Search Results by Category

AI Navigator

AI NavigatorAll information related to {{ key_word }}.

AI Navigation will guide you. Click here for information about {{ key_word }}.

3

3

4

4

11

11

1

1

1

1

1

1

1

1

1

1

3

3

3

3

1 - 20 of 79 results

PowerCo begins Unified battery cell production at Salzgitter Gigafactory, Germany

in Salzgitter, with a new test facility under construction which is set to open in early 2026. The Salzgitter Gigafactory sets new benchmarks for low-carbon dioxide battery cell production. It runs entirely on renewable energy from wind and solar. For the first time, the energy-intensive clean and drying rooms will also be operated with green electricity. In the industry, fossil fuels are typically used for this purpose. Based on VW Group press ...

News Updated at: 2025/12/17

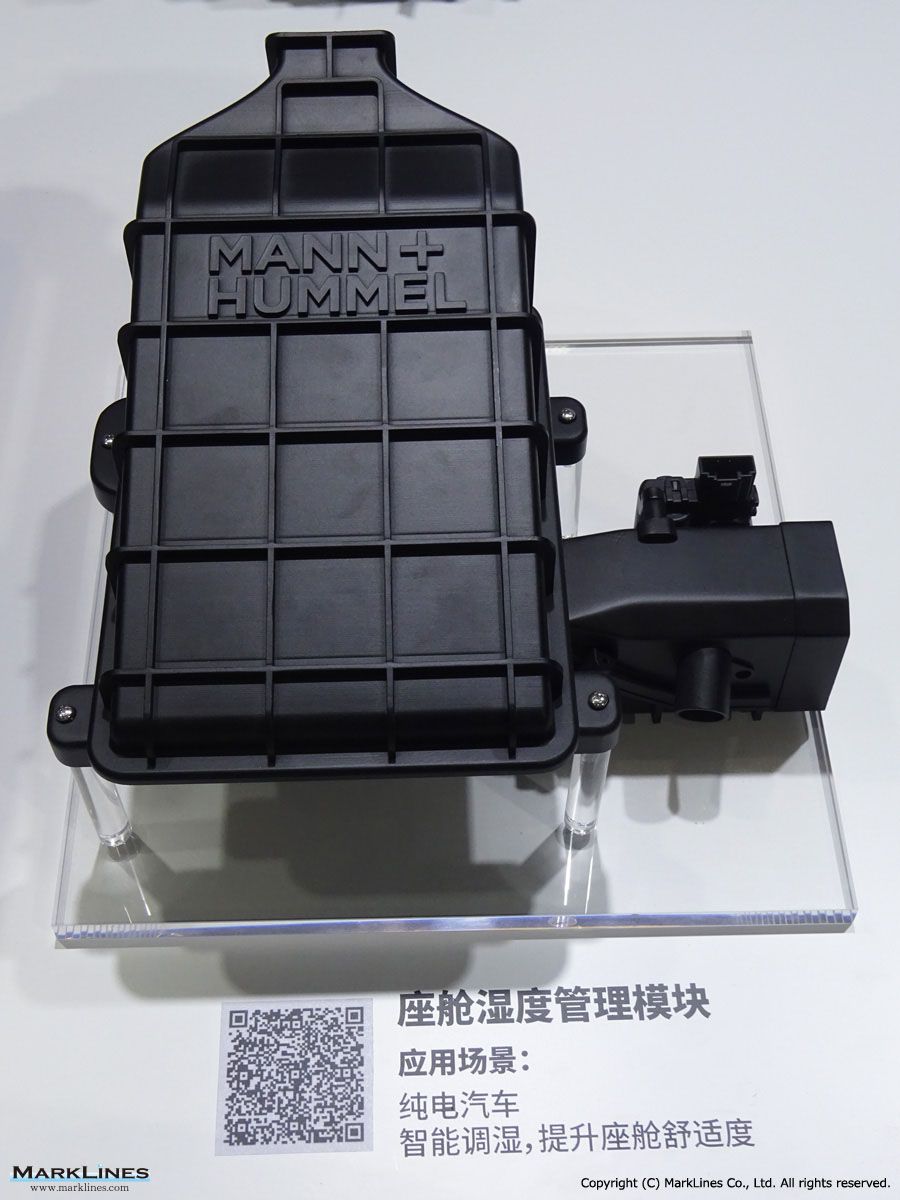

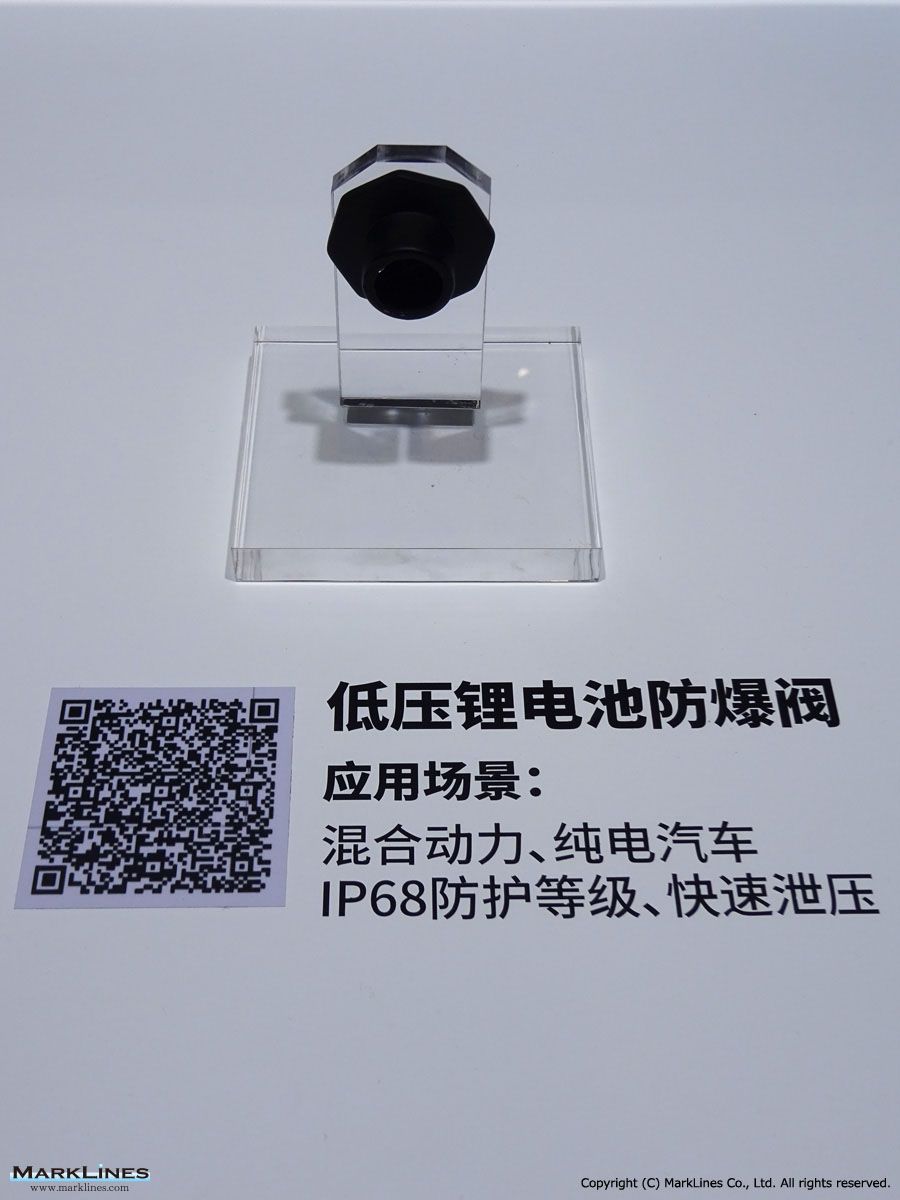

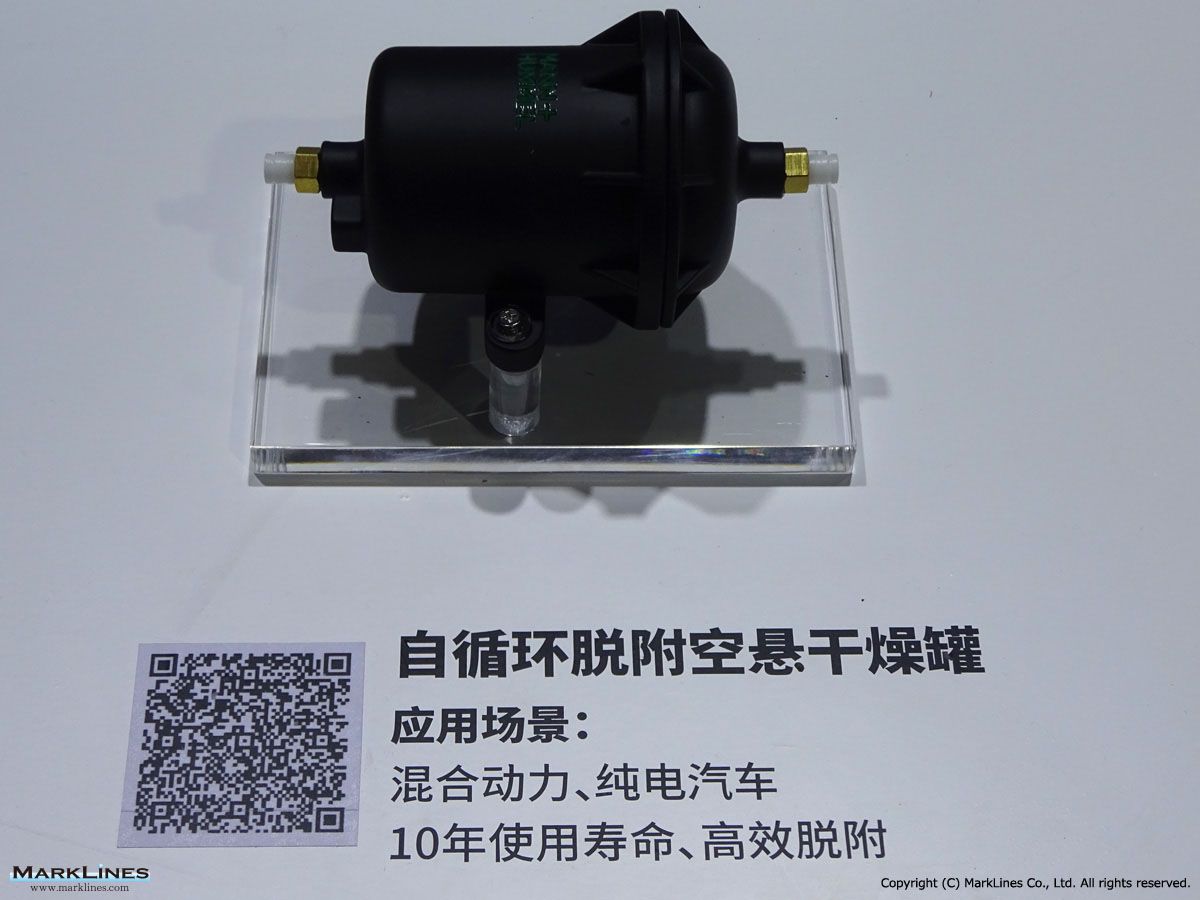

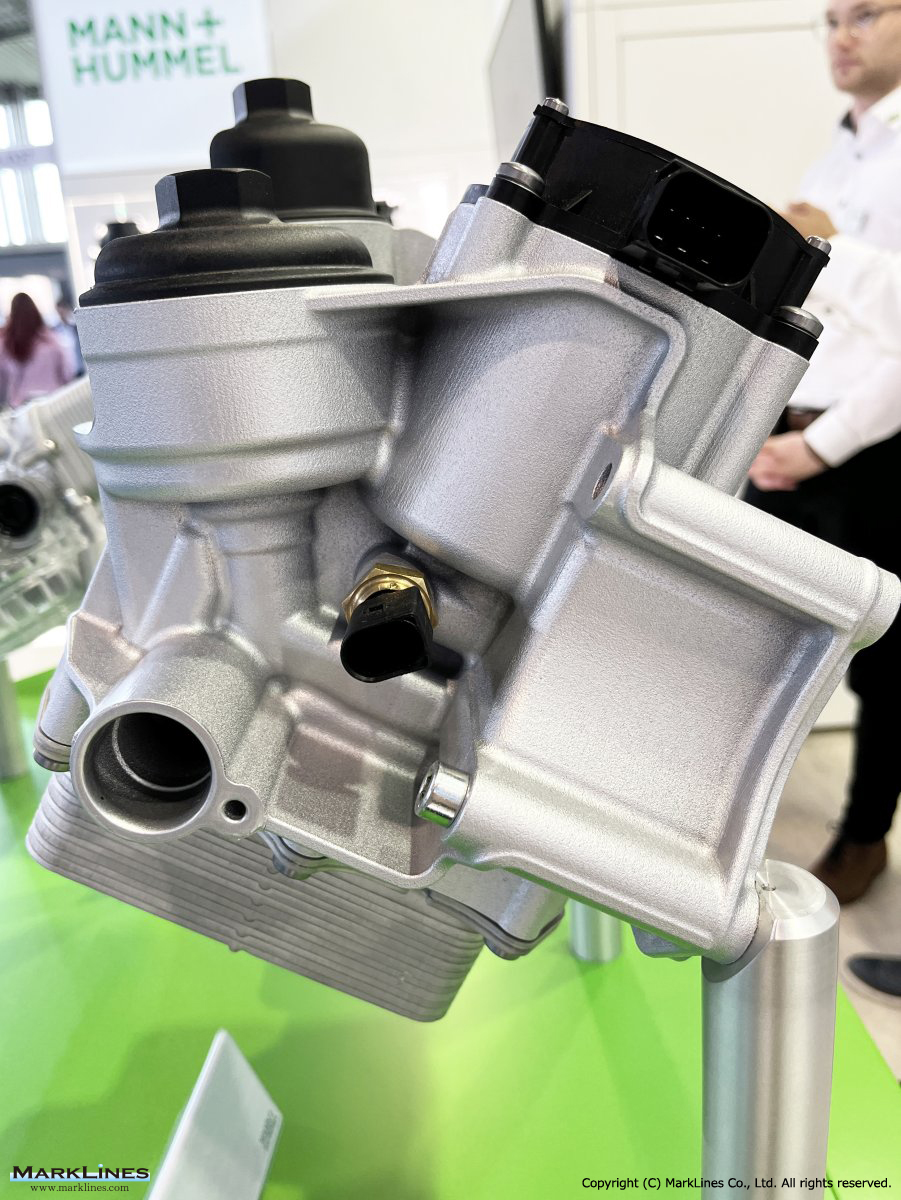

MANN+HUMMEL participates in BMW innovation event on sustainable development of Chinese supply chain

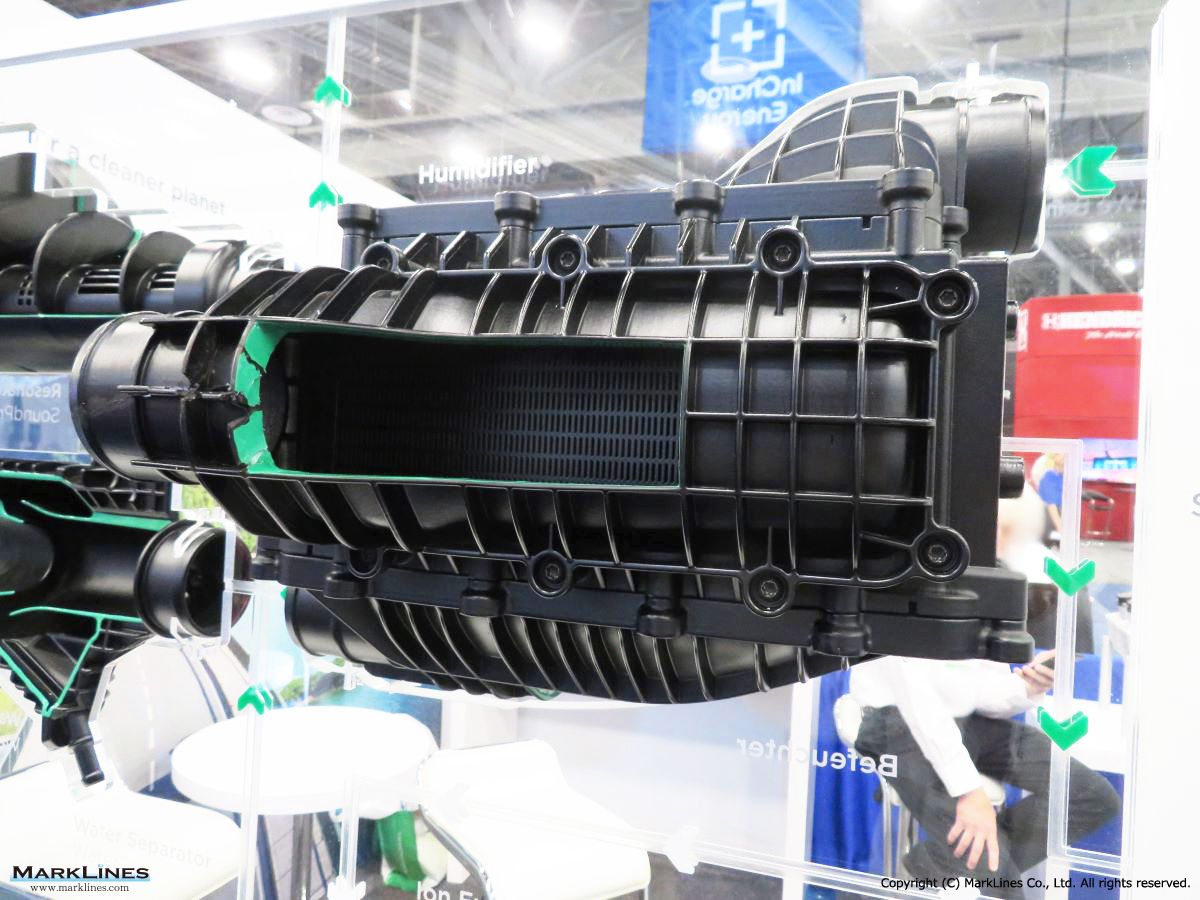

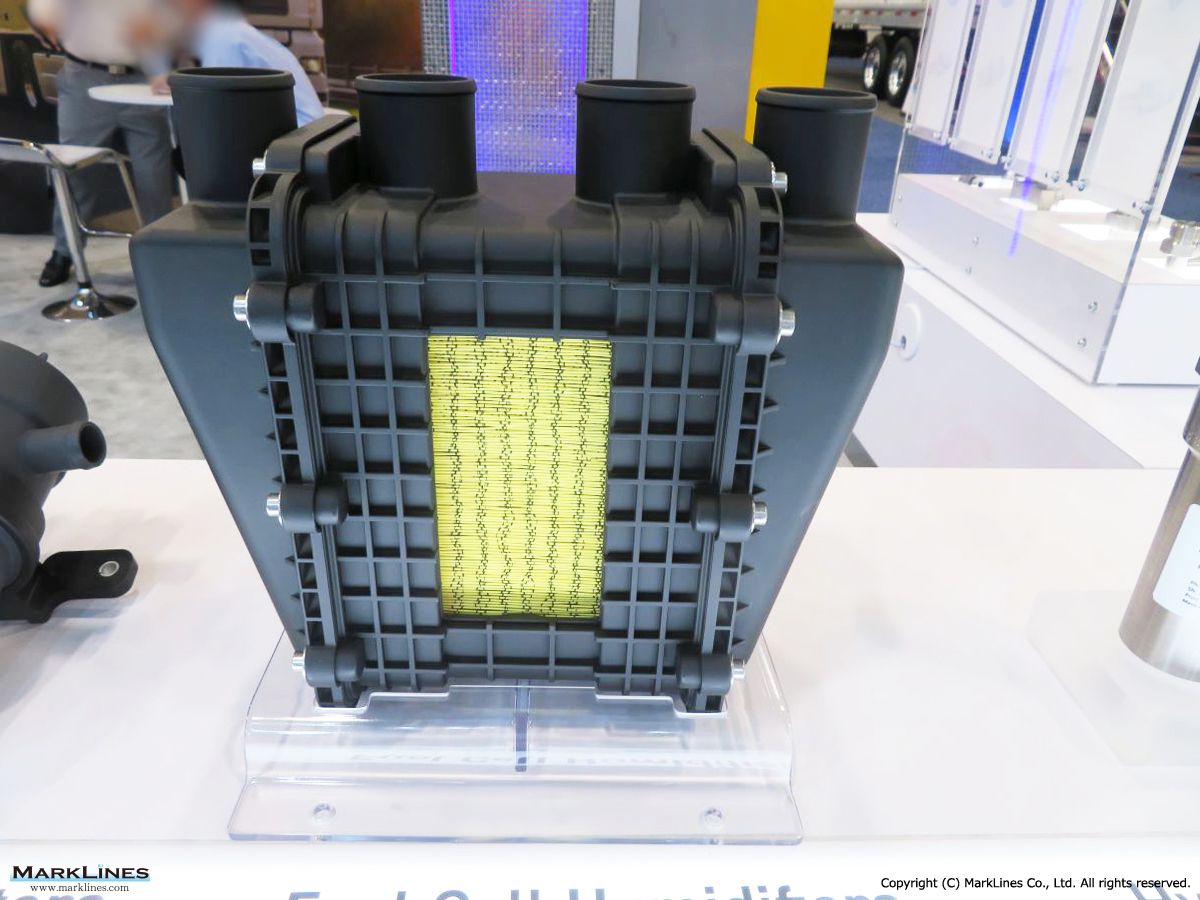

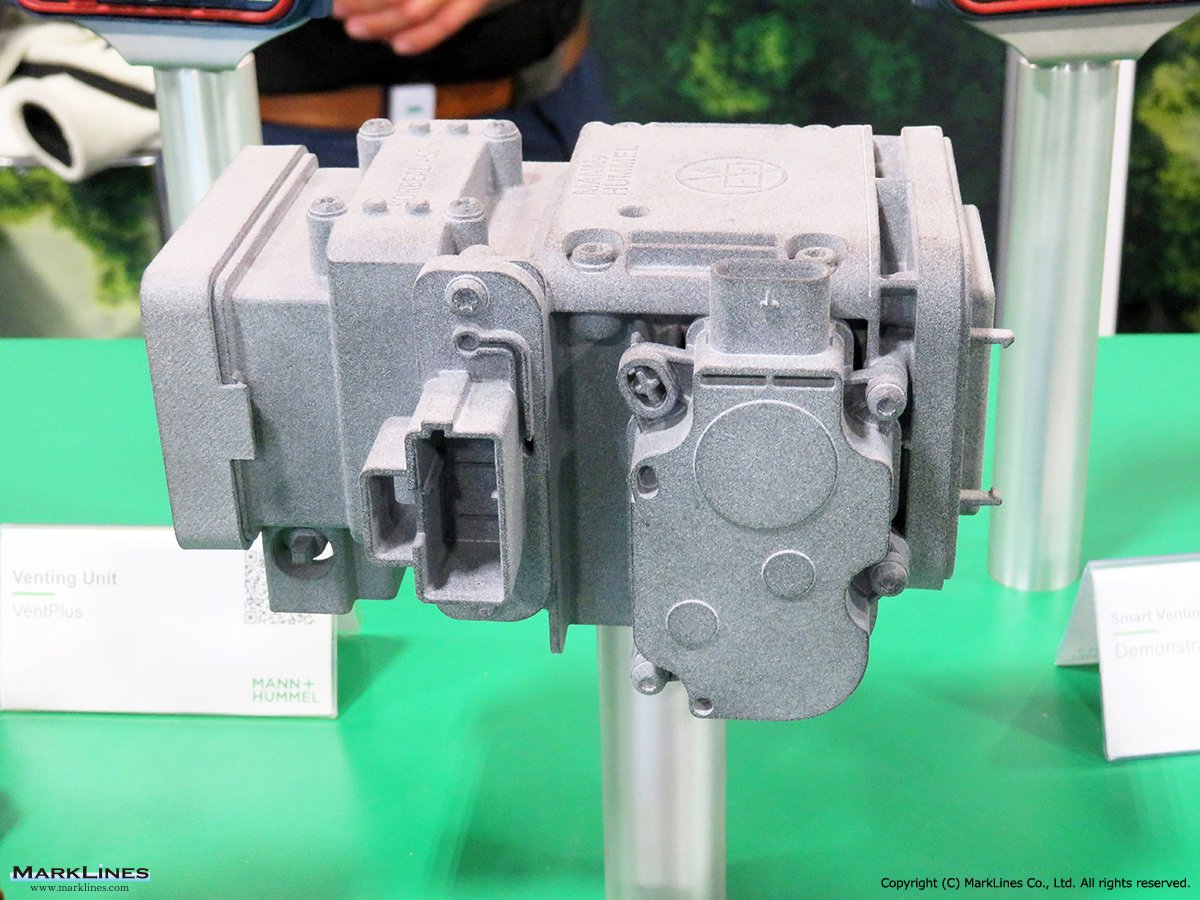

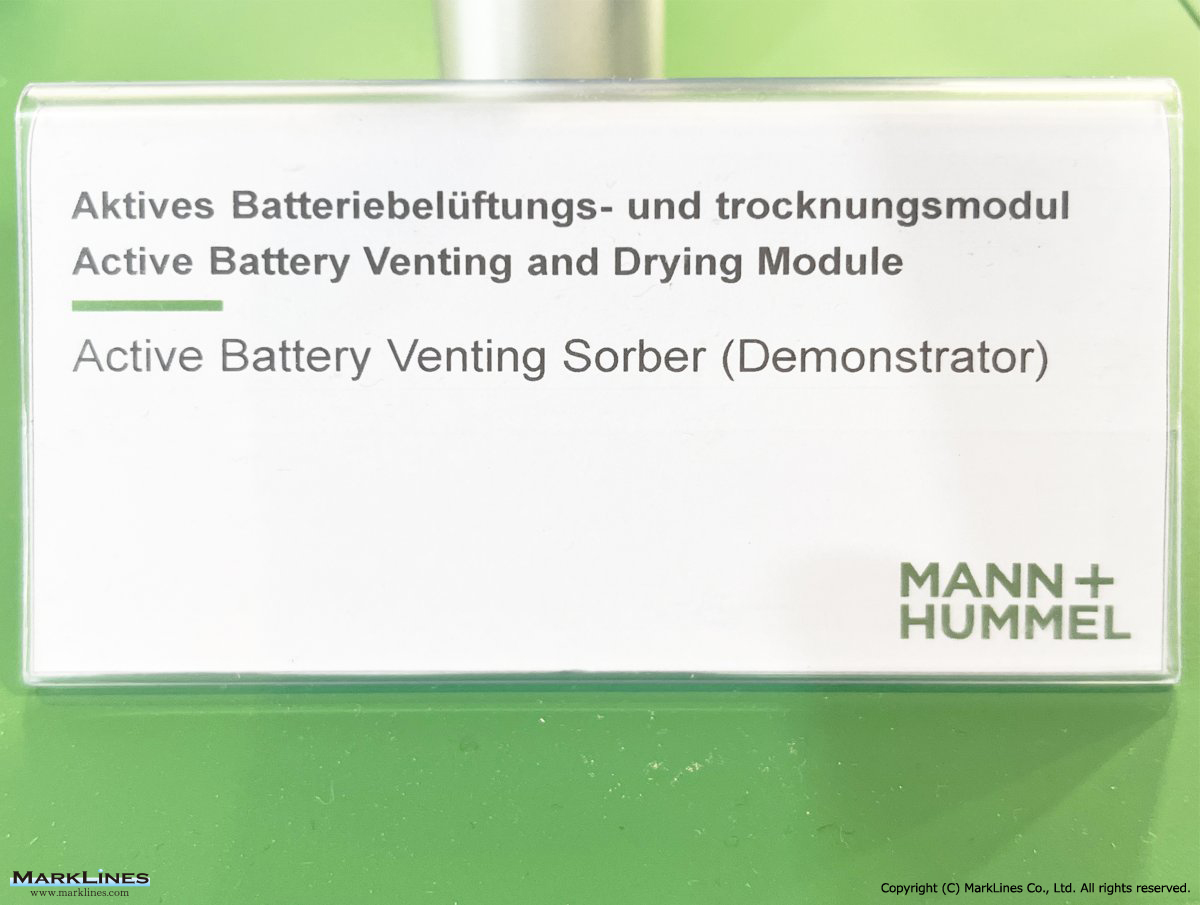

een mobility, including the following.A smokeless explosion-proof valve with instantaneous pressure relief and waterproof designs for higher battery safety under extreme operating conditions.An intelligent in-vehicle humidity control module for reduction of energy consumption and carbon emissions.A drying tank for air suspension systems, which adopts renewable adsorption materials and reduces carbon emissions throughout its life cycle.A bamboo fi...

News Updated at: 2025/11/19

Fraunhofer IWS, Germany, inaugurates DRYplatform for dry electrode coating

rm. DRYplatform enables researchers to develop and scale concepts from scientific approaches to near-industrial demonstrations based on the “DRYtraec” dry-coating process. DRYtraec replaces conventional wet coating of electrodes. This dry-coating process eliminates solvents and energy-intensive drying steps, cutting costs and environmental impact. The platform integrates the process into a complete system: a flexible dry-air multi-chamber des...

News Updated at: 2025/11/05

Nissan partners with LiCAP Technologies to develop ASSB electrode production process technology

artnership with U.S.-based LiCAP Technologies, Inc., which has a proprietary Activated Dry Electrode technology, for the development of production process technology for the cathode electrode of all-solid-state batteries (ASSB). Developing a dry electrode production process eliminating the need for drying and solvent recovery is highly beneficial for the smooth production and commercialization of ASSBs. However, when considering future mass produ...

News Updated at: 2025/08/20

BMW invests EUR 30 million to open custom paintwork centre at Dingolfing plant by 2027

tion with manual detailing. The first coat will be applied automatically, while custom touches such as stripes or contrast colours will be painted by hand before the final clear coat is added. The centre will employ at least 10 people, cut throughput times by about 25%, and lower costs per car. Its drying furnaces will run on electricity instead of gas, using power-to-heat technology. Based on BMW press release...

News Updated at: 2025/08/13

BMW Regensburg plant cuts emissions with electrified paint shop and thermal oil tech

transfer heat instead of relying on gas. This system allows flexible energy use and can run on electricity or gas, making it easier to switch to renewable power even when the local grid can’t yet meet high energy demands. During the New Year production break, BMW replaced one gas-powered top coat drying line with an electric thermal oil system and a new eRTO exhaust air unit. Instead of directly heating air, the new setup uses electric heaters ...

News Updated at: 2025/08/05

AGR, Russia completes paint shop at Kaluga plant for production of TENET vehicles

nt, where the TENET car body undergoes full immersion degreasing and phosphating to prepare the surface for coating. Next, a cataphoresis primer is applied using RoDip technology, which rotates the body in a large 26-meter bath to ensure the coating reaches all areas. The body then enters the first drying chamber, where the primer is heat-treated at up to 200°C. In the final steps, the car receives a secondary primer, base enamel, and clear var...

News Updated at: 2025/07/24

IBU-tec signs EUR 6 million deal with PowerCo SE to advance LFP pCAM production

IBU-tec signs EUR 6 million deal with PowerCo SE to advance LFP pCAM production On July 18, IBU-tec Advanced Materials AG announced it has signed a EUR 6 million deal with PowerCo SE. As part of the deal, IBU-tec will develop an industrialization plan for producing LFP precursor (pCAM) using spray drying technology for automotive use, with a focus on cutting both CAPEX and OPEX. Both companies are continuing joint development projects to move to...

News Updated at: 2025/07/21

Sakuu recognized for Kavian dry electrode printing process for batteries

high-speed, cost-effective Kavian additive manufacturing platform elegantly integrates Sakuu’s innovative dry process manufacturing steps into an all-in-one tool to produce a complete lithium-ion (Li-ion) battery electrode using less than half of the factory footprint of conventional wet coating, drying, and calendering equipment. Kavian’s novel process successfully dry prints cathodes and anodes of various chemistries: NCM, NCA, LFP, graph...

News Updated at: 2025/06/14

Comau partners with Intecells, U.S. to advance cold plasma tech in battery manufacturing

ve how cold plasma is used in making battery cells. Intecells holds a patent for the new technology, and together they aim to help customers add it to their current production lines in a cost-effective way. The cold plasma technology already helps reduce cycle time and energy use during soaking and drying steps. It also increases battery capacity, life cycle, and overall quality across different battery types and sizes. A new version of the plasm...

News Updated at: 2025/06/05

Dürr, Germany and GROB present concept factory for battery cell production at Battery Show Europe

Dürr, Germany and GROB present concept factory for battery cell production at Battery Show Europe On June 3, Dürr and GROB announced that they will present a new concept factory for lithium-ion battery cells at the Battery Show Europe. Key technologies include a dry coating of the electrodes, which does not require a drying process, and powerful Z-folder technology for cell assembly with integrated notching. The Activated Dry Electrode process ...

News Updated at: 2025/06/05

KAMAZ, Russia starts serial painting of Kompas truck cabins at new cabin frame plant

ass 12 (with a berth) models are currently being painted in the serial process. The development of Compass 5 model is planned for Q2 2025. The paint and varnish are applied using an automated "wet-on-wet" technology, where both the secondary primer and enamel are sprayed in the same chamber without drying in between. This saves space and reduces drying time. The painting is carried out using four seven-axis robots. The painting chambers are also ...

News Updated at: 2025/05/06

Renault introduces Jetprint paint process at Maubeuge plant in France

lutionary two-tone painting technology that enhances precision, efficiency, and sustainability, for the production of Renault 4 E-Tech electric. Jetprint Paint uses paint-printing robots to apply the roof and bonnet colors in just six minutes, eliminating the need for manual masking and double oven drying. This integration streamlines production, significantly reduces waste, and saves 1.7 GWh of energy per year, equivalent to powering 350 househo...

News Updated at: 2025/04/25

Parts suppliers to seek business opportunities with in-mold coating technology

s parts since the technology is a method that leads to decarbonization. With the in-mold coating technology, an injection molding machine is equipped with a paint injection unit to inject paint into a mold, and the paint is thermally solidified in the mold. The technology will eliminate coating and drying processes, which were previously performed separately, and make it possible to reduce CO₂ emissions by about 60%. Paint without volatile orga...

News Updated at: 2025/04/18

Tokai Rika’s new steering switch component using in-mold coating technology selected for Toyota Hiace

t time that the in-mold coating technology was adopted for automotive interior parts in Japan. Tokai Rika plans to increase product and color variation, aiming to win orders for applications such as door mirror visors and other exterior parts in 2030. The technology integrates molding, coating, and drying processes to perform them inside the mold in one step. Coating material is poured into a vertical general-purpose forming machine with a dedica...

News Updated at: 2025/04/09

RWTH Aachen University, Germany completes IDEEL Project, Advancing laser-based drying for battery production

RWTH Aachen University, Germany completes IDEEL Project, Advancing laser-based drying for battery production On March 19, the Chair of Production Engineering of E-Mobility Components (PEM) at RWTH Aachen University announced the successful completion of the IDEEL project after three years of research. In the project, funded by the Federal Ministry of Education and Research, the consortium developed a laser-based drying process for battery product...

News Updated at: 2025/03/21

Nippon Paint Automotive Coatings jointly develops environmentally friendly in-mold coating technology

(Uchihamakasei), a subsidiary of Kojima Industries Corporation (Toyota City, Aichi Prefecture). The new in-mold coating technology combines resin molding and surface coating into a single integrated process. The new technology will eliminate the need for coating application booths and post-coating drying ovens, which have been needed for conventional coating methods, and help to reduce CO₂ emissions by 60%. The two companies will share this ne...

News Updated at: 2025/03/05

Daimler Truck's Wörth plant adopts eco-friendly painting process

y truck cab painting process, reducing the carbon footprint of production. Painting which is the biggest energy consumer will see up to 40% energy savings with the new process. The environmentally friendly painting process uses ultra-high-solids paint materials. This process eliminates the need for drying between layers, allowing for a wet-on-wet application in just one painting box. The new system is more efficient, using less paint material and...

News Updated at: 2025/01/29

FAW Jiefang commissions 6DV Super Plant, launches first hydrogen engine

nt is the 6DV engine, the world’s first green and intelligent engine, which delivers a robust power of 640PS and an ultra-high torque of 3,000Nm. For technology, the plant features a proprietary gear assembly process and introduces green energy-saving technologies such as photovoltaics and sludge drying. For efficiency, the lean production lines at the plant offer the optimal layout and the highest production efficiency, with a first-pass yield...

News Updated at: 2024/12/09

RWTH Aachen University, Germany to develop new drying process for production of Li-ion batteries and fuel cells

RWTH Aachen University, Germany to develop new drying process for production of Li-ion batteries and fuel cells On November 25, the Chair of Production Engineering of E-Mobility Components (PEM) of RWTH Aachen University announced that it is working on a new hybrid drying process to produce lithium-ion batteries, fuel cells, and electrolyzers in the two-year “HyDry” research project. The current convection drying systems use hot air from foss...

News Updated at: 2024/11/26

AI Navigator

AI Navigator

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India