Search Results by Category

AI Navigator

AI NavigatorAll information related to {{ key_word }}.

AI Navigation will guide you. Click here for information about {{ key_word }}.

4

4

1

1

3

3

7

7

1

1

2

2

2

2

2

2

4

4

1

1

1 - 19 of 19 results

Mobile World Congress 2025 (2) ITS, SDV solutions

f the NXP Trimension™ NCJ29D6 chipset, which supports secure ranging and short-range radar, enabling applications such as digital key, Child Presence Detection (CPD), kick-sensing for trunk access, and intrusion detection. The setup featured the R&S SMW200A vector signal generator and the R&S FSW26 signal and spectrum analyzer, which together can generate moving UWB radar targets at variable distances of up to a few meters. This enables p...

Market & Tech Reports Updated at: 2025/04/03

Automotive World 2025: Metal Processing Technologies

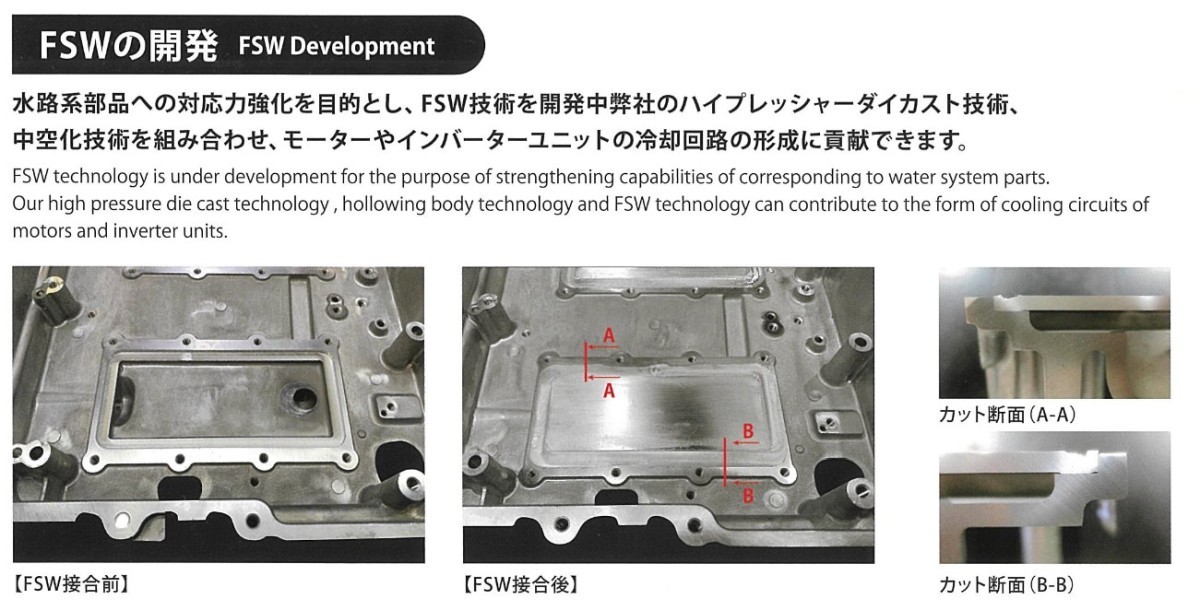

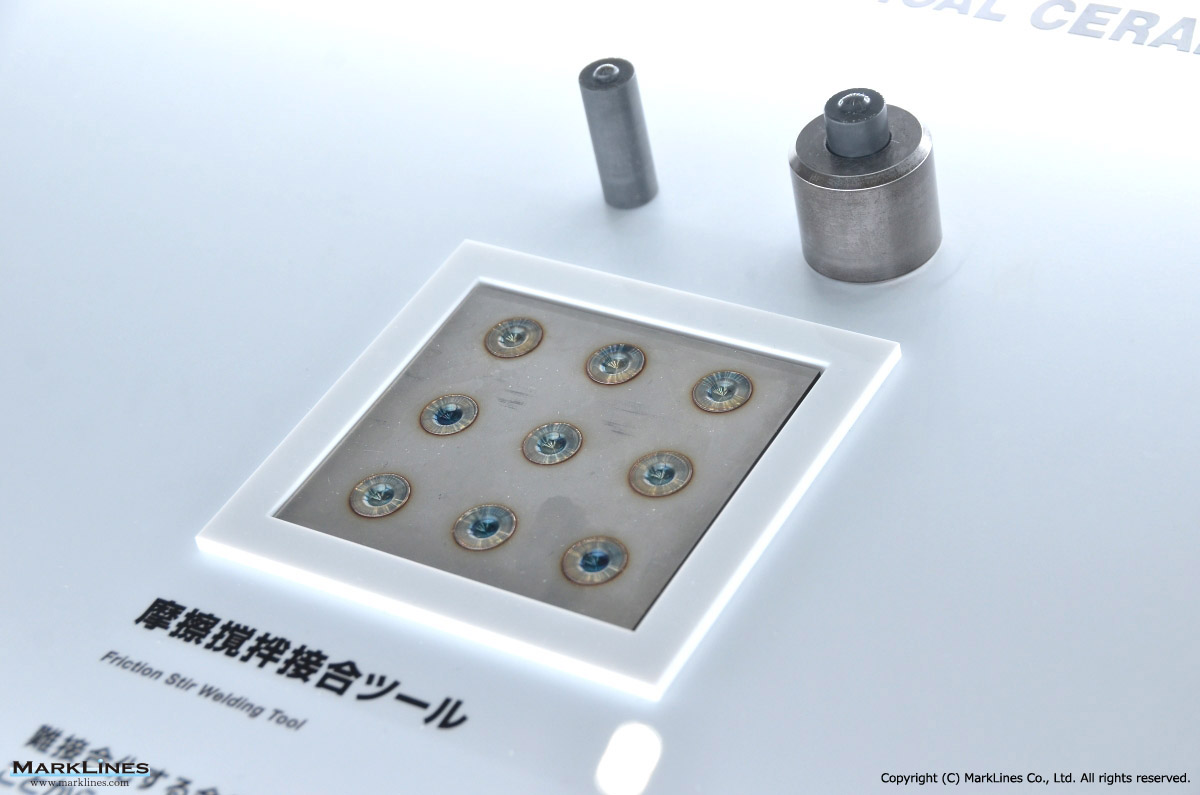

Automotive World 2025: Metal Processing Technologies Door rings, hot stamping equipment, FSW monitors, Mg housings, and more Summary Weight reduction: Integrated body frame components, door rings, multi-material frames Weight reduction: Hot stamping line for European car frame Weight reduction: Aluminum FSW joint real-time monitoring Weight reduction: Magnesium alloy for display housing, etc. EV parts: Forging equipment for EV hollow motor shaft ...

Market & Tech Reports Updated at: 2025/02/04

2024 Japan Die Casting Congress & Exposition: Gigacast

2024 Japan Die Casting Congress & Exposition: Gigacast Thin-walled and high-strength die casting, multiple materials, FSW bonding, etc. Summary Gigacasting Thin wall and high strength aluminum die casting The 2024 Japan Die Casting Congress & Exposition (Dates: November 14 (Thu.) to 16 (Sat.), 2024; Venue: Pacifico Yokohama convention center) was organized by the Japan Die Casting Association. The purpose of the event is to contribute to the d...

Market & Tech Reports Updated at: 2024/12/03

Korea Next Gen Mobility Technology Expo 2024

g 15 different types with different elongation rates and tensile strengths. Alloys and die-cast products ICCU housing for Hyundai Mobis High-pressure die-cast products Display panel for KONEC Co., Ltd. In addition to high-pressure die casting, the company also handles FSW (Friction Stir Welding) processing, and is capable of alloy production, die design and manufacturing, casting, and precision machining meeting cus...

Market & Tech Reports Updated at: 2024/10/10

Honda: Investing JPY 10 trillion in EVs and software by 2030

as the world's first body frame joining and welding technology (technology for welding together materials of multiple different thicknesses), which will be the production technology necessary to achieve the "Thin, Light, and Wise" concept. Manufacturing of thin battery packs Megacast and 3D friction stir welding (FSW) (Source: Honda (May 16, 2024)) The new battery case manufacturing line to be installed at the Anna Engine Plant in O...

Market & Tech Reports Updated at: 2024/08/23

JSAE 2024 in Yokohama: Metal Processing Technology, and EV Materials

cuum die casting High-strength aluminum・Steering arm ・Knuckle Aluminum alloy GD Squeeze EV components Volume production PHV battery case Ryobi DX-30 (AlSi9MnMg) High vacuum die casting EV battery case Aluminum alloy Bottom triple laser welding EV inverter case Ryobi RX10 Die casting → Friction stir welding EV motor case(tapeless) Aluminum alloy Die castingZero draft angle Aluminum doors, cowl members, bumpers, knuckles, etc....

Market & Tech Reports Updated at: 2024/06/06

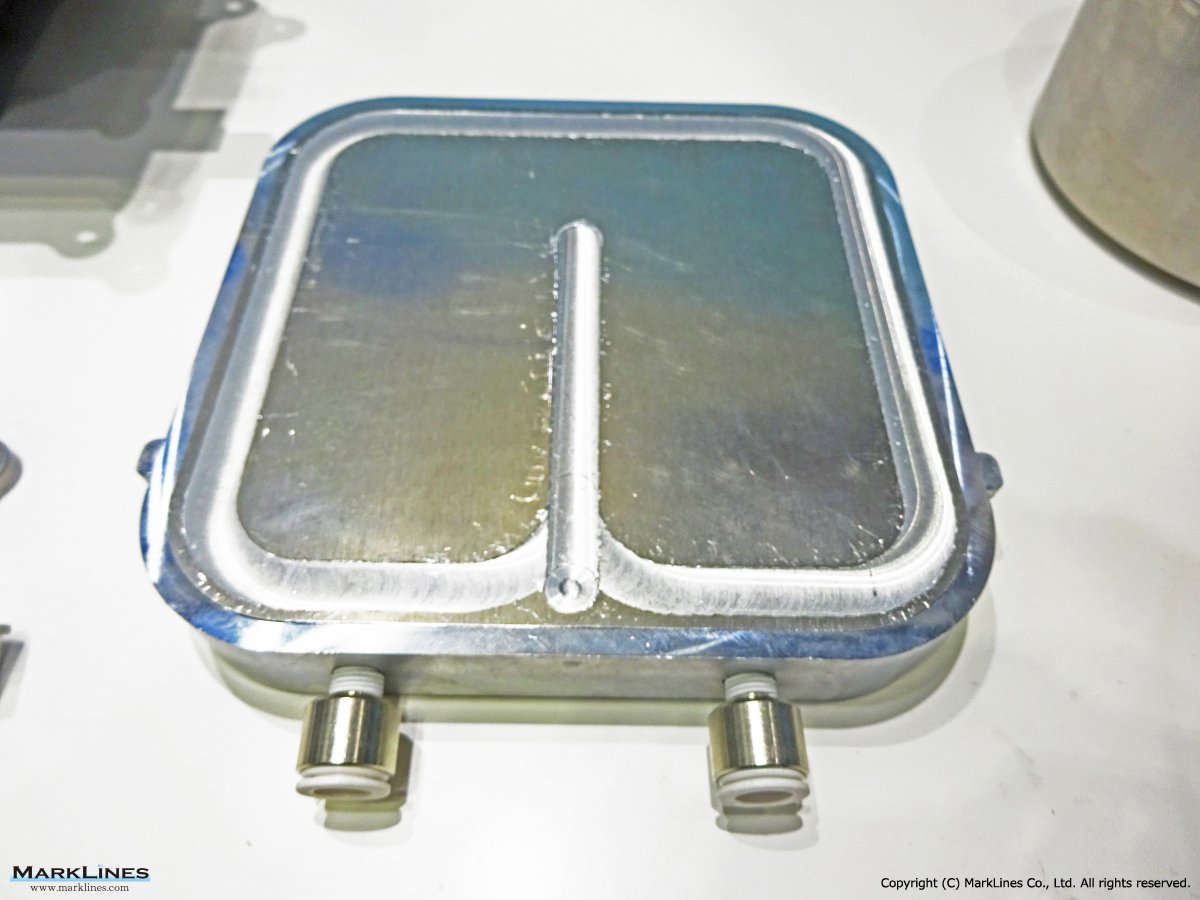

Hyundai Ioniq 5 Teardown: Thermal Management and Charging Systems

iates, Inc.) Coolant Pump 2 (Source: Munro & Associates, Inc.) Water Pump (Source: Munro & Associates, Inc.) ⑧ Battery Pack - High voltage battery Battery cooling plate (Source: Munro & Associates, Inc.) A welded and brazed aluminum cooling plate (pictured right) is provided and FSW (Friction Stir Welding) bonded to the Battery Pack case to provide both cooling and strength. The coolant pumped by the ⑦ Water Pump is introduc...

Market & Tech Reports Updated at: 2023/11/09

JSAE 2023 in Yokohama: Thermal Management, e-Axle Components

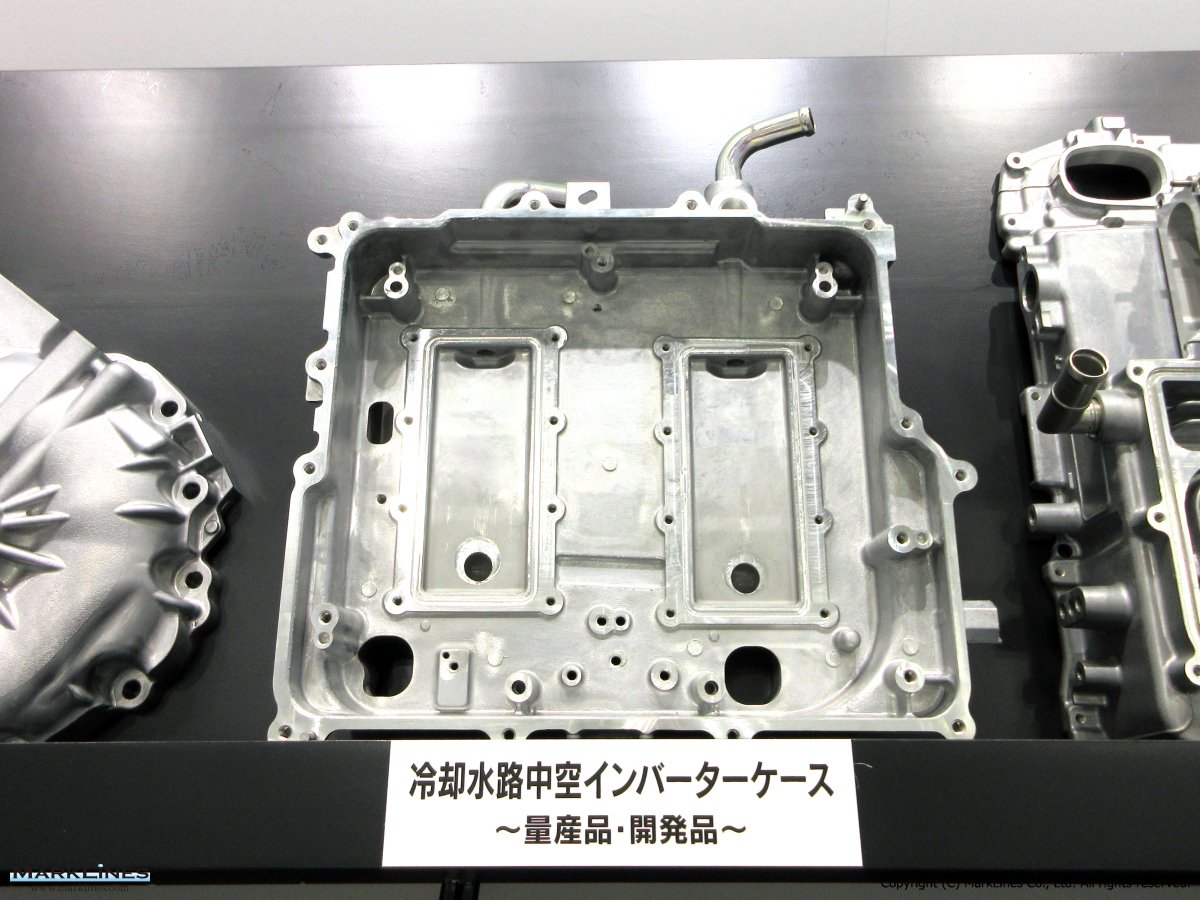

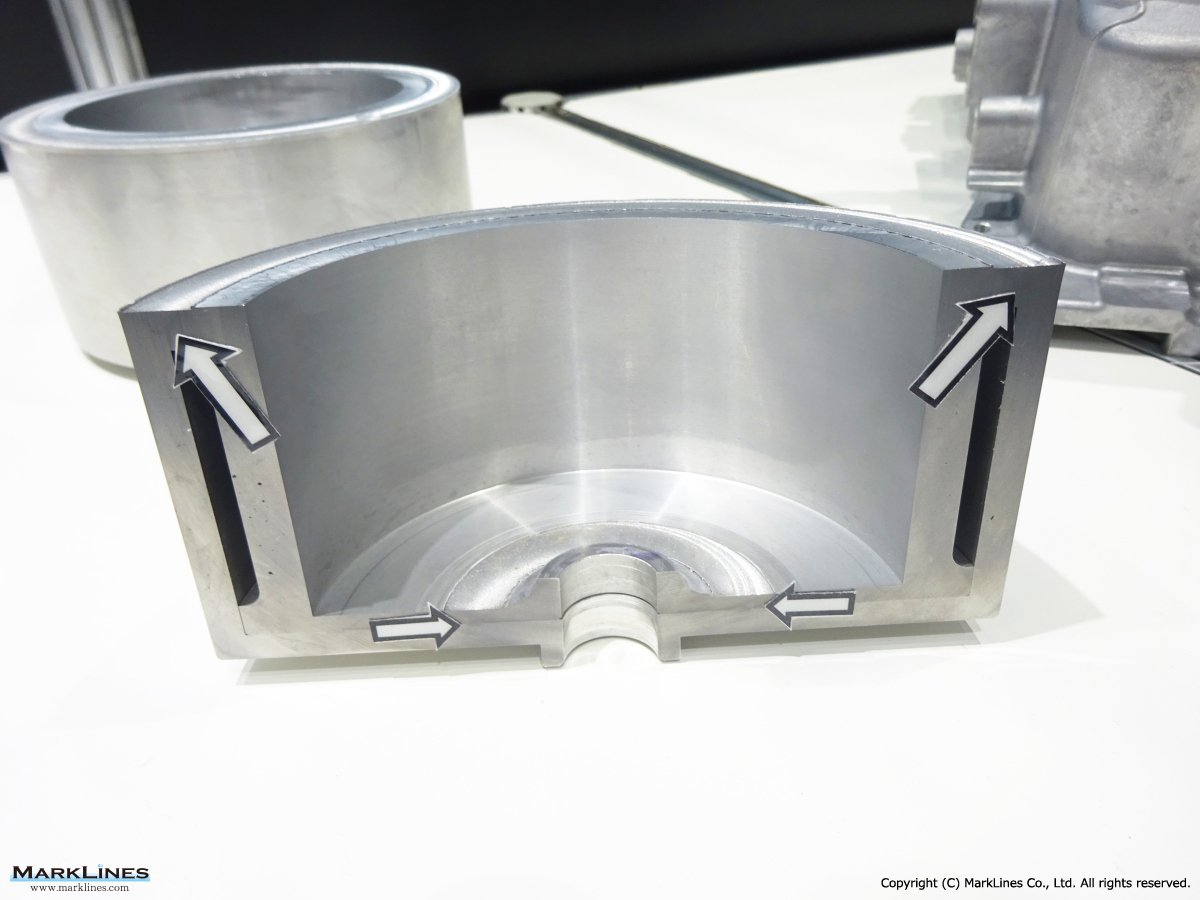

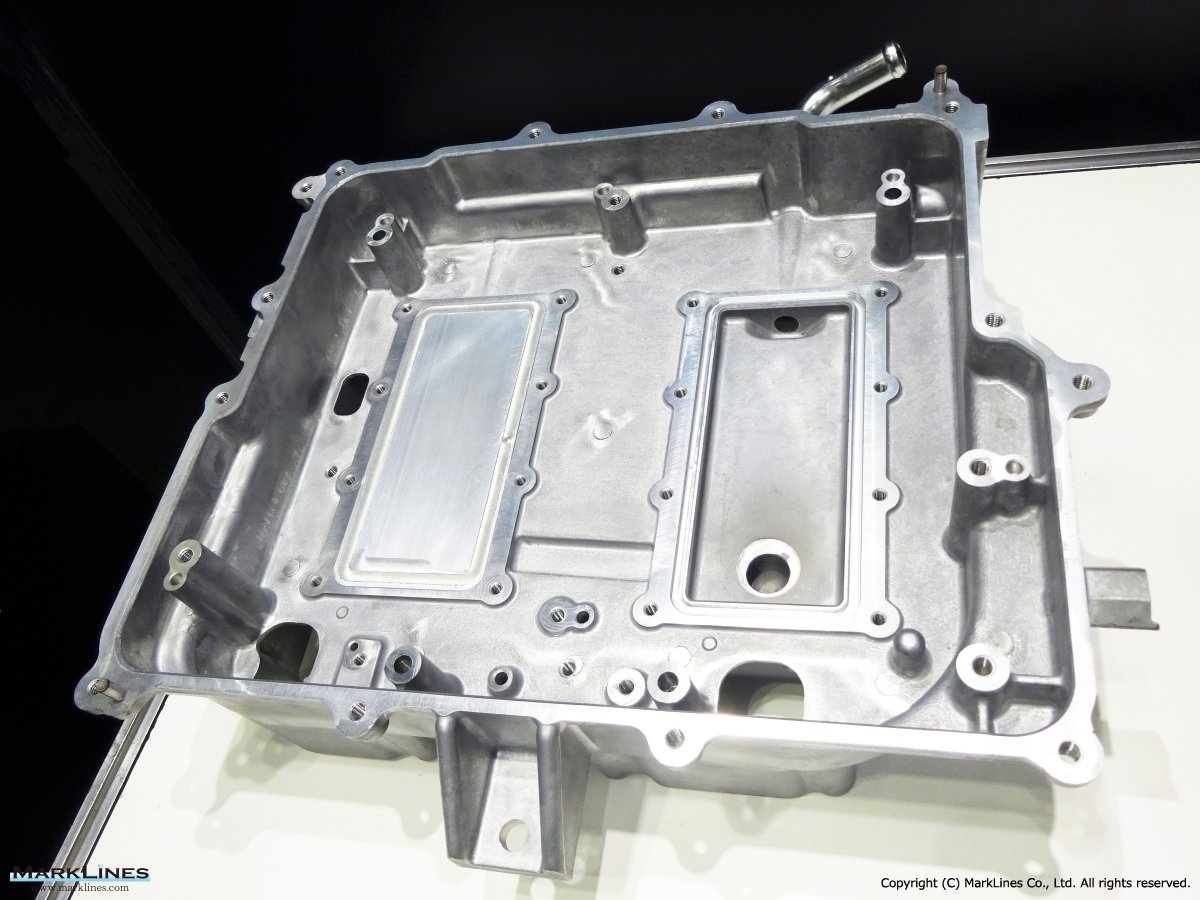

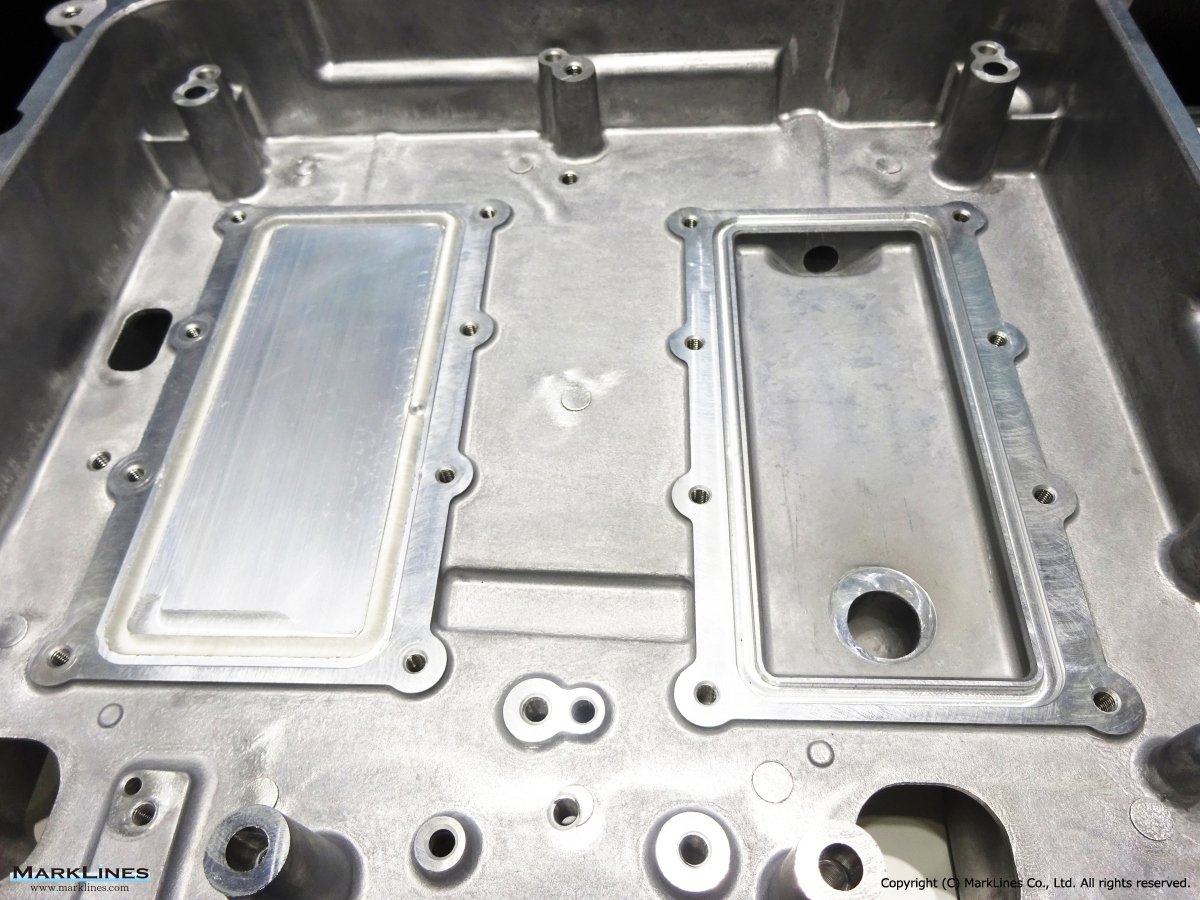

um at the U.S. plant. In the VW UD.3 and ID.4, the battery pack under the vehicle floor is part of the body's strength member, so a sturdy cross-member is placed inside the battery pack. Exhibit of motor housing for Tesla Battery pack cross-member for VW Yanagawa Seiki: Inverter case, FSW (friction stir welding) water-cooled housing Yanagawa Seiki Co., Ltd. (Kyushu Yanagawa Seiki), which handles aluminum die-cast parts, exhibited...

Market & Tech Reports Updated at: 2023/07/10

JSAE 2023 in Yokohama: Metal Processing Technology, and EV Components

ss: 11.1kgMaterial: DX-30Process: High vacuum die casting Thin wall: 1.2mmMass: 3.1kgMaterial: Aluminum alloy ADC12Process: Die casting Exhibited product: Inverter case Exhibited product: Rear suspension tower brace(Toyota Lexus LC500 Convertible) Left: Laser welding specificationRight: FSW (Friction Stir Welding) specificationMaterial: RX-10Process: Die casting Mass: 2.7 kgMaterial: ADC12Process: High vacuum die castingCasting machin...

Market & Tech Reports Updated at: 2023/06/05

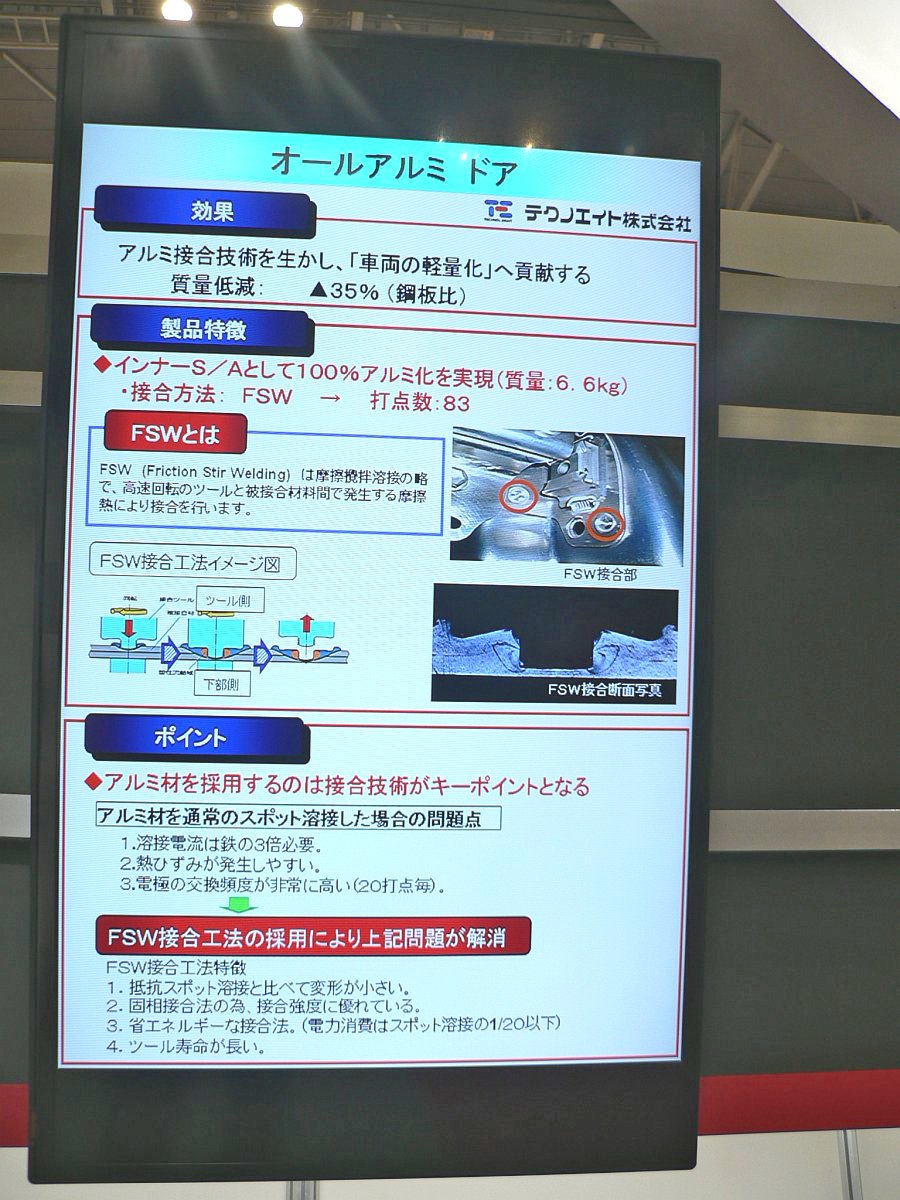

13th Toyota Business Fair 2023: Carbon Neutrality

new Land Cruiser 300 Display panel: Aluminum door components that reduce CO2 emissions Technol Eight manufactured parts are shown in blue. 3000 series and 6000 series aluminum are recycled for casting. Reducing the weight of aluminum door parts with differential thickness welding technology (FSW) significantly reduces CO2 emissions. In addition to the above, the C+walk and COMOVE single-seat mobility vehicles were also on display. Al...

Market & Tech Reports Updated at: 2023/03/30

2022 Japan Die Casting Congress & Exposition: EV Components, Weight Reduction

ts larger than 1 meter with its large die casting machines, and even larger products are possible with laser welding. It can also be applied to products that require airtightness. Zero draft technologyProcess: Die casting Reference exhibit: 2-piece inverter case Reference exhibit: e-Axle case FSW (friction stir welding) Material: Ryobi RH-FProcess: Die casting 500tLeft: FSW (friction stir welding)Right: Laser weldingPorosity suppressi...

Market & Tech Reports Updated at: 2022/12/14

Automotive World Autumn 2022: Electrification-related Technologies

ization and higher output of automotive inverters. There are those in which double-sided cooling power modules are inserted, and those in which water channels with direct-cooling power modules are installed in the inverter case later. Nippon Light Metal combines processing and bonding technologies (FSW, brazing, etc.) to produce these products. A sample coolers for power modules was on display, and the company said that products for boost convert...

Market & Tech Reports Updated at: 2022/09/21

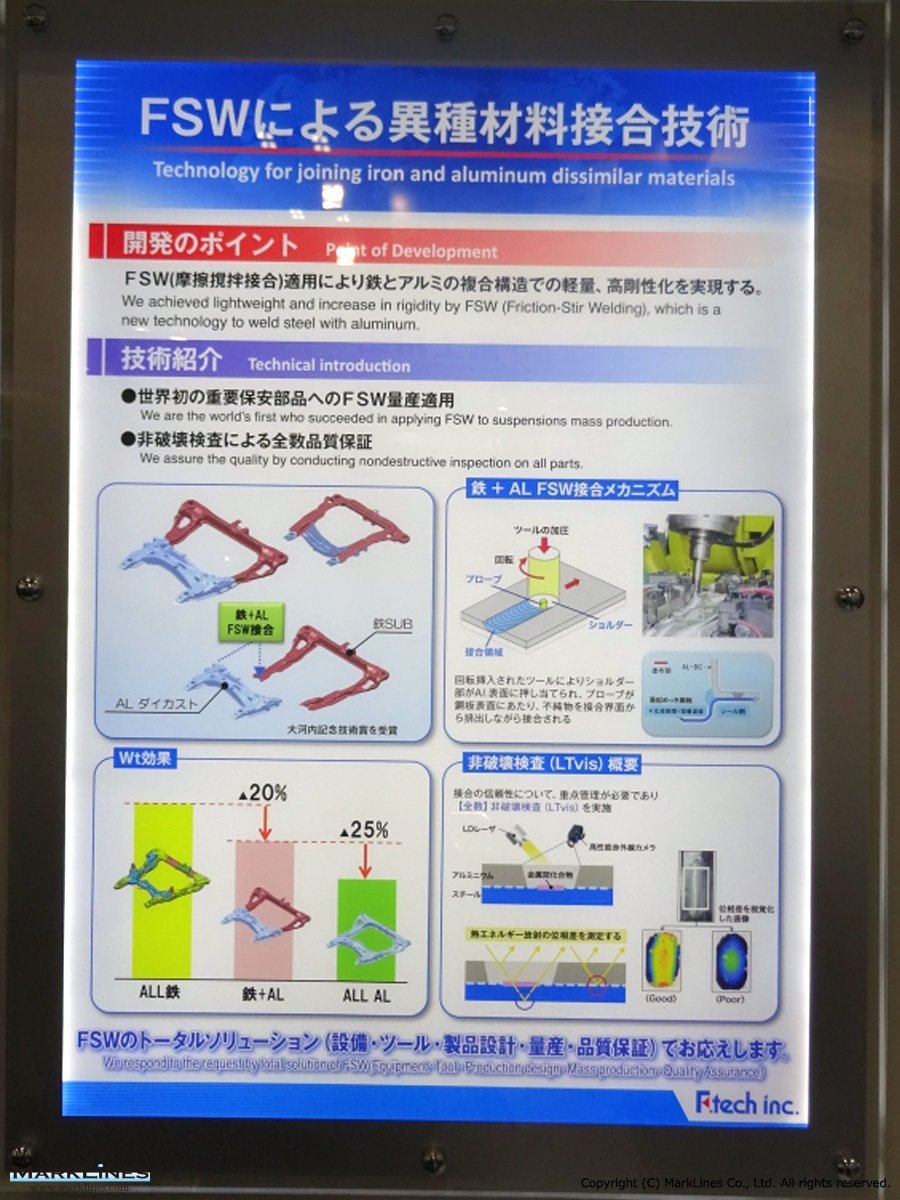

Technology Trends in Dissimilar Metal Joining

turing method of the same joint structure and terminal block Soldering of aluminum components to dissimilar metal members harder than aluminum Japanese laid-open patent application 2015-89550 Musashi Seimitsu Industry Co., Ltd. Toyohashi University of Technology Dissimilar material joining method Friction stir welding of ferrous (iron-based) and aluminum-based materials The number of patent applications related to dissimilar metal join...

Market & Tech Reports Updated at: 2021/10/04

Fuel Cell (FC) Technology in Toyota's New Mirai

to be equipped with mounting points for attaching auxiliary components to the periphery. It needs to be a strong member with a complex shape, so an aluminum die casting process is used. In the new FC system, the upper and lower parts of the stack case are die-cast separately and by joining with FSW (friction stir welding), equal distance between the stacked cells and the stack case is ensured and an increase in part size due to the die-castin...

Market & Tech Reports Updated at: 2021/09/01

JSAE Exposition 2018: Lightweight processing technology and plastic materials

ocess: Aluminum extrusion, aluminum arc welding Door panelMaterial: Outer shell 6000 series, inner shell 5000 series4 different bonding methods are separately and selectively used for aluminum bonding HoodMaterial: Outer shell 6000 series, inner shell 5000 series Aluminum bonding method 1) Friction Stir Welding (FSW)Window frame reinforcements are stacked with tailored blanks but the FSW method is used for welding before blanking 2) Lase...

Market & Tech Reports Updated at: 2018/06/06

Automotive World 2018: Joining of dissimilar materials, high function plastics exhibition

ials is shown.*PBT: Polybutylene terephthalate, TPC: Thermoplastic copolyester Front subframe for Honda Accord (F-Tech)The exhibited product achieves high rigidity and low weight with a composite structure of iron and aluminum. It adopts dissimilar material joining technology based on FSW (Friction Stir Welding). From now on, aluminum frames are expected to meet the needs of contactless charging for EVs and magnetic field compatibil...

Market & Tech Reports Updated at: 2018/02/22

JSAE Exposition 2016: Latest weight saving technologies

the company's hot press forming and welding technologies. It weighs approximately 1.3 kg (a 650 g seatback and 670 g seat surface), 60% lighter than comparable steel parts. Magnesium alloys for making pressed parts are heated to approximately 250 degrees Celsius before stamping. Pipes are formed by friction stir welding (FSW) to ensure high strength. The material costs around JPY 4,500 per kg and the company plans to cut the cost by half to incre...

Market & Tech Reports Updated at: 2016/07/26

Honda Accord Hybrid teardown (Part 1)

. The dampers provide a large damping force when a large stroke is applied and only a small damping force when the stroke is small. This contributes to higher driving stability and ride comfort. All-aluminum front subframe VSA modulator The all-aluminum subframe is assembled with the Friction Stir Welding (FSW) process. The top of the photo points to the vehicle's front. The subframe is 1,100mm in width at top, 830mm at bottom, and...

Market & Tech Reports Updated at: 2014/02/17

JSAE Automotive Engineering Exposition 2013: OEMs

ere many exhibits concerning weight reduction technology that uses steel and safety technology. Concerning weight reduction, Nissan unveiled the white body that uses 1.2GPa ultra high tensile strength sheet of the Infiniti Q50. Honda exhibited a front sub-frame that welds steel and aluminum through Friction Stir Welding. As for safety technology, exhibits included Toyota's Pop-up hood mounted on Toyota New Crown, Daihatsu's first crash-avoidan...

Market & Tech Reports Updated at: 2013/07/05

AI Navigator

AI Navigator

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India