Sort by :

1 - 20 of 388 results

3

3

4

4

3

3

2

2

2

2

5

5

2

2

2

2

1

1

1

1

2

2

1

1

1

1

2

2

1

1

1

1

3

3

11

11

1

1

3

3

AI Navigator

AI Navigator

Japan

Japan USA

USA Mexico

Mexico Germany

Germany China (Shanghai)

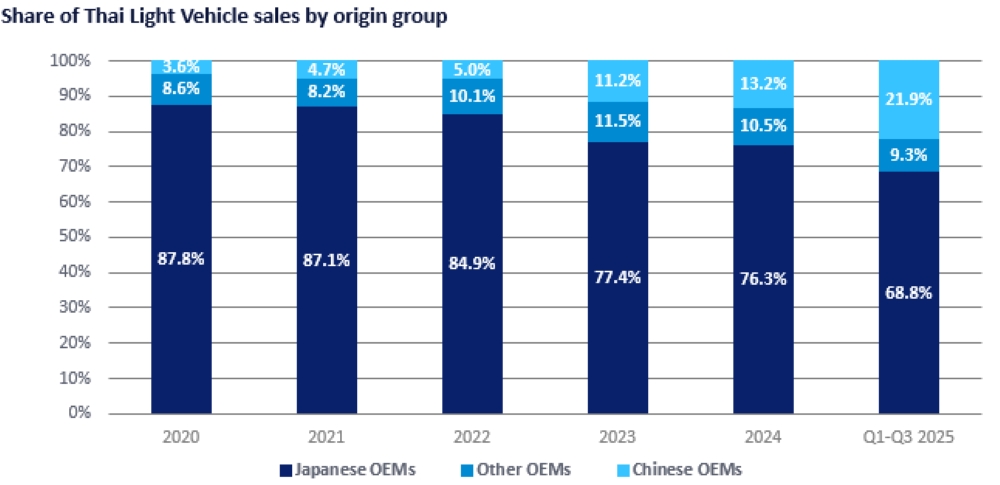

China (Shanghai) Thailand

Thailand India

India