of Renault 4 E-Tech electric. Jetprint Paint uses paint-printing robots to apply the roof and bonnet colors in just six minutes, eliminating the need for manual masking and double oven drying. This integration streamlines production, significantly reduces waste, and saves 1.7 GWh of energy per year, equivalent to powering 350 househo...

OEM Plants Updated at: 2025/12/03

BMW AG, Dingolfing Plant[Germany]

day, with the European market launch set for November 2, 2024. On July 22, BMW Group announced that it has started the use of electricity to purify exhaust air in its paint shops. The new process allows for the high temperatures required for thermal purification of exhaust air from paint booths and drying rooms to be generated electrically by eliminating the need for natural gas. The eRTO (electrically regenerative thermal oxidation) process clea...

OEM Plants Updated at: 2025/12/01

Analysis Report: Lithium-Ion Battery (Japanese, European, U.S. and Korean Markets)

Increased capacity and larger diameter, elimination of electrode tabs, all electrodes at the top end to reduce heat generation in the center, and welding process is omitted. Battery plant: By introducing Maxwell's dry electrode technology, the use of binder solvent during coating is eliminated, the drying process is omitted, solvent recovery equipment is unnecessary, and electricity consumption is reduced. Negative electrode material: Silicon is ...

Market & Tech Reports Updated at: 2025/12/01

BMW Manufacturing Hungary Kft., Debrecen Gyar plant[Hungary]

mono-materials are used for side skirts and apron attachments. On July 22, BMW Group announced that it has started the use of electricity to purify exhaust air in its paint shops. The new process allows for the high temperatures required for thermal purification of exhaust air from paint booths and drying rooms to be generated electrically by eliminating the need for natural gas. The eRTO (electrically regenerative thermal oxidation) process clea...

OEM Plants Updated at: 2025/11/27

FAW-Volkswagen Automotive Co., Ltd. Tianjin Branch[China]

nsumption during the shutdown period in 2021 will be reduced by 21% compared with that in 2020, and the energy guidance manual of Tianjin Branch will be formed at the same time. In terms of hazardous waste reduction, projects such as aqueous solvent precipitation + electro-Fenton process and sludge drying were carried out to reduce hazardous waste per vehicle, from 13.93kg/vehicle in 2020 to 10.57kg/vehicle in 2021. In addition, the Tianjin North...

OEM Plants Updated at: 2025/11/24

Zhengzhou Nissan Automobile Co., Ltd. [China]

Nissan launches The Arc business plan (FY2024-FY2026), regional strategy in China Zhengzhou Nissan starts accepting pre-orders for new Rich 6 Pro pickup truck Zhengzhou Nissan unveils Z9 hardcore pickup truck Zhengzhou Nissan installs photovoltaic power generation system Zhengzhou Nissan implements drying furnace air-fuel ratio transformation project Zhengzhou Nissan actively carries out green logistics work OTING brand announces expansion of mod...

OEM Plants Updated at: 2025/11/24

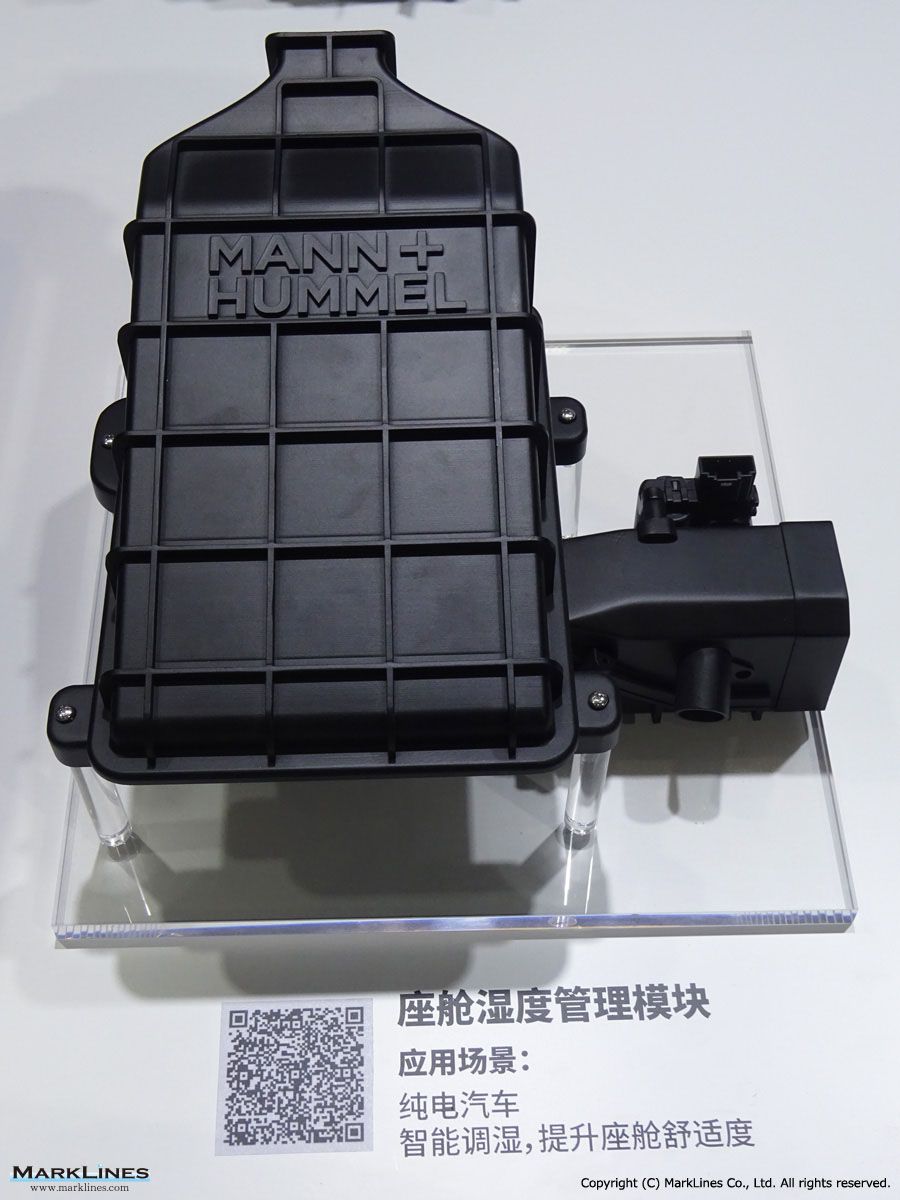

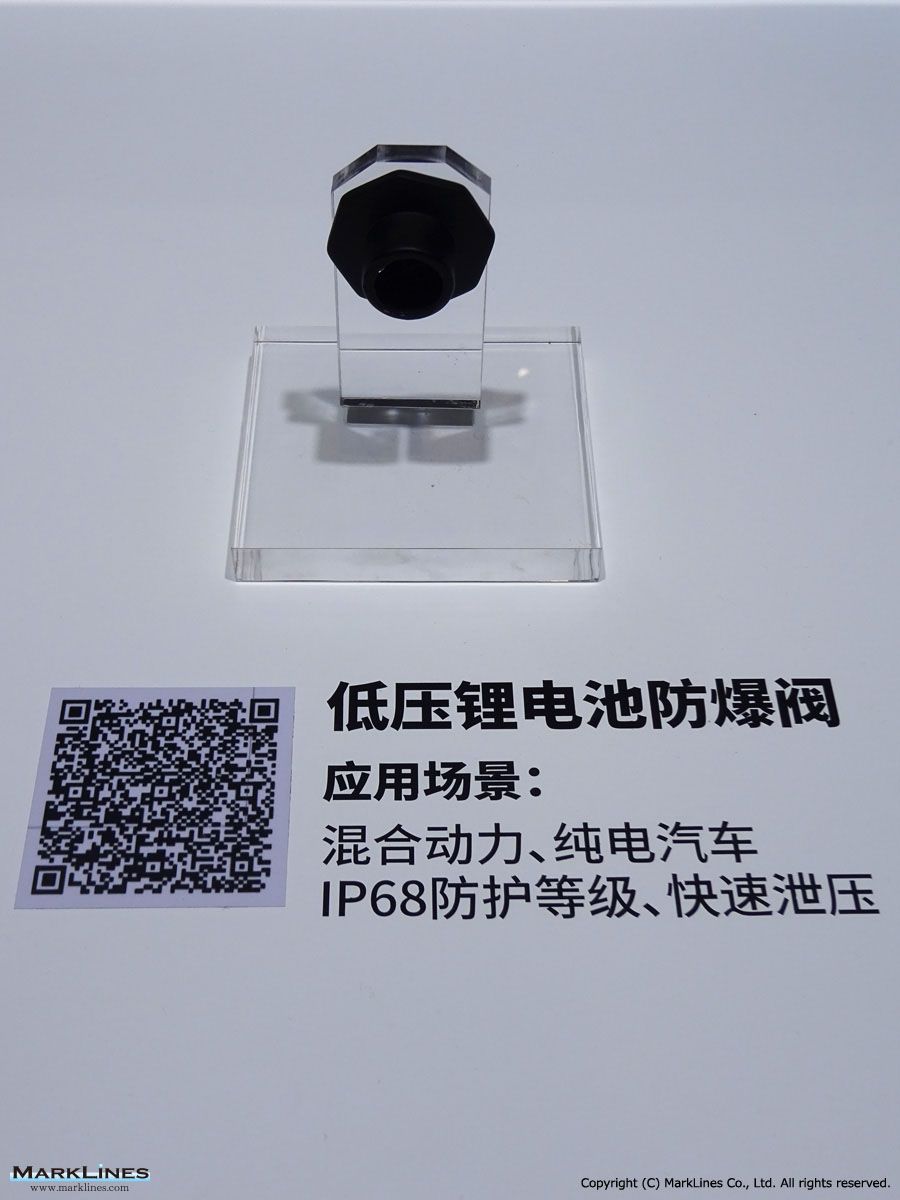

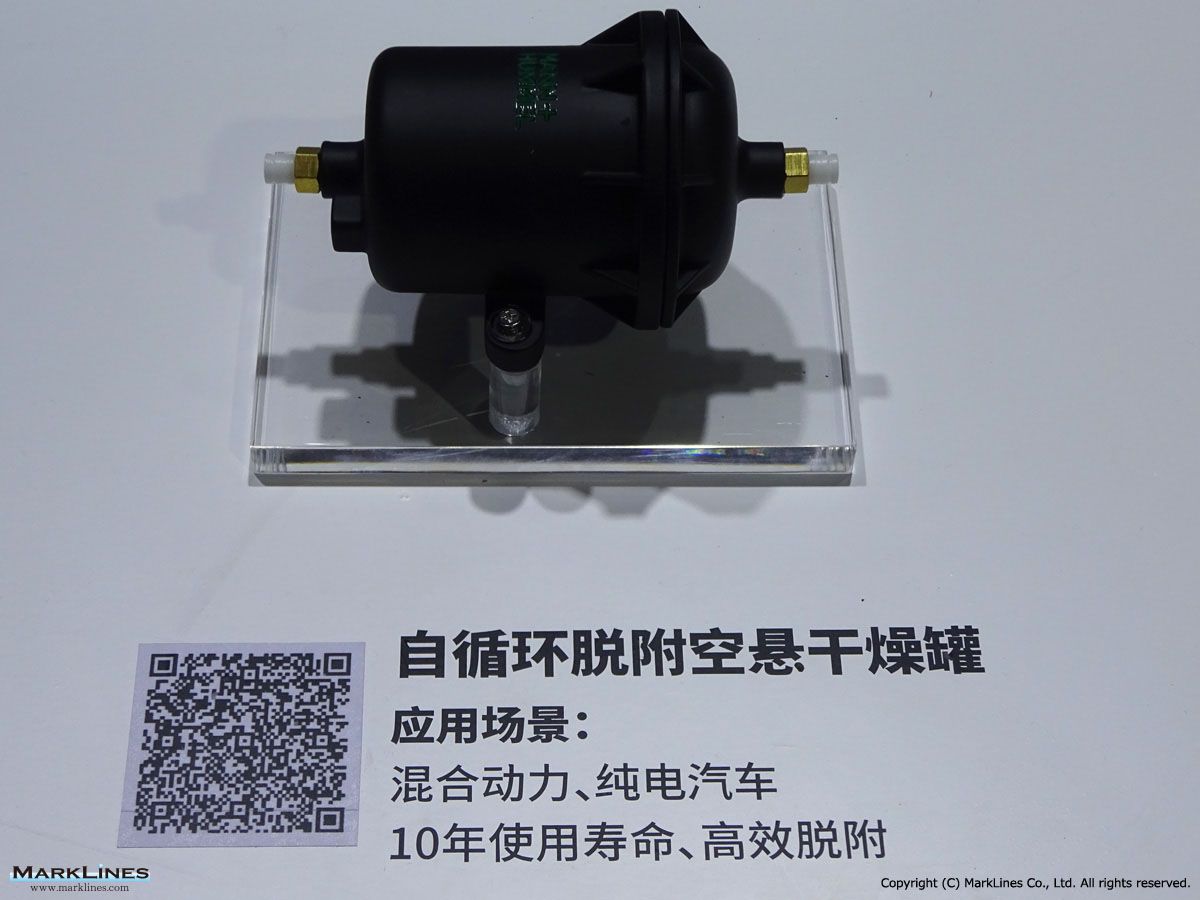

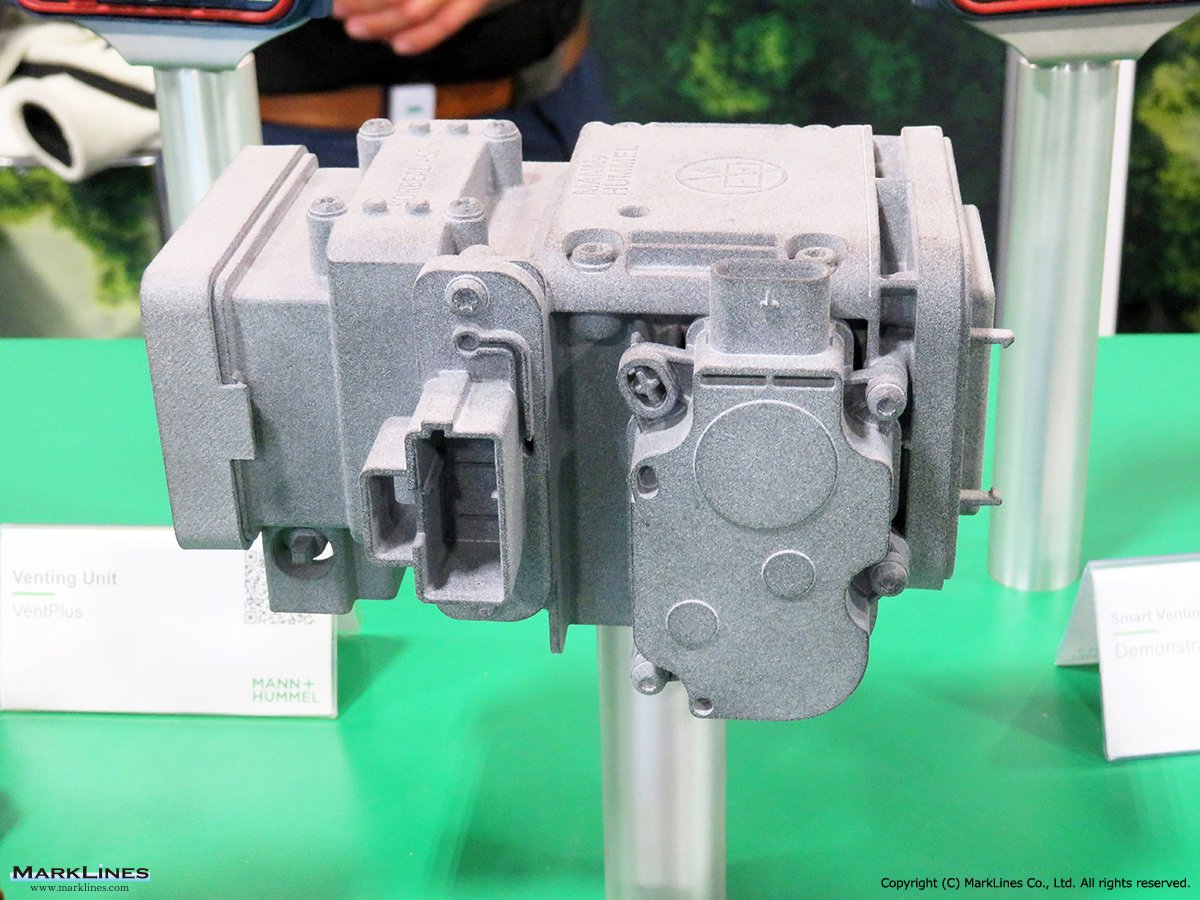

MANN+HUMMEL participates in BMW innovation event on sustainable development of Chinese supply chain

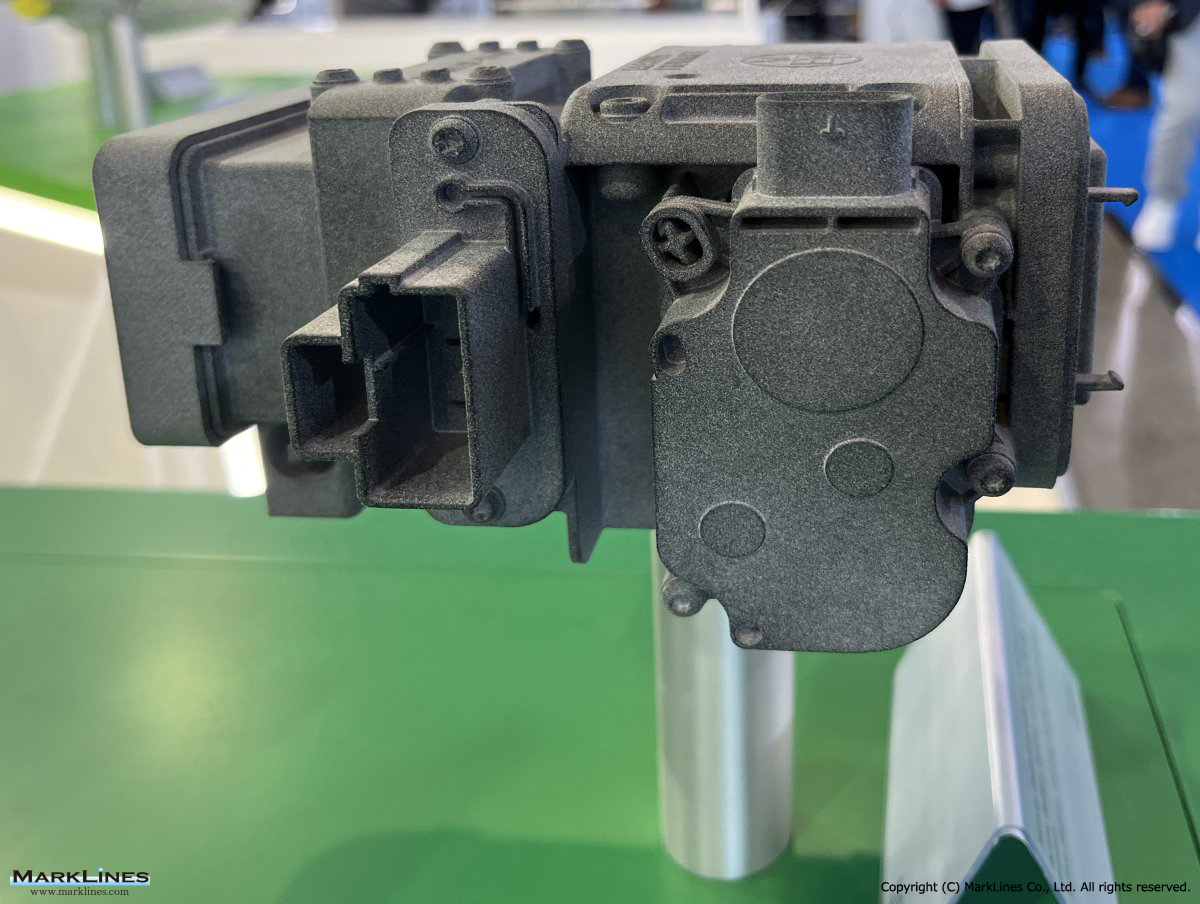

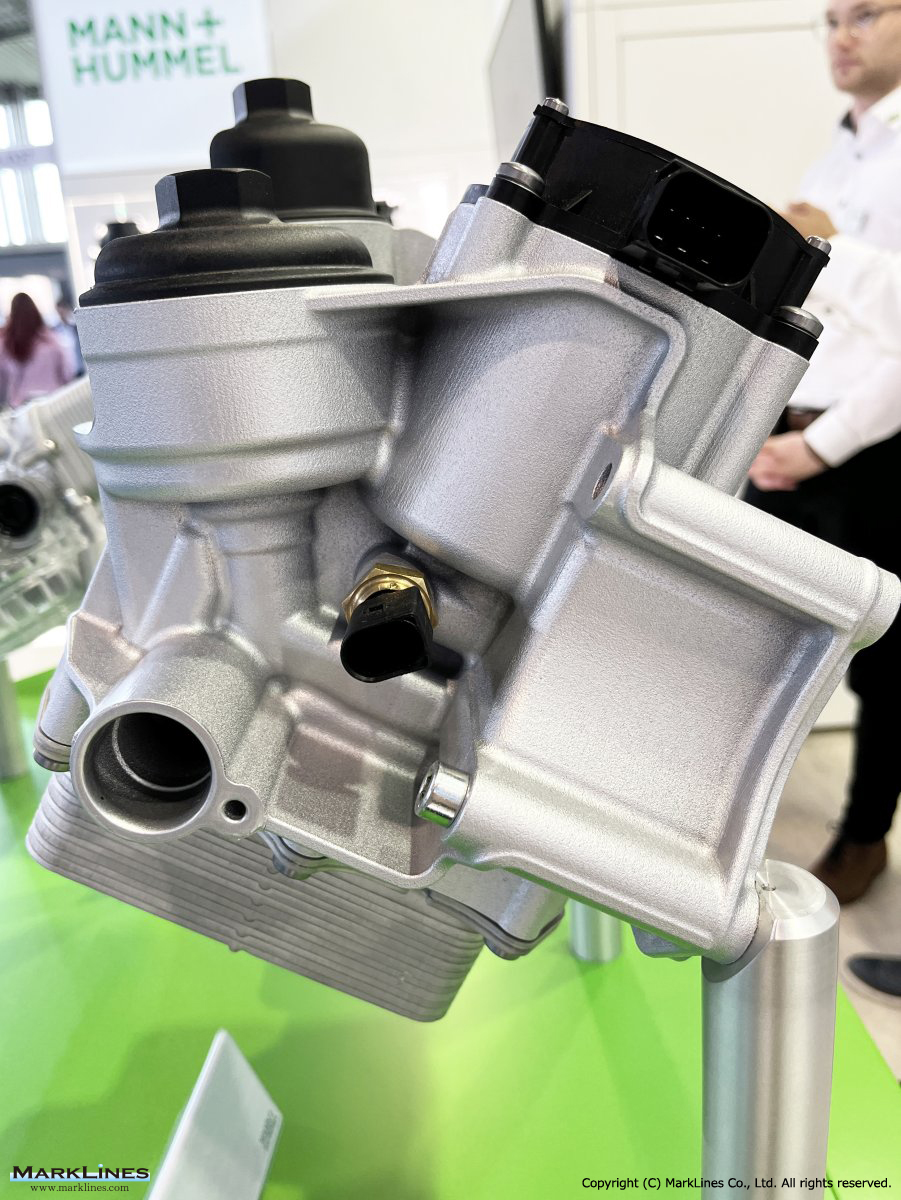

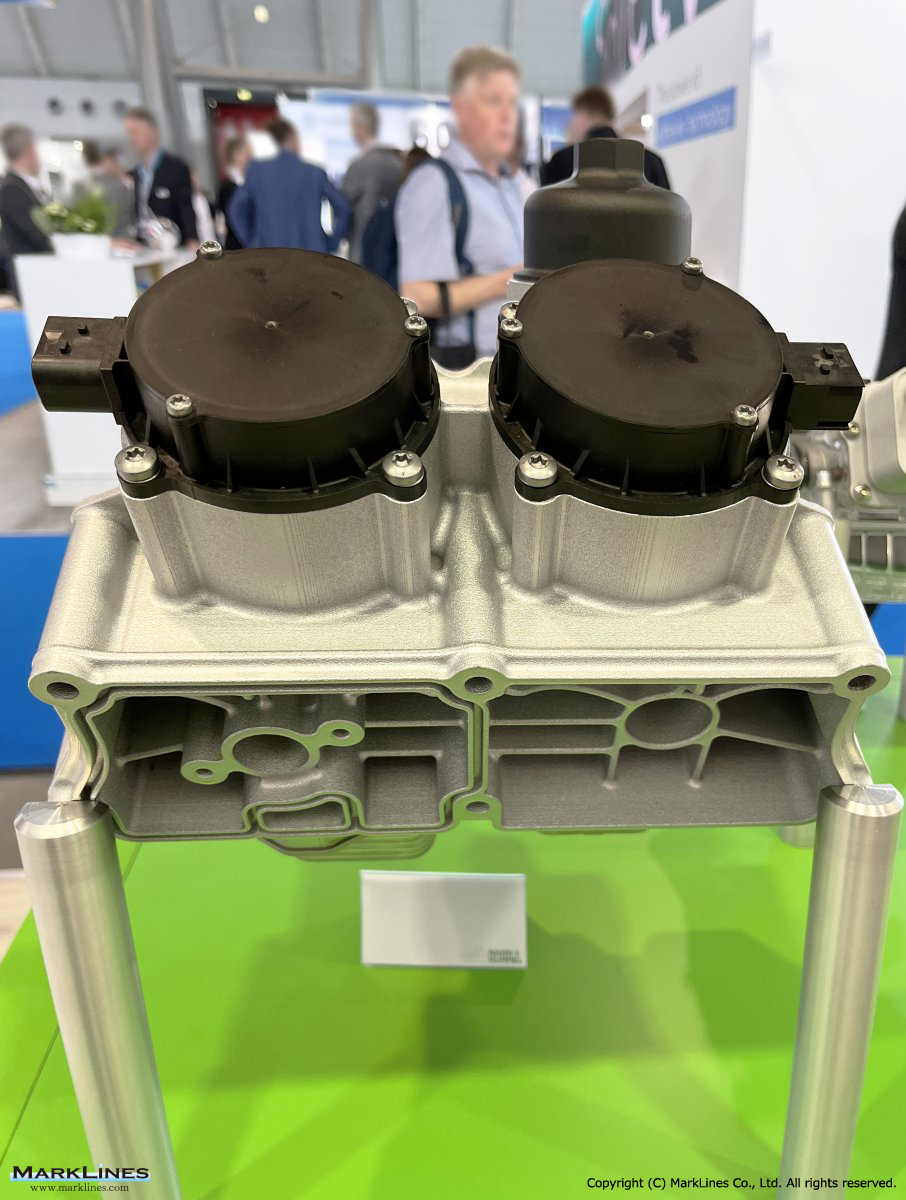

een mobility, including the following.A smokeless explosion-proof valve with instantaneous pressure relief and waterproof designs for higher battery safety under extreme operating conditions.An intelligent in-vehicle humidity control module for reduction of energy consumption and carbon emissions.A drying tank for air suspension systems, which adopts renewable adsorption materials and reduces carbon emissions throughout its life cycle.A bamboo fi...

News Updated at: 2025/11/19

Nissan Motor, Yokohama Plant[Japan]

its in-house developed ASSBs by fiscal year 2028. The press release also announced Nissan’s partnership with U.S.-based LiCAP Technologies, Inc., which has a proprietary dry electrode production process technology. Unlike wet electrode processes, the dry electrode process eliminates the need for drying and recovering organic solvents, significantly contributing to reducing manufacturing costs and environmental impact. By collaborating with LiC...

OEM Plants Updated at: 2025/11/13

AI Navigator

AI Navigator

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India