Search Results by Category

AI Navigator

AI NavigatorAll information related to {{ key_word }}.

AI Navigation will guide you. Click here for information about {{ key_word }}.

4

4

1

1

3

3

7

7

1

1

2

2

2

2

2

2

4

4

1

1

1 - 17 of 17 results

Honda prepares for EV, ICE production on flexible lines at Anna Engine Plant

t Honda auto engine plant in the world. As part of the Honda EV Hub, AEP is one of three production facilities in Ohio that are advancing the concept of flexible motors on the same production lines. AEP has added three new processes to produce the aluminum EV battery case, including: megacasting, friction stir welding (FSW) and Minimum Quantity Lubrication (MQL) machining. When EV production begins in 2026, the EV battery case megacast at AEP w...

News Updated at: 2025/07/22

KUKA, Germany receives order for 12 friction welding cells from major US automaker

KUKA, Germany receives order for 12 friction welding cells from major US automaker On July 9, KUKA announced that it has secured a follow-up order for 12 additional friction welding cells to support the production expansion of a major automotive manufacturer in the U.S. The delivered cells will be installed and commissioned in phases by August 2025. The FSW (friction stir welding) cells, equipped with KUKA KR FORTEC robots and clamping devices s...

News Updated at: 2025/07/10

Honda introduces next-gen technologies for Honda 0 series models

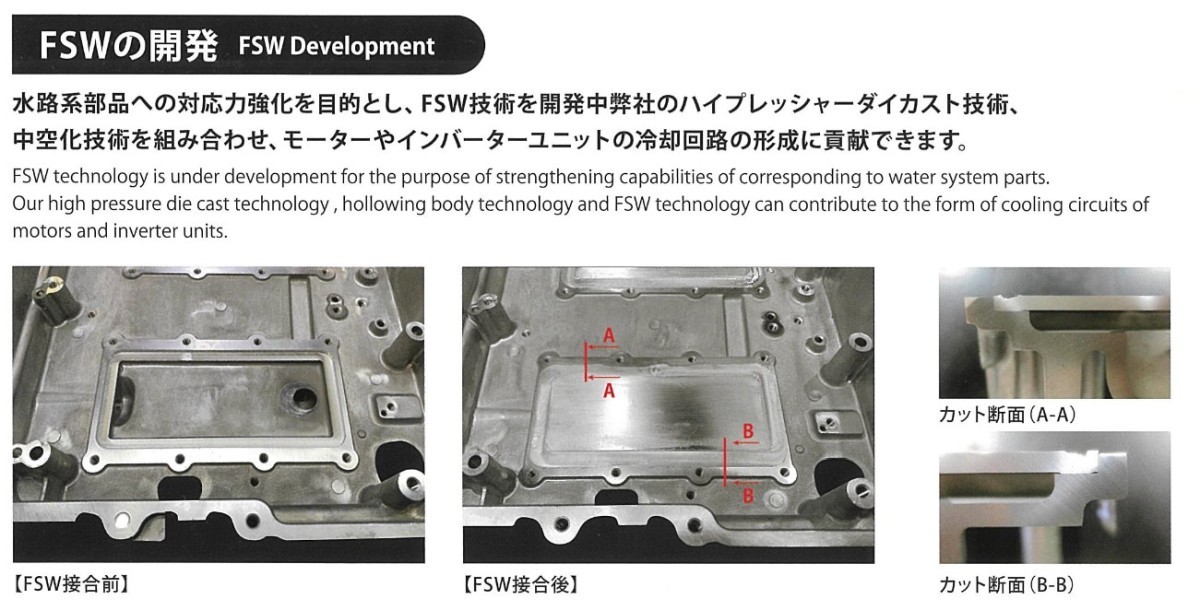

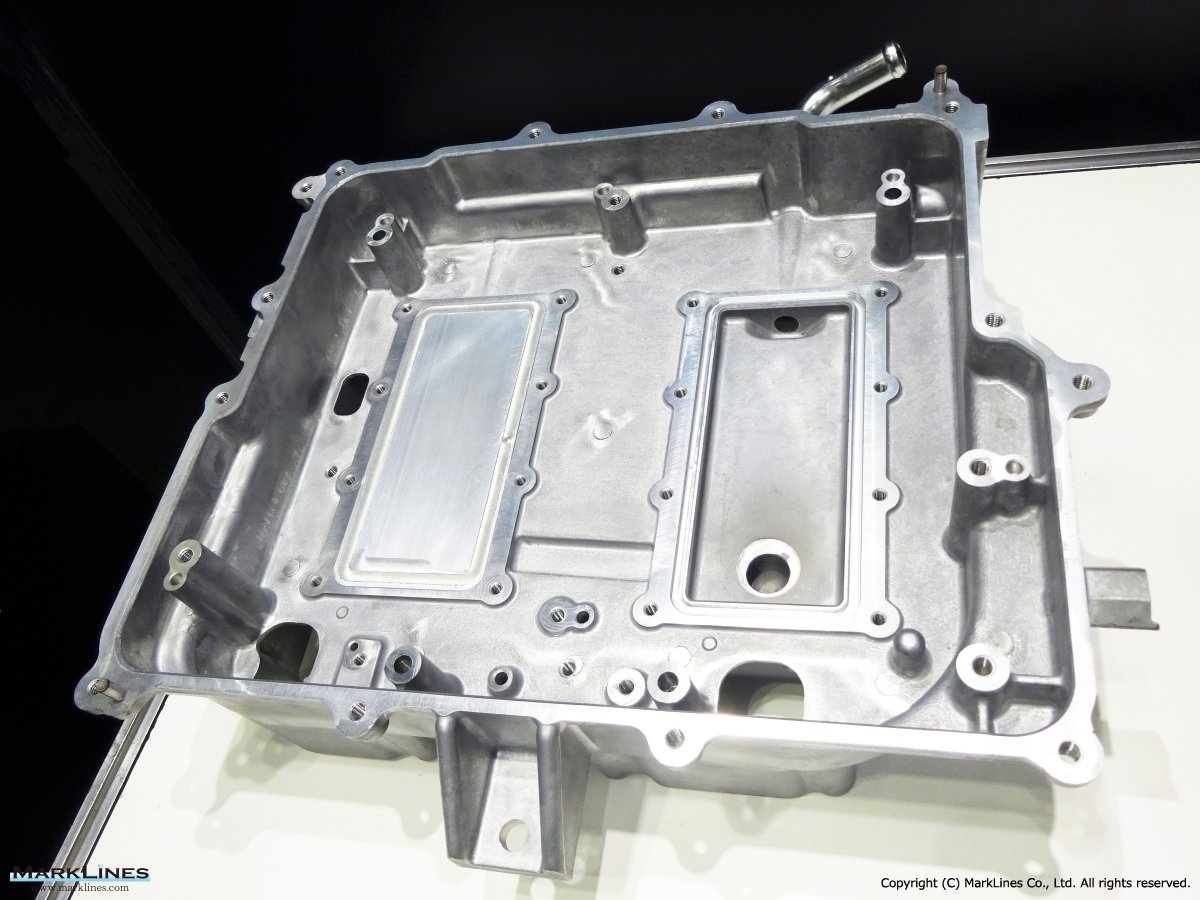

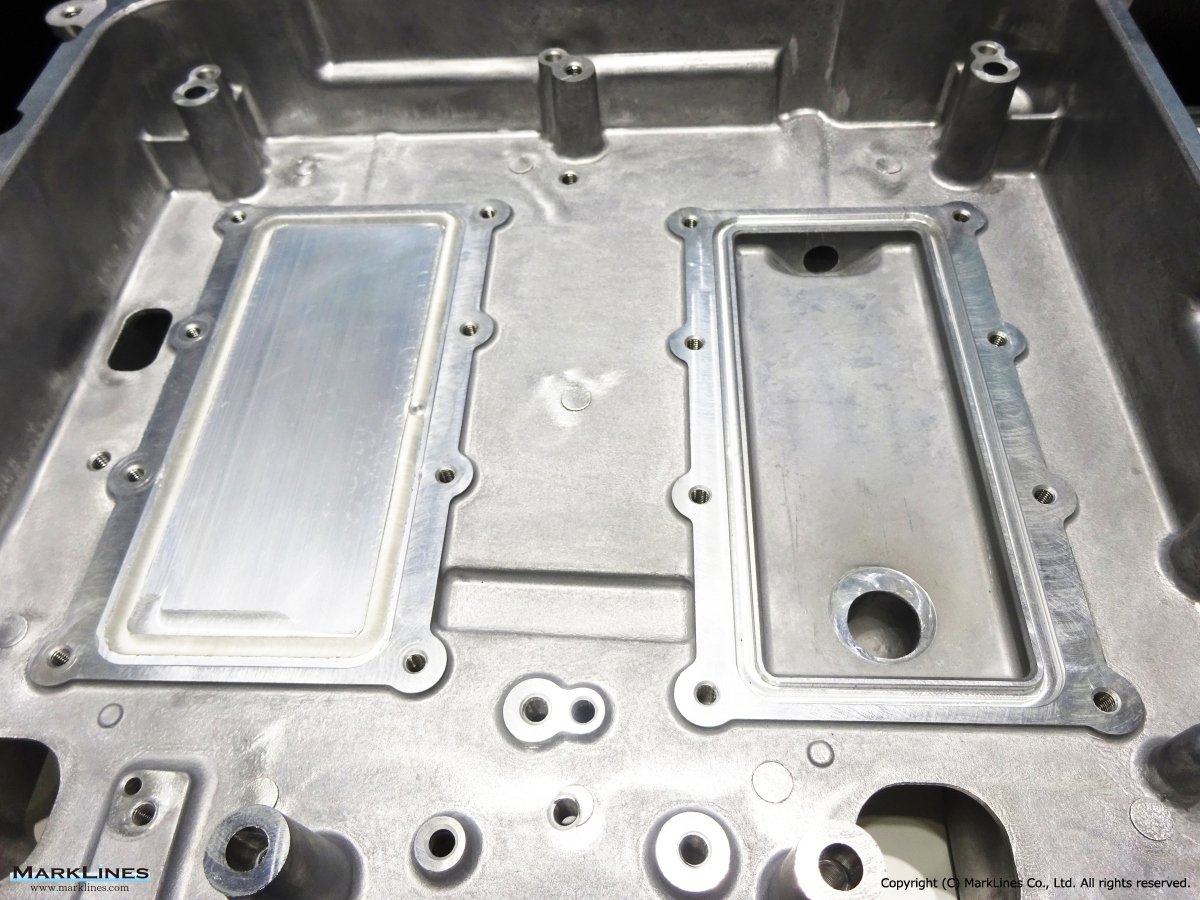

rizontal layout package where the inverter is placed side by side with the motor. With this compact e-Axle, the low-height styling and maximizing of cabin space will be achieved at the same time. The IPU (battery) case will be made approximately 6% thinner through the adoption of megacasting and 3D friction stir welding (FSW) technology. Using a 6,000-ton class megacasting machine, the number of parts will be reduced from more than 60 to 5. By jo...

News Updated at: 2024/10/09

KUKA, Germany wins major order for welding technologies for e-mobility

KUKA, Germany wins major order for welding technologies for e-mobility On June 12, KUKA announced that it is supplying 23 friction stir welding cells with integrated robots for the production of electric vehicles for an automotive customer. This double-digit million range order is the largest single order in this area to date. The FSW cells (FSW stands for Friction Stir Welding) with various technologies and KUKA KR FORTEC robots are integrated i...

News Updated at: 2024/06/13

Endurance Technologies, India to set up a greenfield plant in Sambhajinagar

anufacture machined aluminum die-casting components on its land parcel of 11 acres situated at AURIC, Chh. Sambhajinagar (previously Aurangabad). The facility shall produce aluminum die-casting parts for automotive (ICE and EV) and non-automotive segments, with processes like machining, assemblies, friction stir welding, and surface treatments. It is proposed to install a capacity of 900 MT casting parts per month with an estimated investment of ...

News Updated at: 2024/05/17

Honda progresses in building EV Hub in Ohio

P will now build the IPU case that will contain the EV battery module and serve as the main frame structure for the floor of Honda and Acura EVs.• High-pressure die casting: AEP is preparing to install six, 6,000-ton high-pressure die cast machines that will mega cast the IPU case. • Friction Stir Welding: the IPU case is much larger than anything Honda has die cast before. It will be die-cast in two pieces and welded together seam...

News Updated at: 2024/04/16

Alicon Castalloy Limited, India updates about capex and news order win's during Q1 FY 2024

ntroduced a new part for the e-highway segment, catering to the electrification of highways for a European Customer. Furthermore, they ventured into a new market for autonomous driving by collaborating with Volkswagen Commercials.Alicon Castalloy secured an order worth INR 900 million per annum for Friction Stir Welding technology from a European EV customer. The company also noted an increase in EV product orders from Samsung and introduced a ne...

News Updated at: 2023/08/09

KUKA, Germany designs CO2-neutral battery assembly system for Valmet, Finland

KUKA, Germany designs CO2-neutral battery assembly system for Valmet, Finland On March 30, KUKA AG announced that it is providing robots for process handling for the sustainable production of battery systems for electric vehicles in Uusikaupunki, Western Finland, for automotive supplier Valmet Automotive. It is also installing friction stir welding systems and equipment for end-of-line testing in the assembly line. In the plant, resource-savin...

News Updated at: 2023/03/31

KUKA to present future of Cobot automation in IMTS, US

easily integrates into any manufacturing application from pre-defined production processes to open, unstructured work environments with unpredictable conditions from one job to the next. The LBR iisy is fully embedded into the KUKA Industry 4.0 ecosystem. KUKA will demonstrate advanced automated friction stir welding (FSW), a process that fulfills the growing need for fast, clean, reliable, and cost-effective joining for non-ferrous metals and...

News Updated at: 2022/08/15

TPV Group, Slovenia announces restructuring

ineering Services” program offers product design and process technology solutions. The “E-mobility Aluminum Components program” focuses on electric vehicles, especially battery tray and connecting assemblies. Its competitive advantage lies in technology and process competencies, and use of friction stir welding (FSW). The “Lightweight Steel Components program” encompasses development and production of parts with vital impact on veh...

News Updated at: 2020/06/15

Hydro opens aluminium research lab in Sweden

the global Innovation & Technology (I&T) unit of Extruded Solutions, which includes the product application lab in Finspang and an automotive-focused research and development lab outside Detroit, in Troy, Michigan. The application lab in Finspang carries out robotic welding, hot metal gas forming, friction stir welding, thermal testing and the testing of components, such as crash testing of automotive systems. Eight employees have been trained t...

News Updated at: 2019/09/27

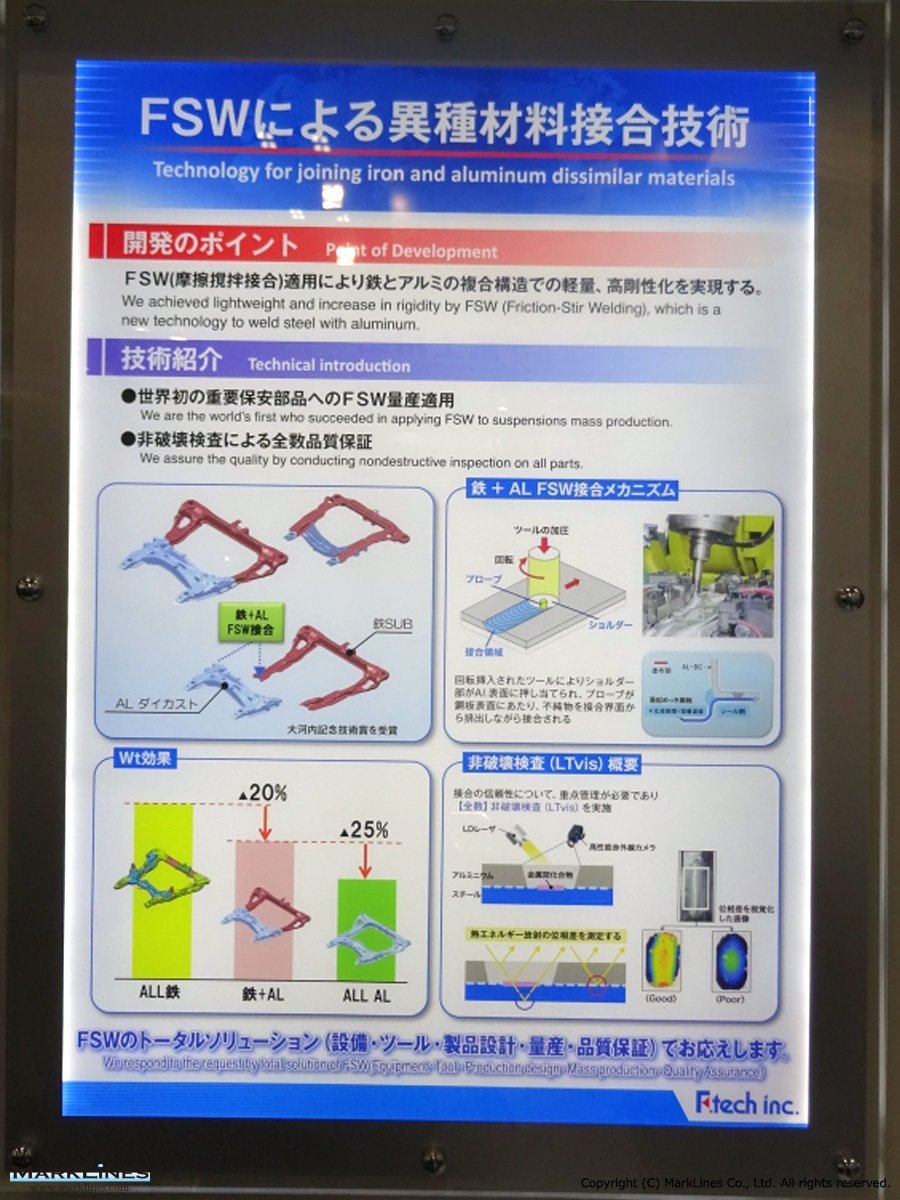

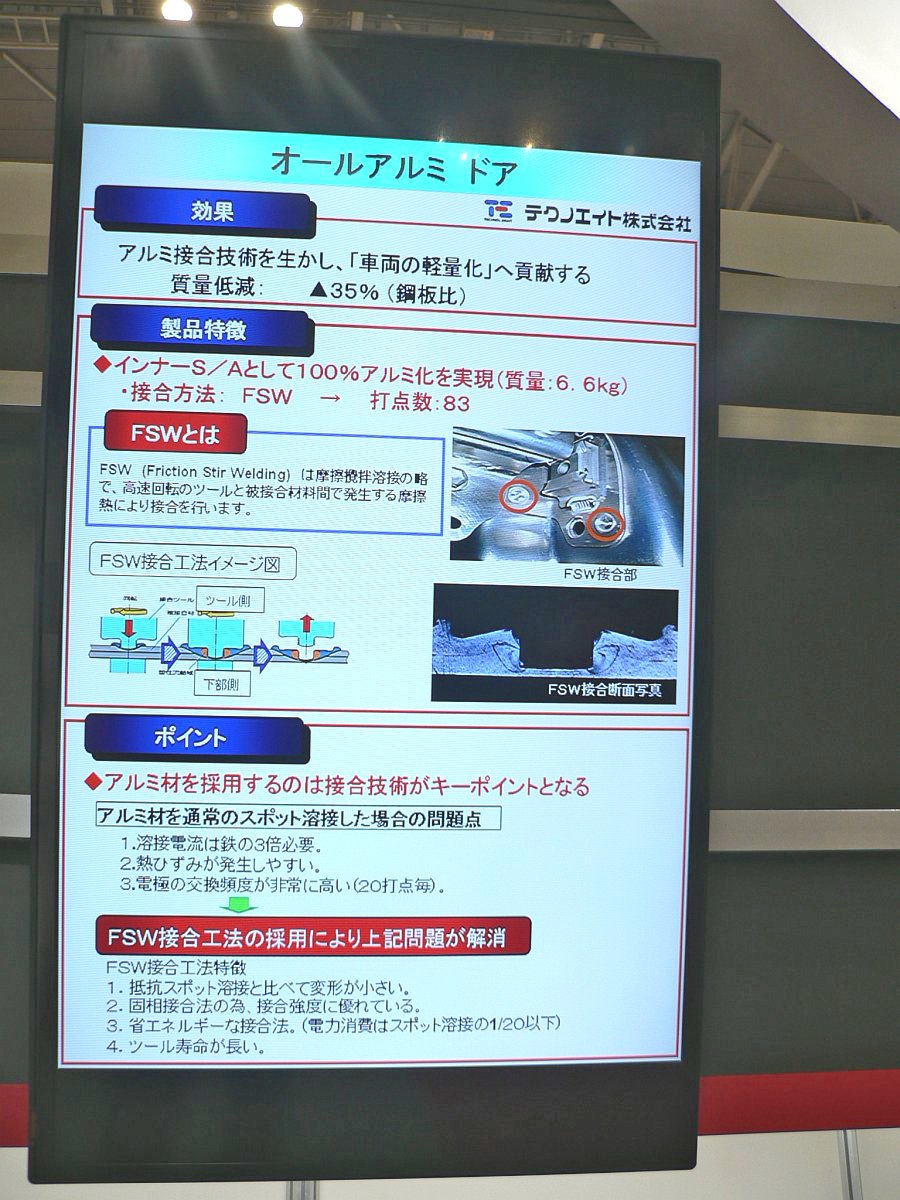

F-Tech to showcase front subframe at “Automotive Engineering Exposition 2019”

F-Tech to showcase front subframe at “Automotive Engineering Exposition 2019” F-Tech Inc. (F-Tech) announced that it will showcase at “Automotive Engineering Exposition 2019”. In addition to chassis components, the company will exhibit the world’s first mass production of front subframe using FSW (Friction Stir Welding) method for joining iron and aluminum, as well as forming press technology, light weight pedal, and light weight axle b...

News Updated at: 2019/04/04

Kikukawa Kogyo to develop magnesium and aluminum welding technology

Kikukawa Kogyo to develop magnesium and aluminum welding technology Kikukawa Kogyo Co., Ltd. (Kikukawa Kogyo), a metal construction material maker, announced that it will develop a friction stir welding technology to weld flame-retardant magnesium alloys and aluminum alloys in order to contribute to the weight reduction of vehicles. Kikukawa Kogyo was selected to receive a subsidy for the improvement of manufacturing, commerce and service managem...

News Updated at: 2018/09/04

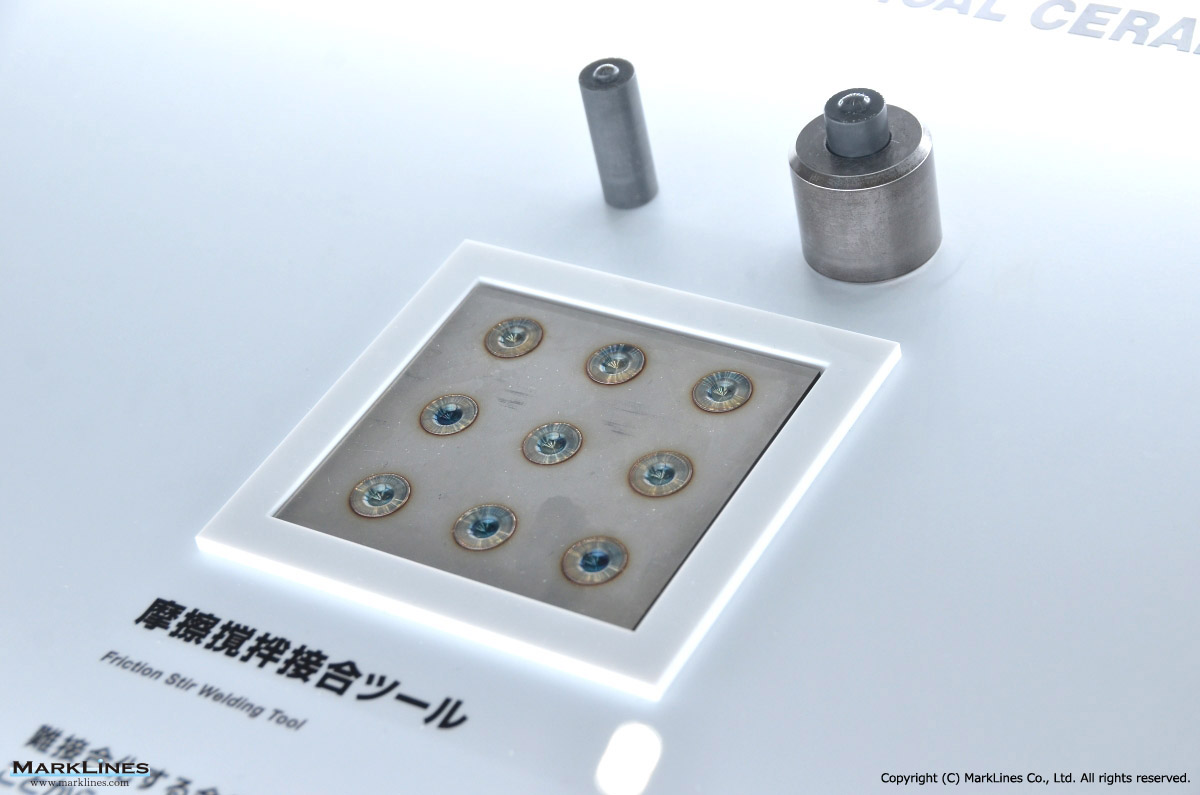

Furuya Metal releases industry's first iridium alloy tool for friction stir welding

Furuya Metal releases industry's first iridium alloy tool for friction stir welding Furuya Metal Co., Ltd. has developed and released the world's first iridium-based alloy tool for friction stir welding (FSW). The iridium alloy tool offers high strength and high ductility at elevated temperatures. This will enable joining of molybdenum, steel and titanium materials that have high melting points. Furuya Metal expects the new tool to become a pract...

News Updated at: 2014/02/12

F-Tech seeking to supply chassis parts to customers other than Honda

F-Tech seeking to supply chassis parts to customers other than Honda F-Tech Inc. will expand sales of its lightweight chassis components based on a technology for joining steel and aluminum also to customers other than Honda. Welding aluminum and steel together has been difficult, but this new technology, developed jointly with Honda R&D Co., Ltd, employs a Friction Stir Welding (FSW) method to bond steel and aluminum, and has been applied to the...

News Updated at: 2012/11/13

Honda develops new technology of continuous welding of steel and aluminum

f the new Accord, which will go on sale shortly in the U.S., said the automaker on September 6. Application of the technology to body frame parts of a mass-production model is said to be the first in the world. Spot welding has been used in the past for steel and aluminum. The new scheme employs “Friction Stir Welding,” which creates bonding between lapped steel and aluminum by moving a rotating tool with high pressure. Honda will apply this ...

News Updated at: 2012/09/07

JFE Steel focusing on application of friction stir welding to automotive steel

JFE Steel focusing on application of friction stir welding to automotive steel JFE Steel Corporation will step up development of friction stir welding (FSW) technology as a new welding technique for automotive steels. It aims to meet high market requirements such as development of thin high tensions steel sheets and connection of materials with different electrical properties, aiming to turn the technology into a practical business solution as ea...

News Updated at: 2006/10/07

AI Navigator

AI Navigator

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India