Search Results by Category

AI Navigator

AI NavigatorAll information related to {{ key_word }}.

AI Navigation will guide you. Click here for information about {{ key_word }}.

2

2

1

1

1

1

2

2

1

1

1

1

5

5

1

1

1

1

3

3

1 - 12 of 12 results

Nissan Motor, Tochigi Plant[Japan]

ant, aiming for full-scale operation in 2030. The stationary power generation system uses solid oxide fuel cells (SOFC), in which Nissan has development experience in automotive use. SOFCs can generate power using a variety of fuels, including ethanol, natural gas, and LP gas. Compared to polymer electrolyte fuel cells (PEFCs) which have a power generation efficiency of 60%, Nissan’s SOFCs are said to achieve a higher efficiency of 70%. Nissa...

OEM Plants Updated at: 2025/07/17

Automotive Cell Company (ACC), Douvrin/Billy-Berclau Plant[France]

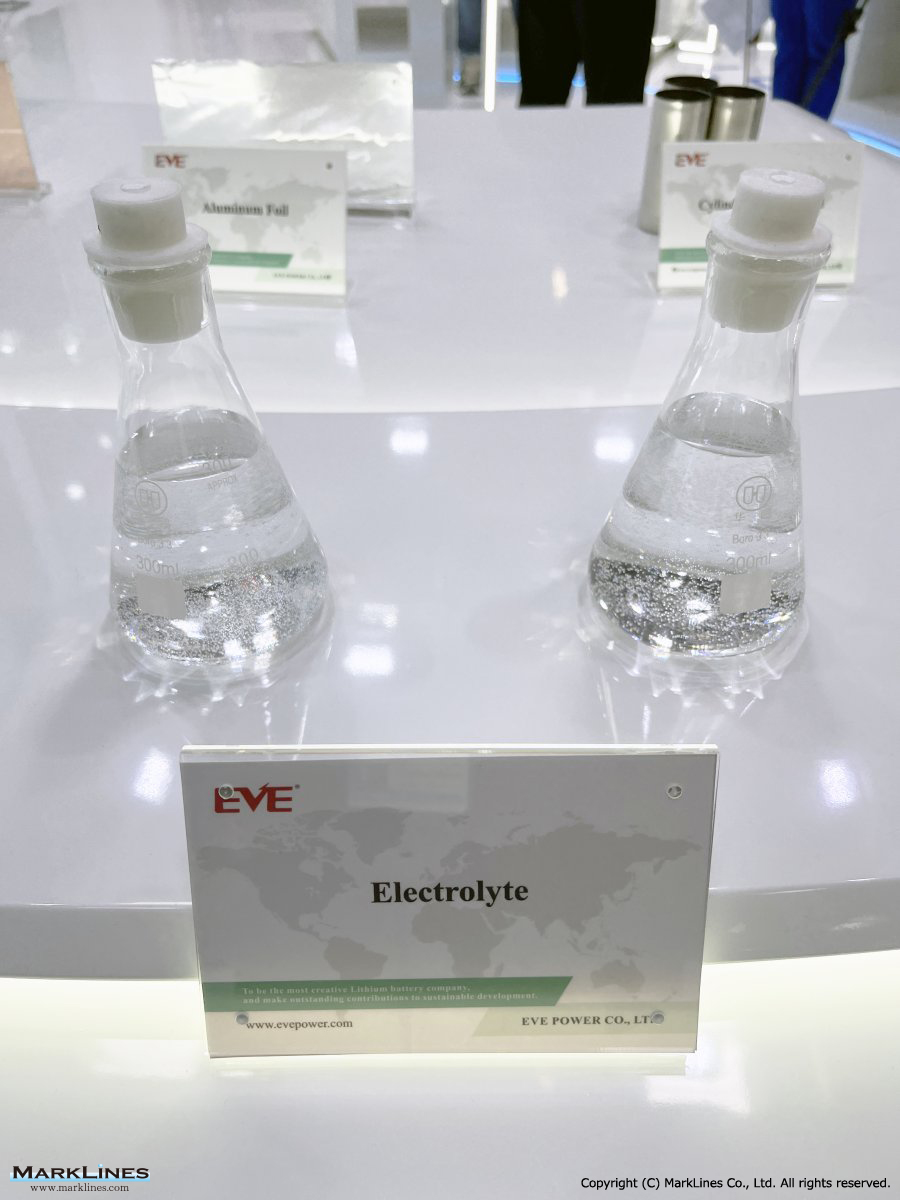

atform, by the end of 2022. 100% of them will have to meet ACC's CSR requirements for the BBD1 plant's start of production by the second half of 2023. For materials considered as priorities on sustainability issues such as cathode active material – the NMC, anode active material – the graphite, electrolyte, copper, or aluminum, the chosen suppliers will need to be at least awarded an EcoVadis gold medal by 2025. EcoVadis also supports ACC in ...

OEM Plants Updated at: 2025/07/07

Automotive Cell Company (ACC)[France]

atform, by the end of 2022. 100% of them will have to meet ACC's CSR requirements for the BBD1 plant's start of production by the second half of 2023. For materials considered as priorities on sustainability issues such as cathode active material – the NMC, anode active material – the graphite, electrolyte, copper, or aluminum, the chosen suppliers will need to be at least awarded an EcoVadis gold medal by 2025. EcoVadis also supports ACC in ...

OEM Plants Updated at: 2025/07/07

Toyota Motor, Teiho Plant[Japan]

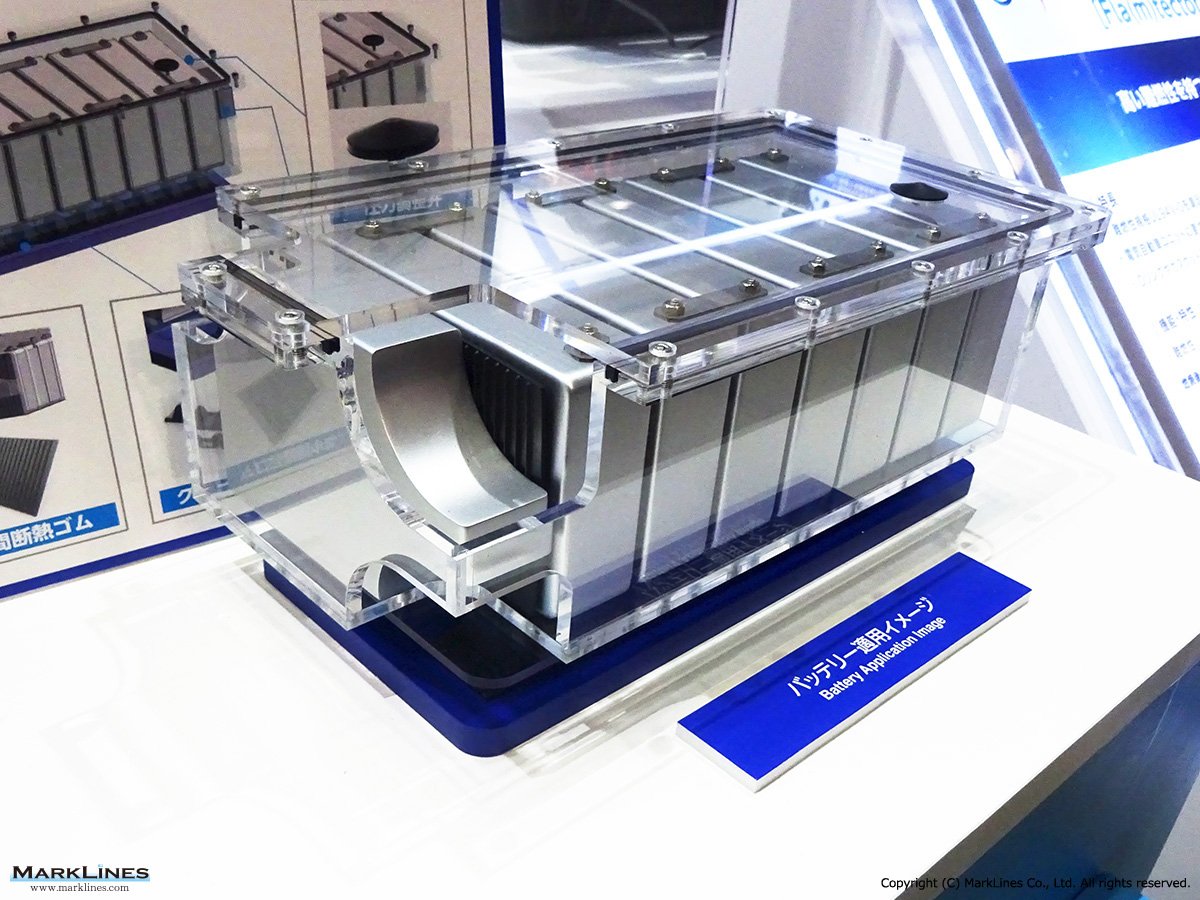

state batteries for electric vehicles (EVs) in 2027-2028. At the Teiho Plant, the process development site and a part of the planned mass production methods were made public. In an all-solid-state battery, ions move through the solid, so ideally the negative electrode, positive electrode, and solid electrolyte layers are in close contact with each other without any gaps. According to the announcement, Toyota has achieved high-speed, high-precisio...

OEM Plants Updated at: 2025/07/07

GAC Aion New Energy Automobile Co., Ltd.[China]

o 0V and temperatures returned to ambient temperature without fire or explosion. GAC Aion’s magazine battery 2.0 technology applies a nano-ceramic heat-resistant layer to significantly reduce the probability of short-circuiting, as well as composite current collector materials and flame retardant electrolyte, which can reduce the heating rate of the battery cells by 20% even if thermal runaway occurs. The technology adopts heat-resistant phase-...

OEM Plants Updated at: 2025/06/27

Audi AG, Ingolstadt Plant[Germany]

ime AWD "Quattro" Audi has debuted the Q5HFC hybrid fuel-cell concept at the 11th Michelin Challenge Bibendumin held in Berlin. The drive is provided by two electric motors; the motors produce a combined peak torque of 420 Nm. The lithium-ion battery has an energy content of 1.3 kWh and the polymer electrolyte membrane (PEM) fuel cell outputs 133 hp. There are two high-pressure cylinders that store hydrogen at 700 bar. Audi announced on December ...

OEM Plants Updated at: 2025/06/18

Mitsubishi Fuso Truck and Bus, Kawasaki Plant[Japan]

r 10 that it will construct a pilot facility at its Kawasaki Plant in collaboration with a Singaporean start-up company, True 2 Materials Pte, Ltd (T2M), to recover materials from used electric vehicle (EV) batteries. Demonstration tests will be conducted in early 2025 to recover anode, cathode and electrolyte materials that can be used as is by battery cell manufacturers. Mitsubishi Fuso aims to maximize value of battery materials and reduce tot...

OEM Plants Updated at: 2025/01/20

Honda R&D Co., Ltd. (Saitama)[Japan]

loor space of approximately 27,400 square meters, the delivery of the main equipment necessary for validation is almost complete, and the line is scheduled to begin operation in January 2025. The manufacturing process will employ a roll-press technique that contributes to densification of the solid electrolyte layer and enables continuous processing. The company aims to improve the degree of interfacial contact between the electrolyte and electro...

OEM Plants Updated at: 2024/12/23

Volkswagen AG, Salzgitter Plant / Power Co SE, Salzgitter Gigafactory[Germany]

ounting for over 65% of the total equipment quantity. Volkswagen announced EUR 30 billion investment to build 6 battery factories in Europe. For the first 20GWh factory in Salzgitter, LEAD will provide Volkswagen with lithium battery equipment including calendaring, roll baking, cell assembly line, electrolyte filling, cell baking, formation & aging, and the whole line logistics. LEAD will become the core supplier for the making of Volkswagen 240...

OEM Plants Updated at: 2024/11/22

Daimler Buses GmbH, Mannheim Plant (formerly EvoBus)[Germany]

z is faster: the new eCitaro G is the first series production city bus in its category anywhere in the world to be equipped with solid-state batteries. They have a very high energy density which is around 25 percent greater than the coming generation of traditional lithium-ion batteries with liquid electrolyte. The result is energy content of 441 kWh for the new eCitaro G. This battery technology is also free of the chemical element cobalt and th...

OEM Plants Updated at: 2024/09/03

PowerCo Canada Inc. St. Thomas Battery Plant[Canada]

n 2027. On April 10 and 11, Volkswagen Group battery unit PowerCo hosted more than 100 prospective suppliers in Toronto fora detailed briefing on its material and logistical requirements for the St. Thomas gigafactory. Needed inputs for the St. Thomas plant include anode active material, separator, electrolyte, and copper and aluminum foils, and cell housings, or cans, as well as lids to enclose finished cells. Annual can volumes across the site...

OEM Plants Updated at: 2024/07/30

SVOLT Energy Technology Co., Ltd.[China]

e battery facility will have a production capacity of 2.5 GWh batteries. The facility will start production in the first half of 2020. SVOLT Energy and JEVE will further collaborate in key fareas of the power battery industry including battery precursors, positive and negative materials, diaphragm, electrolyte, equipment, battery recycling, and upstream/downstream resources. On July 9, SVOLT Energy unveiled a new Die times-series drive battery pr...

OEM Plants Updated at: 2024/07/05

AI Navigator

AI Navigator

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India