Shindengen's SiC Devices

Outline

”Maximizing energy conversion efficiency for the benefit of humanity and society."

Since our founding in 1949, Shindengen Electric Manufacturing Company’s business has centered on power electronics, which has been represented in our power semiconductors, switching power supplies, and car electronics devices. Over the years, we have developed countless products that meet the expectations and trust of our customers worldwide.

As one of the few manufacturers in the world that combines device technology, circuit technology, and packaging technology, we are developing products such as power semiconductors and DC/DC converters for EV quick chargers, AC chargers, and environmentally friendly vehicles.

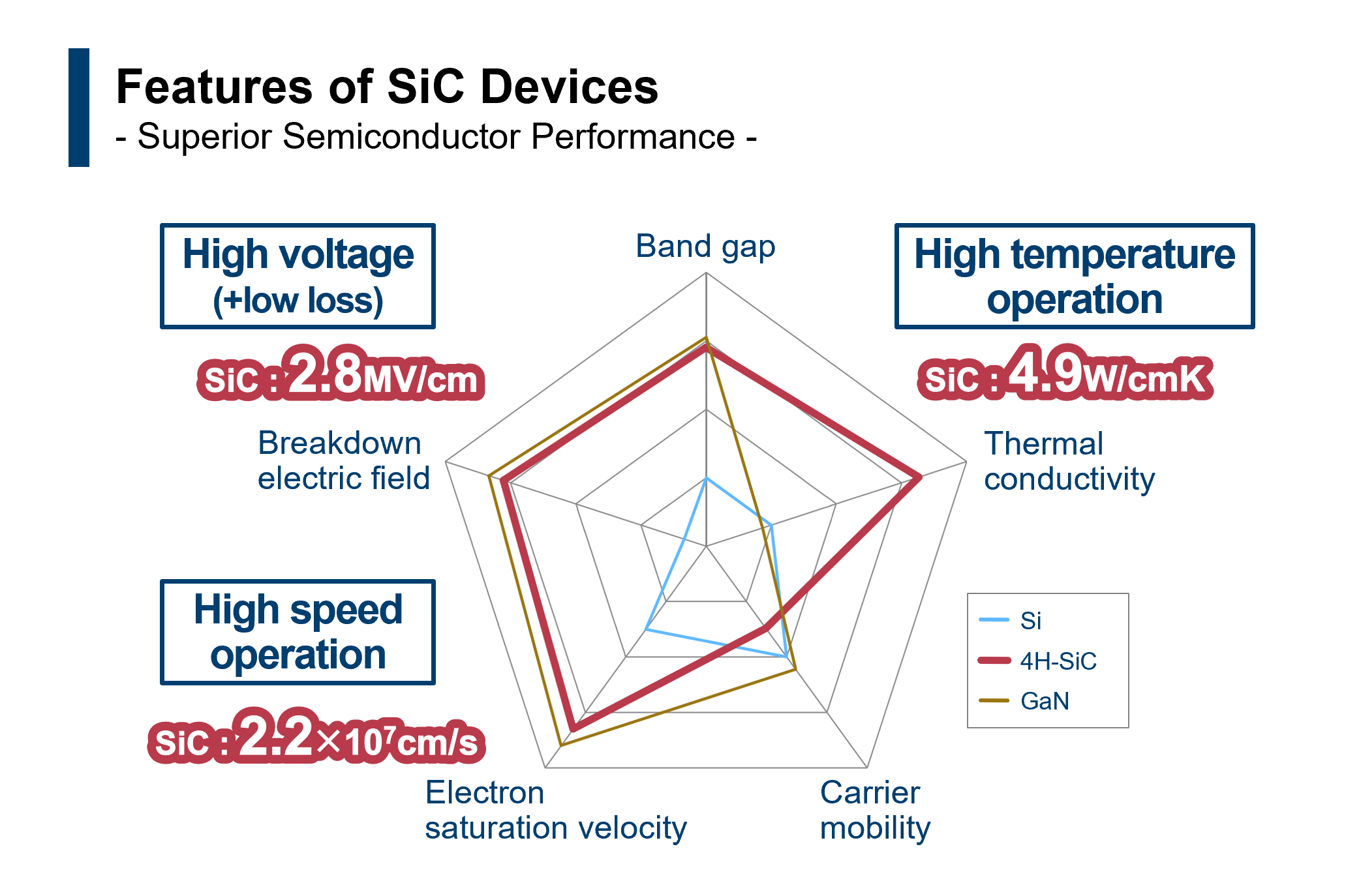

SiC (Silicon Carbide) devices, which support the next generation of power electronics, possess numerous characteristics that surpass conventional silicon (Si) devices.

With high efficiency, high voltage resistance, and the ability to operate at high temperatures, SiC devices are attracting attention across a wide range of applications—from industrial equipment to electric vehicles and renewable energy sectors.

At Shindengen, we leverage cutting-edge SiC technology to develop high-performance, highly reliable products that meet our customers’ needs.

Since our founding in 1949, Shindengen Electric Manufacturing Company’s business has centered on power electronics, which has been represented in our power semiconductors, switching power supplies, and car electronics devices. Over the years, we have developed countless products that meet the expectations and trust of our customers worldwide.

As one of the few manufacturers in the world that combines device technology, circuit technology, and packaging technology, we are developing products such as power semiconductors and DC/DC converters for EV quick chargers, AC chargers, and environmentally friendly vehicles.

SiC (Silicon Carbide) devices, which support the next generation of power electronics, possess numerous characteristics that surpass conventional silicon (Si) devices.

With high efficiency, high voltage resistance, and the ability to operate at high temperatures, SiC devices are attracting attention across a wide range of applications—from industrial equipment to electric vehicles and renewable energy sectors.

At Shindengen, we leverage cutting-edge SiC technology to develop high-performance, highly reliable products that meet our customers’ needs.

Feature

■ SiC Schottky Barrier Diodes (SiC-SBD)

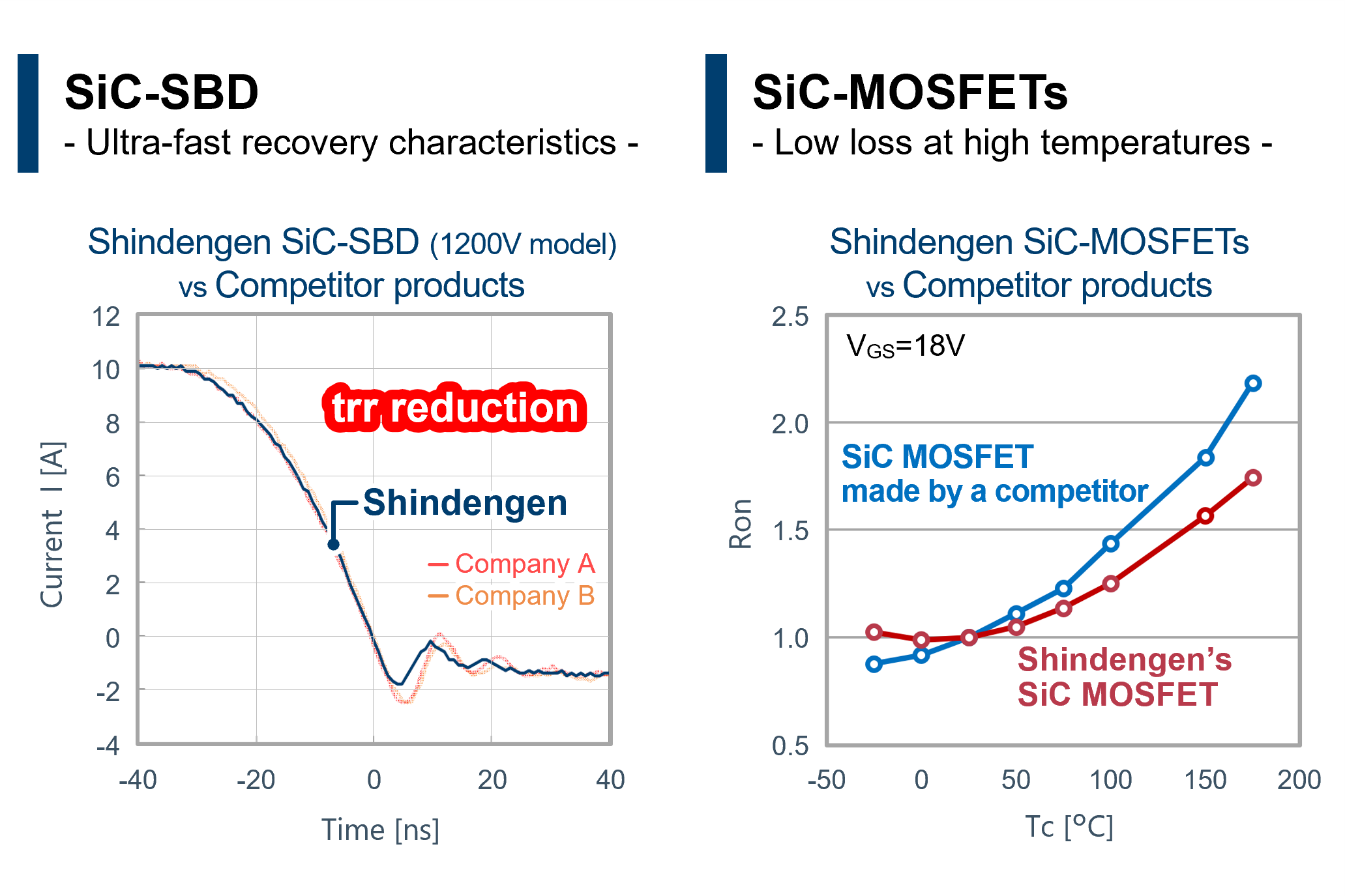

We are expanding our lineup of SiC Schottky Barrier Diodes (SiC-SBD) with compact surface-mount packages, offering 650V and 1200V options.SiC-SBDs feature ultra-fast recovery characteristics (reduced trr), high voltage resistance, and high-temperature operation, enabling significant reductions in switching losses and improved efficiency.

In addition, we plan to develop automotive-grade products and introduce a new series focused on achieving even lower VF, providing a product range that meets diverse application requirements.

■ SiC-MOSFETs

SiC-MOSFETs feature low switching losses, excellent high-temperature performance, and enable high-speed operation.

Furthermore, due to their low on-resistance, they serve as a replacement for conventional switching devices such as IGBTs in applications above 650V, contributing to the downsizing of equipment and cooling units in inverters and converters.

■ SiC-MOSFET Modules

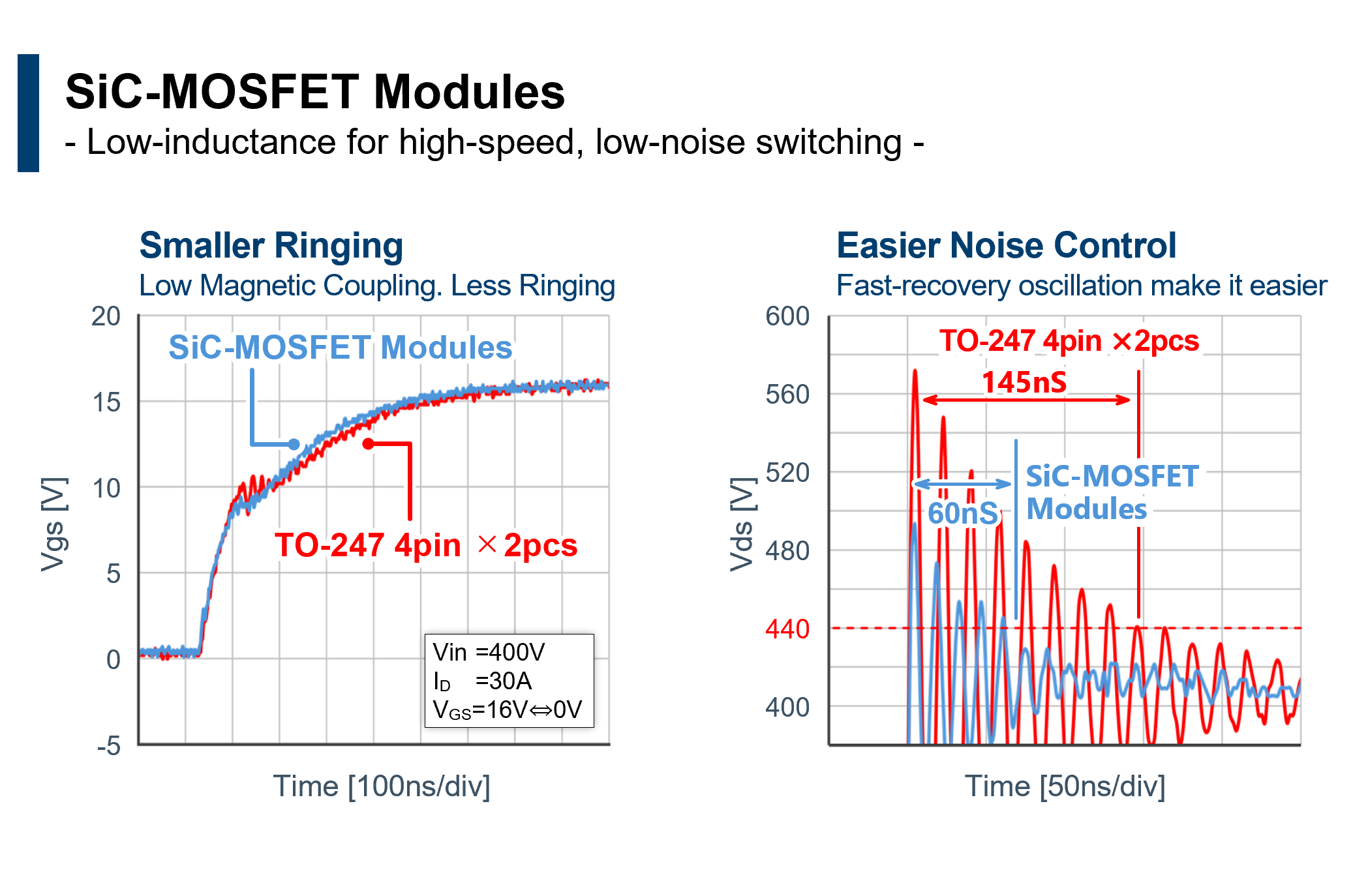

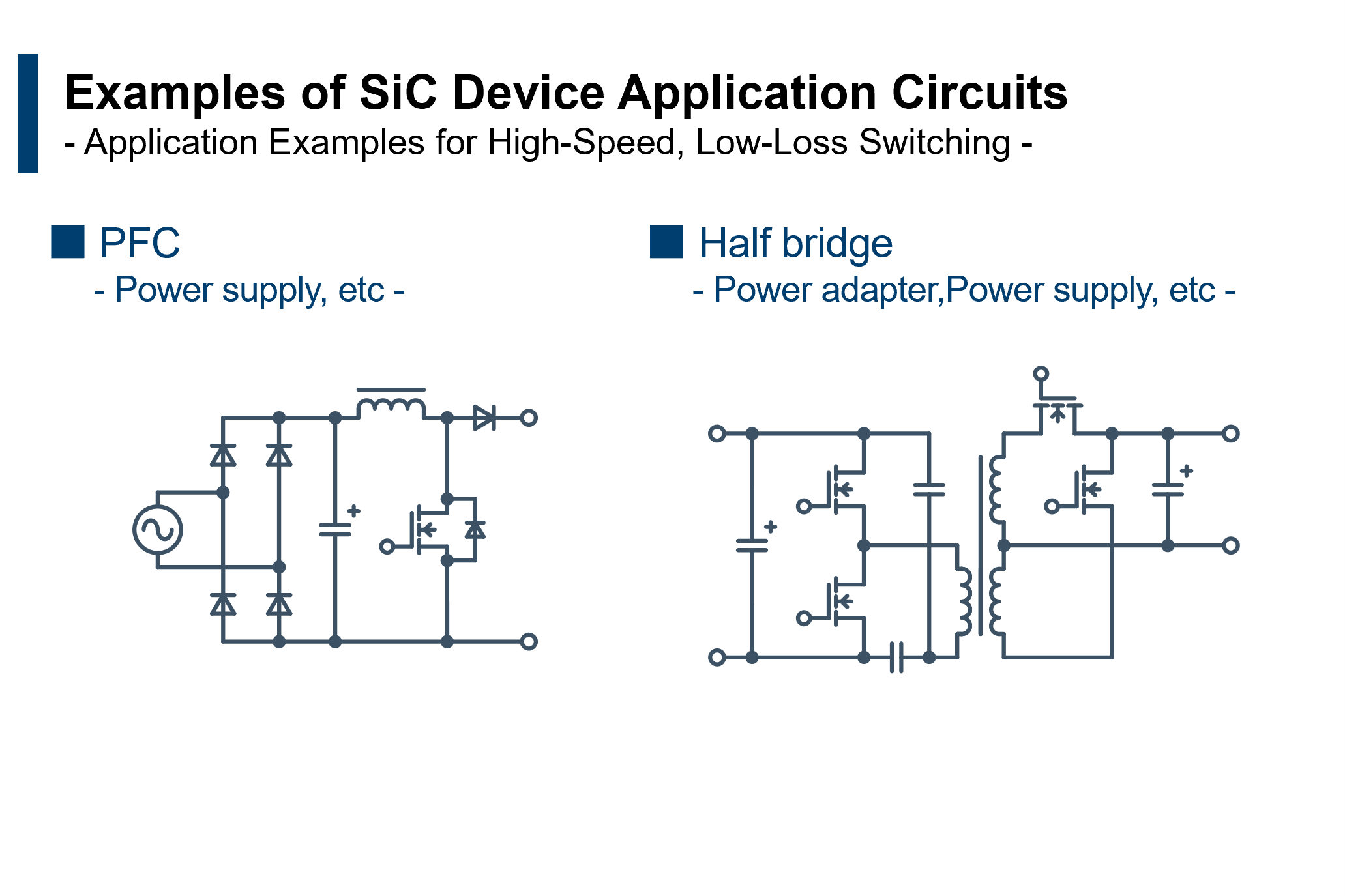

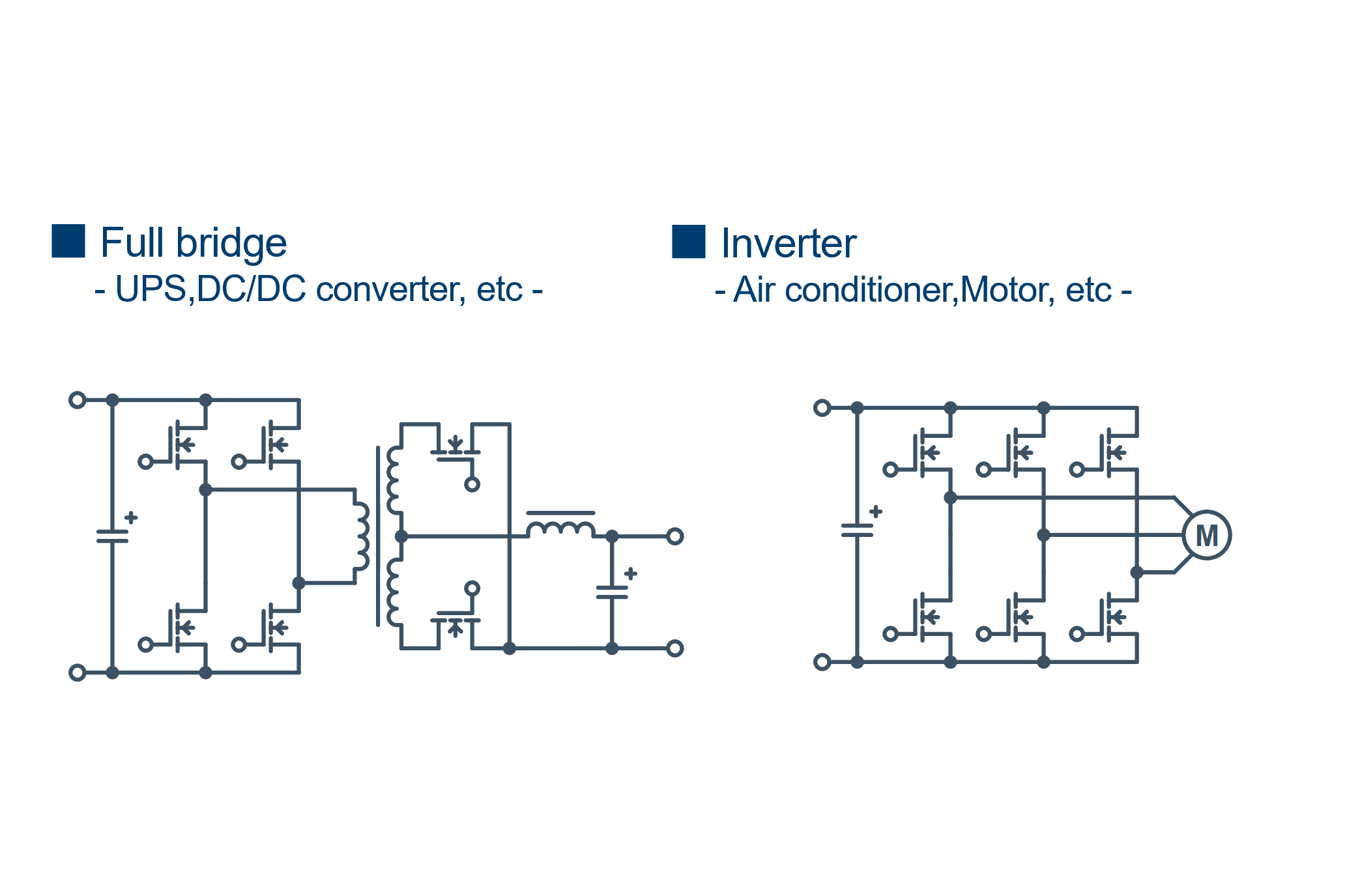

Power semiconductors used in various applications such as full-bridge converters, bridgeless PFC, inverter circuits, and H-bridge motor drive circuits are increasingly required to achieve higher power conversion efficiency.

To meet these demands, Shindengen is developing SiC MOSFET modules designed for high efficiency and low noise.

We are expanding our lineup of SiC Schottky Barrier Diodes (SiC-SBD) with compact surface-mount packages, offering 650V and 1200V options.SiC-SBDs feature ultra-fast recovery characteristics (reduced trr), high voltage resistance, and high-temperature operation, enabling significant reductions in switching losses and improved efficiency.

In addition, we plan to develop automotive-grade products and introduce a new series focused on achieving even lower VF, providing a product range that meets diverse application requirements.

■ SiC-MOSFETs

SiC-MOSFETs feature low switching losses, excellent high-temperature performance, and enable high-speed operation.

Furthermore, due to their low on-resistance, they serve as a replacement for conventional switching devices such as IGBTs in applications above 650V, contributing to the downsizing of equipment and cooling units in inverters and converters.

■ SiC-MOSFET Modules

Power semiconductors used in various applications such as full-bridge converters, bridgeless PFC, inverter circuits, and H-bridge motor drive circuits are increasingly required to achieve higher power conversion efficiency.

To meet these demands, Shindengen is developing SiC MOSFET modules designed for high efficiency and low noise.

Product URL

https://www.shindengen.com/products/semi/sic_device/

Use・Results

■ SiC Schottky Barrier Diodes (SiC-SBD)

• PFC circuits

• Switching

• Reverse current protection

• Secondary rectification

• Reverse current protection, etc.

■ SiC-MOSFETs

・PFC circuits

・Server power supplies

・Industrial equipment power supplies

・Consumer appliances

・On-Board chargers

・Automotive DC/DC converters, etc

■ SiC-MOSFET Modules

・Bridge less PFC circuits

・Full bridge converter, etc

• PFC circuits

• Switching

• Reverse current protection

• Secondary rectification

• Reverse current protection, etc.

■ SiC-MOSFETs

・PFC circuits

・Server power supplies

・Industrial equipment power supplies

・Consumer appliances

・On-Board chargers

・Automotive DC/DC converters, etc

■ SiC-MOSFET Modules

・Bridge less PFC circuits

・Full bridge converter, etc

Company information

Company name

SHINDENGEN ELECTRIC MANUFACTURING CO., LTD.

Company URL

Company PR

Since our establishment in 1949, Shindengen has been active in the power electronics sector as a rare type of manufacturer bringing together three core technologies: device technology, circuit technology, and packaging technology. We hold our mission as “maximizing energy conversion efficiency for the benefit of humanity and society.” Under this mission, we continue to protect the environment by maximizing environmental-friendliness with our combined core technologies while we respond to our customer needs.

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

China (Shanghai) Thailand

Thailand India

India