Search Results by Category

AI Navigator

AI NavigatorAll information related to {{ key_word }}.

AI Navigation will guide you. Click here for information about {{ key_word }}.

3

3

4

4

11

11

1

1

1

1

1

1

1

1

1

1

3

3

3

3

1 - 20 of 27 results

Japan Mobility Show 2025: Hydrogen, Batteries

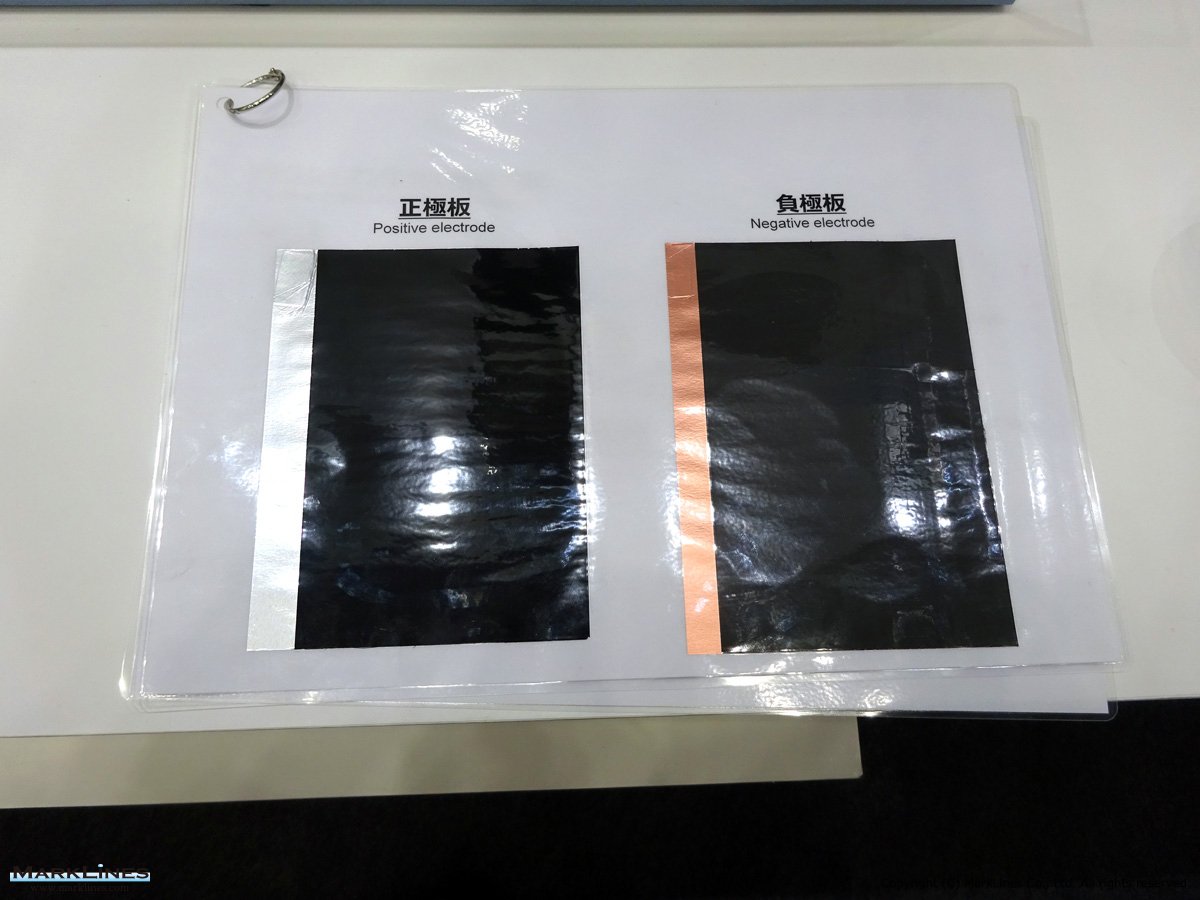

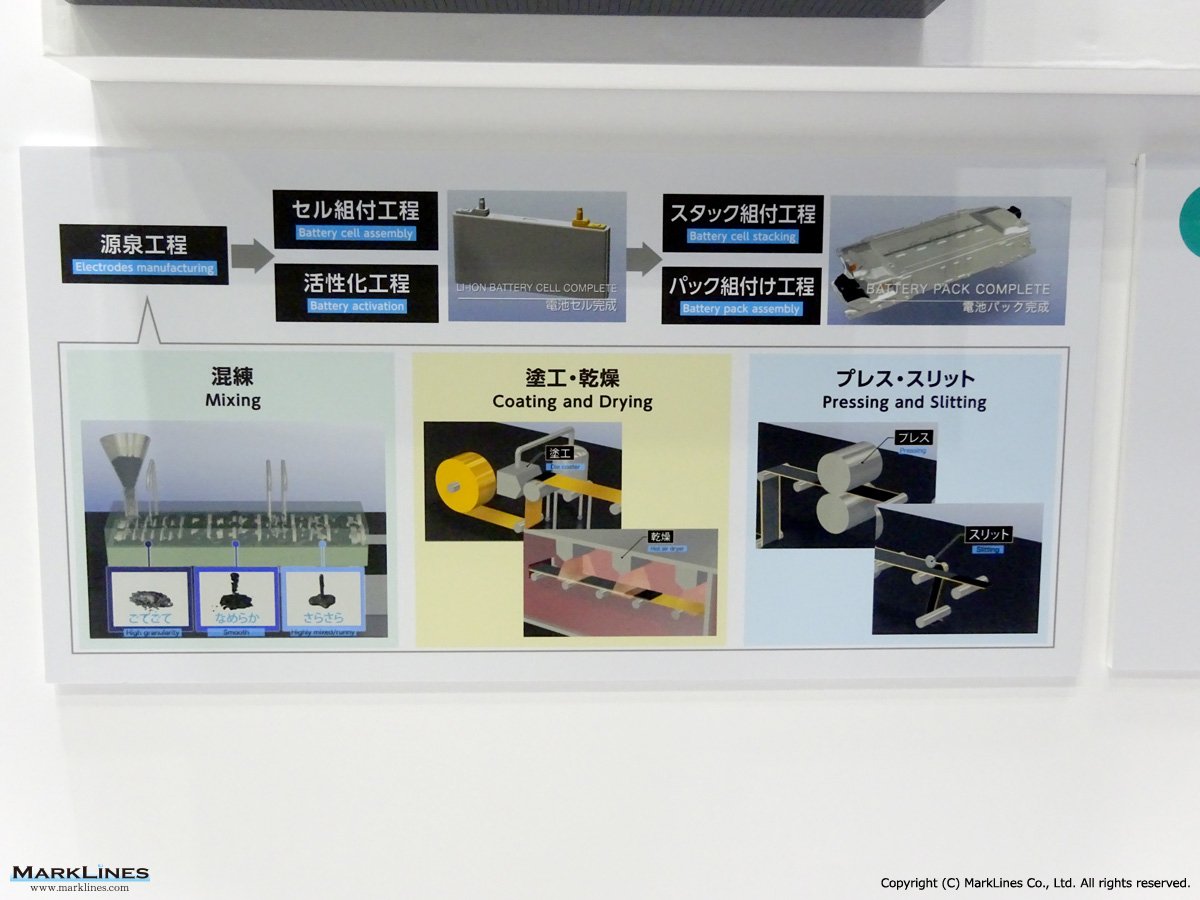

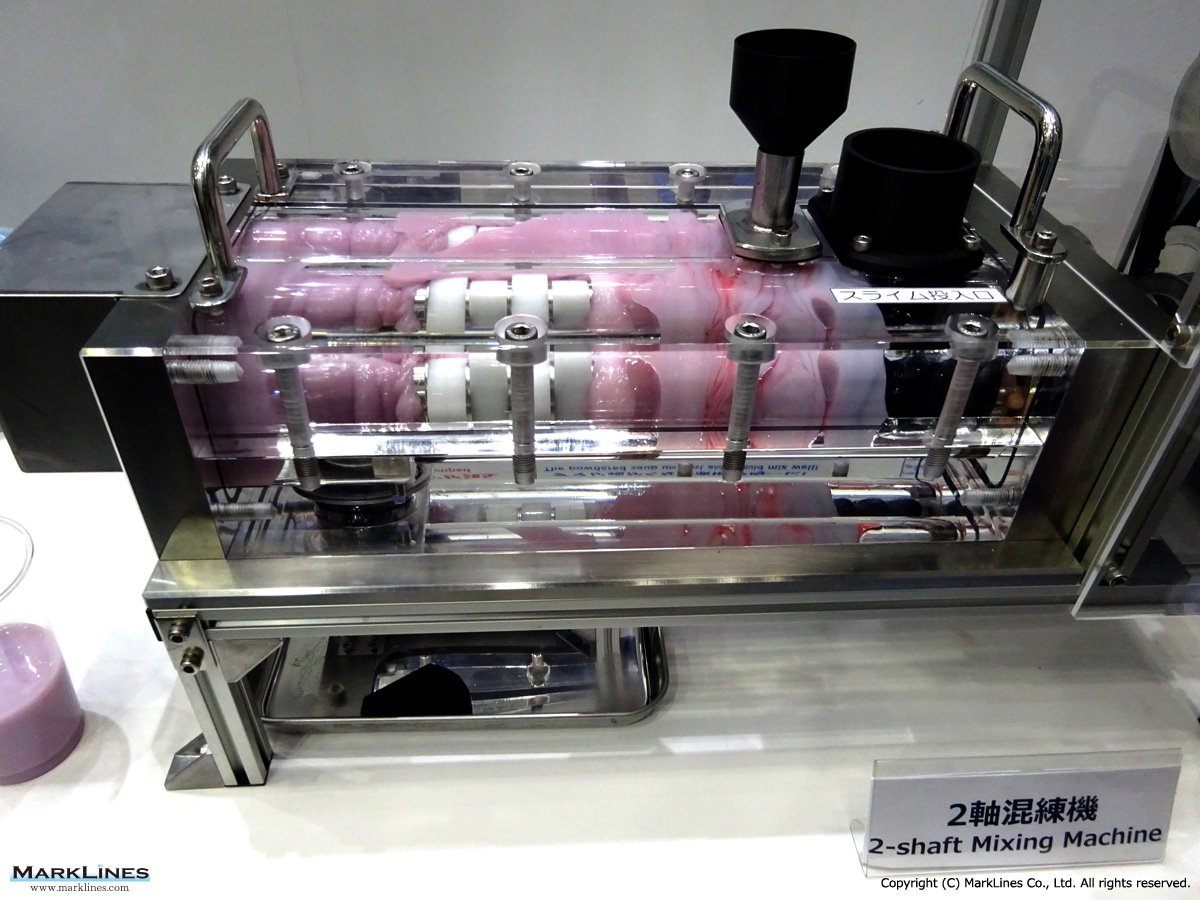

tphone battery. Display comparing battery capacity of various electric vehicles Of the six co-exhibitors, JTEKT Corporation (JTEKT) was in charge of the battery production equipment, and displayed 1/30 scale miniature models of the equipment for each process, including mixing, coating/drying, and pressing/slitting, and used panels to introduce efforts to improve productivity and reduce CO2 emissions. They also demonstrated how to mi...

Market & Tech Reports Updated at: 2025/12/11

Analysis Report: Lithium-Ion Battery (Japanese, European, U.S. and Korean Markets)

Increased capacity and larger diameter, elimination of electrode tabs, all electrodes at the top end to reduce heat generation in the center, and welding process is omitted. Battery plant: By introducing Maxwell's dry electrode technology, the use of binder solvent during coating is eliminated, the drying process is omitted, solvent recovery equipment is unnecessary, and electricity consumption is reduced. Negative electrode material: Silicon is ...

Market & Tech Reports Updated at: 2025/12/01

JSAE 2025 in Yokohama: Battery Technologies

ainless steel battery cooling plate Futaba Industrial Co., Ltd. exhibited battery cooling plates and other products made from aluminum and stainless steel. Steel materials require corrosion-resistant coating, which requires large amounts of electricity due to electrodeposition coating and baking/drying, but the use of stainless steel (uncoated) reduces costs (compared to aluminum) and CO2 emissions during manufacturing, contributing to carbon ...

Market & Tech Reports Updated at: 2025/06/27

Analysis Report: Lithium-Ion Battery (Japan, Europe, North America and Korea)

Increased capacity and larger diameter, elimination of electrode tabs, all electrodes at the top end to reduce heat generation in the center, and welding process is omitted. Battery plant: By introducing Maxwell's dry electrode technology, the use of binder solvent during coating is eliminated, the drying process is omitted, solvent recovery equipment is unnecessary, and electricity consumption is reduced. Negative electrode material: Silicon is ...

Market & Tech Reports Updated at: 2024/10/18

Battery Technologies: Battery life extension, safety components, etc.

ortant. Futaba Industrial Co., Ltd.: Stainless steel battery cooling plate Battery cooling plates and other products using stainless steel were exhibited. Steel materials require corrosion-resistant coating, which requires large amounts of electricity due to electrodeposition coating and baking/drying, but the use of stainless steel (uncoated) reduces costs (compared to aluminum) and cuts CO2 emissions during manufacturing, contributing to ca...

Market & Tech Reports Updated at: 2024/07/10

ACT Expo 2024 (1) Hydrogen vehicles and technologies

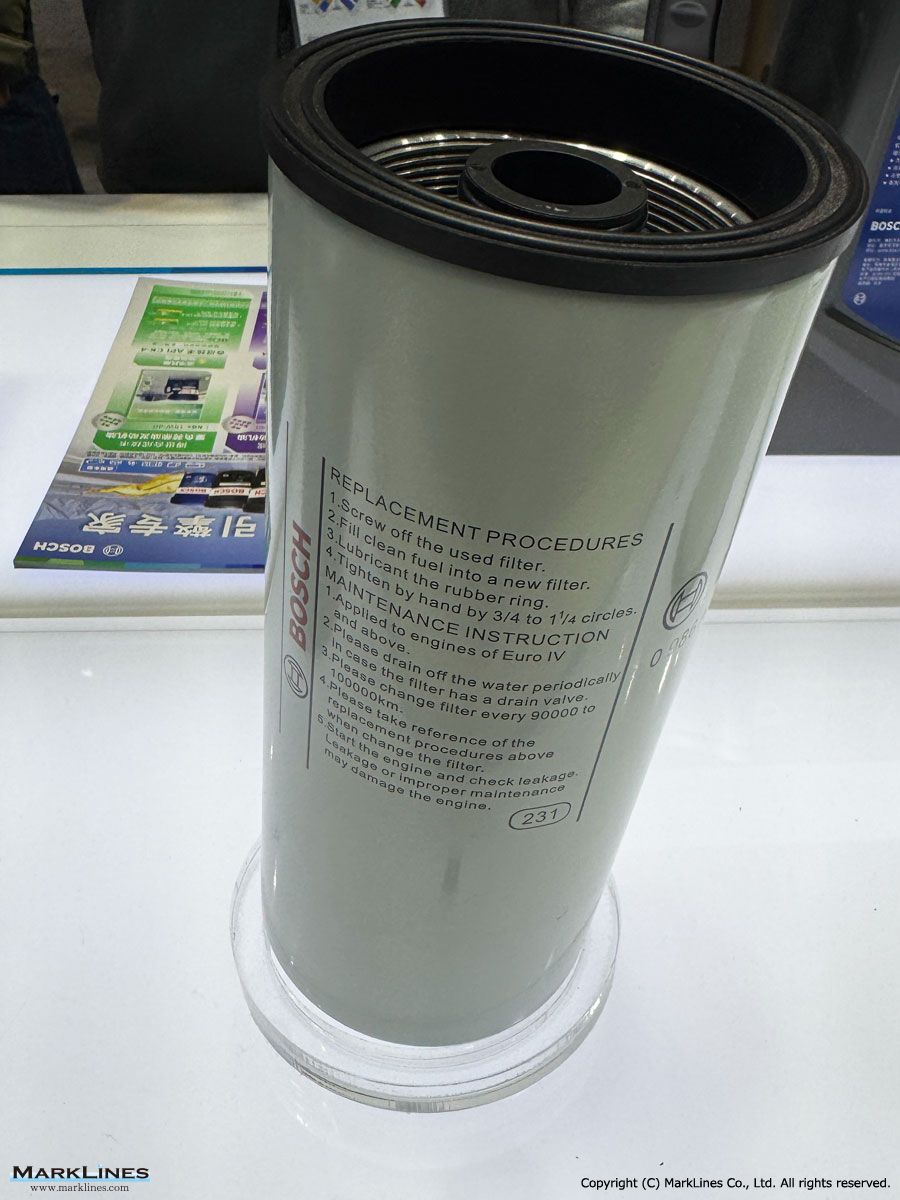

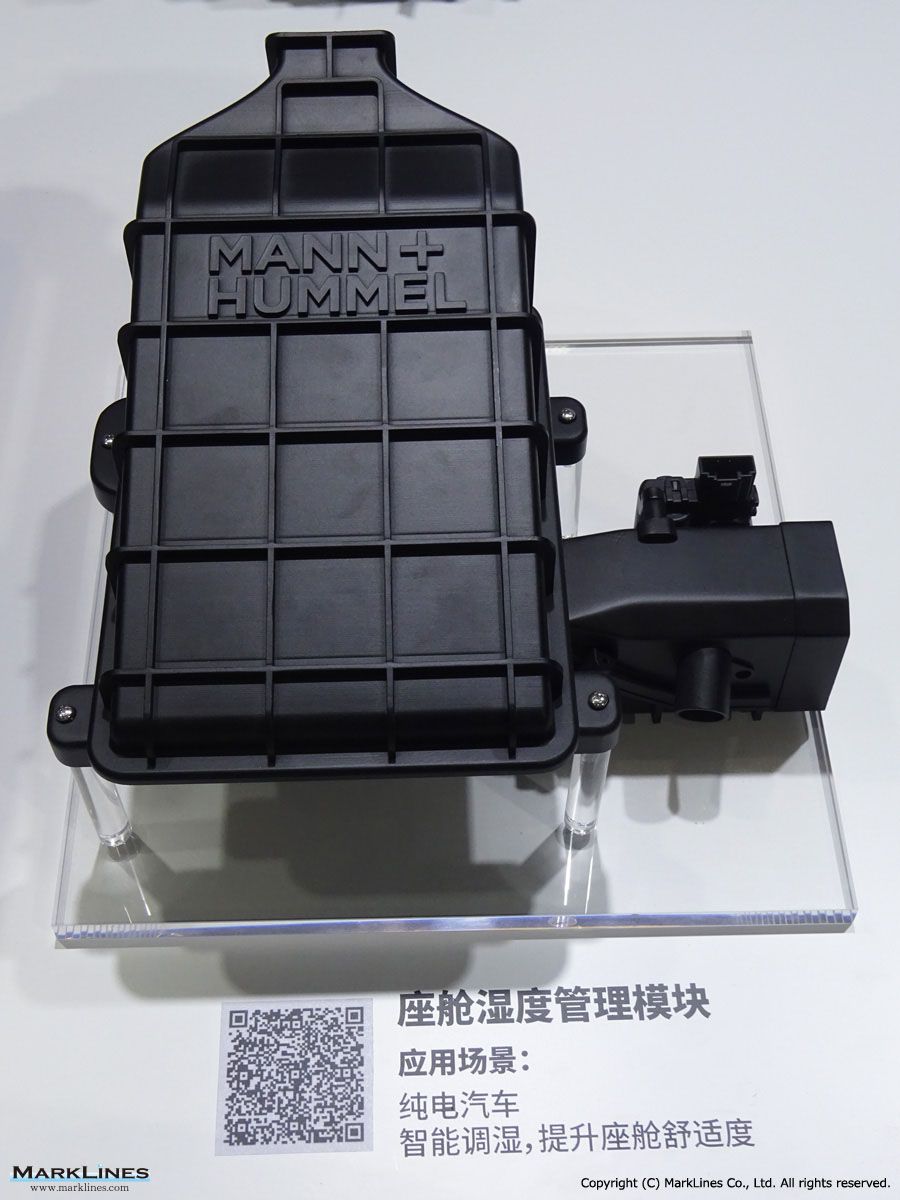

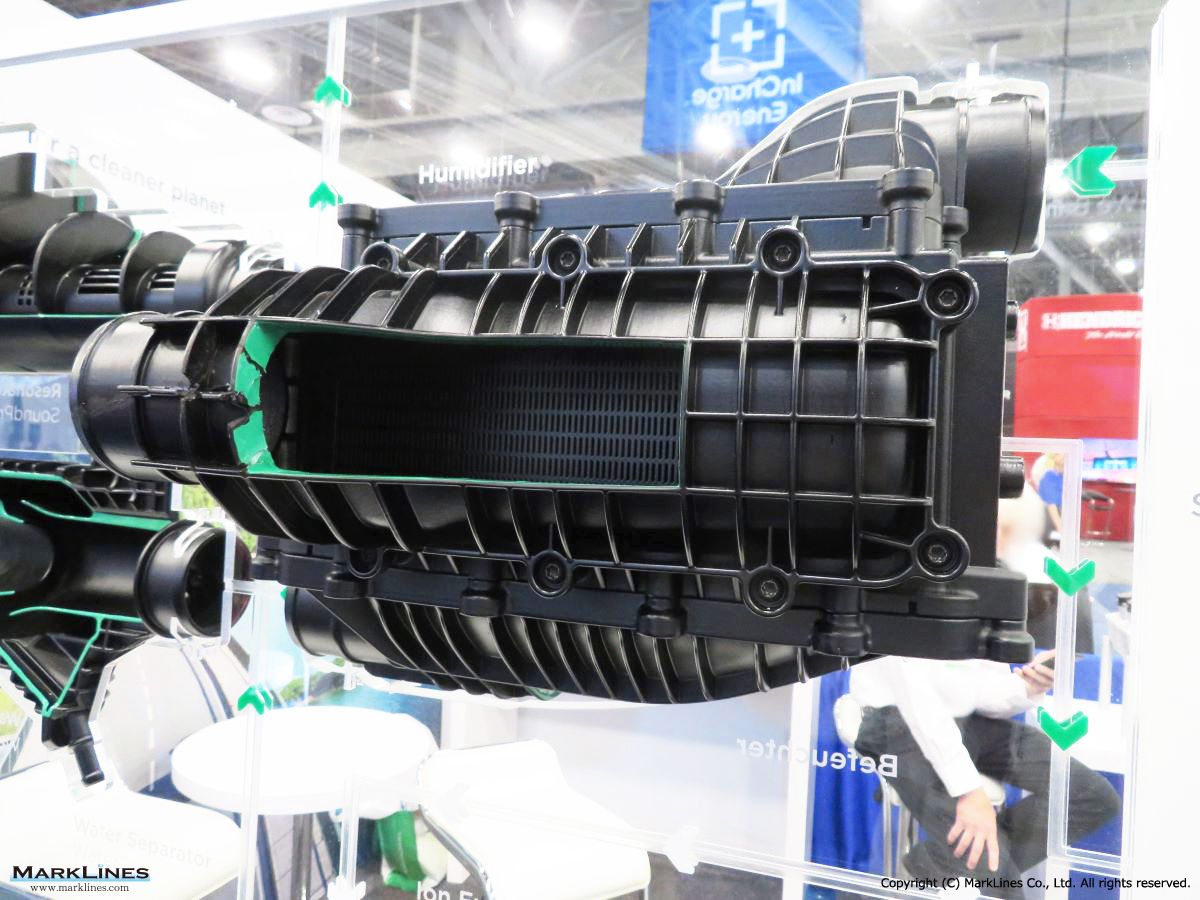

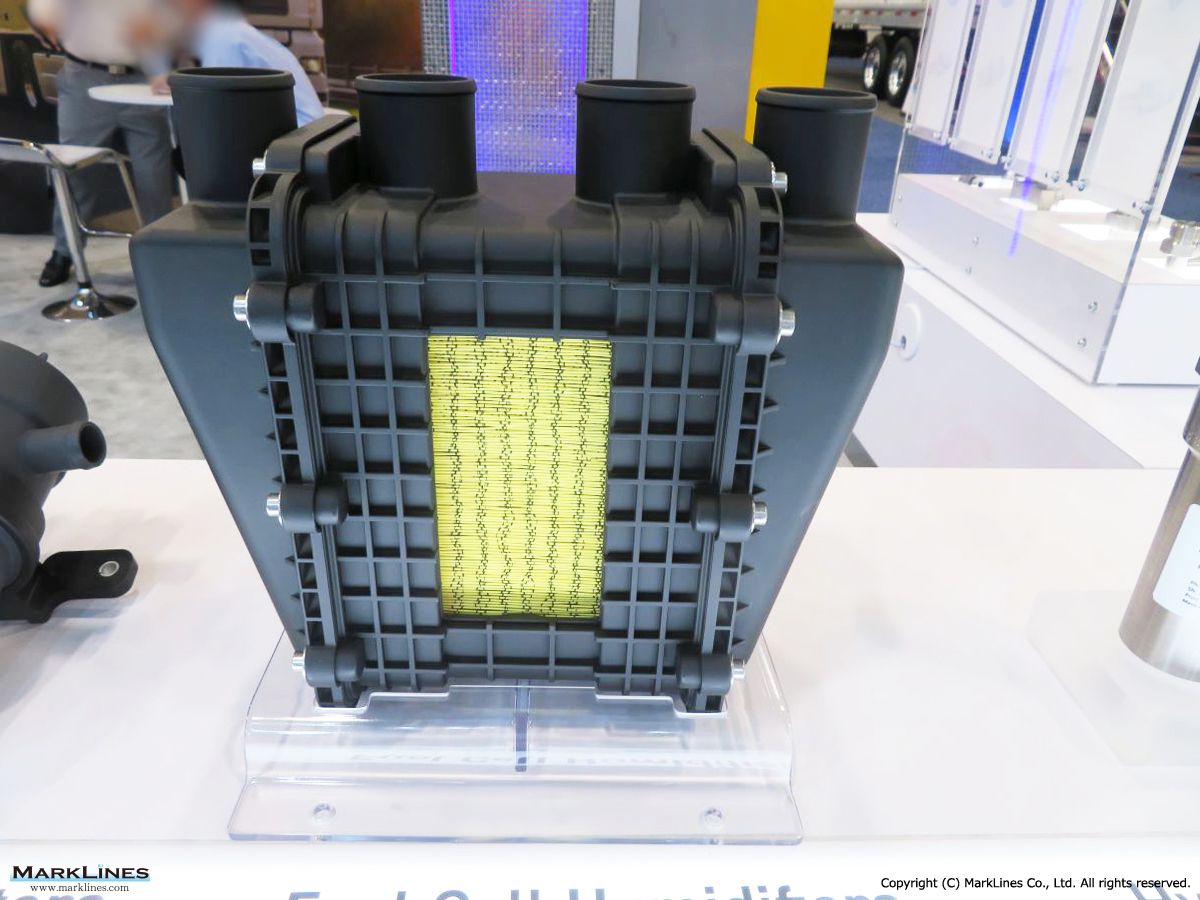

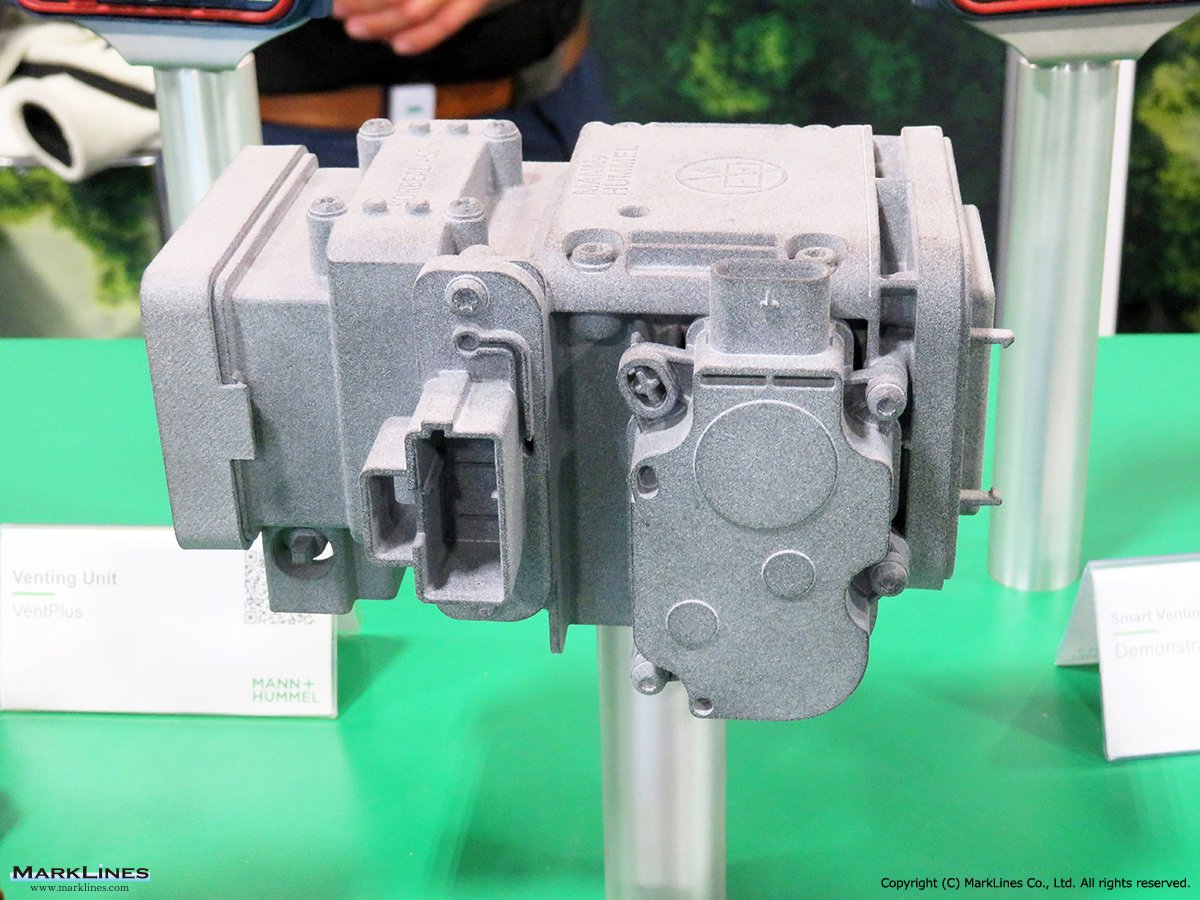

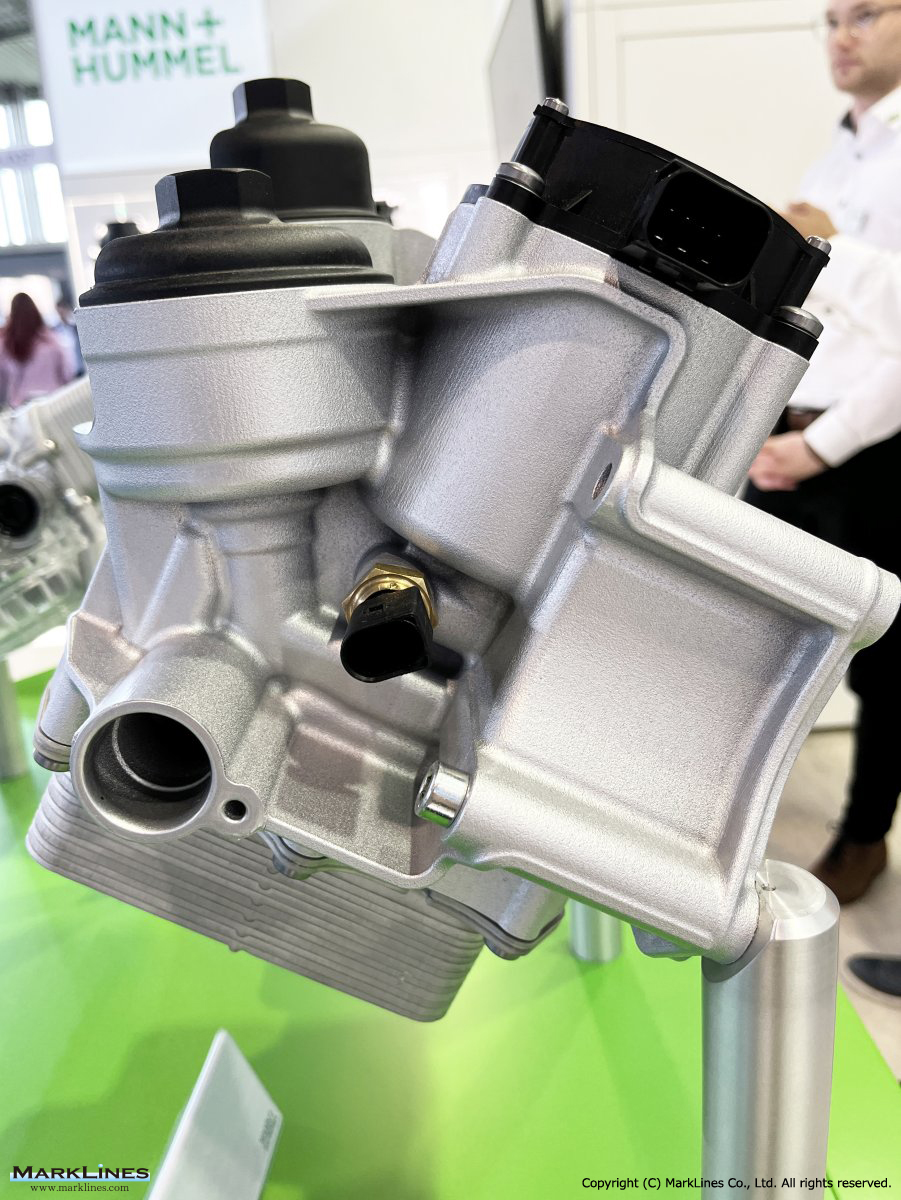

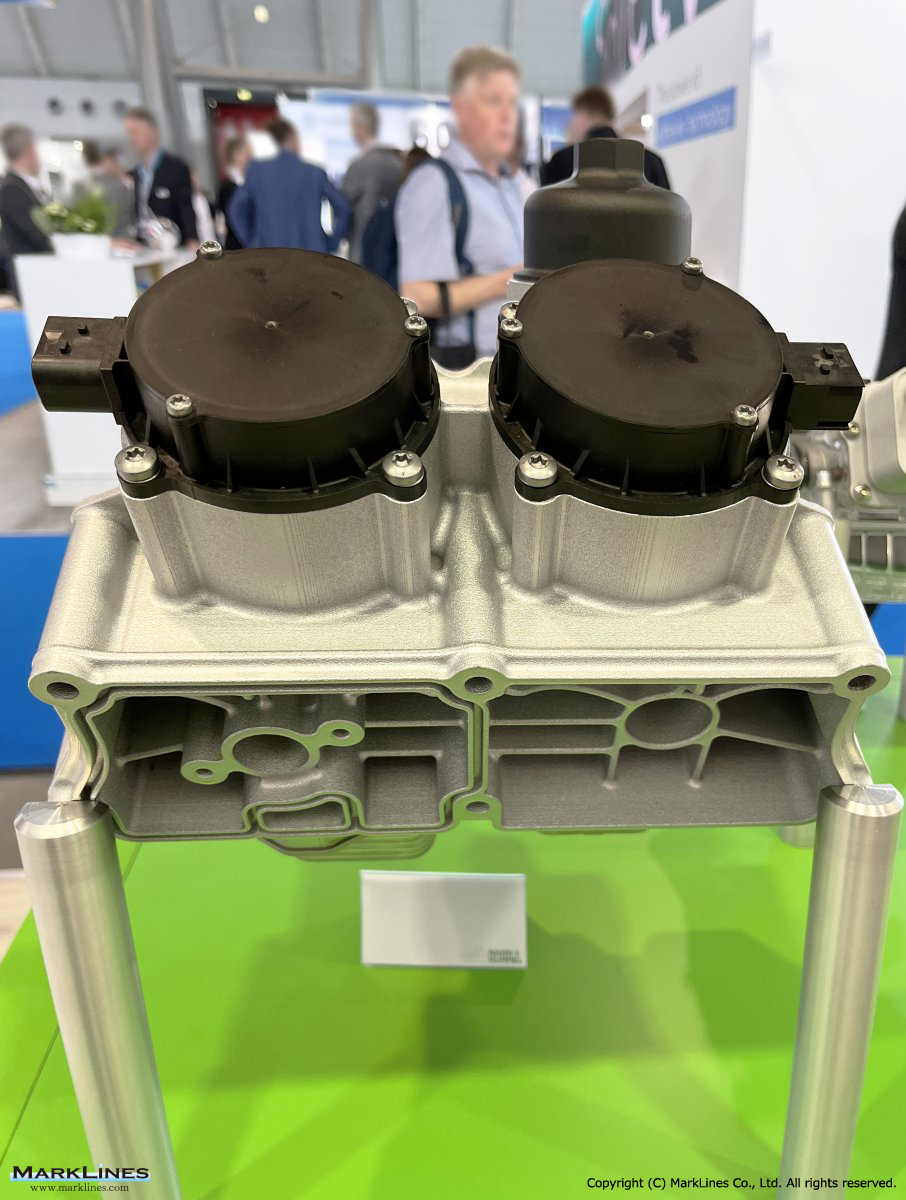

showed filtration systems and solutions for fuel cells generating between 150 and 200 kW. Products shown include a cathode air cleaner to protect the fuel cell stack from airborne contaminants, and a humidifier to ensure high-quality fuel cell performance by preventing the fuel cell membranes from drying out. MANN+HUMMEL also showed a cathode water separator which removes water and ice from the cathode supply and exhaust air streams, and an ion ...

Market & Tech Reports Updated at: 2024/06/19

SAE China 2023 (3): All Solid-State Battery Technology Seminar

ocess, there is a risk that the electrolyte will react with polar solvents. Methods for uniform dispersion/penetration of the electrolyte into the porous positive electrode pore structure need to be considered. - Using lithium negative electrode to reduce cost. - Large-scale effects reduce costs. Drying process - Extrusion + Rolling: Placed on the collector through an extrusion device and then rolled (polymer). - Rolling or spray coating: Proce...

Market & Tech Reports Updated at: 2023/12/25

Analysis Report: Lithium-Ion Battery (Japan, Europe, North America and Korea)

mination of electrode tabs, all electrodes at the top end to reduce heat generation in the center, and welding process is omitted. Battery plant: With the introduction of Maxwell Technologies Korea Co., Ltd.’s dry electrode technology, the use of organic solvents during coating is eliminated, the drying process is omitted, solvent recovery equipment is not required, and power consumption is also reduced. Negative electrode material: Silicon is ...

Market & Tech Reports Updated at: 2023/11/01

Cell Development for the Batteries of Future Electric Vehicles

s have to be dried after the materials are coated. This is very energy-intensive, and it also means that process solvents that are harmful to the environment are commonly used on the cathode. “We are working on various approaches to improve these processes. One of these is the optimization of the drying process, for example using infrared light or lasers, which require less energy and solvents. The second approach is to use dry coating. In this...

Market & Tech Reports Updated at: 2023/10/20

Shanghai International Carbon Neutrality Expo 2023: Low Carbon Transportation Forum

gn Change research styles that rely upon a large number of test cycles to find the best method, shorten design time, reduce materials used for testing, and make the design portion of the process green and low-carbon. Low-carbon technologies in manufacturing Avoid energy consumption due to solvent drying in the coating process by eliminating the use of solvents in all processes. Reduce costs by applying multiple battery systems, and make the par...

Market & Tech Reports Updated at: 2023/07/11

JSAE 2023 in Yokohama: Battery Technologies

ba Industrial: Stainless steel battery cooling plate Futaba Industrial Co., Ltd. Exhibited battery cooling plates and other products using stainless steel. Steel materials require corrosion-resistant coating, which requires large amounts of electricity due to electrodeposition coating and baking drying, but the use of stainless steel (no coating) reduces costs (compared to aluminum) and generates less CO2 emissions during manufacturing, contri...

Market & Tech Reports Updated at: 2023/07/04

21st CTI Symposium (1): Keeping Pace during Electric Mobility Transformation

technical data. Another issue which needs to be tackled is the high CO2 footprint for the production of EVs, especially for the material and cell production. This can be significantly reduced by using green energy and improvement of the production chain. Currently much energy is required for the drying of the electrodes and the maintenance of the dry room environment. Prof. Dr. Kwade mentioned the solvent-free dry-electrode coating technology,...

Market & Tech Reports Updated at: 2023/01/12

Analysis Report: Lithium-Ion Battery (Japanese, European, North American and Korean Markets)

mination of electrode tabs, all electrodes at the top end to reduce heat generation in the center, and welding process is omitted. Battery plant: With the introduction of Maxwell Technologies Korea Co., Ltd.’s dry electrode technology, the use of organic solvents during coating is eliminated, the drying process is omitted, solvent recovery equipment is not required, and power consumption is also reduced. Negative electrode material: Silicon is ...

Market & Tech Reports Updated at: 2022/11/11

VW Group (Part 1): Annual production capacity of 3.5 million EVs by 2026

quipment Co., Ltd. (Lead Intelligent) announced on June 21, 2022 that VW has signed a cooperation agreement to adopt Lead Intelligent's 20GWh lithium battery equipment and solutions. The Salzgitter Plant in Germany will use this 20GWh lithium battery facility. Equipment includes rolling, pole piece drying, assembly line, liquid filling, cell drying, forming equipment, package assembly, etc. 24M Technologies U.S. semi-solid-state lithium-ion bat...

Market & Tech Reports Updated at: 2022/10/19

Carbon Neutral Initiatives at German Automakers' Plants

he Dingolfing plant also has two cathodic dip coating (KTL) lines. These lines are also being updated as vehicles become larger, with Line 1 already in operation from 2020 and Line 2 scheduled to start operation from 2022. BMW AG, Dingolfing Plant The Regensburg Plant in Germany has optimized the drying process in the paint shop, and by 2020 only one of the two drying tubes were put into operation. As a result, natural gas consumption was reduc...

Market & Tech Reports Updated at: 2022/10/14

Battery Manufacturing, Supply Chains, and Chemistry Evolution

igh Power cell is possible at the UKBIC (UK battery industrialization centre) facility. Additionally, the company is planning to establish a Gigafactory in the UK in 2025. Regarding cell manufacturing, AMTE Power covers the whole cell production process from wet (slurry preparation, coating & drying, calendering) to dry (electrodes cutting, cell assembly, electrolyte filling / formation) processes: Wet and dry cell production process ...

Market & Tech Reports Updated at: 2022/01/31

Development of Fuel Cell Vehicles (FCVs) and Expansion of Applications

l vulcanized adhesion to thermoplastic adhesion. To speed up the development process, an example of improvement of the development process using modeling and simulation was introduced, where the catalyst layer was modeled and the structure of ionomer and carbon was linked to performance, and the drying conditions that suppressed agglomeration were linked to the production process. It is said that the speed was increased by incorporating condit...

Market & Tech Reports Updated at: 2021/04/15

Analysis Report: Airbag (U.S. and European Markets)

caused injury and death; it was the largest automotive recall in U.S. history. Takata claimed that the issue has only been shown to affect vehicles in hot and humid locations. However, NHTSA determined that root cause was that the airbags used an ammonium nitrate-based propellent without a chemical drying agent. In June 2017, Takata filed for Chapter 11 Bankruptcy protection. In April 2018, the surviving global assets (those assets that were not ...

Market & Tech Reports Updated at: 2020/09/07

Battery Cells Made in Germany - Overcoming Obstacles

atteries, for example, mixing methods for the electrode components,” says Möller. In addition, the Fraunhofer researchers are developing high-precision laser cutting and welding procedures and electrode coatings that contain no solvents. These can be applied in dry form and require no additional drying process. Stacking facility for small-scale production ARE SOLID-STATE CELLS WHERE THE FUTURE LIES? No external cooling, a smaller foot...

Market & Tech Reports Updated at: 2020/07/20

Analysis Report: Airbags (U.S./E.U. Markets)

caused injury and death; it was the largest automotive recall in U.S. history. Takata claimed that the issue has only been shown to affect vehicles in hot and humid locations. However, NHTSA determined that root cause was that the airbags used an ammonium nitrate-based propellent without a chemical drying agent. In June 2017, Takata filed for Chapter 11 Bankruptcy protection. In April 2018, the surviving global assets (those assets that were not ...

Market & Tech Reports Updated at: 2019/04/24

AI Navigator

AI Navigator

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India